I. Common Metal Deburring Methods

Here are the 10 easiest methods to deburr metal:

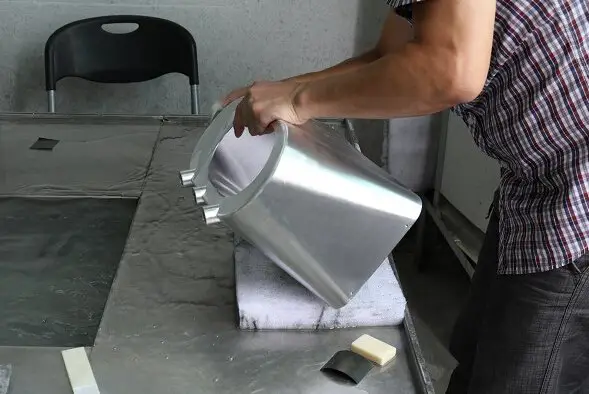

1. Deburring manually

The removal of burrs is carried out using a file, sandpaper, and a high-quality tool to polish the workpiece.

This method does not require a high level of technical skill from the worker, and it is suitable for products with small burrs and a simple structure.

Therefore, it is widely used in many businesses to remove burrs.

There are two types of files: manual and pneumatic. The manual file is more expensive, and its deburring efficiency is not very high. It is also difficult to remove complex cross holes with this method.

Note: The manual file’s higher cost, low deburring efficiency, and difficulty in removing complex cross holes are its disadvantages.

Disadvantages: Expensive labor cost, low efficiency, and difficulty in removing complex cross holes.

Applicable objects: Aluminum alloy die castings with simple product structure and low technical requirements for workers.

2. Deburring with punch

The removal of burrs can be done using a punch mold in a punching machine.

A punching die requires both rough and fine blanking dies, and a sizing die may also be needed.

This method is suitable for simple products and provides better efficiency and deburring results compared to manual methods.

Disadvantages: It requires a certain cost for the production of rough and fine blanking dies, and it may also require the production of sizing dies.

Applicable Objects: Suitable for aluminum alloy die castings with simple parting surfaces. The efficiency and deburring effect are better than manual methods.

3. Deburring by grinding

The method of removing burrs through vibration, sandblasting, and roller is widely used by enterprises.

The disadvantage of deburring by grinding is that sometimes the removal is not very clean and may require subsequent manual processing or other deburring methods.

This method is suitable for a large number of small products.

Disadvantages: The removal is not always thorough, and additional manual processing or use of other deburring methods may be necessary to remove residual burrs.

Applicable objects: Suitable for large batches of small aluminum alloy die castings.

4. Deburring by freezing

This method involves using a temperature drop to quickly make the burrs brittle and then blasting them off with pellets. It is ideal for workpieces with small burr wall thickness and smaller size.

However, the cost of the necessary equipment can be high, ranging from 30,000 to 40,000 USD.

Applicable object: Suitable for aluminum alloy die castings with thin burr walls and small volumes.

5. Deburring by thermal explosion

The method of thermal deburring, also known as explosion deburring, involves passing gas into a furnace and then causing it to explode instantaneously. The energy produced by the explosion is used to dissolve the burr.

While this method is mainly used for high precision parts in industries such as automotive and aerospace, it comes with several drawbacks.

The required equipment is very expensive, often costing over 150,000 USD, and operating it requires highly skilled technology.

Additionally, the removal of burrs is often inefficient and can result in side effects like rust and deformation.

Disadvantages: Expensive equipment (prices in the hundreds of thousands), high operational technical requirements, low efficiency, and side effects (rust and deformation).

Applicable objects: Mainly used in high-precision fields such as automobiles and aerospace for precision parts.

6. Deburring by engraving machine

The method of removing burrs using an engraving machine is cost-effective, usually costing several thousands of dollars.

This method is appropriate for removing burrs with simple spatial structures and positions.

Applicable Objects: Suitable for products with simple spatial structures and regular burr removal positions.

7. Chemical deburring

The method of chemical deburring utilizes the principle of electrochemical reaction to remove burrs from metal components in a selective and automated manner.

It is ideal for addressing internal burrs that are challenging to remove, particularly small burrs on components such as pump bodies and valve bodies.

Applicable object: This method is appropriate for removing internal burrs that are hard to remove, and small burrs (with a thickness less than 7 wires) found on pump bodies, valve bodies, and other similar components.

8. Electrolytic deburring

The method of removing burrs from metal parts through electrolysis.

However, this method can have some adverse effects as the electrolyte is corrosive and can cause the surface near the burr to lose its luster and even affect dimensional accuracy.

Hence, it is necessary to clean and rust-treat the workpiece after electrolytic deburring.

This method is suitable for removing burrs in concealed parts of the workpiece and complex shapes, and is known for its high production efficiency, with operations typically taking only a few seconds to several tens of seconds.

It can be applied to the oil line holes of gears, connecting rods, valve bodies, crankshafts, and for rounding sharp corners.

Disadvantages: the corrosive nature of the electrolyte, which can affect the original luster on the surface near the burr and affect dimensional accuracy.

Aluminum alloy die castings need to be cleaned and treated against rust after deburring.

Applicable objects: suitable for deburring gear, connecting rod, valve body and crankshaft oil line orifices, as well as rounding sharp corners, etc.

9. High-pressure water jet deburring

The method of removing burrs and flying edges using the instantaneous impact of water for cleaning purposes.

This equipment is highly expensive and mainly used in the automotive core and the hydraulic control system of engineering machinery.

Disadvantage: Expensive equipment.

Applicable object: Mainly used for the hydraulic control system of automotive core and engineering machinery.

10. Ultrasonic deburring

Conventional vibration grinding may have difficulties in removing burrs in holes.

The abrasive flow machining process involves pushing abrasives through two opposing abrasive cylinders, causing it to flow back and forth within the channel formed by the workpiece and fixture.

The grinding effect is produced by the abrasive entering and flowing through restricted areas.

The extrusion pressure is adjustable within the range of 7-200 bar (100-3000 psi), making it suitable for various stroke lengths and cycle times.

Applicable Object: It is capable of handling 0.35mm microporous burrs without secondary burrs, and its fluid characteristics allow for burr removal in complex positions.

11. Abrasive flow deburring

Conventional vibration grinding has difficulty in removing burrs in holes.

The typical abrasive flow machining process (two-way flow) involves pushing abrasives through two vertically opposite abrasive cylinders, causing it to flow back and forth in the channel formed by the workpiece and fixture.

Wherever the abrasives enter and flow through a restricted area, it will cause a grinding effect.

The extrusion pressure is controlled at 7-200bar (100-3000 psi), making it suitable for different strokes and cycle times.

Applicable Objects: This method can handle 0.35mm microporous burrs without causing secondary burrs, and its fluid characteristics make it suitable for removing burrs in complex positions.

12. Magnetic deburring

Magnetic Abrasive Machining is a process in which strong magnetic fields are used to arrange magnetic abrasive particles along magnetic lines of force.

The abrasive particles are adsorbed on magnetic poles to form an “abrasive brush” that exerts pressure on the surface of the workpiece.

As the magnetic pole rotates the “abrasive brush,” it moves along the surface of the workpiece while maintaining a gap, thereby achieving surface finishing.

Advantages: low cost, wide processing range, and convenient operation.

Processing factors: abrasive material, magnetic field strength, workpiece speed, etc.

13. Robot grinding unit

The principle behind robot deburring is similar to manual deburring, with the only difference being the use of a robot to perform the task.

The use of programming technology and force control technology in robot deburring allows for flexible grinding, which allows for the transformation of pressure and speed.

Compared to manual deburring, robot deburring offers several advantages, including improved efficiency, improved quality, and a higher cost.

However, deburring milling parts can be more complex and expensive, as multiple burrs can form in different positions and sizes.

In such cases, it is crucial to select the correct process parameters to minimize the size of the burr.

II. What Is Metal Burrs?

Burr refers to a metal residue or microscopic metal particles that remain on the surface of metal as a result of casting, milling, or electroplating processes.

The appearance of burrs on metal workpieces significantly lowers their quality standards, so it is crucial to prevent or remove them.

One of the dangers posed by burrs is that they are easily cut.

Therefore, a secondary operation known as deburring is usually necessary to remove them.

Deburring and edge finishing of precision parts can account for as much as 30% of the cost of the finished parts, and these secondary finishing operations are often difficult to automate, making burrs a persistent problem.

III. Types of Metal Burrs

When I work with metals, I often encounter different types of metal burrs. It is crucial to understand these types to properly address them during the deburring process. In this section, I will discuss the metal burrs I frequently encounter.

The first type of burr I come across is a Poisson burr. This occurs when metal is folded over the edge of the adjacent surface while cutting, creating a raised and rough edge. This type of burr is usually thin and can be easily removed with a deburring tool.

Another type of burr is the rollover burr. It is formed when the metal is pushed aside during the cutting process, causing a rounded edge. The rollover burr can be more challenging to remove than the Poisson burr due to its shape, but it is possible with the correct tool and technique.

The tear burr is another burr I regularly encounter. This is caused by the tearing of metal during the cutting process, resulting in a jagged and irregular edge. To remove tear burrs, I often need to use more force and a more aggressive deburring tool.

When working with sheet metal, I sometimes see breakout burrs. These are caused by the metal being fractured or ripped from the opposite side of the cutting tool’s exit point. Breakout burrs can be quite large and might need a combination of tools and techniques to properly remove them.

In some cases, I come across oxide burrs—also known as heat-affected burrs. These are formed when heat from the cutting process causes the metal to oxidize, creating a raised edge. Removing oxide burrs typically requires a combination of mechanical and chemical methods to ensure both the burr and the oxidation are dealt with appropriately.

Finally, there are microburrs, which are small burrs that are barely visible to the naked eye. They might not seem like a big issue, but they can still cause problems if not addressed. To remove microburrs, I often use precision tools or polishing techniques.

In summary, these are the different types of metal burrs I frequently encounter. Understanding them helps me to properly address them during the deburring process and ensures I produce high-quality, burr-free metal parts.

I like this weblog very much, Its a rattling nice position to read and obtain info .

I always was concerned in this subject and still am, thankyou for putting up.

We hand deburr our CPM10V punch and dies with brass. It mostly works but you can feel a microscopic remnant on the edge. The tools are interference fit so a burr can destroy the cutting edge if it is not managed. I am looking for a method to improve the process and eliminate some of the manual work.

Try 3m 15micron micro polishing paper. It sticks to a palm sander and works not to affect the edge quality.

I work with gang punch assemblies of 3mm punches with about a 3mm gap between. The process after grinding sharp is using brass rods to break the bur while looking through a microscope. It is tedious and not so effective. I have found damage caused by burr coming loose while the die is in operation. The palm sander is not the right tool for the space. I may give the polish paper a try as I can’t get even a small stone in many places.