Ever wondered why brushless motors outperform brush motors? Brushless motors offer efficiency and durability, thanks to their electronic commutation, reducing friction and wear. In contrast, brush motors, though simpler and cost-effective, suffer from maintenance issues due to brush friction. This article dives into the distinct principles, performance, and applications of both motor types, helping you understand their strengths and limitations. Discover how these differences impact everything from speed regulation to operational stability. Dive in to learn which motor suits your needs best and why.

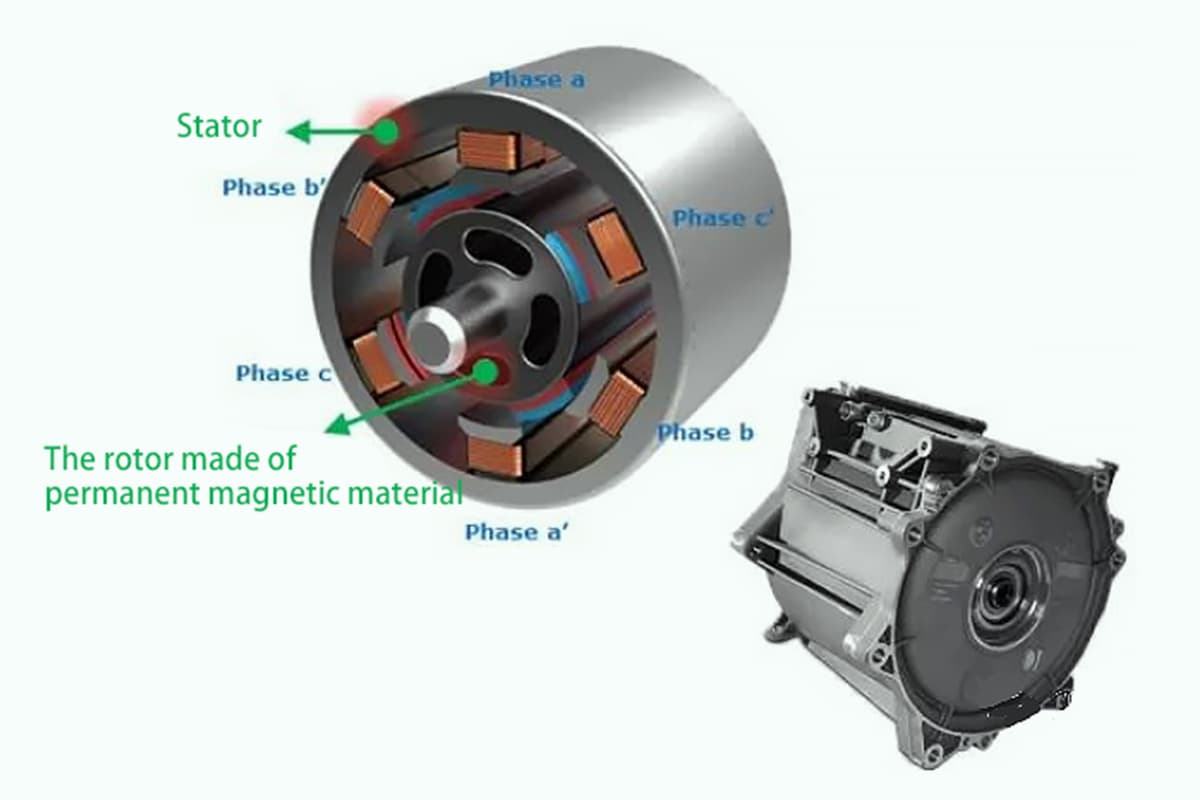

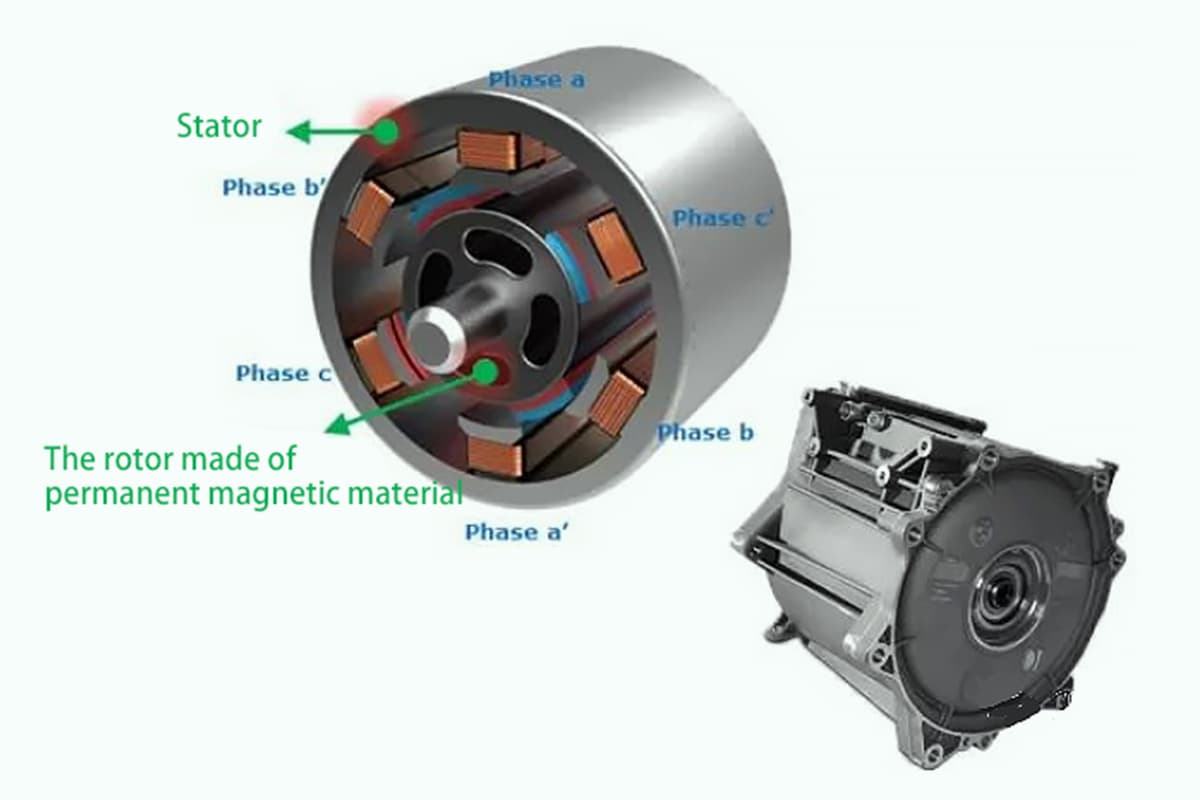

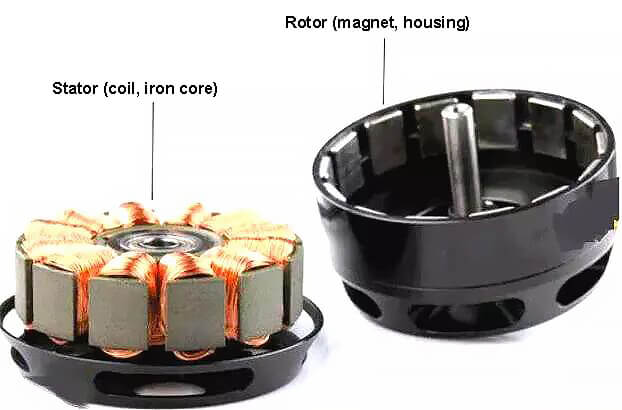

A Brushless DC motor is a mechatronics product that consists of a motor body and a driver.

Unlike synchronous motors that require a starting winding on the rotor to start under heavy load with variable frequency speed regulation, the brushless DC motor operates in a self-control mode. It does not produce oscillation or become out of step when there are sudden changes in the load.

The majority of small and medium-sized brushless DC motors utilize rare earth neodymium iron boron (Nd-Fe-B) magnets due to their high magnetic energy level.

As a result, the rare earth permanent magnet brushless motor has a smaller frame size than a three-phase asynchronous motor with the same capacity.

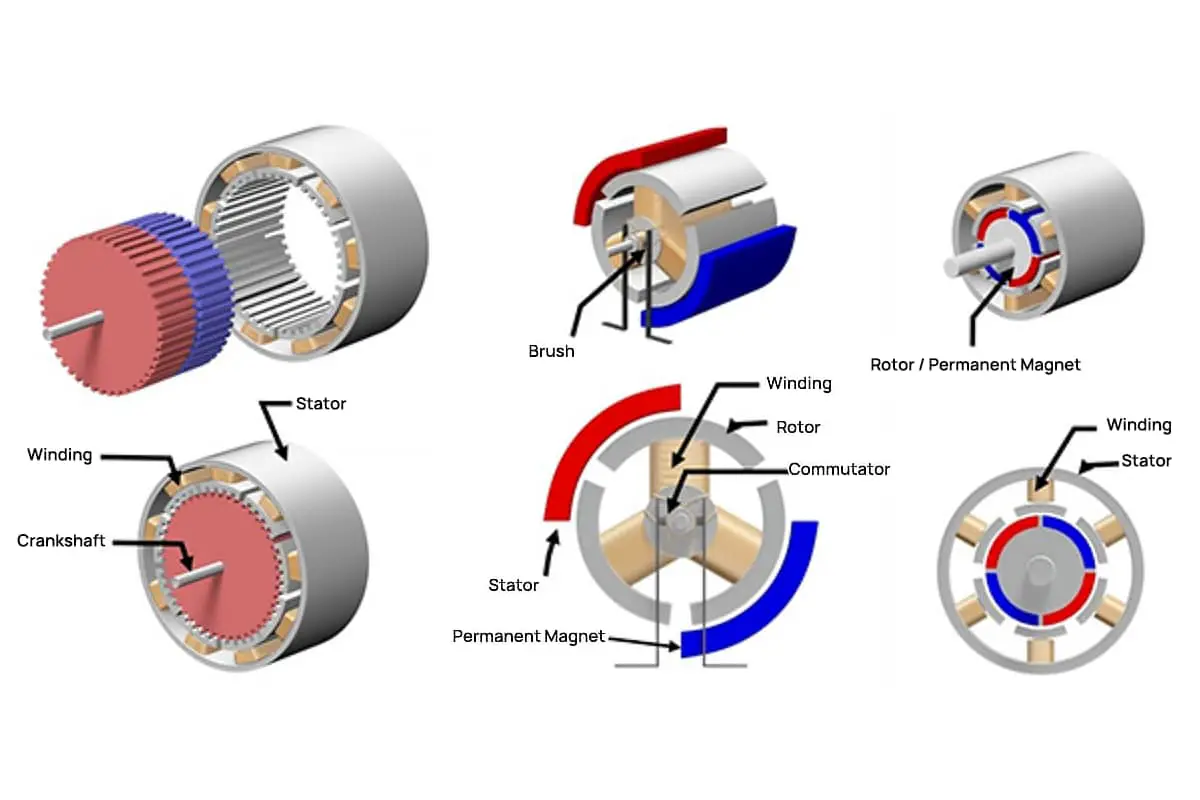

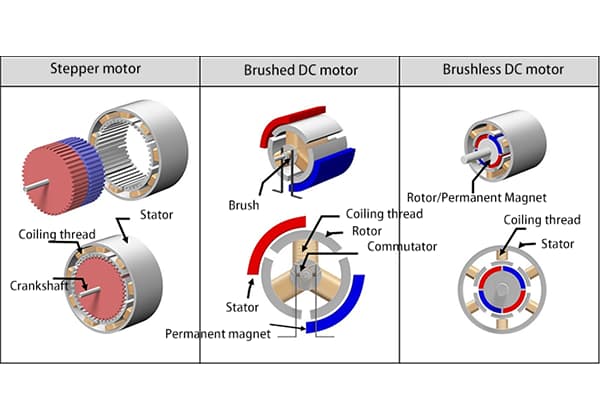

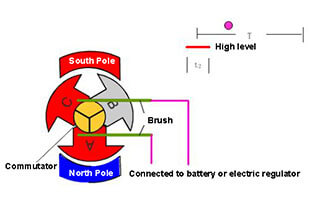

A brush motor is a rotating motor that uses a brush device to convert electrical energy into mechanical energy (as a motor) or mechanical energy into electrical energy (as a generator). Unlike brushless motors, a brush device is used to introduce or draw voltage and current.

The brush motor is the foundation of all motors, possessing several advantageous features such as fast start, timely braking, smooth speed regulation over a broad range, and a relatively simple control circuit.

The brushed motor is the first type of motor that we come into contact with, and it is often used as a model to illustrate motors in physics classes during middle school.

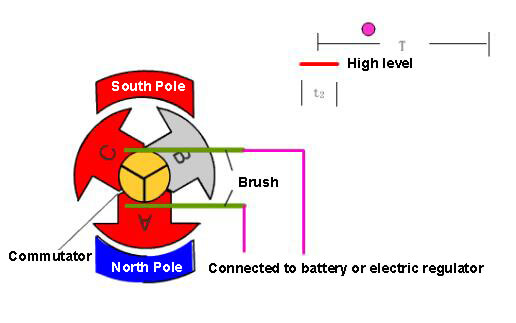

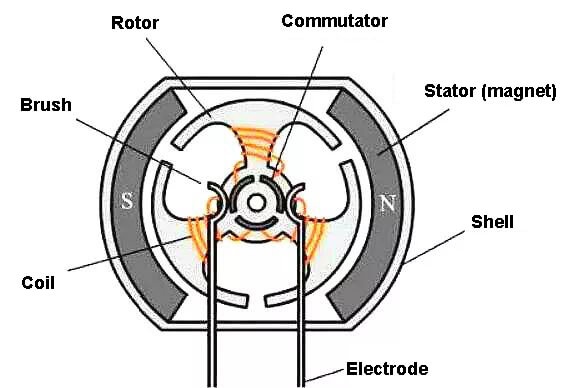

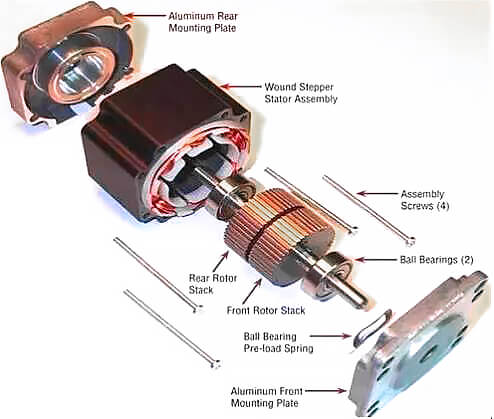

The main components of a brushed motor are the stator, rotor, and brushes.

Rotating torque is generated through a rotating magnetic field, which allows for the output of kinetic energy.

The brushes and commutator are in constant contact and friction, and they play the important roles of conduction and commutation during rotation.

The brush motor utilizes mechanical commutation, where the magnetic poles remain stationary while the coil rotates.

During operation, the coil and commutator rotate, while the magnetic steel and carbon brush remain stationary. The commutator and brush rotating with the motor enable the completion of the alternating change of coil current direction.

In a brush motor, this process involves arranging the two power input terminals of each group of coils into a ring. The power input terminals are separated from each other by insulating materials and formed into a cylinder connected with the motor shaft.

A small column made of two carbon elements (carbon brush) is used to pass the power supply. The carbon brush moves from two specific fixed positions under the action of spring pressure. Energizing a group of coils is achieved by pressing the two points on the upper coil power input ring cylinder.

As the motor rotates, different coils or different poles of the same coil are energized at different times. This creates a suitable angle difference between the N-S pole of the magnetic field generated by the coil and the N-S pole of the nearest permanent magnet stator. The magnetic field attracts and repels each other, generating force and driving the motor to rotate.

The carbon brush slides on the coil connector, similar to a brush on an object surface, hence the term carbon “brush”. However, sliding between them causes rubbing and loss, necessitating regular replacement of the carbon brush.

Furthermore, alternating on-off between the carbon brush and the coil connector generates electric sparks, produces electromagnetic break, and interferes with electronic equipment.

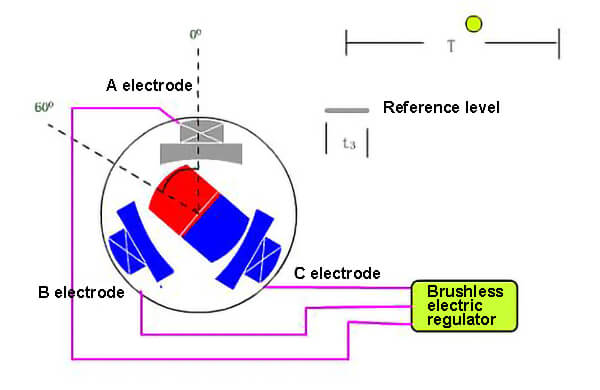

In a brushless motor, commutation is accomplished by the control circuit within the controller. Typically, this involves a Hall sensor and controller, although more advanced technology such as a magnetic encoder may also be utilized.

The brushless motor employs electronic commutation, with the coil remaining stationary while the magnetic pole rotates.

To detect the position of the permanent magnet’s magnetic pole, the brushless motor utilizes a set of electronic equipment that incorporates the hall element.

Based on this detection, the electronic circuit timely switches the current direction in the coil to ensure that the motor generates magnetic force in the correct direction to drive it.

The brush motor’s disadvantage is eliminated in the brushless motor.

These circuits are known as motor controllers.

The controller of the brushless motor can also achieve several functions that a brush motor cannot, such as adjusting the power switching angle, braking, reversing, locking, and stopping the power supply to the motor by utilizing the braking signal. The electronic alarm lock of battery cars takes full advantage of these functions.

A brushless DC motor, which comprises a motor body and driver, is a standard mechatronics product.

Because the brushless DC motor operates in a self-control mode, it does not require a starting winding on the rotor, such as the synchronous motor that starts under a heavy load with variable frequency speed regulation. Nor does it produce oscillation or become out of step when there is a sudden change in the load.

As early as the 19th century when the motor was first developed, the practical motor was brushless. This refers to the AC squirrel cage asynchronous motor, which became widely used after the generation of AC.

However, the asynchronous motor has many insurmountable defects, which hindered the development of motor technology. In particular, the brushless DC motor was not commercially available for a long time. It was only in recent years, with the rapid advancement of electronic technology, that it became available for commercial operation.

Nevertheless, the brushless DC motor still belongs to the category of AC motors.

Soon after the invention of the brushless motor, the DC brushless motor was developed. The DC brushless motor is popular because of its simple mechanism, easy production and processing, convenient maintenance, and easy control.

The DC motor also has characteristics such as fast response, large starting torque, and the ability to provide rated torque from zero speed to rated speed. As a result, it became widely used as soon as it was introduced.

The DC brush motor has several advantages, including fast starting response, significant starting torque, stable speed change, minimal vibration from zero to maximum speed, and the ability to drive more massive loads during starting.

On the other hand, the brushless motor has some drawbacks such as high starting resistance (inductive reactance), resulting in a low power factor and relatively small starting torque. It also produces a buzzing sound during starting and strong vibrations, and it can only drive smaller loads during starting.

The brush motor is regulated by voltage, ensuring stable starting, braking, and constant speed operation.

On the other hand, brushless motors are typically controlled by digital frequency conversion. This process involves converting AC to DC, then back to AC, and using frequency changes to control the speed.

As a result, brushless motors may experience unstable performance and significant vibration during starting and braking. They only become stable when operating at a constant speed.

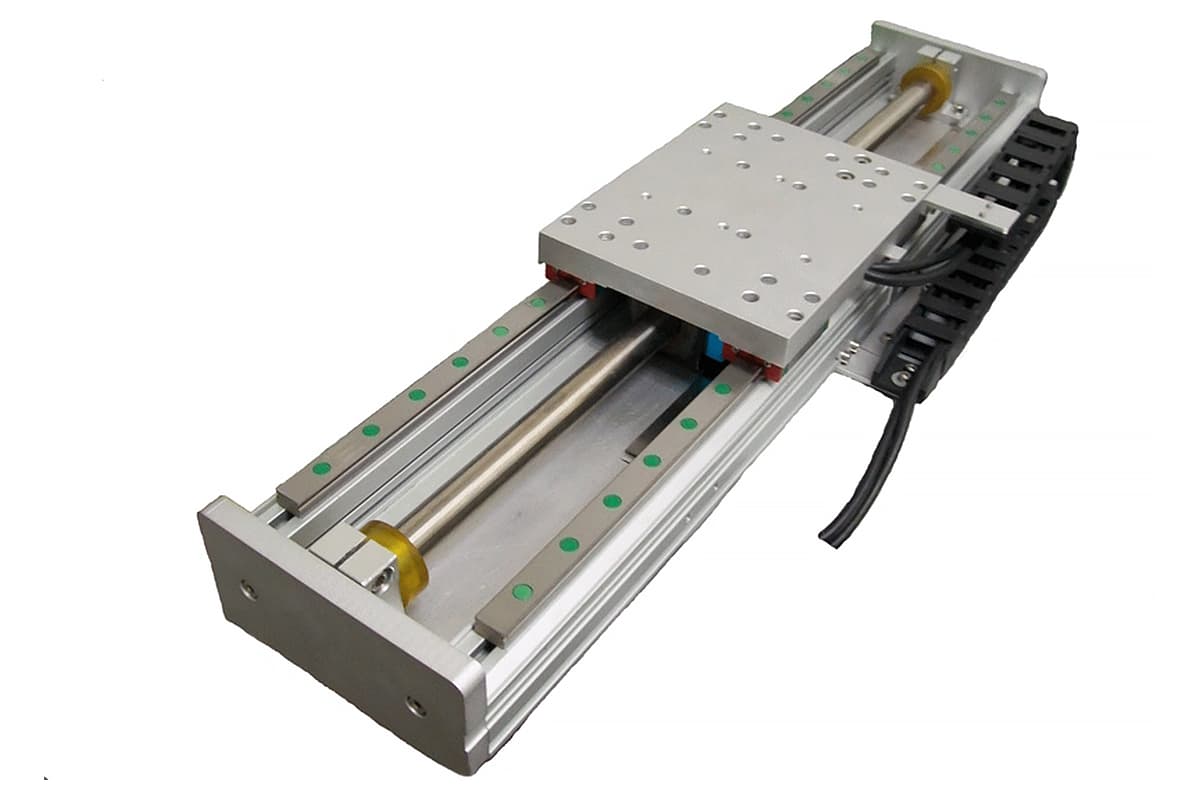

A DC brushless motor is typically combined with a reducer and decoder to increase the motor’s output power and improve control accuracy.

With a control accuracy that can reach 0.01 mm, the motor can stop the moving parts at almost any desired position.

DC motors control all precision machine tools.

However, the brushless motor is not stable during starting and braking, and the moving parts will stop at different positions each time.

To achieve the desired position, a locating pin or stopper must be used.

The DC brush motor is widely used due to its simple structure, low production cost, large number of manufacturers, and mature technology. It is commonly utilized in factories, processing machine tools, precision instruments, and other applications.

In the event of motor failure, simply replacing the carbon brush will suffice. Each carbon brush costs only a few yuan, making it an affordable solution.

On the other hand, the technology for brushless motors is still immature, the price is high, and the range of applications is limited. It is best suited for constant speed equipment such as variable frequency air conditioners and refrigerators. If the brushless motor is damaged, it can only be replaced.

The brushless motor eliminates the need for brushes, resulting in a significant change: there is no electric spark generated during its operation. This has a direct impact on reducing the interference caused by electric sparks to remote control radio equipment.

A brushless motor operates without brushes, resulting in significantly reduced friction, smoother operation, and much lower noise levels. These benefits greatly contribute to the operational stability of the model.

Since a brushless motor operates without brushes, the main source of wear and tear is on the bearing. From a mechanical perspective, brushless motors are nearly maintenance-free. When required, a simple dust removal maintenance is all that is necessary.

The control of the two motors is achieved through voltage regulation. Brushless DC motors use electronic commutation and can be realized with digital control, whereas traditional analog circuits like thyristors can be used for commutation through carbon brush in brush DC motors, making it relatively simple.

1. The speed regulation process of a brush motor involves adjusting the power supply voltage of the motor. The adjusted voltage and current are converted through the commutator and brush to change the strength of the magnetic field generated by the electrode, thereby changing the speed. This process is known as variable voltage speed regulation.

2. In contrast, the speed regulation process of a brushless motor involves keeping the voltage of the motor power supply unchanged while changing the control signal of electric regulation. The switching rate of high-power MOS transistor is altered by a microprocessor to change the speed. This process is called variable frequency speed regulation.