Ever wondered what happens to steel when it undergoes extreme temperature changes? This article explores the critical points, quenching temperatures, and Ms points in steel, revealing how these factors influence its strength and durability. By understanding these thermal properties, you’ll gain insights into the complex science of steel treatment and its practical applications in manufacturing. Read on to discover how precise temperature control can enhance the performance of steel components in various industries.

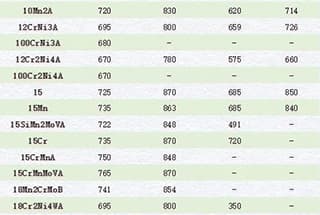

| Grade | Critical point / ℃ | |||

| Ac1 | Ac3 or Accm | Ar1 | Ar3 | |

| 10 | 725 | 870 | 682 | 850 |

| 10Mn2A | 720 | 830 | 620 | 714 |

| 12CrNi3A | 695 | 800 | 659 | 726 |

| 100CrNi3A | 680 | – | – | – |

| 12Cr2Ni4A | 670 | 780 | 575 | 660 |

| 100Cr2Ni4A | 670 | – | – | – |

| 15 | 725 | 870 | 685 | 850 |

| 15Mn | 735 | 863 | 685 | 840 |

| 15SiMn2MoVA | 722 | 848 | 491 | – |

| 15Cr | 735 | 870 | 720 | – |

| 15CrMnA | 750 | 848 | – | – |

| 15CrMnMoVA | 765 | 870 | – | – |

| 18Mn2CrMoB | 741 | 854 | – | – |

| 18Cr2Ni4WA | 655~695 | – | – | – |

| 20 | 735 | 855 | 680 | 835 |

| 20Mn | 735 | 854 | 682 | 835 |

| 20Mn2 | 690 | 820 | (610) | (760) |

| 20Mn2B | 730 | 835 | 613 | 730 |

| 20MnVB | 720 | 840 | 635 | 770 |

| 20MnTiB | (720) | 843 | 625 | 795 |

| 20MnMoB | 738 | 850 | 693 | 750 |

| 20Cr | 766 | 838 | 702 | 799 |

| 20CrV | 768 | 840 | 704 | 782 |

| 20CrMnB | – | 890 | 622 | 749 |

| 20CrNi | 735 | 805 | 660 | 790 |

| 20CrNi3A | 710 | 790 | – | – |

| 20Cr2Ni4A | 705 | 770 | 575 | 660 |

| 22CrMnMo | 710 | 830 | 620 | 740 |

| 30 | 732 | 813 | 677 | 796 |

| 30Mn2 | 718 | 804 | 627 | 727 |

| 30Mn | 734 | 812 | 675 | 796 |

| 30SiMnMoV | 740 | 845 | – | – |

| 30Si2Mn2MoWV | 739 | 798 | – | – |

| 30CrMnSi | 760 | 830 | 670 | 705 |

| 30CrMo | 757 | 807 | 693 | 763 |

| 30CrMnTi | 765 | 790 | 500 | 740 |

| 30CrMnSiNi2A | 750~760 | 805~830 | – | – |

| 30CrNi3 | 705 | 750 | – | – |

| 35SiMn | 750 | 830 | 645 | – |

| 35CrMoV | 755 | 835 | 600 | – |

| 35CrMo | 755 | 800 | 695 | 750 |

| 35CrMnSi | 760 | 830 | 670 | 705 |

| 38Cr | 740 | 780 | 693 | 730 |

| 38CrMoAl | 800 | 840 | 730 | – |

| 37CrNi3 | 710 | 770 | 640 | – |

| 38CrSi | 763 | 810 | 680 | 755 |

| 40 | 724 | 790 | 680 | 760 |

| 40Mn | 726 | 790 | 689 | 768 |

| 40Mn2 | 713 | 766 | 627 | 704 |

| 40MnB | 730 | 780 | 650 | 700 |

| 40MnVB | 730 | 774 | 639 | 681 |

| 40Cr | 743 | 782 | 693 | 730 |

| 40CrV | 755 | 790 | 700 | 745 |

| 40CrMnMo | 735 | 780 | 680 | – |

| 40CrSi | 755 | 850 | – | – |

| 40CrMnSiMoV | 780 | 830 | – | – |

| 40CrMnSiMoVRe | 725 | 850 | 625 | 715 |

| 40Cr 5M02VSi | 853 | 915 | 720 | 830 |

| 40SiMnMoVRe | 765 | 900 | 625 | 730 |

| 40CrNi | 731 | 769 | 660 | 702 |

| 40CrNiMo | 710 | 790 | – | – |

| 40CrMo | 730 | 780 | – | – |

| 45 | 724 | 780 | 682 | 751 |

| 45Mn2 | 715 | 770 | 640 | 720 |

| 45Mn2V | 725 | 770 | – | – |

| 45Cr | 721 | 771 | 660 | 693 |

| 50 | 720 | 765 | 690 | 720 |

| 50Mn | 720 | 760 | 660 | – |

| 50Mn2 | 710 | 760 | 596 | 680 |

| 50Cr | 721 | 771 | 660 | 692 |

| 50CrV | 752 | 788 | 688 | 746 |

| 50CrMn | 750 | 775 | – | – |

| 55 | 727 | 774 | 690 | 755 |

| 55Si2Mn | 775 | 840 | – | – |

| 55Si2MnB | 764 | 794 | – | – |

| 55Si2MnVB | 765 | 803 | – | – |

| 60 | 727 | 766 | 690 | 743 |

| 60Mn | 727 | 765 | 689 | 741 |

| 60Si2Mn | 755 | 810 | 700 | 770 |

| 65 | 727 | 752 | 696 | 730 |

| 65Mn | 726 | 765 | 689 | 741 |

| 70 | 730 | 743 | 693 | 727 |

| 85 | 723 | 737 | – | 695 |

| T7 | 730 | 770 | 700 | – |

| T8 | 730 | – | 700 | – |

| T10 | 730 | 800 | 700 | – |

| T11 | 730 | 810 | 700 | – |

| T12 | 730 | 820 | 700 | – |

| SiMn | 760 | 865 | 708 | – |

| 9SiCr | 770 | 870 | 730 | – |

| CrWMn | 750 | 940 | 710 | – |

| 3Cr2W8V | 820 | 1100 | 790 | – |

| 3Cr2W8 | 810 | 1100 | – | – |

| W18Cr4V | 820 | 1330 | 760 | – |

| W9Cr4V2 | 810 | – | 760 | – |

| 3Cr 3Mo 3VNb | 836~948 | – | 771~923 | – |

| Cr12V | 810 | – | 760 | – |

| Cr12MoV | 815 | – | – | – |

| Cr 12Mo | 810 | 1200 | 760 | – |

| 5C rMnMo | 710 | 760 | 650 | – |

| 5CrNiMo | 710 | 770 | 680 | – |

| GCr15 | 745 | 900 | 700 | – |

| GCr15SiMn | 770 | 872 | 708 | – |

| 1Cr13 | 730 | 850 | 700 | 820 |

| 2Cr13 | 820 | 950 | 780 | – |

| 3Cr13 | 780~850 | – | – | – |

| 4Cr13 | 790~850 | – | – | – |

| Cr17Ni2 | 810 | – | 710 | – |

| 9Cr18 | 830 | – | 810 | – |

| 4Cr9Si2 | 900 | 970 | 810 | 870 |

| 4Cr10Si2Mo | 850 | 950 | 700 | 845 |

| Mn13 | – | – | – | – |

| Grade | Quenching heating temperature (℃) | Ms /℃ |

| 10 | 900~920(water)or no heat treatment | 450 |

| 10Mn2A | 850~857(water) | – |

| 12CrNi3A | 860(oil)780~810(oil) | (420) |

| 100CrNi3A | 860(oil)780~810(oil) | 150 |

| 12Cr2Ni4A | 860(oil)780(oil) | 400 |

| 100Cr2Ni4A | 880(oil)780(oil) | 125 |

| 15 | 890~920(water) | 450 |

| 15Mn | 850~900(water) | 410 |

| 15SiMn2MoVA | 880(oil) | 275 |

| 15Cr | 860(oil) 780~810(oil) | – |

| 15CrMnA | 840~870(oil)810~840(oil) | 400 |

| 15CrMnMoVA | 965~985(air or oil) | 372 |

| 18Mn2CrMoB | 920(air or oil) | 320 |

| 18Cr2Ni4WA | 950(air)860~870(oil) | 310 |

| 100Cr2Ni4WA | – | 75 |

| 20 | 900~950(water) | 425 |

| 20Mn | 850~900(water) | (420) |

| 20Mn2 | 860~880(water)880~910(oil) | 370 |

| 20Mn2B | 860~880(oil) | – |

| 20MnVB | 860~880(oil) | 230 |

| 20MnTiB | 860~890(oil) | – |

| 20MnMoB | 850~890 (oil) | – |

| 20Cr | 860~880(oil) | (390) |

| 20CrV | 870~900(oil) | – |

| 20CrMnB | 860~880(water or oil) | – |

| 20CrNi | 840~880(water or oil) | (410) |

| 20CrNi3A | 820~-840(oil) | (340) |

| 20Cr2Ni4A | (330) | |

| 22CrMnMo | 830~850(oil) | – |

| 30 | 850~890(water or oil) | 380 |

| 30Mn2 | 820~840(water)830~850(oil) | 340 |

| 30Mn | 850~900(oil) | 355 |

| 30SiMnMoV | 850~890(oil) | |

| 30Si2Mn2MoWV | 950(oil) | 310 |

| 30CrMnSi | 870~890(oil) | 320 |

| 30CrMo | 850~880(water or oil) | 345 |

| 30CrMnTi | 870~890(oil) | – |

| 30CrMnSiNi2A | 890~900(oil) | 314 |

| 30CrNi3 | 830(oil) | 305 |

| 35SiMn | 880~900(oil) | (330) |

| 35CrMoV | 900~920(water or oil) | – |

| 35CrMo | 820~840(water)830~850(oil) | 271 |

| 35CrMnSi | 850~870(oil) | – |

| 38Cr | 860(oil) | 250 |

| 38CrMoAl | 930~950(oil) | (370) |

| 37CrNi3 | 820(oil) | (280) |

| 38CrSi | 900~920(water or oil) | (330) |

| 40 | 830~880(water or oil) | (340) |

| 40Mn | 820~860(water or oil) | – |

| 40Mn2 | 810~850(oil) | (340) |

| 40MnB | 820~860(oil) | – |

| 40MnVB | 830~870(oil) | – |

| 40Cr | 830~860(oil) | (355) |

| 40CrV | 880(oil) | 218 |

| 40CrMnMo | 840~860(oil) | – |

| 40CrSi | 900~920(water or oil) | (320) |

| 40CrMnSiMoV | 920 (oil) | 290 |

| 40CrMnSiMoVRe | 930 (oil) | 270 |

| 40Cr 5M02VSi | 1000(air) | 325 |

| 40SiMnMoVRe | 930 (oil) | 300~305 |

| 40CrNi | 820~840 | 271 |

| 40CrNiMo | 850(oil) | 320 |

| 40CrMo | 820~840(water) | 360 |

| 45 | 780~860(water or oil) | (345) |

| 45Mn2 | 810~840(oil) | 320 |

| 45Mn2V | 840-860 (water) | 310 |

| 45Cr | 820 ~ -840 (oil) | (355) |

| 50 | 820~850 (water or oil) | (320) |

| 50Mn | 780 ~ 840 (water or oil) | 320 |

| 50Mn2 | 810-840 (oil) | 325 |

| 50Cr | 820 (oil) | 250 |

| 50CrV | 860 (oil) | (270) |

| 50CrMn | 840~860 (oil) | (250) |

| 55 | 790~830(water)820~850 (oil) | (290) |

| 55Si2Mn | 850~880(water or oil) | (280) |

| 55Si2MnB | 870(oil) | – |

| 55Si2MnVB | 880(oil) | – |

| 60 | 780~830(water or oil) | 270 |

| 60Mn | 790~820(oil or 160℃nitrate) | 270 |

| 60Si2Mn | 840~860(water or oil) | 305 |

| 65 | 780~830(water or oil) | 270 |

| 65Mn | 790-820(oil or 160℃nitrate) | 270 |

| 70 | 780~830(water or oil) | 230 |

| 85 | 780~820(water or oil) | 220 |

| T7 | 800~820(water) | 250~300 |

| T8 | 780~820(water) | 225~250 |

| T10 | 770~790(water) | 175~210 |

| T11 | 770~790(water) | 200 |

| T12 | 770~790(water) | – |

| SiMn | 780~840(water, oil or nitrate) | (250) |

| 9SiCr | 860~870(oil) | (170) |

| CrWMn | 800~830(oil) | (250) |

| 3Cr2W8V | 1050~1100(oil) | (340) |

| 3Cr2W8 | 1075~1130(oil) | 330 |

| W18Cr4V | 1280~1300(oil) | (220) |

| W9Cr4V2 | 1225~1240(oil) | (200) |

| 3Cr 3Mo 3VNb | 1060~1090(oil) | 385 |

| Cr12V | 1040~1080(oil) | 180 |

| Cr12MoV | 1040~10501120~1130(air or) | (<185) |

| Cr 12Mo | 950~1000(oil) | (225) |

| 5C rMnMo | 820~850(oil) | (220) |

| 5CrNiMo | 830~860(oil) | (220) |

| GCr15 | 820~850(oil) | (240) |

| GCr15SiMn | 820~840(oil) | – |

| 1Cr13 | 980~1050(oil) | (350) |

| 2Cr13 | 980~1050(oil) | 320 |

| 3Cr13 | 980~1050(oil) | (240) |

| 4Cr13 | 980~1050(oil) | 145~270 |

| Cr17Ni2 | 950~970(oil) | 357 |

| 9Cr18 | 1050~1075(oil) | – |

| 4Cr9Si2 | 1000~1050(oil) | – |

| 4Cr10Si2Mo | 1010~1050(oil or air) | – |

| Mn13 | 1050(oil or water) | 200 |

Note: the data in brackets in the table need further study because:

1. Different data provide different data for the same steel type, but only one is selected in this table:

2. The data of the same steel type is gathered from different data.