What’s the real difference between cast aluminum and die-cast aluminum? This article dives into the distinct manufacturing processes and properties that set these two types of aluminum apart. From the methods used in casting to their heat treatment capabilities and applications in various industries, you’ll discover the key factors that influence the choice between cast and die-cast aluminum. Get ready to understand how these differences impact the strength, quality, and usability of aluminum parts in everyday products.

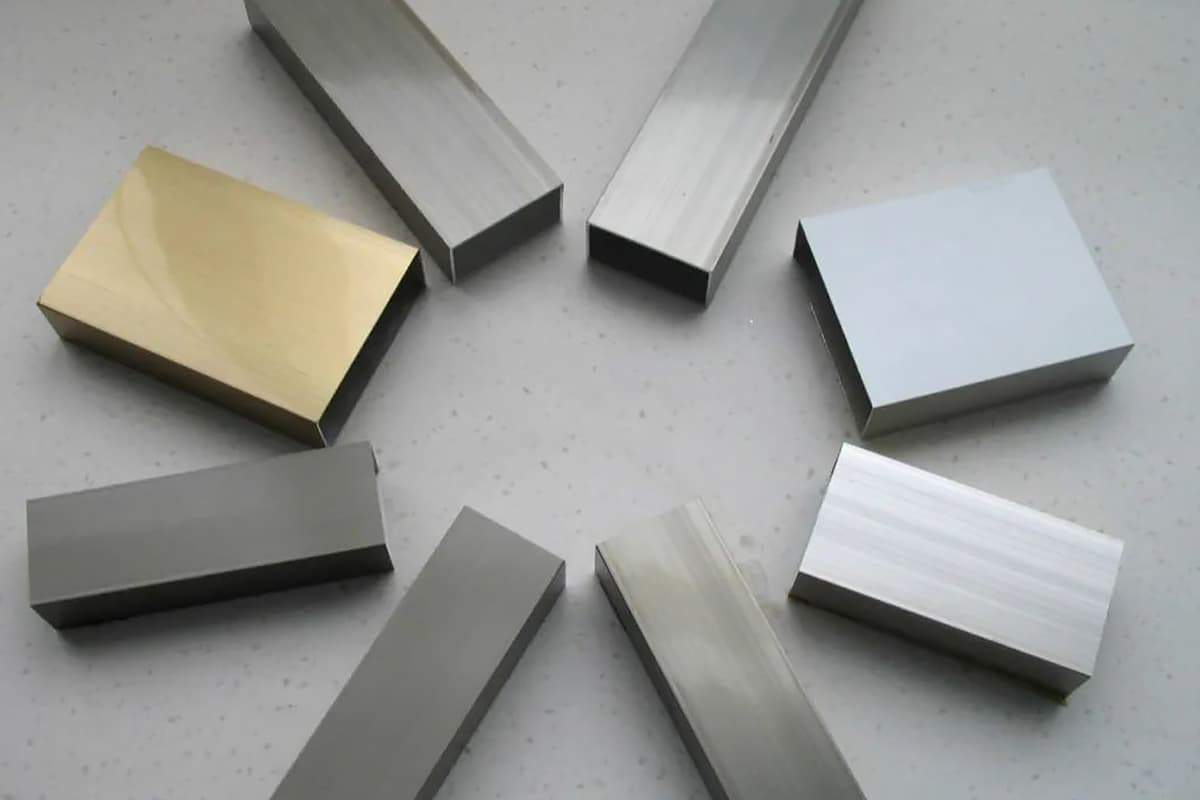

Cast aluminum” generally refers to aluminum castings made through the casting process, while “die-cast aluminum” refers to aluminum castings made through high-pressure die-casting. The primary difference between the two is the casting process used.

In the casting process, methods such as sand casting, dewaxing casting, gravity casting, low-pressure casting, ceramic mold casting, and gypsum mold casting are used. The die casting process, on the other hand, is a type of high-pressure die casting produced using a cold chamber die casting machine.

The aluminum grades used in the two processes are different, with ZL representing cast aluminum alloys in China’s national standard GB and YL representing cast aluminum alloys.

Cast aluminum castings can typically be strengthened through heat treatment, with T6 heat treatment being the most common method. However, die castings are not suitable for T6 heat treatment due to the large amount of gas densely distributed within them. This is because the temperature of T6 heat treatment is close to the melting point of aluminum alloys and the gas in the die casting will expand and be forced out of the casting surface, leading to surface damage and rendering the casting unusable.

Due to the dot protrusion after the gas runs out, the appearance of the casting is seriously damaged and cannot be used.

Aluminum alloy gravity casting and aluminum alloy low-pressure casting belong to the metal mold casting process and are used to produce aluminum castings. The molds are made of hot work die steel, such as H13.

These casting processes can produce the same brand of cast aluminum alloy, with similar pouring temperature and mold opening time, as well as compactness, strength, and other mechanical properties of the aluminum castings.

However, there are still differences between aluminum alloy gravity casting and aluminum alloy low-pressure casting in terms of forming principle, aluminum casting structure, labor intensity, batch number, development time, etc., as shown in the figure below.

| Forming principle | Aluminum casting structure | labour intensity | Minimum batch | Development time | Mold cost | |

|---|---|---|---|---|---|---|

| Aluminum alloy gravity casting | Using gravity | Complex and diverse | high | 100 | short | less |

| Aluminum alloy low pressure casting | Using air pressure | single | commonly | 500 | long | Higher |

According to the comparison shown above, aluminum alloy gravity casting is ideal for producing products with multiple varieties, small batch sizes, short development cycles, and high quality requirements, while aluminum alloy low-pressure casting is ideal for products with large batch sizes, thin walls, and structures that are suitable for the low-pressure casting process.

The long development cycle of the latter benefits the improvement of production technology throughout the manufacturing process.

A typical product produced through aluminum alloy low-pressure casting is an automobile wheel rim. Its structure is well-suited for the low-pressure casting process and the high volume of production allows sufficient time to improve production technology.

In contrast, typical products produced through aluminum alloy gravity casting are industrial robot castings. These aluminum castings require small production batches, high product quality, and a short development cycle. The aim is to produce high-quality aluminum castings without any pores or sand holes in a very short time.

Aluminum die casting is a sophisticated manufacturing process that offers significant advantages in producing complex parts and components across various industries. This high-pressure casting method involves injecting molten aluminum into a precision-engineered mold cavity, enabling the creation of intricate geometries that would be challenging or cost-prohibitive to produce through alternative methods such as extrusion, machining, or investment casting.

The most commonly used aluminum alloys in die casting are 383 (AlSi10Cu3) and 413 (AlSi12(Fe)), chosen for their optimal fluidity, castability, and mechanical properties. These alloys exhibit exceptional characteristics, including high thermal conductivity, excellent corrosion resistance, and superior strength-to-weight ratios. Additionally, they provide effective electromagnetic interference (EMI) and radio frequency interference (RFI) shielding, making them ideal for electronic enclosures and automotive components.

The die casting process consists of several critical stages:

This process allows for high-volume production with cycle times as short as 30-60 seconds per part, significantly reducing costs compared to other manufacturing techniques.

Key considerations in aluminum die casting design include:

Pressure Role

In aluminum die casting, high pressure is a critical factor in producing precise, high-quality components. Molten aluminum is injected into the mold cavity at pressures typically ranging from 10,000 to 20,000 psi (69 to 138 MPa). This extreme pressure ensures complete mold filling, capturing intricate details and producing parts with tight tolerances (often ±0.002 inch or ±0.05 mm) and excellent surface finish (as low as 63 μin or 1.6 μm Ra). The high pressure also enhances metal density and minimizes porosity, resulting in improved mechanical properties.

Solidification and Cavities

As the molten aluminum fills the mold cavity, rapid solidification occurs, with cooling rates often exceeding 1000°C/s. This quick solidification is crucial for achieving fine grain structure and superior mechanical properties. To prevent cavity formation and ensure uniform solidification, advanced thermal management techniques are employed. These include strategic placement of cooling channels, use of vacuum-assisted die casting (VADC) to remove trapped gases, and application of intensification pressure (up to 15,000 psi or 103 MPa) during solidification to compensate for shrinkage and minimize porosity.

Draft and Parting Line Considerations

Draft angles and parting lines are critical design elements in die casting. Standard draft angles range from 0.5° to 2° for external surfaces and 0.75° to 3° for internal surfaces, depending on part geometry and depth. Proper draft facilitates part ejection and reduces wear on the die.

Parting lines require careful placement to minimize flash and optimize part quality. Advanced CAD/CAM software and flow simulation tools are used to optimize parting line location, often incorporating stepped or complex parting surfaces to achieve the best compromise between part quality, tool complexity, and production efficiency. Flash thickness is typically controlled to less than 0.005 inch (0.13 mm) through precise die alignment and clamping force control.

Creating Complex Shapes

Aluminum die casting excels in producing complex shapes with intricate details. Modern die design allows for the creation of thin walls (down to 0.04 inch or 1 mm), deep ribs (aspect ratios up to 10:1), and complex core pulls for internal features. Multi-slide die casting machines enable the production of parts with undercuts and side-action features without the need for secondary operations.

Advanced simulation software, such as flow and solidification modeling, helps optimize gate locations, runner systems, and overflow designs to ensure complete filling of complex geometries. This capability, combined with the process’s ability to consolidate multiple components into a single part, makes aluminum die casting ideal for producing lightweight, high-strength components for industries like automotive (e.g., transmission cases, engine blocks) and aerospace (e.g., structural components, housings).

Mechanical Properties

Cast aluminum parts are renowned for their exceptional strength-to-weight ratio, making them ideal for applications where weight reduction is crucial without compromising structural integrity. Depending on the specific alloy and heat treatment, these components can achieve tensile strengths ranging from 150 MPa to over 300 MPa. Their lightweight nature (with a density of approximately 2.7 g/cm³) contributes to improved fuel efficiency in automotive applications and enhanced maneuverability in aerospace designs. While generally softer than cast iron or steel, aluminum castings can be heat-treated to increase hardness, with some alloys reaching up to 150 Brinell hardness numbers (BHN).

Thermal and Electrical Characteristics

Aluminum die casts exhibit excellent thermal properties, with a melting point around 660°C (1220°F) and the ability to maintain structural integrity at operating temperatures up to 200°C (392°F) for some high-temperature alloys. Their thermal conductivity, typically ranging from 96 to 167 W/(m·K), is approximately 4 times that of steel, facilitating rapid heat dissipation in applications such as engine components or heat sinks. Electrically, cast aluminum parts boast a conductivity of about 37% IACS (International Annealed Copper Standard), making them effective for EMI/RFI shielding in electronic enclosures while offering a cost-effective alternative to copper in certain electrical applications.

Corrosion and Wear Resistance

The inherent corrosion resistance of cast aluminum parts stems from the rapid formation of a protective oxide layer upon exposure to air. This passivation process provides excellent protection against atmospheric corrosion, with some alloys offering enhanced resistance through the addition of elements like magnesium or silicon. For severe environments, surface treatments such as anodizing can further improve corrosion resistance. Wear resistance in aluminum castings can be significantly enhanced through the use of silicon-rich alloys (e.g., A356 or A390), which form hard silicon particles within the microstructure, or through the application of surface hardening treatments like hard anodizing.

Efficiency and Volume

The aluminum die casting process excels in producing complex geometries with high dimensional accuracy and surface finish. Modern high-pressure die casting machines can achieve cycle times as low as 30-60 seconds per part, enabling production rates of up to 120 parts per hour for medium-sized components. The achievable tolerances of ±0.002″ to ±0.004″ (±0.05 to ±0.1 mm) allow for the production of near-net-shape parts, minimizing post-casting machining operations. This efficiency, coupled with the ability to cast thin walls (down to 0.5 mm in some cases) and intricate details, makes aluminum die casting particularly suitable for high-volume production in industries such as automotive, where a single vehicle may contain over 100 die-cast aluminum components.

Die cast aluminum is a versatile material that finds extensive applications across various industries due to its exceptional mechanical properties, cost-effectiveness, and manufacturability. This section explores the diverse uses of die cast aluminum in key sectors, highlighting its unique advantages and innovative applications.

Automotive Industry: Die cast aluminum has revolutionized the automotive sector by enabling significant weight reduction and improved fuel efficiency. Its high strength-to-weight ratio makes it ideal for critical components such as engine blocks, cylinder heads, transmission housings, and structural elements of vehicle chassis. Advanced aluminum alloys, such as A380 and A383, offer excellent fluidity and superior mechanical properties, allowing for the production of complex, thin-walled parts with tight tolerances. Moreover, aluminum’s thermal conductivity enhances heat dissipation in powertrain components, contributing to improved engine performance and longevity.

Industrial Applications: In the industrial sector, die cast aluminum components are integral to manufacturing equipment and machinery. The material’s corrosion resistance, dimensional stability, and ability to withstand diverse operating conditions make it suitable for applications ranging from heavy machinery to precision instruments. Die cast aluminum is extensively used in pneumatic and hydraulic systems, pump housings, valve bodies, and gearboxes. Its excellent machinability allows for post-casting operations, enabling the production of high-precision parts with complex geometries. Furthermore, aluminum’s recyclability aligns with sustainable manufacturing practices, reducing the environmental impact of industrial operations.

Electronics and Telecommunications: The electronics industry leverages die cast aluminum for its thermal management properties and EMI shielding capabilities. Complex housings for RF filter boxes, heat sinks, and networking equipment benefit from aluminum’s excellent thermal conductivity and ability to dissipate heat efficiently. Die cast aluminum enclosures provide robust protection against electromagnetic interference, ensuring the reliable operation of sensitive electronic components. The material’s lightweight nature is particularly advantageous in portable electronic devices, where weight reduction is crucial. Additionally, aluminum’s compatibility with various surface finishing techniques allows for enhanced aesthetics and functionality in consumer electronics.

Emerging Applications: Die cast aluminum is finding new applications in emerging technologies. In the renewable energy sector, it is used for solar panel frames and wind turbine components, offering durability and corrosion resistance in outdoor environments. The aerospace industry is increasingly adopting die cast aluminum for non-critical components to reduce aircraft weight. In the rapidly growing electric vehicle market, die cast aluminum is being used innovatively for battery enclosures and structural components, contributing to extended range and improved performance.

In conclusion, die cast aluminum’s versatility, coupled with advancements in alloy development and casting technologies, continues to expand its applications across industries. Its unique combination of lightweight properties, strength, thermal management capabilities, and cost-effectiveness makes it an indispensable material in modern manufacturing, driving innovation and efficiency in diverse sectors.