What causes laser cutting heads to fail, and how can you prevent it? This article delves into common contamination issues affecting fiber laser cutting head lenses and offers practical solutions to maintain optimal performance. Learn about improving installation methods, ensuring effective sealing, and using proper maintenance techniques to extend the lifespan of your equipment. Discover the key steps to prevent lens pollution, reduce maintenance costs, and boost your cutting head’s efficiency. Read on to understand the vital practices that can keep your laser cutting operations running smoothly.

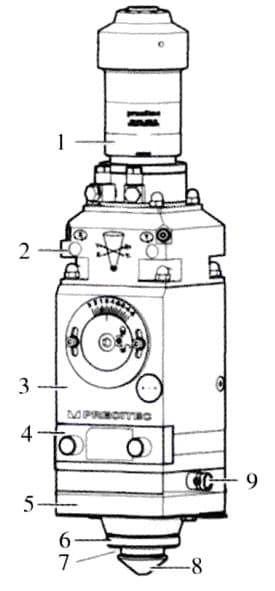

In the current fiber laser cutting machine market, two cutting head series dominate: the LightCutter (Figure 1) and ProCutter (Figure 2), both manufactured by PRECITEC, a renowned German precision engineering company. These cutting heads are critical components that significantly influence the performance, efficiency, and cut quality of fiber laser cutting systems.

These two series of cutting heads are suitable for laser power within the following ranges: LightCutter≤2500W, ProCutter≤6000W.

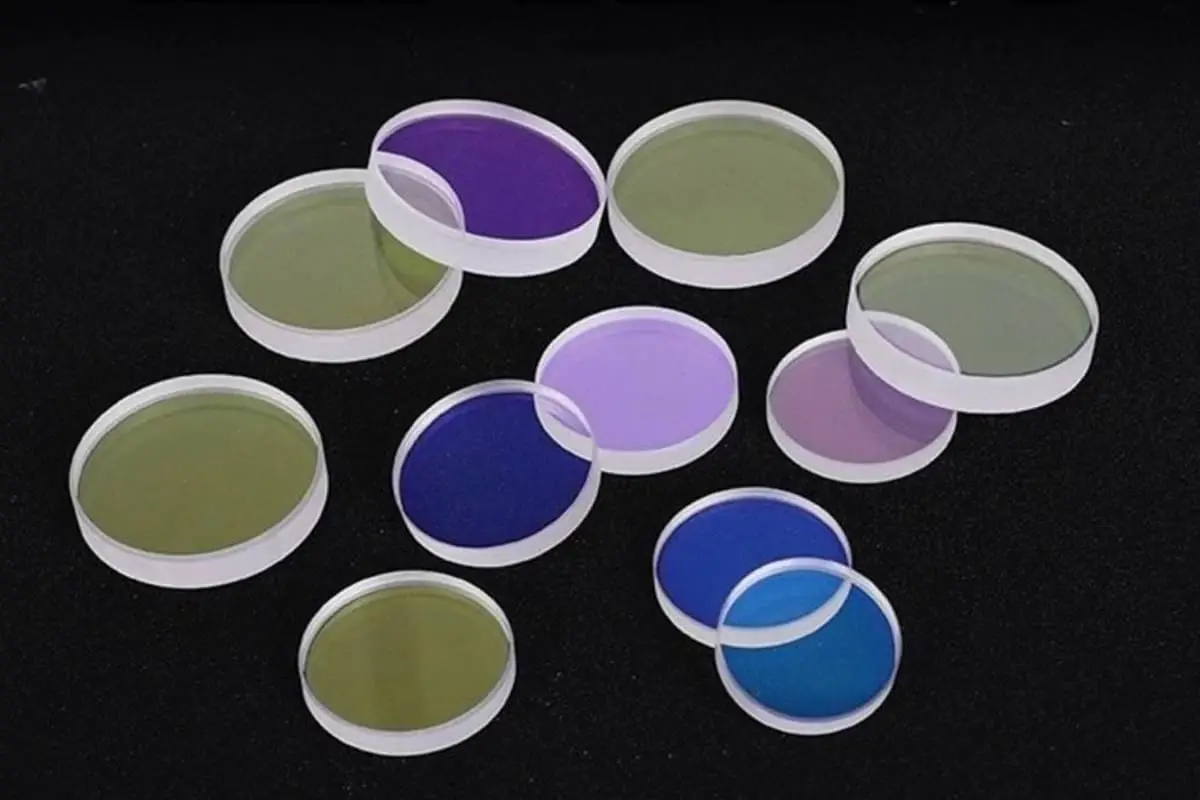

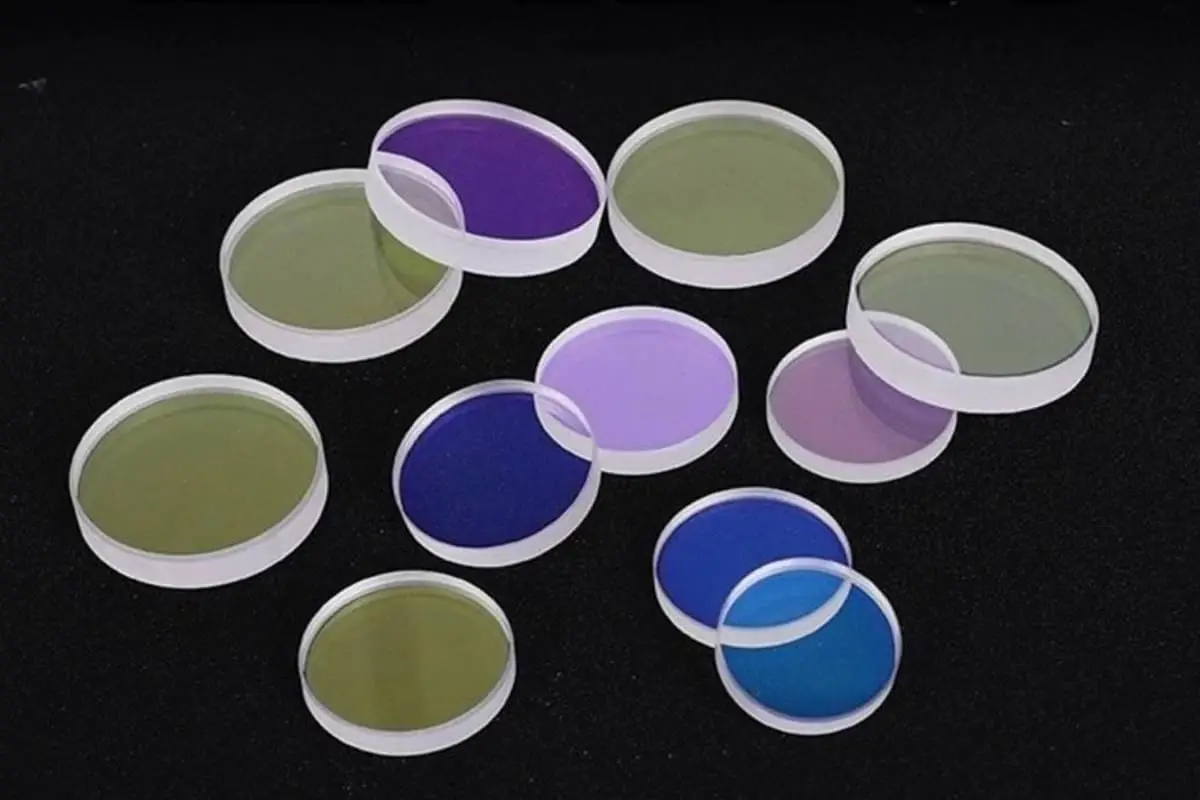

As shown in Figure 3, the optical components inside the cutting head consist of 2 collimating mirrors, 3 focusing mirrors, and 4 protective mirrors. The pollution of these lenses directly affects the cutting process of the machine tool.

Based on long-term process trials and extensive customer usage analysis, the main factors causing pollution in the cutting head are as follows:

①Improper installation method of fiber optic head.

②Poor sealing effect of the cutting head.

③Improper method of replacing protective mirrors.

④Unreasonable processing control timing.

⑤Unscientific cutting process data.

⑥Use of substandard vulnerable parts for the cutting head (protective mirrors, O-ring seals, etc.).

⑦Improper operation and usage by the end customer.

⑧Incorrect maintenance and repair method for the cutting head.

Related reading: Black Spots on Laser Cutting/Welding Lens: Causes and Solutions Explored

While achieving absolute pollution-free cutting heads is challenging, there are methods that can be employed to prolong the time between pollution occurrences and reduce the severity of pollution. This can help increase the lifespan of the cutting head and lower maintenance and repair costs.

Addressing the factors listed above that contribute to pollution of the cutting head, respective measures can be taken as follows:

Improvements can be made to the installation method by ensuring that the fiber optic head is inserted horizontally into the cutting head and securely locked.

It is important to maintain a clean environment during the installation process, and if there are a significant number of suspended particles (dust) in the surrounding area, it is recommended to perform this task before 6:00 am, i.e., before the start of the work shift.

Given the current level of mechanical manufacturing, even with the most advanced German technology, it is not possible to achieve absolute sealing for laser cutting heads. During the subsequent use, it is inevitable that dust will enter and contaminate the lenses.

The main cause of this issue is the temperature rise of the cutting head during cutting process (normal cutting can be achieved when the cutting head temperature is <55°C).

This leads to an increase in internal pressure, causing some gases to be released from the cutting head into the surrounding environment.

When the cutting head stops operation (after the work shift), the internal temperature decreases to the ambient temperature, resulting in the internal pressure being lower than the ambient pressure.

Dust-contaminated gases from the environment will then be drawn into the cutting head until the internal and external pressures reach equilibrium, thus polluting the cutting head.

To address this problem, the approach is to maintain a positive pressure (higher than the ambient pressure) inside the cutting head to isolate the entry of dusty gases from the environment.

The following methods can be employed for improvement:

①Continuously supply clean, dry, and oil-free gas into the cutting head. (Nitrogen is recommended, with a pressure of 0.15 bar ≤ P < 0.3 bar).

②Install a breathing system to maintain a positive pressure inside the cutting head at all times.

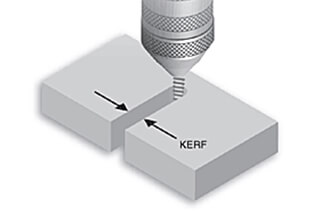

When replacing the protective lens, it is required to do so quickly. At the same time as removing the protective lens window box (Figure 3), immediately seal the window on the cutting head with adhesive tape (sealing the installation opening of the protective lens window box).

Additionally, ensure that no dirty objects come into contact with the protective lens, and operators should refrain from speaking (to prevent saliva from splashing onto the protective lens).

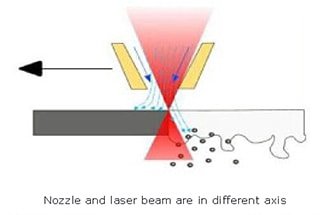

The speed of light propagation is faster than the transmission speed of gas. When cutting or puncturing, there can be a delay in cutting gas, resulting in the laser starting the processing before the cutting gas reaches the required pressure or flow rate, leading to contamination of the protective lens.

The following improvement methods can be implemented:

1. Modify the timing of laser emission and gas release (cutting gas) by instructing gas release, waiting for a certain period (gas waiting), emitting laser, and then processing.

2. Maintain a certain air pressure (protective gas) throughout the entire processing process.

The processing sequence should be as follows: instruct the release of protective gas, pre-process the sheet metal (read processing data and define the origin), instruct the release of puncturing gas, instruct the release of puncturing laser, instruct the release of cutting gas, instruct the release of cutting laser (cutting contour), complete the contour cutting, quickly position to the next contour, instruct the release of puncturing gas, instruct the release of puncturing laser, instruct the release of cutting gas, instruct the release of cutting laser (cutting contour), complete the contour cutting, repeat the cycle, finish the cutting process, turn off the protective gas, and end the program.

The use of rational cutting process data helps to prevent the occurrence of contamination in the cutting head due to abnormal cutting.

The use of qualified consumables such as protective lenses and O-rings contributes to the sealing of the cutting head.

Follow the instructions provided by the equipment supplier to correctly operate and use the machine tool.

Ensure that the cutting head is clean and dry, and perform daily cleaning.

By implementing the aforementioned contamination prevention methods, the contamination of optical lenses inside the fiber cutting head is significantly improved.

Practical application has shown that with regular maintenance and careful attention to detail, frequent part cutting failures can be avoided, thus prolonging the lifespan of the lenses and enhancing the equipment’s production efficiency.

.jpg)