Have you ever wondered which laser welding method is more efficient for your project, fiber or CO2? This article explores the fundamental differences between fiber laser and CO2 laser welding, focusing on aspects like energy absorption, melting efficiency, and suitability for various welding speeds. By understanding these key differences, you’ll be better equipped to choose the right laser welding technology for your specific needs. Dive in to learn how each type performs under different conditions and discover which one offers the best efficiency for your applications.

The main difference between fiber laser and CO2 laser welding lies in their absorption rate of laser energy.

(1) The fiber laser has a shorter wavelength, resulting in less plasma production and higher energy density that is more concentrated. However, this also means a higher utilization rate of laser energy and a greater recoil pressure of metal vapor, making it challenging to find a balance between penetration and non-penetration.

(2) On the other hand, CO2 laser welding has a higher heat conduction loss power, leading to a larger inclination angle of the front wall of the small hole and a greater amount of plasma production. This helps to balance and adjust the distribution and absorption of laser energy, making the process window between penetration and non-penetration wider.

References are as follows:

The formation of welds differs greatly between fiber laser and CO2 laser welding. Research suggests that these differences stem from the coupling characteristics between the laser wavelengths and the materials being welded.

In laser welding, the strength of the coupling between the laser and the material can be evaluated through the melting efficiency.

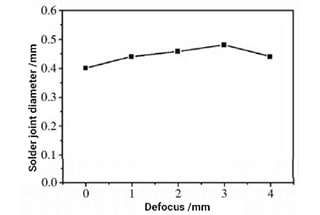

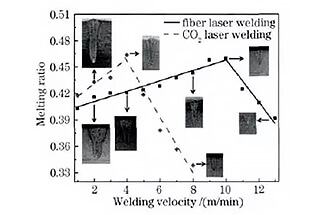

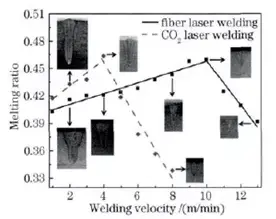

A comparison of the melting efficiency of fiber laser and CO2 laser welding is provided below.

To calculate the melting efficiency, the cross-sectional area of the weld is used. The results of the calculation are depicted in the accompanying figure.

The melting efficiency of both fiber laser and CO2 laser welding experiences an initial increase before decreasing as the welding speed increases. The peak melting efficiency for fiber laser welding occurs at a speed of approximately 10m/min, while for CO2 laser welding it occurs at a speed of about 4m/min.

The relationship between melting efficiency and welding speed is related to the energy coupling behavior during laser welding.

According to the principle of energy conservation, the total absorptivity (AK) of the deep penetration hole when exposed to the incident laser can be expressed as follows:

AK=(PF+ PEY+Po+ PL)/P

In the equation, PEV represents the power required for partial metal evaporation during welding, Po represents the power consumed by overheating of the molten pool metal, and PL represents the power lost through heat conduction.

According to research, the mass of laser welding evaporation (MeV) is very small and can therefore be ignored in the equation.

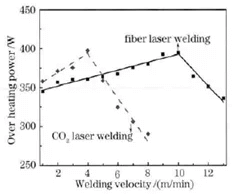

The pattern of variation of the superheat power of the molten pool (Po) with welding speed is similar to that of melting efficiency, but the proportion of superheat power to the total laser output power is relatively small.

A portion of the heat conduction power (PL) that passes through the melting front is utilized for plate melting, while the remainder is lost to the base metal through heat conduction.

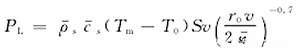

The power lost through heat conduction across the melting front can be expressed as follows:

In the equation, 2r0 represents the width of the weld and S represents the cross-sectional area of the weld.

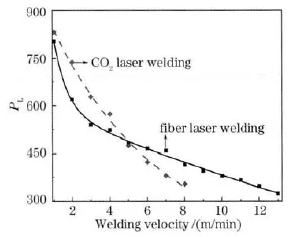

The relationship between PL and welding speed can be determined by substituting the cross-sectional product and fusion width of the weld, as measured in experiments, into the above formula. This is shown in the accompanying figure.

As observed in the figure, the power lost through heat conduction decreases with an increase in welding speed. This decrease is more pronounced at low welding speeds and becomes less significant at higher welding speeds.

The relationship between the total absorptivity (AK) of the deep penetration hole and welding speed for both fiber laser and CO2 laser welding is depicted in the accompanying figure.

As shown in the figure, the variation of the total absorptivity with welding speed for the two laser welding processes is similar, starting with a slow decrease before rapidly decreasing.

However, the critical speed at which this transition from slow to rapid decrease occurs is different for each laser welding process; it occurs at 10m/min for fiber laser welding and 4m/min for CO2 laser welding.

The differences in total absorptivity between the two laser welding processes are related to the extent to which the entire laser beam enters the deep penetration hole. When the welding speed is low, the laser beam is able to fully enter the deep penetration hole, resulting in a less pronounced effect on the total absorption rate.

However, at higher welding speeds, the front part of the beam may no longer be able to vaporize the front point of the small orifice, preventing it from entering the hole and causing a rapid decrease in the total absorption rate of the incident laser.

The total absorptivity and heat conduction loss power are the primary factors affecting melting efficiency. Based on the melting efficiency, it can be concluded that fiber laser welding is more suitable for medium to high-speed welding when the welding process is otherwise similar, while CO2 laser welding is better suited for low-speed welding.