Have you ever wondered about the differences between S30408 and 304 stainless steel? In this blog post, we’ll dive into the key distinctions between these two commonly used materials. Our expert mechanical engineer will provide insights into their chemical composition, corrosion resistance, and welding properties. Discover which one is better suited for your specific application and learn valuable information to make informed decisions.

30408 stainless steel, also known as S30408, is a widely used stainless steel material in pressure equipment. It is nationally recognized under the standard number 06Cr19Ni10.

This material, due to its excellent corrosion resistance, welding processability, and comprehensive properties (including corrosion resistance and formability), is extensively used in the manufacture of pressure vessel machinery and other related fields.

Among various types of stainless steels, 30408 stainless steel is the most commonly used, often referred to as food-grade stainless steel or 18/8 stainless steel.

In addition, 30408 stainless steel is not only applicable in industrial sectors such as chemical, food, pharmaceutical, papermaking, oil, and nuclear power, but it is also widely used in the manufacture of components for construction, containers, and vehicles.

Its chemical composition mainly includes elements such as chromium (Cr), nickel (Ni), manganese (Mn), and silicon (Si), which endow it with excellent corrosion resistance and high-temperature strength.

It’s worth noting that although the price of 30408 stainless steel may be slightly higher than 304 stainless steel, in terms of usage scope, S30408 can replace 304, but not vice versa. This indicates that 30408 stainless steel offers higher value and applicability in certain applications.

There are three key differences between S30408 and 304 stainless steel:

So which one is better – S30408 or 304? And what are the differences between them? It’s important to consider the safety of using these materials in food applications. I will delve into these three points in greater detail.

Is Stainless Steel S30408 the same as 304?

S30408 is a designation for one of the austenitic stainless steels according to the UNS numbering system.

S30408 stainless steel is equivalent to 06Cr19Ni10, which is a common type of stainless steel material.

The corresponding UNS number for 304 is S30400, so S30408 and 304 are not identical.

The UNS numbering system is a system that assigns numerical codes to 18 different series of metals and alloys. The UNS number consists of a single letter prefix followed by five Arabic numerals. The prefix letter usually represents the metallicity, such as “S” for stainless steel. The number that follows, such as 304, is the grade code that indicates the Cr Ni content of the austenitic 300 series stainless steel.

Different Cr Ni content percentages result in different grade codes, such as 301, 316, and 321. So, S30408 is the UNS numerical code for stainless steel with a specific Cr Ni content percentage.

| Standard name | UNS code | Grade | C | Mn | P | S | Si | Cr | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| American Standard | ASTM A240M-15a | S30400 | 304 | 0.07 | 2.00 | 0.045 | 0.03 | 0.751 | 7.5-19.58 | 8.0-10.5 | .. |

| China standard | GB/T24511-2017 | S30408 | 06Cr19Ni10 | 0.08 | 2.00 | 0.035 | 0.015 | 0.751 | 8.0-20.08 | 8.0-10.5 | 0.1 |

| Japanese standard | JISG4305:2012 | SUS304 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 8.0-20.08 | 8.0-10.5 | .. | |

| European Standard | EN10028-7:2016 | 1.4301 | 0.07 | 2.00 | 0.045 | 0.015 | 1.00 | 7.5-19.58 | 8.0-10.5 | 0.1 | |

Note: The proportion is expressed as a percentage, i.e. “%”. Unless otherwise stated, the components listed in the table are the maximum values.

The chemical composition of S30408 and 304 stainless steel is slightly different. For instance, 304 requires a lower carbon content, whereas S30408 requires lower levels of phosphorus and sulfur, and a higher content of chromium.

The chemical composition standards for S30408 and 304 materials can be found in the S30408 and 304 chemical composition comparison table above.

Both S30408 and 304 stainless steel are considered food-grade materials and meet the national standards for food-grade stainless steel.

In terms of safety, both S30408 and 304 stainless steel can be used for items such as kettles, children’s cups, food containers, and cookware.

What are the main differences between 30408 stainless steel and 304 stainless steel in terms of performance?

The primary differences in performance between 30408 stainless steel and 304 stainless steel are reflected in the following areas:

1. Chemical Composition Differences:

30408 stainless steel differs from 304 stainless steel in terms of chemical composition. Specifically, 30408 requires lower phosphorus and sulfur content, as well as a higher chromium content.

Additionally, 30408 belongs to the 304L series, with a chemical composition primarily of 18% Cr, 8-12% Ni, and 0.03% or less C. Compared to 304, 30408 has a slightly higher Ni content but a lower carbon content.

2. Corrosion Resistance:

The corrosion resistance of 30408 is slightly superior to that of 304 stainless steel. This might be due to its higher nickel content, which helps improve corrosion resistance.

3. Strength and High-Temperature Resistance:

The strength and high-temperature resistance of 30408 are superior to those of 304 stainless steel. This means that 30408 performs better in environments with higher temperatures and pressures, making it suitable for more demanding applications.

4. Usage Differences:

Due to the aforementioned performance differences, 30408 is more commonly used in high-end machinery, aerospace, military, and other fields. Meanwhile, 304 stainless steel is widely used in various industrial fields, including but not limited to food processing and architectural decoration.

Mechanical Properties of Austenitic Steel after Solution Treatment at Room Temperature

| Number code | S30408 | ||

| Grade | 06Cr19Ni10 | ||

| Specified plastic extension strength RPo. 2/MPa | Not less than | 220 | |

| Specified plastic extension strength RP1.0/MPa | 250 | ||

| Tensile strength Rm/MPa | 520 | ||

| Elongation after fracture A% | 40 | ||

| Hardness value | HBW | Not greater than | 201 |

| HRB | 92 | ||

| HV | 210 | ||

Mechanical Test Requirements

| Yield Strength | Tensile Strength | Elongation in 2 in or 50mm. min | Hardness.max | |

|---|---|---|---|---|

| Mpa | Mpa | % | BrinellHBW | Rockwell |

| 205 | 515 | 40 | 201 | 92 HRBW |

In terms of mechanical properties, there is little difference between stainless steel S30408 and 304. The yield strength, tensile strength, elongation, and hardness of the two can be compared and analyzed by referring to the table above.

Mechanical properties limit the use of materials, and the strength and hardness of 304 cold-rolled stainless steel coils are higher than those of S30408 hot-rolled stainless steel coils, though the latter has better processing performance and plasticity.

It’s important to note that S30408 stainless steel coils are mostly hot rolled, while the plasticity of 304 cold-rolled stainless steel is reduced, affecting its stamping performance.

S30408 stainless steel, commonly known as 304 stainless steel, is renowned for its excellent corrosion resistance, primarily due to its chemical composition. The alloy contains at least 18% chromium and 8% nickel. Chromium forms a thin, passive oxide layer on the surface, which acts as a protective barrier against further corrosion. Nickel enhances this protective effect, especially in acidic environments, making the steel more durable and resistant to a variety of corrosive conditions. Studies have shown that the combination of chromium and nickel significantly improves the longevity of stainless steel components in industrial applications.

S30408 stainless steel performs exceptionally well in a wide range of atmospheric environments. It resists corrosion effectively in rural and urban atmospheres and can withstand marine environments, although it is not as robust as higher-alloyed stainless steels like 316 in highly saline conditions. For example, in outdoor architectural features, S30408 has been used successfully for decades, demonstrating its durability against varying weather conditions. Its application in coastal infrastructure, such as railings and cladding, underscores its capability to resist corrosion in marine settings.

The nickel content in S30408 enhances its resistance to moderately aggressive organic acids, such as acetic acid and formic acid. This is particularly beneficial in the food processing and chemical industries, where stainless steel equipment frequently comes into contact with these substances. Additionally, S30408 can withstand exposure to several inorganic acids, although its performance in highly concentrated or hot acid solutions may be limited compared to more specialized stainless steels. For instance, in food processing plants, equipment made from S30408 has shown excellent resistance to acidic food products, ensuring long-term hygiene and safety.

While S30408 offers excellent general corrosion resistance, it is susceptible to pitting and crevice corrosion in environments containing chlorides, such as seawater and de-icing salts. Pitting occurs when localized areas of the metal lose their protective oxide layer, leading to small but deep cavities. Crevice corrosion can occur in confined spaces where chloride ions become concentrated. For example, in marine applications, components like boat fittings must be designed to avoid areas where chlorides can accumulate and initiate corrosion.

S30408 stainless steel is vulnerable to stress corrosion cracking (SCC) in chloride-containing environments, particularly at elevated temperatures. SCC is a failure mechanism that occurs when tensile stress and a corrosive environment act together, leading to the development of cracks. To mitigate SCC, it is essential to minimize tensile stresses through proper design and fabrication techniques and to avoid exposure to high-chloride environments, especially at temperatures above 60°C (140°F). For instance, in petrochemical plants, careful material selection and design considerations help prevent SCC in equipment exposed to high temperatures and chloride-rich environments.

Intergranular corrosion can occur in S30408 stainless steel when it is exposed to temperatures between 450°C and 850°C (840°F and 1560°F). In this temperature range, chromium carbides can precipitate at grain boundaries, depleting the surrounding areas of chromium and making them susceptible to corrosion. The low carbon content in S30408 (≤0.08%) helps reduce the risk of intergranular corrosion, making it suitable for welded structures where post-weld heat treatment is not feasible. For example, in the construction of storage tanks, S30408 is often chosen to ensure structural integrity over long periods.

While S30408 offers robust corrosion resistance in many environments, other stainless steel grades may be more suitable for severe conditions. For instance, 316 stainless steel, with its higher molybdenum content, provides better resistance to pitting and crevice corrosion in chloride-rich environments. Therefore, for applications involving prolonged exposure to aggressive chemicals or high-chloride conditions, 316 stainless steel may be preferred. Comparative studies have shown that 316 stainless steel outperforms S30408 in highly corrosive settings, such as chemical processing plants.

Due to its excellent corrosion resistance, S30408 is widely used in various industries. In the food processing industry, it is used for making kitchen sinks, food preparation surfaces, and storage tanks, where hygiene and resistance to organic acids are critical. In the chemical industry, it is employed in equipment and piping systems that handle mildly corrosive substances. Its use in marine environments includes components like boat fittings and dock hardware, where exposure to seawater requires a material that can withstand corrosion. For example, S30408 has been used in the construction of boat hulls and marine hardware, demonstrating its effectiveness in resisting corrosion in harsh marine environments.

S30408 stainless steel, an austenitic alloy, exhibits excellent weldability, making it a preferred choice in various industrial applications. Its chemical composition, primarily consisting of chromium (18-20%) and nickel (8-10.5%), enhances its ability to form strong and durable welded joints. The alloy can be welded using all standard fusion and resistance welding processes, ensuring versatility and ease of fabrication.

The welding processing performance of 30408 stainless steel is primarily manifested in the following aspects:

Fusion welding processes such as Gas Tungsten Arc Welding (GTAW or TIG), Gas Metal Arc Welding (GMAW or MIG), and Shielded Metal Arc Welding (SMAW) are commonly used for S30408. These methods offer several advantages:

For instance, in the fabrication of pressure vessels and chemical processing equipment, GTAW is often used to achieve precise and clean welds, ensuring the durability and reliability of the components.

Resistance welding processes such as Spot Welding and Seam Welding are also effective for S30408 stainless steel. These methods are particularly useful for joining thin sections and mass production applications:

For example, in the automotive industry, resistance welding is used to join body panels and exhaust components, ensuring strong and corrosion-resistant joints.

For thin sections of S30408, post-weld heat treatment is generally not required, simplifying the welding process and reducing production costs. However, for thicker sections or critical applications, post-weld annealing may be necessary to relieve residual stresses and restore corrosion resistance.

The distribution of ferrite in the welded joints of S30408 can influence their mechanical properties. Maintaining an appropriate balance of ferrite and austenite is crucial to prevent hot cracking and ensure the toughness of the welds. Typically, filler materials with a composition similar to S30408, such as ER308L, are used to achieve the desired ferrite content.

S30408 stainless steel retains its mechanical properties well after welding. For example, the tensile strength before welding is typically around 515 MPa, and after welding, it remains close to this value. The yield strength is about 205 MPa before welding and shows minimal reduction post-welding. Studies have shown that welded joints maintain good impact resistance across a wide temperature range, ensuring performance in dynamic load applications such as aerospace and chemical processing equipment.

The corrosion resistance of S30408 welded joints is comparable to that of the base metal, provided that proper welding techniques are followed. The high chromium and nickel content ensures the formation of a protective oxide layer, preventing corrosion in various environments. However, in chloride-rich environments, additional precautions, such as using higher alloyed filler materials, may be necessary to enhance corrosion resistance.

30408 stainless steel exhibits superior weldability and ductility, making it widely used in the fabrication of high-temperature pressure vessels and pipelines. This material is not only suitable for welding operations at room temperature, but it also maintains its mechanical properties in high-temperature environments, meeting the demands of specific industrial applications.

Austenitic S30408 stainless steel displays robust low-temperature resistance, implying that even at lower temperatures, its welded joints can maintain stable mechanical properties. This makes it suitable for applications in low-temperature environments such as liquefied natural gas.

During the welding process, using specific welding rods can ensure that the welded metal has good resistance to intergranular corrosion. This is especially important for equipment that needs to be used in corrosive environments for a long time, such as stainless steel applications of Cr19Ni9 and Cr19Ni11Ti operating at temperatures below 300°C.

Manufacturing of Equipment and Machinery with High Comprehensive Performance Requirements:

Due to its excellent welding processing performance, S30408 stainless steel is extensively used in the manufacturing of pressure vessel type mechanical equipment. This material not only meets the requirements for corrosion resistance but also is favored for its excellent formability.

At elevated temperatures, S30408 stainless steel maintains commendable mechanical properties, making it suitable for high-heat applications. The tensile strength and yield strength of S30408 decrease moderately with rising temperatures, ensuring the material can still support structural loads without significant deformation. For example, in applications like heat exchangers and furnace components, where sustained high temperatures are common, S30408’s ability to retain strength and ductility is crucial.

The thermo-viscoplastic behavior of S30408 is characterized by changes in its stress-strain relationship under varying temperatures and strain rates. As temperature increases, the material exhibits a reduction in yield strength and an increase in strain hardening. This behavior is modeled through refined stress-strain equations that help predict the material’s response in dynamic thermal environments. For instance, in high-temperature industrial processes, understanding these characteristics ensures that components made from S30408 can withstand operational stresses without failure.

High temperatures can induce microstructural changes in S30408, affecting its mechanical performance. Pre-strain and strain rate influence these changes, with high-temperature pre-strain potentially altering the steel’s impact properties. Despite these changes, S30408 maintains a stable austenitic microstructure, which is crucial for applications requiring long-term exposure to elevated temperatures, such as in petrochemical reactors and power plant boilers.

S30408 stainless steel performs well at cryogenic temperatures, maintaining good mechanical properties. The material undergoes a martensitic transformation at low temperatures, which impacts its stress-strain relation. This transformation increases the material’s strength while slightly reducing its ductility. This property is particularly beneficial in cryogenic storage tanks and components used in liquefied natural gas (LNG) applications, where maintaining structural integrity at extremely low temperatures is critical.

Low-cycle fatigue tests at low temperatures reveal that S30408 exhibits a nonlinear stress-strain curve without a yield plateau, indicating high strength and significant ductility. The fatigue life of the material decreases with increasing strain amplitude, yet it shows considerable cyclic hardening and energy dissipation capacity. These characteristics are advantageous in applications involving cyclic loading at low temperatures, such as in aerospace components and cryogenic piping systems.

The martensitic transformation in S30408 at low temperatures enhances its mechanical properties by increasing strength. This transformation is influenced by the strain rate and the extent of plastic deformation. Understanding this behavior is essential for designing components that need to operate efficiently in low-temperature environments, such as in the aerospace and defense industries, where materials are often exposed to extreme cold.

S30408 stainless steel exhibits excellent hysteretic performance, beneficial for applications involving cyclic loading. The material’s symmetric hysteresis loops indicate a fine energy dissipation capacity, making it suitable for seismic retrofitting of structures and in components subject to repetitive stress.

S30408 is known for its high resistance to both high and low temperatures, ensuring stability and performance across a wide temperature range. This makes it a reliable choice for applications where temperature fluctuations are frequent and significant, such as in thermal processing equipment and cryogenic systems.

In summary, the performance of S30408 stainless steel at elevated and low temperatures underscores its versatility and robustness, making it an excellent material for a variety of demanding industrial applications.

S30408 stainless steel, recognized for its excellent corrosion resistance, mechanical properties, and weldability, is a versatile material used across various industries. Its unique combination of properties makes it suitable for applications where durability, hygiene, and aesthetic appeal are crucial.

S30408 stainless steel is extensively used in the food and beverage industry due to its excellent corrosion resistance and ease of cleaning. Specific applications include:

In the chemical and petrochemical industries, S30408 stainless steel is valued for its resistance to various chemicals and corrosive environments. Applications include:

The hygiene and corrosion resistance properties of S30408 stainless steel make it an excellent choice for medical and pharmaceutical applications. These include:

S30408 stainless steel is favored in the architectural and construction industries for its aesthetic appeal, durability, and resistance to environmental factors. Applications include:

The automotive and aerospace industries utilize S30408 stainless steel for its high strength, corrosion resistance, and ability to withstand extreme temperatures. Applications include:

S30408 stainless steel is also prevalent in household and commercial products due to its durability, aesthetic appeal, and ease of maintenance. Applications include:

S30408 stainless steel is employed in the energy and environmental sectors for its corrosion resistance and ability to withstand harsh conditions. Applications include:

Nuclear Reactors: Utilized in critical components where high strength and resistance to radiation-induced corrosion are essential.

Comparing S30408 and SS 304 stainless steel is crucial for various industrial applications. Understanding the cost differences helps industries make informed decisions, optimizing both performance and budget.

The cost of S30408 and SS 304 stainless steel is generally very similar due to their widespread availability and extensive use. Both materials are produced in large quantities by numerous suppliers worldwide, which helps to keep their prices aligned. The minimal cost difference between the two is often influenced more by external factors such as market conditions, supplier pricing strategies, and geographic location rather than significant intrinsic differences.

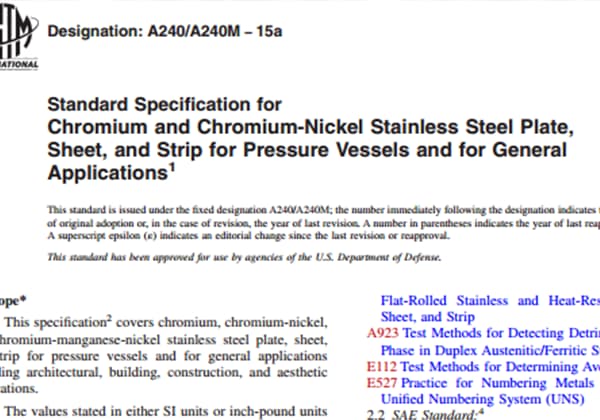

S30408 follows the ASTM A240 standard, while SS 304 adheres to the AISI standard. ASTM A240 specifies the chemical composition and mechanical properties of chromium and chromium-nickel stainless steel plates, sheets, and strips. The AISI standard provides guidelines for the chemical composition and mechanical properties of stainless steels. Both standards ensure that the materials meet specific requirements, maintaining their reliability and performance. These differences in standards do not significantly impact the cost.

The chemical compositions of S30408 and SS 304 are nearly identical, with both containing similar levels of chromium, nickel, and other elements. For instance, both grades typically contain around 18-20% chromium and 8-10.5% nickel. These similarities result in comparable corrosion resistance, mechanical properties, and weldability. While S30408 may offer slightly enhanced properties due to its specific formulation, such as improved resistance to certain corrosive environments, these improvements do not translate into significant cost differences.

The price of stainless steel, including S30408 and SS 304, can vary based on market conditions, supplier pricing, and geographic location. For example, fluctuations in the cost of raw materials like nickel and chromium can impact the price. Additionally, manufacturing processes and transportation expenses can influence the final cost. However, the intrinsic cost of S30408 and SS 304 remains relatively consistent, with no major cost difference between the two grades. Buyers may find slight variations in pricing depending on the supplier and location, but these differences are typically minimal.

Both S30408 and SS 304 are used in a wide range of applications, including food processing equipment, chemical processing plants, medical devices, automotive parts, and architectural components. The versatility and performance of both materials in these applications ensure that their costs remain comparable. Users often choose between S30408 and SS 304 based on specific requirements, such as enhanced corrosion resistance or improved weldability, but these considerations do not lead to major price differences.

When procuring S30408 or SS 304 stainless steel, buyers should consider factors such as supplier reliability, product availability, and additional services offered. Both materials are widely available from numerous suppliers, ensuring competitive pricing and accessibility. Buyers may benefit from customized dimensions, surface treatments, and packaging options provided by suppliers. Additionally, seeking suppliers with consistent quality and good customer service can enhance the procurement process.

In summary, the cost comparison between S30408 and SS 304 stainless steel shows that they are essentially priced similarly. Any variations in cost are more related to external factors such as supplier and location rather than the materials’ intrinsic properties.

Below are answers to some frequently asked questions:

The chemical composition of S30408 stainless steel, which is equivalent to the commonly known 304 stainless steel, is characterized by specific maximum and range values for several elements. It includes a maximum of 0.08% Carbon (C), a maximum of 2.00% Manganese (Mn), a maximum of 0.045% Phosphorus (P), a maximum of 0.030% Sulfur (S), and a maximum of 1.00% Silicon (Si). Additionally, it contains 18.0-20.0% Chromium (Cr) and 8.0-11.0% Nickel (Ni). These specifications are consistent with standards such as ASTM A276/A276M, EN 10216-5 1.4301, and GB/T 20878-2007.

S30408 (304L) and SS 304 (Type 304) stainless steels are both renowned for their corrosion resistance, but there are some important differences between them. S30408, also known as 304L, has a lower carbon content (typically 0.035% max) compared to SS 304 (0.08% max). This lower carbon content in 304L reduces the risk of sensitization during welding, which is the formation of chromium carbides at grain boundaries that can lead to intergranular corrosion.

In terms of general corrosion resistance, 304L slightly outperforms SS 304. The higher nickel content in 304L further enhances its resistance to corrosive environments. While both materials are resistant to a variety of atmospheric conditions and corrosive media, SS 304 is more susceptible to intergranular corrosion when exposed to specific temperature ranges due to its higher carbon content. This makes 304L preferable in situations where welding is involved, as it maintains its corrosion resistance without the risk of sensitization.

In environments with high chloride concentrations, such as coastal or marine settings, SS 304 is more prone to pitting and crevice corrosion. The slight edge in corrosion resistance of 304L can be particularly beneficial in these environments. Overall, while both stainless steels are highly corrosion-resistant, 304L’s lower carbon content and higher nickel content provide it with a slight advantage, making it more suitable for applications requiring extensive welding and heightened corrosion resistance.

S30408 stainless steel, also known as AISI 304 or SUS304, is an austenitic stainless steel alloy known for its versatility and wide range of applications. This alloy is highly valued for its excellent corrosion resistance, formability, and mechanical properties.

In industrial and commercial contexts, S30408 is extensively used in the chemical industry for containers and equipment due to its resistance to corrosion from various chemicals. The food processing industry also benefits from this material, using it for equipment, utensils, and appliances to maintain hygiene and prevent corrosion. Additionally, the petrochemical, automotive, and aerospace industries employ S30408 for various machinery components and parts.

Architecturally, S30408 stainless steel is favored for its aesthetic appeal and durability. It is used in handrails, balustrades, and other decorative elements. A notable example includes its use in cladding the Gateway Arch in St. Louis, Missouri, and in exterior accents for buildings.

In household applications, this stainless steel is commonly found in kitchen appliances, sinks, troughs, and cookware, thanks to its ease of fabrication and corrosion resistance.

In civil engineering, particularly for seismic protection, S30408 is used in structural components like buckling-restrained braces (BRBs) due to its excellent low-cycle fatigue properties, high strength yield ratio, and energy dissipation capacity.

Other applications of S30408 stainless steel include medical instruments, transportation equipment, and communication devices, where its corrosion resistance and ease of fabrication are critical. It is also used in vaporizers and was notably employed in the construction of early SpaceX Starships.

Overall, the combination of excellent corrosion resistance, formability, and mechanical properties makes S30408 stainless steel a preferred material across various industries and applications.

Welding S30408, which is equivalent to 304 stainless steel, can be done effectively, although it poses certain challenges, particularly when welding dissimilar metals. The key to successful welding lies in understanding and addressing the material’s chemical and metallurgical characteristics, selecting appropriate welding methods and materials, and managing the thermal conditions during and after welding.

S30408 has a different chemical composition and metallurgical structure compared to other steels, such as ASTM A387 GR22. This can lead to issues like alloy element migration and the formation of undesirable compounds, such as chromium carbide, during welding. To mitigate these issues, techniques like TIG (GTAW) and arc welding (SMAW) are recommended due to their lower fusion ratios and dilution rates. These techniques help minimize the formation of unwanted microstructures and reduce thermal stress.

When selecting welding materials, nickel-based electrodes (e.g., ENi6182 and SNi6082) are preferred because they help prevent carbide formation, reduce the transition layer, and inhibit carbon migration. For filler metals, 309 stainless steel is often used when welding austenitic stainless steels like S30408 to structural steels, as it offers good compatibility and reduces corrosion risks.

Preheating and controlling the interpass temperature are crucial steps in the welding process. A preheating temperature of about 200°C is recommended to prevent cold cracking and ensure proper welding. Additionally, maintaining an interpass temperature below 100°C helps preserve the weld’s integrity and prevent excessive thermal stress.

Post-welding heat treatment is essential to relieve residual stresses and prevent cracking. Performing a heat treatment at 690 ± 10°C for 2 hours or at 350°C for 2 hours immediately after welding can effectively remove residual stress and avoid cracks.

Despite these challenges, weld joints between S30408 and other materials like ASTM A387 GR22 can achieve satisfactory mechanical properties if the appropriate methods and materials are used. Such welds can pass tensile, bending, and impact tests, indicating that they meet performance requirements.

In summary, while welding S30408 requires careful consideration of its properties and the use of specific techniques and materials, it is feasible to achieve reliable weld joints with the proper approach.

You can purchase S30408 stainless steel from various suppliers on platforms like Alibaba and Made-in-China. These platforms offer a range of products, including plates, sheets, and rolls from different manufacturers. The prices for S30408 stainless steel fluctuate based on raw material costs and market conditions, so it is advisable to contact suppliers directly for the most current pricing.

S30408 stainless steel is available in various dimensions, with widths typically ranging from 1000 to 2500mm, lengths from 2000 to 12000mm, and thicknesses from 0.3mm to 300mm. Custom sizes can also be arranged based on your specific requirements.

To purchase, you will need to make an inquiry with the suppliers on these platforms. They will provide quotes based on your needs, including any custom dimensions or finishes you might require. This direct communication ensures you receive accurate and up-to-date pricing and product details.