What makes copper busbar welding so crucial yet challenging? This article delves into the high conductivity, thermal properties, and specific welding techniques required for copper busbars in power construction. From understanding thermal cracking to mastering TIG welding methods, it offers a comprehensive guide on achieving optimal welding results. Learn about the intricacies of welding materials, pre-welding preparations, and key process parameters that ensure high-quality welds, setting a new standard in welding technology.

Copper busbar welding is not common in our company’s power construction due to its high requirements and difficulty. However, copper busbars, with their superior conductivity, were chosen for the electrical busbars in the coal-fired power plant.

After conducting welding experiments and product welding applications, the welding subsidiary has essentially mastered the welding technology of copper busbars, laying a foundation for future copper busbar welding in our company and advancing our welding technology to a new level.

The connection of copper busbars in power stations mainly involves two methods: bolt fastening and welding. Copper has excellent electrical conductivity, thermal conductivity, heat resistance, and formability. Industrial pure copper is not less than 99.5% ωcu.

The thermal conductivity of pure copper at room temperature is 8 times greater than that of carbon steel. To heat a pure copper workpiece to its melting temperature, a large amount of heat is required.

Therefore, a concentrated heat source is needed during welding; otherwise, heat will dissipate quickly. Preheating should be performed on the workpiece when welding pure copper.

Various copper base materials always contain a certain amount of impurities that form a low-melting eutectic. The presence of a low-melting eutectic film in the solidified workpiece or heat-affected zone can cause cracks under welding stress.

Pores in the copper weld metal are mainly caused by hydrogen. When pure copper contains a certain amount of oxygen or when CO gas is dissolved in pure copper, pores may also be caused by water vapor and by the reaction of CO with O to generate CO2 gas.

Generally, pores are distributed in the center of the weld and near the fusion line.

During welding, copper inevitably undergoes oxidation and burnout to some extent, resulting in various welding defects. This could potentially lead to a decrease in the strength, plasticity, corrosion resistance, and electrical conductivity of the welded joint.

In the copper fusion welding process, the grain size in the weld and heat-affected zone significantly increases, affecting the mechanical properties of the joint to a certain degree.

To improve the performance of the joint, it’s not only crucial to minimize thermal effects but also to control the impurity content of the weld, and to modify the weld metal through alloying.

While gas welding and manual tungsten inert gas (TIG) welding are commonly employed for copper, advanced manufacturing practices prioritize TIG welding for superior quality and precision in copper fabrication.

Manual TIG welding, also known as Gas Tungsten Arc Welding (GTAW), offers distinct advantages for copper joining:

For medium-thickness copper (typically 3-12mm), TIG welding is particularly advantageous due to its balance of heat input control and penetration capability. In specialized applications or for thicker sections, pulsed TIG or automated processes may be considered to further optimize weld quality and productivity.

The welding materials for copper refer to welding wires and fluxes. Filling welding wire: When performing manual TIG welding, it’s necessary to manually add filling welding wire. The brand, composition of the welding wire, and the welding processability, joint mechanical properties, and corrosion resistance are all closely related.

When choosing the filling welding wire, the first considerations must be the base metal’s brand, plate thickness, product structure, and construction conditions.

Therefore, when welding copper busbars, a filling welding wire with a composition similar to the base metal is selected. The technical parameters of the copper welding wire are shown in Table 1.

Table 1: Technical Parameters of Copper Welding Wire

| Grade | GB Standard Model | Primary chemical composition | Mass Fraction (%) | Melting Point | Primary Use |

| HS201 (Scu-2) | HSCu | Sn-1.1 | Si-0.4 | 1050 | Pure Copper Tungsten Arc Welding (Use of Flux 301) |

| HS201(Scu-2) | Mn-0.4 | Copper (remained) |

Technical Parameters of Copper Welding Wire

Solder: During argon arc welding, the surface of molten pool metal tends to oxidize to form cuprous oxide (Cu2O). Its presence often leads to defects such as weld porosity, cracks, and slag inclusions. Technical parameters of the solder are shown in Table 2.

Pre-welding preparation primarily refers to the cleaning of the workpiece and welding materials, and the design and processing of the groove before welding.

It’s crucial to clean the surface of the welding wire and both sides of the copper plate groove within 30mm to remove grease, moisture, oxides, and other impurities. Groove processing is performed with an air chisel or a beveling machine.

The copper welding groove processing types are presented in Table 3.

Table 2: Technical Parameters for Welding Flux

| Grade | Primary Components (by Mass Fraction) % | Melting Point(℃) | Application Scope | |||||

| Na2B407 | H3B03 | NaF | NaCl | KCI | Other | |||

| CJ301 | 16.5-18.5 | 76-79 | – | – | – | AIP04 4-5.5 | 650 | Copper Gas Welding |

Table 3: Types of Welding Groove Processing for Copper

| Material Name | Plate Thickness (mm) | Diagram | Bevel Type | Joint Type | Joint Structure Dimensions | ||

| a | b (mm) | P (mm) | |||||

| Pure Copper | ≤3 | I-Shape | Butt Joint | – | 1-2 | ||

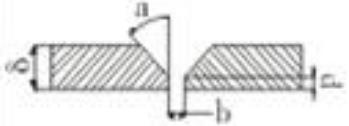

| ≥4 |  | V-Shape | Butt Joint | 30°-35° | b | 1-2 | |

| ≤12 |  | Single V-Shape | T-Joint | 50°~60° | 2-3 | 1-2 | |

Note: ‘b’ can be set according to the on-site joint gap and process requirements.

Table 4: Welding process parameters for copper

| Plate Thickness (mm) | Tungsten Electrode Diameter (mm) | Welding Wire Diameter (mm) | Welding Current (A) | Chlorine Gas Flow (L/min) | Preheat Temperature (°C) |

| 1-4 | 2.0 | 2.0 | 140-220 | 15-16 | 200-300 |

| 5-12 | 2.5 | 2.0 | 240-260 | 16-18 | 600-650 |

5.1 The copper busbar welding environment should maintain an ambient temperature above 5°C to ensure optimal weld quality and prevent moisture-related issues;

5.2 High-purity argon (99.99% or higher) is used as the shielding gas to protect the weld pool from atmospheric contamination;

5.3 HS201 pure copper wire is the recommended welding filler material for copper busbars. The flux CJ301 should be thoroughly mixed with anhydrous ethanol to achieve a paste-like consistency. This flux mixture is then applied to the beveled surfaces of the weldment prior to welding to improve wetting and reduce oxidation;

5.4 Preheating the welding wire and coating it with CJ301 flux enhances deoxidation and improves weld quality;

5.5 Manual tungsten arc welding (GTAW) utilizing direct current electrode positive (DCEP) is the preferred welding process. Refer to Table 4 for specific welding parameters optimized for pure copper;

5.6 The welding machine should be well-maintained, featuring precise current control and user-friendly operation to ensure consistent weld quality;

5.7 Copper busbar preheating can be achieved through either electrical resistance heating or controlled flame heating, with the choice depending on equipment availability and workpiece geometry;

5.8 For optimal preheating:

– Thickness δ < 4mm: Moderate preheating is sufficient

– Thickness δ ≥ 4mm: Preheat to 600-650°C to improve weldability and reduce thermal gradients

5.9 Minimize welding under restraint conditions to prevent distortion and cracking. Strictly control interpass temperature, employing small oscillation techniques and low heat input to manage thermal stresses;

5.10 Implement tack welds with a minimum length of 10mm. Distribute at least three tack welds evenly along the joint to maintain proper alignment;

5.11 For workpieces with thickness δ > 4mm, utilize a multi-layer, multi-pass welding technique to ensure proper fusion and minimize distortion;

5.12 Promptly remove any high-temperature oxidation (black spots) from the weld area. Perform thorough interpass cleaning using a dedicated stainless steel wire brush to maintain weld purity;

5.13 Conduct a comprehensive quality check of tack welds before proceeding with full welding. Ensure absence of defects such as cracks, lack of fusion, or porosity;

5.14 Implement rigorous in-process quality control:

– After tack welding

– Between weld layers

– Upon completion of welding

Adhere strictly to welding procedure specifications (WPS) requirements to guarantee consistent weld quality and structural integrity.