What’s the difference between undissolved and proeutectoid ferrite in steel? This article dives into the distinct microstructures that result from different heat treatment processes. By exploring the characteristics and formation conditions of undissolved ferrite and proeutectoid ferrite, you’ll gain a clear understanding of their roles in steel’s mechanical properties. Learn how these microstructures impact strength and toughness, and why their identification is crucial in metallurgy. Read on to enhance your knowledge of these fundamental concepts in steel treatment.

The definition of ferrite: Pure iron has body-centered cubic lattice α- Fe below 912 ℃, carbon soluble in α- Fe and the interstitial solid solution is called ferrite, which is represented by the symbol F.

Because the diameter of the body-centered cubic lattice gap of α-Feis very small, the solubility of carbon in it is very small.

At 600 ℃, the solubility is only 0.0057%, and at 727 ℃, the maximum solubility is only 0.0218%.

Therefore, the mechanical properties of ferrite are almost the same as that of pure iron, with good plasticity and toughness (A ≈ 30% – 50%, KU ≈ 128-160J) and low strength and hardness (Rm ≈ 180-280MPa, 50-80HBW).

Ferrite has ferromagnetism below 770 ℃ and loses magnetism above 770 ℃.

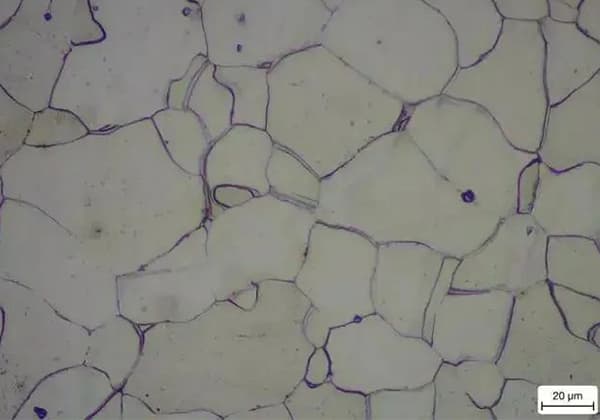

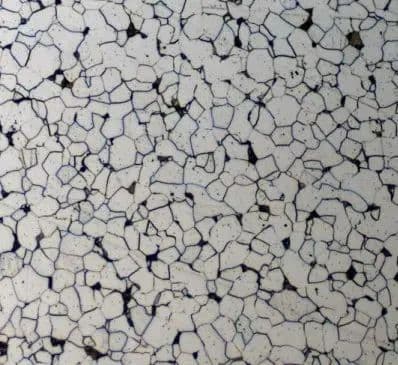

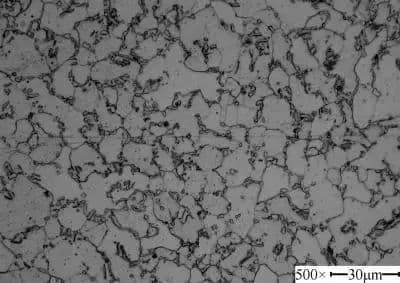

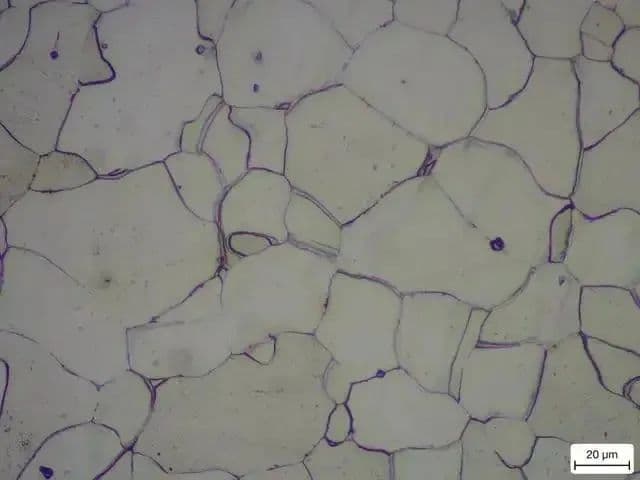

Fig. 1 Microstructure of Ferrite

As shown in Fig. 1, the microstructure of ferrite is bright polygonal grains, and the grain boundary is easy to be corroded, showing irregular black lines.

However, due to the different heat treatment processes selected, ferrite often presents different forms in materials.

Without sufficient experience, it is easy to be confused.

This article mainly shares the difference between “undissolved ferrite and proeutectoid ferrite”.

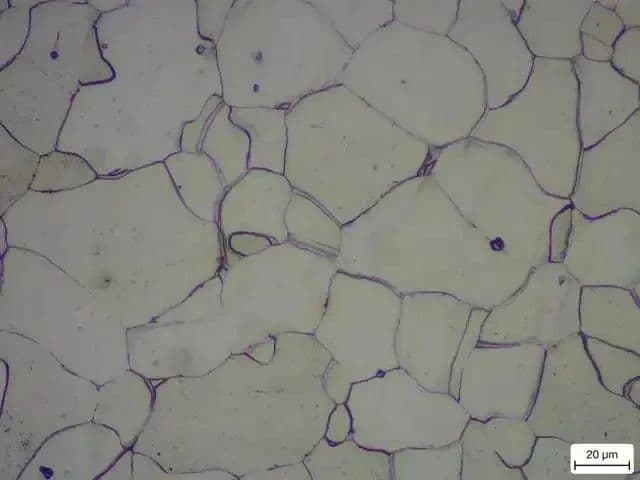

Undissolved ferrite is the microstructure obtained after hypoeutectoid steel is heated to Ac1-Ac3 and quenched (i.e. undercooled quenching).

It is white polygonal and has obvious grain boundaries.

The matrix of martensite and retained austenite is slightly dark.

Fine adjustment focusing will find that white undissolved ferrite and martensite are on the same plane.

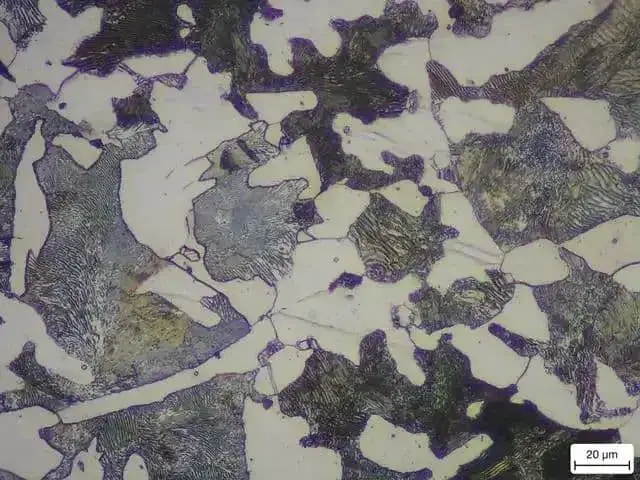

As shown in Fig. 2, the microstructure morphology of 45 steel after water quenching at 760 ℃ for 30min is shown.

The white polygonal phase is insoluble ferrite, the gray white phase is quenched martensite and residual austenite, and the dark phase is lath martensite.

Fig. 2 White polygonal undissolved ferrite

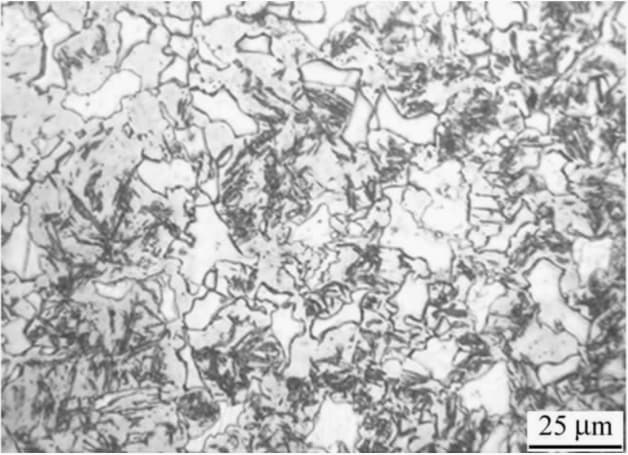

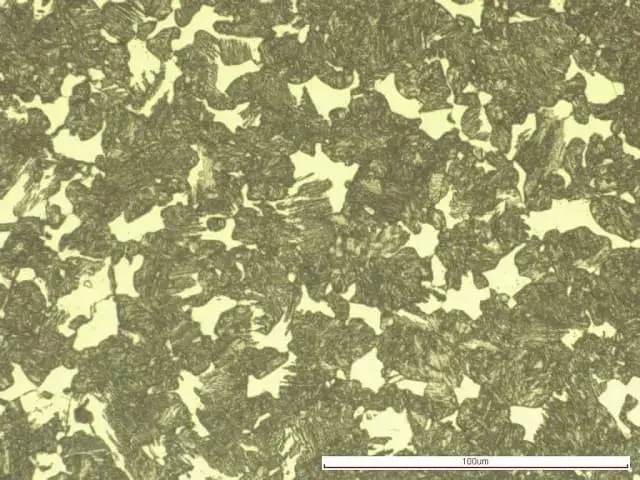

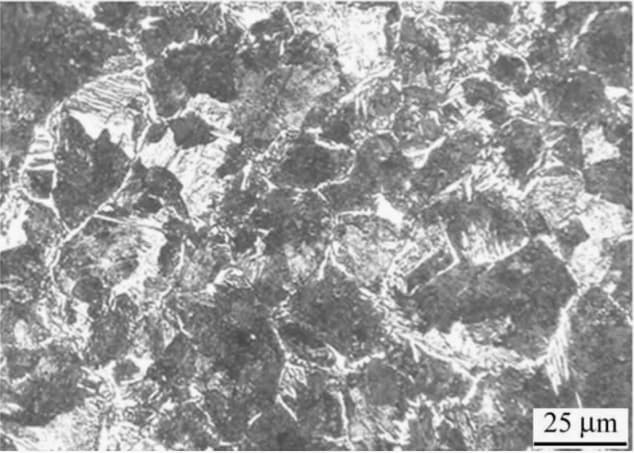

The proeutectoid ferrite is the white network structure that precipitates at the grain boundary when hypoeutectoid steel is heated to above Ac3 and quenched, due to the slow cooling rate.

The microstructure often contains black globular quenched troostite.

As shown in Fig. 3, the microstructure of 45 steel heated at 880 ℃ for 30min and oil quenched is composed of white fine reticulated proeutectoid ferrite, dark quenched troostite, gray white martensite and a small amount of feathery upper bainite along the grain boundary precipitated during quenching because the cooling rate is less than the critical cooling rate.

Fig. 3 White fine reticular proeutectoid fines

This article shared with you the identification of undissolved ferrite and proeutectoid ferrite. Although there is only one knowledge point, if you can fully understand one knowledge point every day, you can also achieve the effect of “little makes a mickle”.