How can manufacturers tackle the challenges of drilling deep holes with precision and efficiency? This article dives into the world of deep hole drilling tools, exploring various types and their specific applications. You’ll learn about the latest advancements in drill bit technology, their characteristics, and how to overcome common obstacles in deep hole machining. Get ready to enhance your knowledge and boost your manufacturing processes with these crucial insights.

Deep hole machining is a challenging aspect of mechanical engineering and a current hot topic in processing. As the demands for complex deep hole machining increase, requiring both high precision and efficiency, mastering the performance and application range of various deep hole drills becomes crucial.

This article mainly introduces the characteristics, application range, and considerations of various deep hole drill bits.

In mechanical manufacturing, a cylindrical hole with a depth exceeding ten times its diameter is generally called a deep hole.

Deep holes are categorized based on the ratio of hole depth (L) to diameter (D), usually divided into general deep holes, medium deep holes, and special deep holes. (Note: The larger the L/D ratio, the more challenging the machining process.)

Deep hole drills are categorized into external and internal chip removal types. External chip removal includes gun drills and integral carbide deep hole drills (which can be with or without cooling holes); internal chip removal includes BTA deep hole drills, ejector drills, and DF system deep hole drills. The types and application ranges of deep hole drills are as follows.

| type | Scope of use |

| External chip removal deep hole drill (gun drill) | Used for processing Φ 2- Φ Deep holes with a length to diameter ratio of 20mm, L/D>100, accuracy of H8-H10, and surface roughness value of Ra=12.5-3.2um have lower production efficiency than internal chip removal deep hole drills |

| BTA internal chip removal deep hole drill | Used for processing Φ 6- Φ A deep hole with a length to diameter ratio of 60mm, L/D>100, accuracy of H7-H9, and surface roughness value of Ra=3.2um, with a production efficiency more than three times that of external chip removal |

| Spray suction drill | Used for processing Φ 16- Φ In the case of 60mm and low cutting fluid pressure, other performance is the same as that of internal chip removal deep hole drilling |

| DF system deep hole drill | A drill pipe is supported by cutting fluid, reducing vibration, providing a larger chip removal space, high machining efficiency, and good accuracy. It can be used for high-precision deep hole machining; The production efficiency is 3-6 times higher than that of gun drills and 3 times higher than that of BTA internal chip drills |

Named for their initial use in the military industry for machining gun barrels and cannons, gun drills are effective for a wide range of deep hole machining, from mold steel, fiberglass, Teflon, and other plastics to high-strength alloys (like P20 and chrome-nickel iron alloys). In deep hole machining with strict tolerance and surface roughness requirements, gun drills ensure dimensional accuracy, positional accuracy, and straightness.

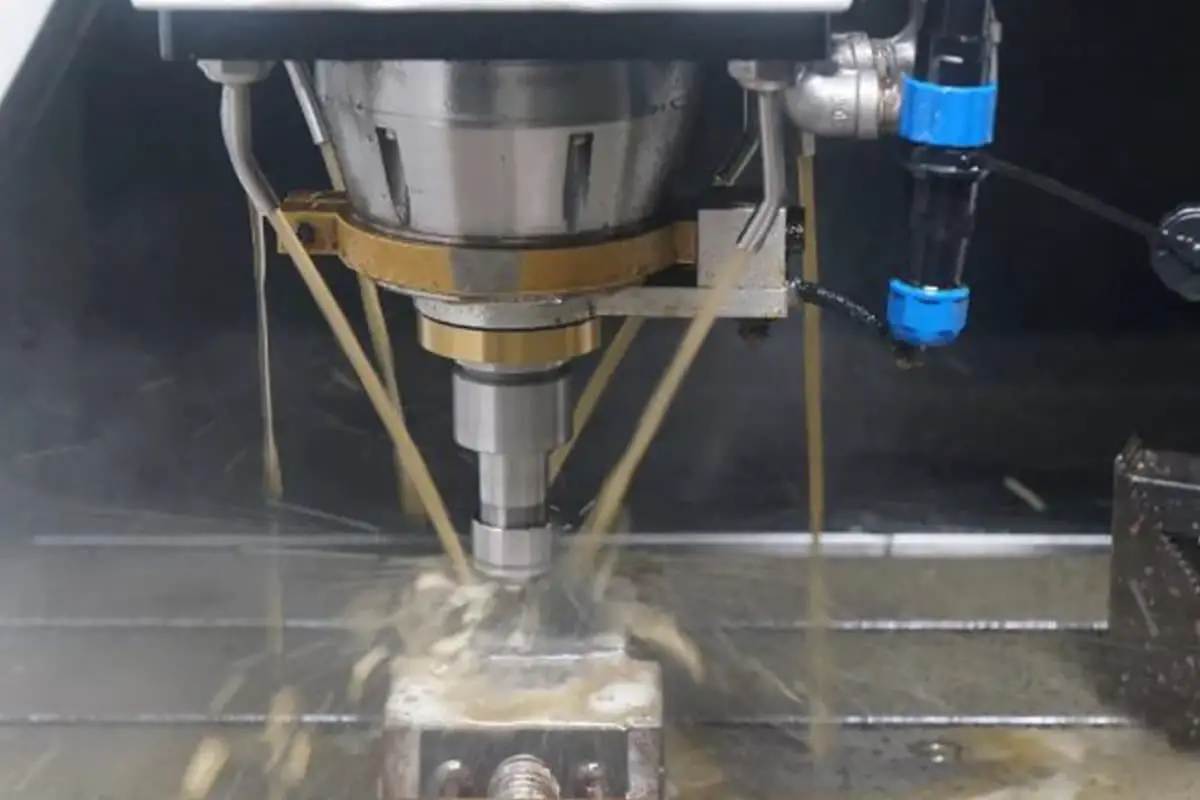

Working principle of the gun drill system: Cutting fluid enters the drill rod through the oil inlet at the tailstock, cools and lubricates the drill head, and ejects chips through the external V-shaped groove. This system is primarily used for small diameter deep holes (less than 20mm).

Gun drill applications: Gun drills (external chip removal deep hole drills) are mainly used for machining holes with diameters of φ2–20mm, aspect ratios L/D >100, precision IT8–IT10, and surface roughness values Ra=12.5–3.2μm. They are less efficient than internal chip removal deep hole drills.

To accommodate more complex large diameter deep hole machining requirements, the BTA internal chip removal deep hole drilling technology was developed. As chips are ejected internally, avoiding contact with the machined surface, BTA offers higher surface quality and a wider range of hole diameters compared to gun drilling.

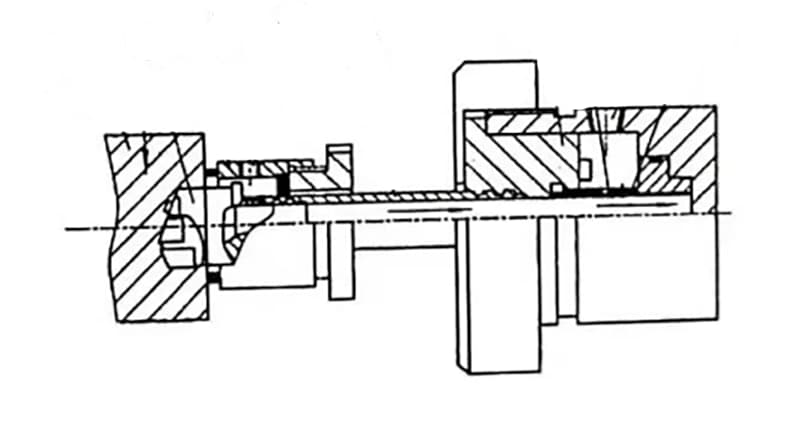

In the BTA system, both the drill head and rod are hollow cylinders. The working principle is illustrated below: Pressurized cutting fluid enters the oiler, flows through the annular space formed between the drill rod and hole wall to the cutting area for cooling and lubrication, and pushes chips into the chip exit on the drill head, which are then ejected through the inner cavity of the rod.

Internal chip removal deep hole drills are suitable for machining diameters above 20mm, aspect ratios up to 100, precision IT7–IT10, and surface roughness Ra3.2–1.6μm. Their production efficiency is more than three times that of external chip removal.

Main drawbacks of BTA internal chip removal deep hole drills: Special machine tools are required, along with a cutting fluid chip separation device using gravity sedimentation or electromagnetic separation for recycling the cutting fluid. Additionally, a high-pressure zone forms between the workpiece and oiler during cutting, necessitating a reliable seal before drilling.

The internal chip removal deep hole drilling system suffers from significant loss in the annular fluid channel, requiring higher pressure and flow rates during machining. To address this, the market has developed a more efficient and higher quality drilling technology – the ejector drill.

The ejector drill employs the principle of fluid dynamics’ ejector effect, using a dual-tube internal chip removal method invented with concentric drill rods. The tool is connected to the machine through a connector, and the ejector drill system uses a double-layered tubular drill rod. 2/3 of the pressurized cutting fluid enters the annular space between the inner and outer drill rods, flowing towards the cutting area for cooling and lubrication, and pushing the chips into the inner cavity of the drill rod.

The remaining 1/3 of the cutting fluid is injected at high speed from crescent-shaped nozzles on the inner drill rod, creating a low-pressure area within the inner cavity, which sucks in the cutting fluid carrying chips. Under the dual action of injection and suction, chips are rapidly ejected from the outlet.

The oil supply in ejector drilling is through a rotating connector, and the guide seat primarily serves a supporting role, allowing it to be detached from the workpiece. This is highly advantageous for five-axis machining, often involving non-planar surfaces where the guide seat cannot be in direct contact with the workpiece. Additionally, the vacuum effect created during ejector drilling facilitates chip removal, offering greater flexibility in use.

Ejector drills are mainly suitable for machining holes with aspect ratios not exceeding 100 and diameters ranging from 18 to 65mm, with precision levels between IT9 and IT11.

The DF system deep hole drill, also known as a single-tube ejector drill, is abbreviated from “Double Feeder”. This tool, developed in the mid-1970s by Nippon Metal Company Ltd., Japan, evolved from the standard ejector drill. It combines the chip ejection method of the standard BTA internal chip removal deep hole drill with the chip suction method of the ejector drill.

Its single drill rod is supported by cutting fluid, reducing vibration and allowing larger chip removal space, resulting in higher efficiency and precision. It is suitable for high-precision deep hole machining; its production efficiency is 3 to 6 times that of gun drills and three times higher than BTA internal chip removal drills, but at a higher cost.

The above drill head configurations indicate that regardless of the chip removal method, the system comprises the workpiece, tools, special accessories, machine tools, and control systems.

The special accessories depend on the cutting fluid supply method, chip removal method, and the relative motion between the workpiece and the tool. Hence, deep hole machining requires specialized equipment and accessories, making the equipment structure complex and costly.

Ensure the concentricity of the spindle and tool guide bushing, tool bar support bushing, and workpiece support bushing; maintain a clear and normal cutting fluid system; avoid center holes on the machined end face and drilling on inclined surfaces; keep chip shapes normal, avoiding straight band-shaped chips; use higher speeds for through-hole machining, reducing speed or stopping the machine as the drill is about to break through to prevent damage to the drill.

Deep hole machining generates significant cutting heat, which is difficult to dissipate, requiring sufficient cutting fluid for tool lubrication and cooling.

Typically, a 1:100 emulsion or extreme pressure emulsion is used; for higher precision and surface quality requirements or when machining tough materials, choose extreme pressure emulsion or high-concentration extreme pressure emulsion. The cutting oil’s kinematic viscosity is usually chosen at (40°C) 10–20cm²/s, with a fluid flow rate of 15–18m/s; use lower viscosity cutting oils for smaller diameters; for high-precision deep hole machining, a cutting oil mixture of 40% extreme pressure sulfurized oil + 40% kerosene + 20% chlorinated paraffin can be used.

The pressure and flow rate of the cutting fluid are closely related to the hole diameter and machining method, as detailed in the reference table.

| External chip removal deep hole drill | Internal chip removal deep hole drill | ||||

| Aperture /mm | Pressure /MPa | Flow rate /(L/min) | Aperture /mm | Pressure /MPa | Flow rate /(L/min) |

| 4-10 | 2.5-6 | 8-20 | 8-15 | 5-6.5 | 20-50 |

| 10-15 | 2-5 | 20-30 | 15-25 | 4-5.5 | 50-70 |

| 15-20 | 1.5~4.5 | 30-40 | 25-35 | 3-4. 5 | 70-100 |

| 20-25 | 1.5-4 | 40-50 | 35-45 | 2.5-3.5 | 100-125 |

| 25-30 | 1.5-3 | 50-60 | 45-80 | 2-3 | 125-200 |

Deep hole machining holds a vital position in the field of mechanical machining, accounting for about 40% of hole machining. The continuous emergence of new high-hardness and high-value difficult-to-machine deep hole workpieces

demands higher processing depths, precision, and efficiency. As a key process and challenging aspect, only by understanding the concept of deep holes, the characteristics and challenges of deep hole machining, and comprehensively knowing the types, structures, and application ranges of various deep hole drill bits, can the efficiency of deep hole machining be improved.