How can different gases impact the efficiency of laser cutting? This article explores the performance of air, oxygen, and nitrogen as cutting gases, comparing their effects on various metals. You’ll discover which gas offers the best speed, quality, and cost-effectiveness for specific applications. By understanding these differences, you can optimize your laser cutting process to improve production outcomes and reduce costs.

Air, the essential “gas of life” we breathe daily, is composed of approximately 78% nitrogen, 21% oxygen, 0.93% argon, 0.04% carbon dioxide, and trace amounts of other gases including neon, helium, methane, and hydrogen. Water vapor, while variable, can constitute up to 4% of the atmosphere in humid conditions.

Now, let’s delve into the benefits of air cutting in the laser cutting process.

The cutting principle of air closely resembles that of nitrogen in laser cutting processes. It harnesses laser energy to melt the metal while utilizing high-pressure gas to expel the molten material from the kerf. During this process, some metal substances may undergo oxidation or combustion, resulting in the formation of metal oxides on the cut surface. Common oxides include gray solid alumina (Al2O3), black solid magnetite (Fe3O4), and copper(II) oxide (CuO).

Air, ubiquitous in the atmosphere, can be harnessed for cutting applications through a series of preparatory steps. It is initially compressed into an air storage tank, then subjected to filtration, cooling, and drying processes to remove contaminants such as moisture and oil. This treatment renders the air suitable for cutting operations. The natural composition of air, containing approximately 21% oxygen, partially compensates for the absence of pure oxygen or nitrogen in the cutting process.

Theoretically, air cutting can be applied to any metal material that can be melted by laser energy. However, the effectiveness and quality of the cut may vary depending on factors such as material thickness, thermal conductivity, and the specific laser parameters employed. The presence of oxygen in air can lead to exothermic reactions with certain metals, potentially enhancing cutting speeds but also influencing the cut edge quality and surface oxidation.

The air cutting method offers a cost-effective alternative to using pure gases, making it particularly suitable for non-critical applications or materials less prone to oxidation. However, for precision cutting or when working with highly reactive metals, other assist gases like nitrogen or argon may be preferable to minimize oxidation and achieve superior edge quality.

Evaluation of cutting performance on stainless steel, carbon steel, and aluminum alloy plates using a 6kW laser cutting machine with air and nitrogen/oxygen as the cutting gases.

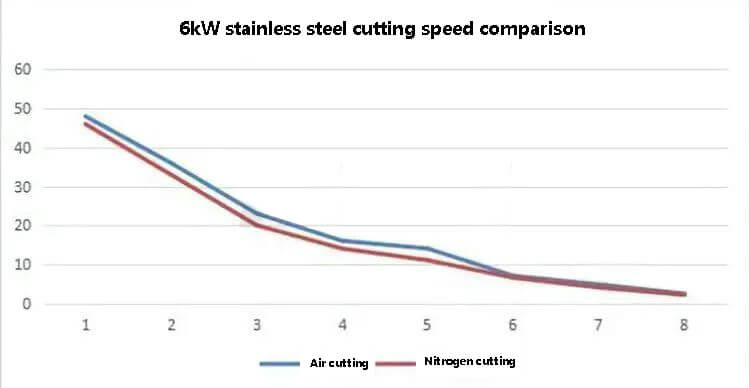

Experiment 1: comparison of nitrogen and air cutting stainless steel

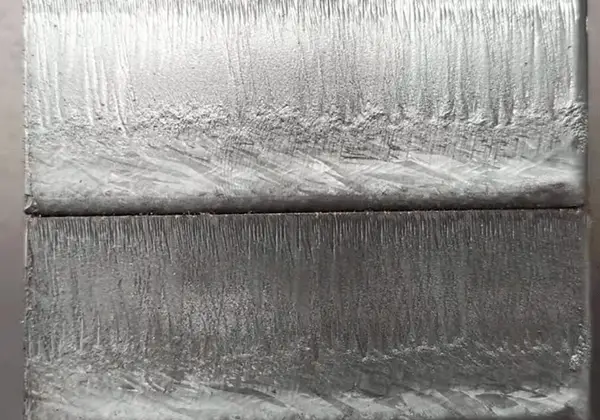

⊙ Comparison of nitrogen and air cutting section effect

⊙ Comparison of nitrogen and air cutting speed

Effect analysis:

The figure above displays the cutting results of 10mm to 4mm stainless steel, in that order.

Compared to nitrogen cutting, the cut section using air appears darker, but there is no slag present. After polishing, the cut section can also achieve a brighter appearance.

In terms of speed, air cutting of stainless steel is slightly faster than nitrogen, but the difference is not significant.

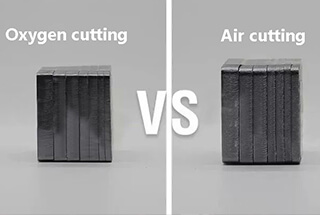

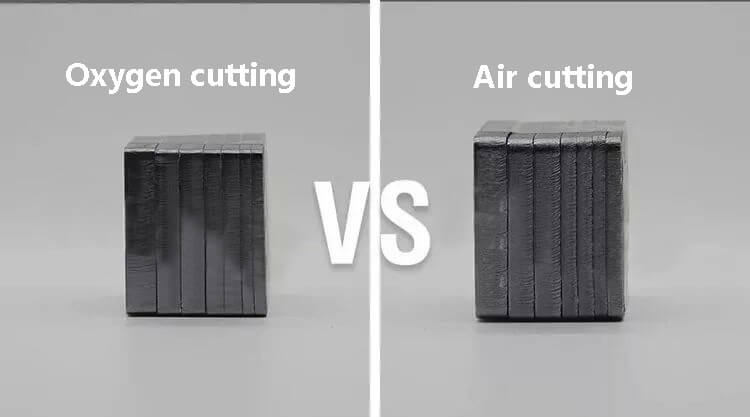

Experiment 2: comparison of oxygen and air cutting carbon steel

⊙ Comparison of oxygen and air cutting section effects

⊙ Comparison of air and oxygen cutting speed

Effect analysis:

The above figure displays the cutting results of 10mm to 3mm carbon steel, in that order.

Compared to oxygen cutting, 8mm carbon steel has slight slag residue, and the 10mm carbon steel has more severe slag residue.

Therefore, air cutting is not recommended for cutting carbon steel plates thicker than 10mm.

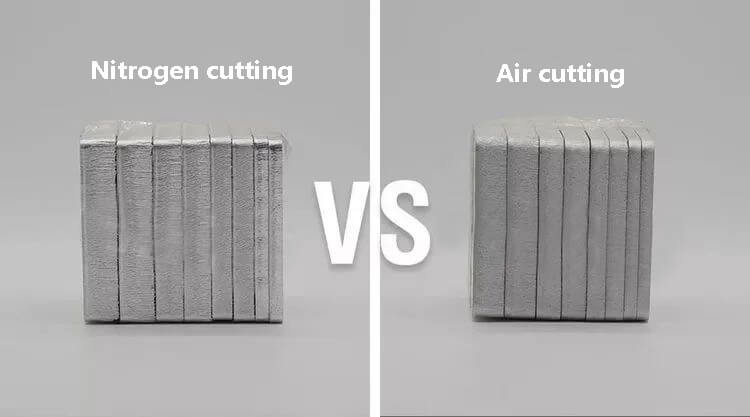

Experiment 3: comparison of nitrogen and air cutting aluminum alloy

⊙ Comparison of nitrogen and air cutting section effect

⊙ Comparison of nitrogen and air cutting speed

Effect analysis:

The above figure displays the cutting results of 10mm to 3mm aluminum plates, in that order.

Compared to nitrogen cutting, air cutting results in a finer section and less slag residue.

In terms of speed, air cutting of aluminum plates is slightly faster than nitrogen, but the difference is not significant.

Experiments were conducted to evaluate the performance and efficiency of air versus nitrogen/oxygen cutting on various materials and plate thicknesses.

The comprehensive assessment revealed that air cutting is a cost-effective option for applications with less stringent requirements. Utilizing air as the cutting assist gas can significantly reduce production costs compared to nitrogen or oxygen.

However, it is crucial to note the following considerations when opting for air cutting:

1. Air Quality: The compressed air must be meticulously treated to ensure optimal cutting performance. This treatment should include:

2. Maintenance: Regular and thorough maintenance of the air treatment system is essential, including:

Neglecting these maintenance procedures can lead to:

3. Process Optimization: To determine the most cost-effective cutting solution that aligns with specific production requirements, manufacturers should consider:

By carefully evaluating these factors and balancing them against production needs, manufacturers can achieve higher quality outcomes while optimizing costs. This approach ensures that the chosen cutting method not only meets technical specifications but also aligns with overall production efficiency and economic considerations.