Why choose one welding method over another? This article dives into the key differences between laser welding and resistance welding, explaining their principles, advantages, and applications. Discover how laser welding offers precision and speed with minimal heat distortion, while resistance welding excels in simplicity and cost-effectiveness for joining metals. By understanding these differences, you’ll be able to select the most suitable welding technique for your specific needs, enhancing both efficiency and quality in your projects.

Resistance welding

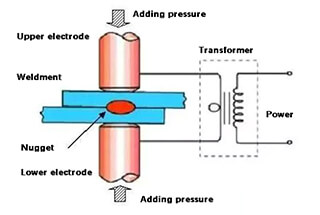

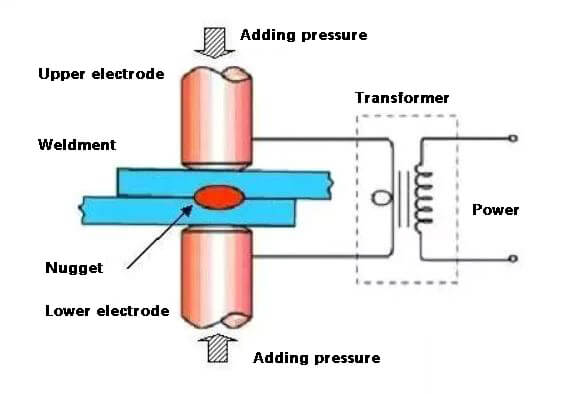

Resistance welding is a sophisticated joining process that utilizes electrical resistance to generate heat for fusing metals or thermoplastic materials. This technique involves applying controlled pressure through electrodes while passing a high-intensity electric current through the workpieces at their contact interface. The localized heat generated by the material’s resistance to current flow causes melting at the joint, creating a strong metallurgical bond upon cooling. Key advantages include rapid cycle times, minimal surface preparation, and suitability for automation in high-volume production environments.

Laser welding is an advanced, high-precision joining method that employs a focused, high-energy density laser beam as the heat source. This non-contact process offers exceptional control over heat input, resulting in narrow heat-affected zones and minimal distortion. Laser welding excels in producing high-quality, hermetic seals with deep penetration and fine, aesthetically pleasing weld beads. Its versatility allows for welding a wide range of materials, including dissimilar metals, with speeds up to 10 meters per minute in some applications. The process’s inherent cleanliness, coupled with its ability to be easily integrated into automated production lines, makes it increasingly popular in industries demanding high precision and repeatability, such as aerospace, medical device manufacturing, and automotive.

Classification of Resistance Welding Equipment

Based on the welding process, resistance welding equipment can be categorized into:

According to the energy supply mode, resistance welding equipment is classified as:

Classification of Laser Welding Equipment

Laser welding equipment can be categorized based on the welding method:

According to the laser beam delivery system and laser source, laser welding equipment is divided into:

Each type of welding equipment offers specific advantages in terms of weld quality, process control, energy efficiency, and application versatility. The choice of welding equipment depends on factors such as material properties, joint design, production volume, and required weld characteristics. Modern welding systems often incorporate advanced features like real-time monitoring, adaptive control, and integration with automated production lines to enhance productivity and ensure consistent weld quality.

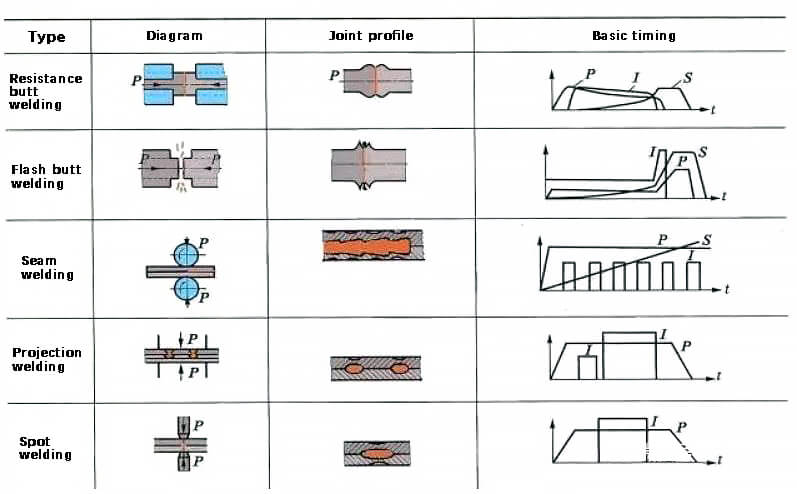

Resistance welding methods mainly include spot welding, seam welding, projection welding and butt welding (resistance butt welding and flash butt welding)

Spot welding is a type of resistance welding in which two metal pieces are joined by heating them at the point of contact. The metal is melted and welded together by resistance heating caused by pressing the pieces between two cylindrical electrodes in a lap joint configuration.

Spot welding is mainly used for sheet welding.

Process of spot welding

① Prepress to ensure good contact with the workpiece.

② Power on to form nugget and plastic ring at the welding joint.

③ Power off forging to make the nugget cool and crystallize under the continuous action of pressure to form a solder joint with dense structure and no shrinkage cavity and crack.

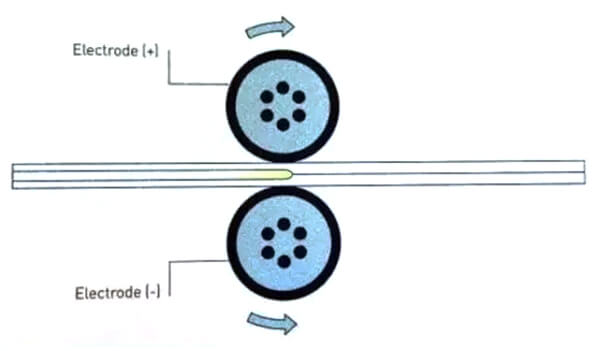

Seam welding is similar to spot welding in its process, but instead of using cylindrical electrodes, it utilizes a rotating disc-shaped roller electrode. The metal pieces to be welded are positioned in a lap or butt joint and placed between the two roller electrodes. The roller applies pressure and rotates, continuously or intermittently applying power to create a continuous weld.

Seam welding is commonly used for welding structures that require regular welds and seals, and is typically used on metal plates that are less than 3mm in thickness.

Projection welding is a type of spot welding that involves the use of pre-formed bumps on the workpiece. During the projection welding process, one or more nuggets can be formed at the joint simultaneously.

Resistance butt welding is a process that joins metal pieces in a butt joint configuration by bringing their end faces into close contact, heating them to a plastic state through resistance heating, and then quickly applying pressure after turning off the power to complete the welding.

This method is primarily used for welding metal pieces with simple shapes, with a diameter or side length less than 20mm, and low strength requirements.

Flash butt welding is a process that joins metal pieces in a butt joint configuration by gradually bringing the end faces into close contact, heating these points of contact through resistance heating, creating a flash under the influence of high current, melting the metal at the end, and then quickly applying pressure after turning off the power when the metal reaches the desired temperature within a certain depth range.

The joint quality of flash welding is superior to that of resistance welding, and the mechanical properties of the welded joint are equivalent to those of the base metal. There is no need to clean the surface of the joint before welding.

Flash butt welding is frequently used for welding crucial metal pieces and can be used to weld both the same metal or different metals, as well as metals ranging from 0.01mm metal wire to 20000mm metal bars and profiles.

Non-destructive testing limitations remain a significant challenge in resistance welding quality assurance. Current evaluation methods primarily rely on destructive testing of process samples and workpieces, supplemented by various monitoring technologies. This approach, while informative, cannot provide real-time, in-situ quality assessment of each weld, potentially leading to undetected defects in production components.

The lap joint configuration, prevalent in spot and seam welding, introduces structural inefficiencies. It not only increases the overall weight of the component but also creates stress concentration zones around the weld nugget interface. This geometric discontinuity results in reduced tensile strength and compromised fatigue performance of the joint, particularly under dynamic loading conditions.

Resistance welding equipment is characterized by high power requirements and sophisticated automation systems, contributing to substantial capital investment and maintenance costs. The widespread use of high-power single-phase AC welding machines can introduce power quality issues, such as voltage fluctuations and harmonic distortions, potentially disrupting the stability of the electrical grid. This necessitates careful power management strategies and may require additional power conditioning equipment in industrial settings.

Laser welding offers precise heat control, minimizing thermal input and reducing the heat-affected zone (HAZ). This results in minimal deformation and residual stress, preserving the material’s mechanical properties.

The process can be conducted in controlled environments, including vacuum or inert gas atmospheres, enhancing weld quality and allowing for reactive material joining.

High-speed automated welding is achievable through CNC systems and robotic integration, significantly increasing productivity and repeatability.

Deep penetration welding produces high aspect ratio welds, with depth-to-width ratios up to 10:1, enabling single-pass joining of thick materials.

Unlike arc or electron beam welding, laser welding is immune to magnetic field interference, ensuring consistent beam delivery and precise workpiece alignment.

The versatility of laser welding allows for joining a wide range of materials, including dissimilar metals with varying thermal and electrical properties.

As a non-contact process, laser welding eliminates electrode contamination and wear, reducing consumable costs and maintenance downtime.

The absence of physical contact also minimizes tool wear and workpiece deformation. Unlike electron beam welding, laser welding doesn’t require vacuum chambers or X-ray shielding, simplifying operation and reducing infrastructure costs.

Beam splitting and fiber optic delivery systems enable multi-station operation, maximizing equipment utilization and production flexibility.

For thin materials and fine wires, laser welding’s precise energy control prevents remelting and distortion issues common in arc welding processes.

Advanced laser systems have demonstrated single-pass welding capabilities for plates up to 32mm thick, drastically reducing cycle times and eliminating the need for filler material in many applications.

The highly focused beam allows for micro-welding applications, joining small components with minimal heat input and distortion.

Optical beam delivery systems provide exceptional positioning flexibility, allowing welding in confined spaces and complex geometries inaccessible to traditional welding methods.

This adaptability extends to joining metals with significantly different physical properties, such as thermal conductivity or electrical resistance, enabling novel material combinations in product design.

Laser welding stands out as a cutting-edge technology that offers significant advantages over traditional resistance welding, including superior joint quality, enhanced precision, and improved cost-effectiveness in high-volume production scenarios.

This advanced welding technique provides numerous benefits, such as:

Laser welding’s versatility makes it applicable across a wide range of industries, from automotive and aerospace to electronics and medical device manufacturing. As Industry 4.0 continues to evolve, laser welding is poised to play a crucial role in future welding processes, particularly in automated and robotic welding systems.

While the initial capital investment for laser welding equipment can be substantial, the long-term return on investment often justifies the cost. Factors contributing to this include:

In conclusion, despite the higher upfront costs, laser welding’s capabilities, production efficiency, and overall benefits significantly outweigh those of conventional welding methods. As the technology continues to advance and become more accessible, it is likely to become an indispensable tool in modern manufacturing processes.