Have you ever struggled with dimensioning your mechanical drawings? Proper dimensioning is crucial for clear communication and efficient manufacturing. In this blog post, an experienced mechanical engineer shares valuable insights and practical tips to help you master the art of dimensioning. Discover the key principles, best practices, and common pitfalls to avoid, so you can create precise and professional drawings that meet industry standards. Get ready to take your dimensioning skills to the next level!

Basic Requirements for Dimensioning in Part Drawings

Dimensions in part drawings must be marked in accordance with industry standards, ensuring completeness, clarity, and rationality. This approach is crucial for both design integrity and manufacturing efficiency.

Requirements for Rational Dimensioning:

(1) Design Compliance: Dimensions must meet design specifications to ensure the overall quality and functionality of the machine or component.

(2) Manufacturing Feasibility: Dimensions should facilitate efficient manufacturing processes and enable straightforward quality inspection procedures.

To effectively meet these requirements, engineers and drafters must possess:

Key Considerations for Rational Dimensioning:

The dimensions in the part drawing shall not only meet the requirements of correctness, integrity and clarity, but also make the dimensions reasonable.

Definition of rationality of dimensions on part drawing:

Whether the dimensions are reasonable or not, the key points are as follows:

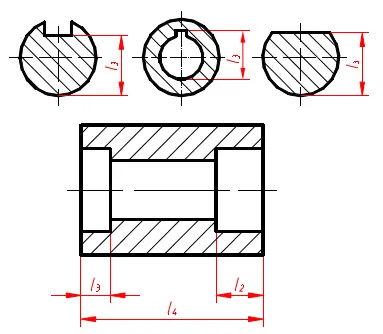

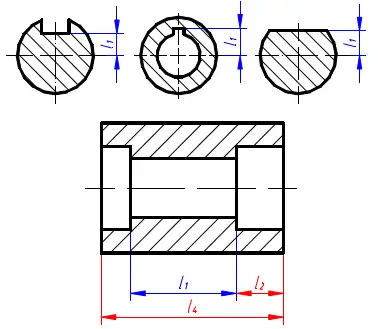

1. Main and non main dimensions

Main dimensions:

Dimensions that affect the specification and performance of components or machines, such as mating dimensions, dimensions to determine the exact position of parts in components, connection dimensions, installation dimensions, and dimensions that affect the interchangeability and working accuracy of parts.

Non main dimensions:

Such as external outline dimension, non fit dimension, dimension used to meet the mechanical properties, structural shape and process requirements of parts, etc.

Main dimensions shall be directly indicated:

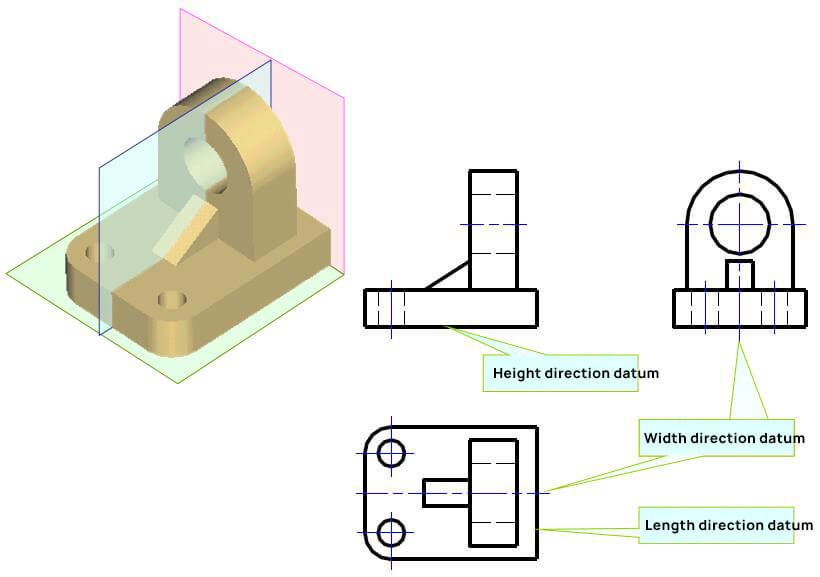

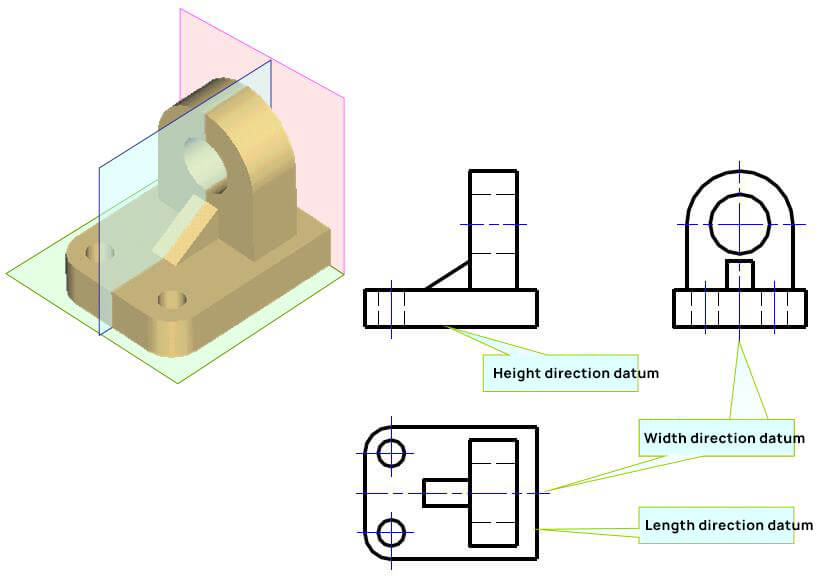

2. Dimension datum of parts

Datum: select a group of geometric elements on the part as the basis for determining the mutual position relationship of other geometric elements.

According to different purposes, the benchmark is divided into design benchmark and process benchmark.

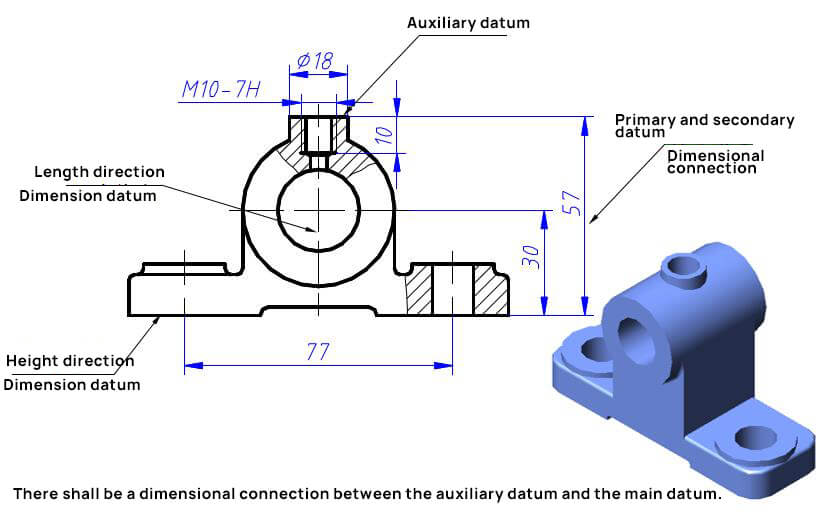

Design datum: the datum used to determine the exact position of the part in the assembly. Usually, one of them is selected as the main dimension datum.

Process benchmark: the benchmark for processing and measurement, which is often used as the auxiliary dimension benchmark.

Elements often used as datum: important bottom surface, end face, symmetrical plane, assembly joint surface, axis of main hole or shaft, etc.

Dimension datum selection:

There shall be a dimensional connection between the auxiliary datum and the main datum.

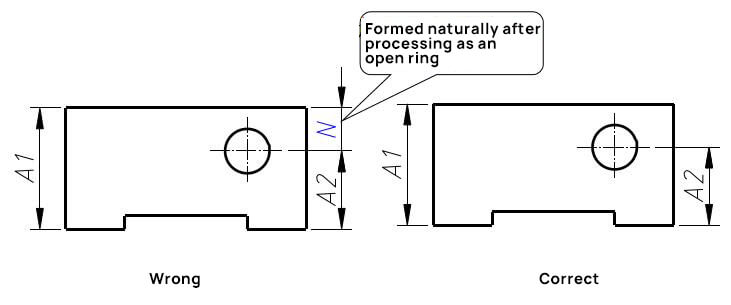

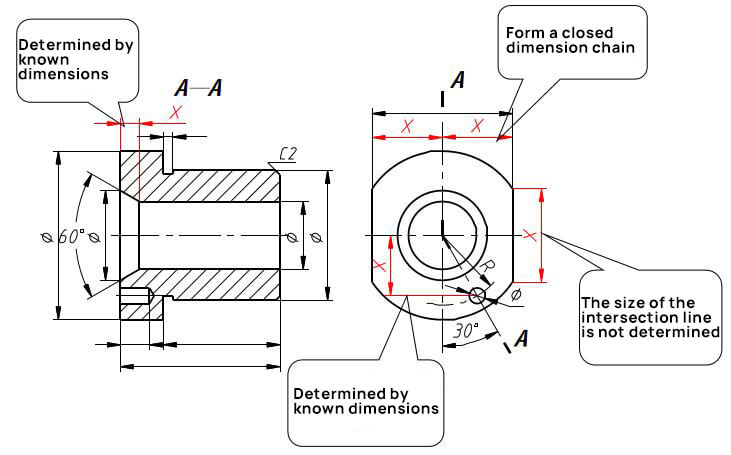

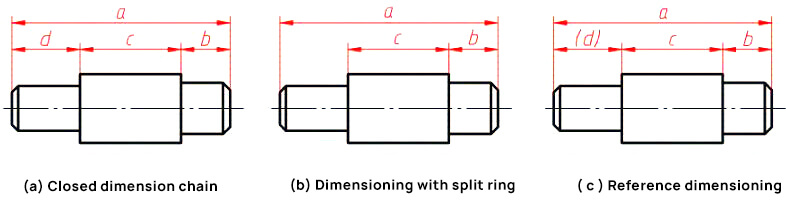

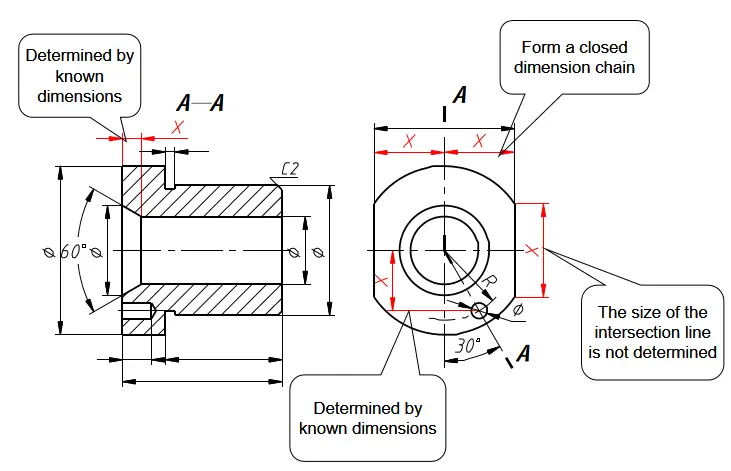

3. Closed dimension chain

The dimensions of parts in the same direction can be connected end to end and listed in the form of dimension chain.

However, it should be avoided to form a closed dimension chain.

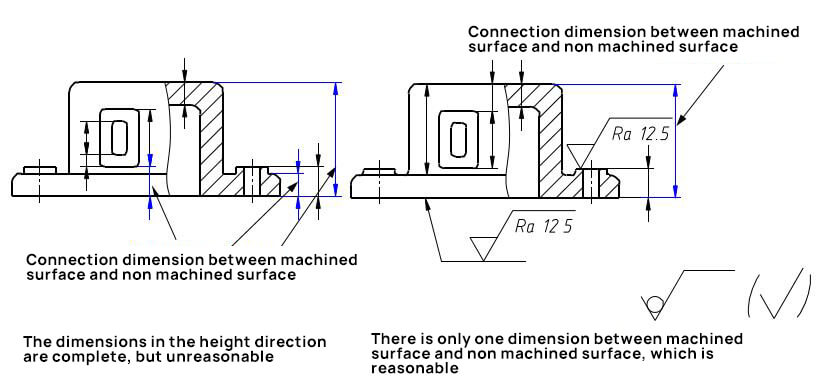

4. Only one non machined surface can be connected with the machined surface in the same direction.

The blank size and processing size shall be marked separately as far as possible to facilitate drawing reading.

5. Mark the dimensions according to the processing sequence

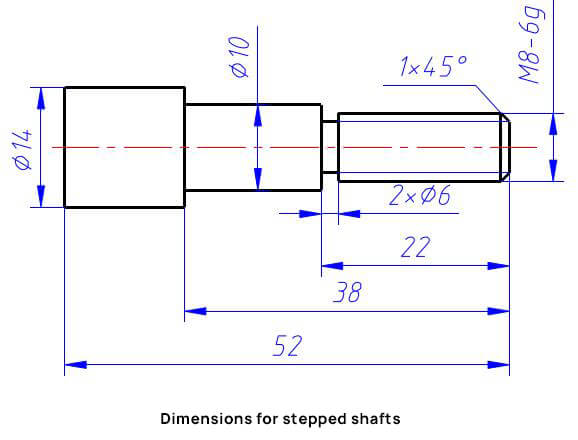

Dimensions for stepped shafts

Processing sequence

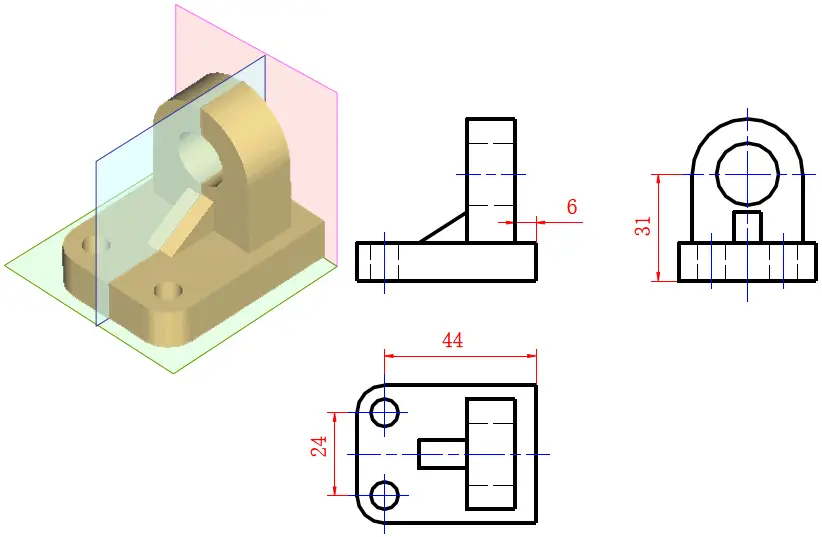

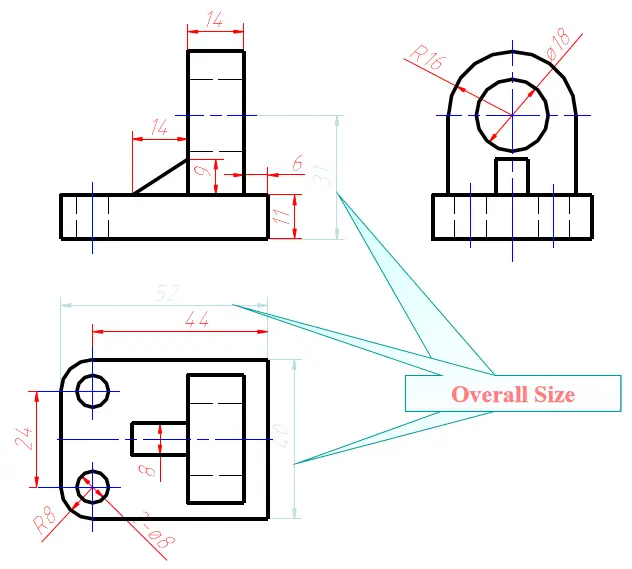

General methods and steps:

(1) Analyze the function of part structure shape and understand the combination relationship with adjacent parts;

(2) Distinguish the primary and secondary dimensions, determine the design basis and mark the main dimensions;

(3) Select the process benchmark and note all non main dimensions with shape analysis method.

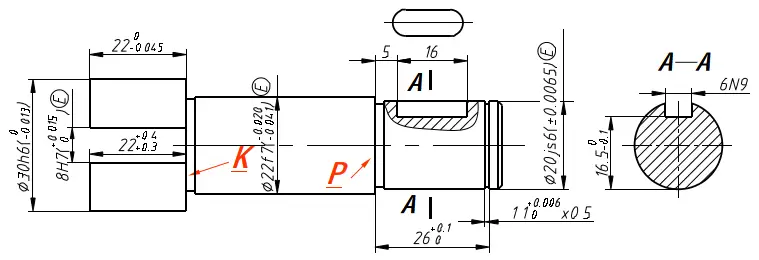

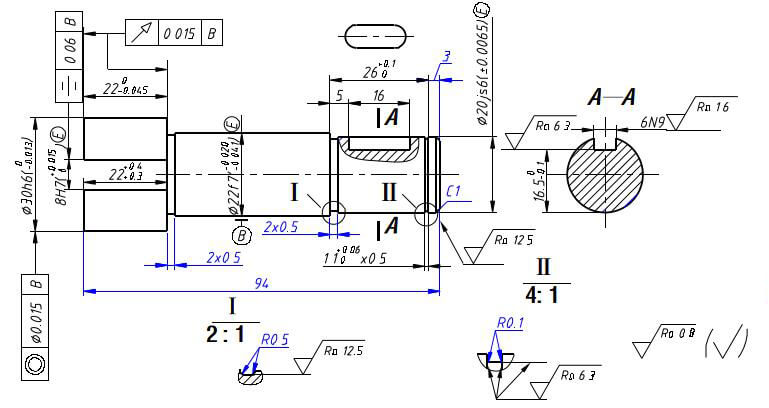

Example: vane pump shaft

(2) Mark the main dimensions and their deviations from the design basis.

(3) Considering the processing and manufacturing requirements, select the appropriate process benchmark, note all other dimensions, select the left and right end faces of the shaft as the process benchmark, and mark other dimensions.

Mark the surface structure requirements, geometric tolerance and other technical requirements.

(4) Check

Whether the main dimensions and design basis are appropriate, whether there are omissions, whether the dimension value and its deviation meet the design requirements, and whether they are coordinated with the relevant dimensions on the part drawing of relevant parts.

Check whether the dimensions are complete.

Check whether the setting size and positioning size are complete according to the structural shape of the parts.

Check whether it meets the national standard.

1. Earnestly implement national standards.

There are standard values for length, diameter, angle, taper and its deviation, which should be selected generally;

Standard structural elements (gear teeth, threads, etc.) shall be marked with dimensions and deviations according to regulations.

2. The dimensions shall be complete, but there shall be no redundant dimensions.

3. In order to facilitate the reading of drawings, the dimensions required for the same type of work shall be marked centrally, such as the dimensions of keyway on shaft.

4. The size of the contact shall be consistent.

Each part in the component has the relationship of fit, connection, transmission, position, etc. When marking the size of their connection, the dimension datum, marking content and marking form shall be coordinated as far as possible.

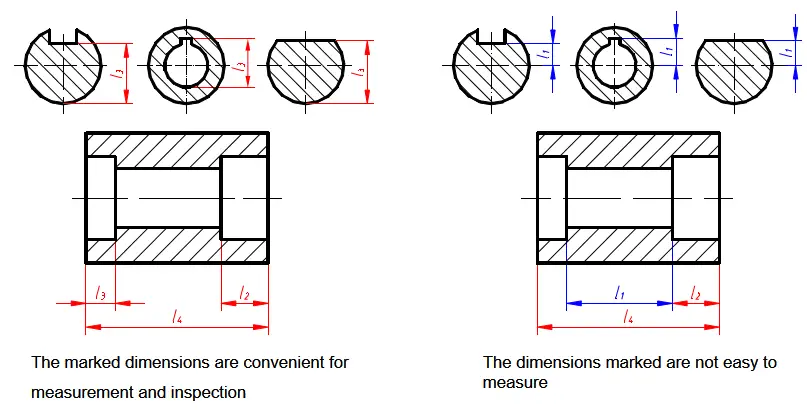

5. Consider the requirements of convenient measurement and inspection.

The marked dimensions are convenient for measurement and inspection

The dimensions marked are not easy to measure

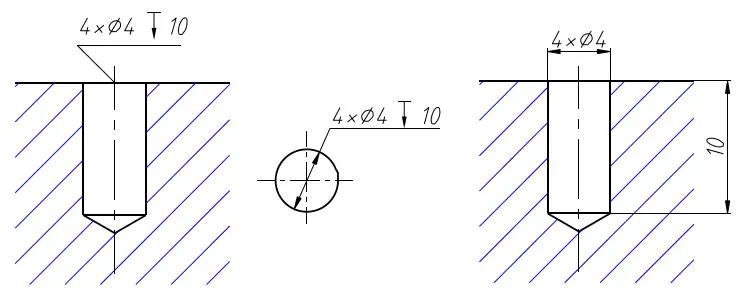

(1) Light hole

Simplified injection method Ordinary note method

Simplified injection method Ordinary note method

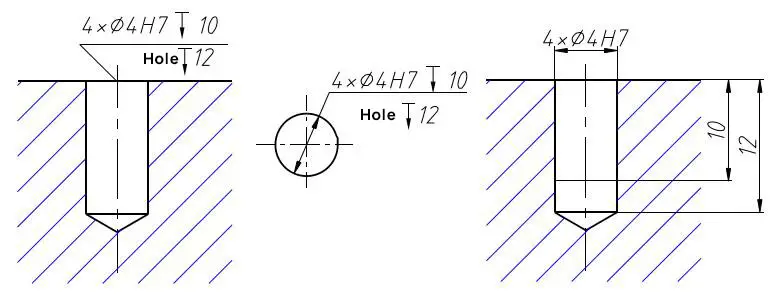

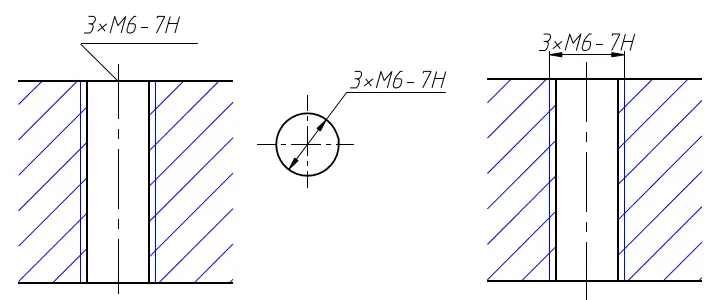

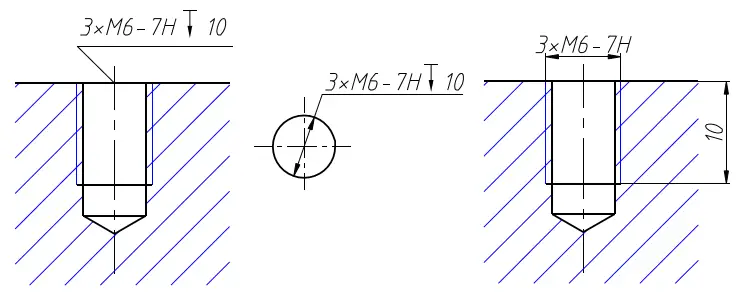

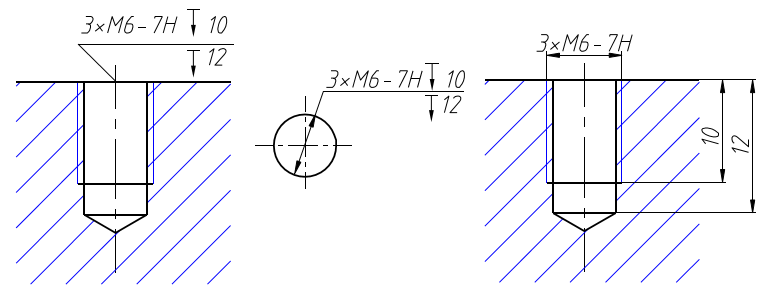

(2) Screw hole

Simplified injection method Ordinary note method

Simplified injection method Ordinary note method

Simplified injection method Ordinary note method

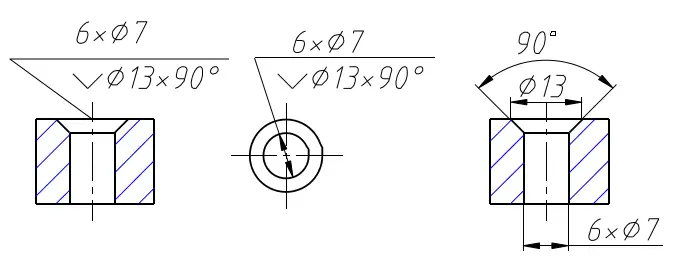

(3) Counterbore

Simplified injection method Ordinary note method

Simplified injection method Ordinary note method

Generally, the size should be marked as an opening, that is, there should be no redundant size.

At this time, the ring with the lowest accuracy requirement is not marked with size, which is called an opening ring.

In some cases, in order to avoid addition and subtraction during processing, the dimension of the split ring is marked with brackets, which is called “reference dimension“.

Generally, the reference dimension is not inspected in production.

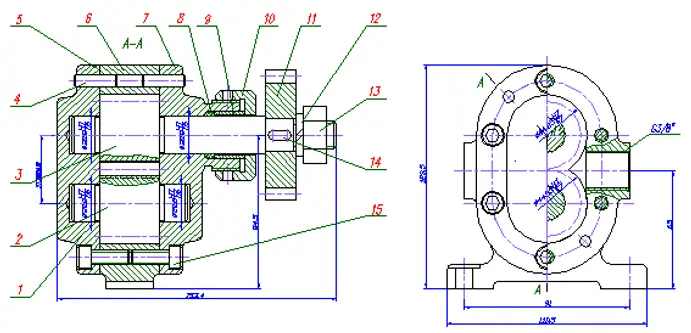

1. Basic requirements for dimensioning of assembly

2. Dimension classification and dimension datum

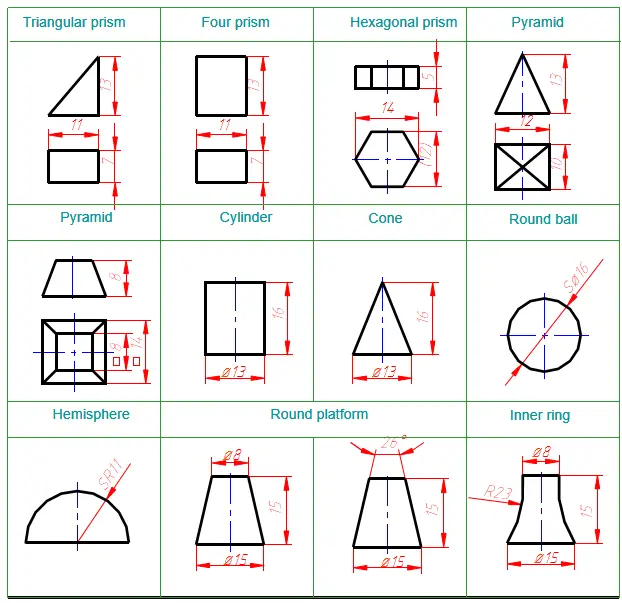

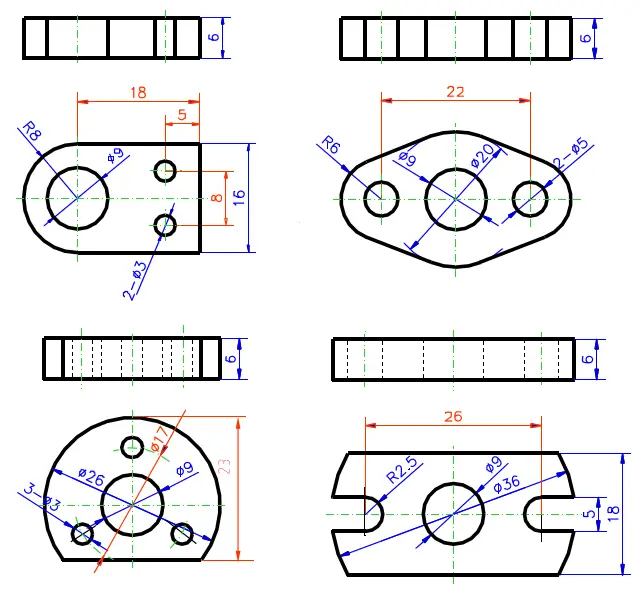

3. Basic shape dimension annotation method

4. Overall dimension annotation

5. Dimension marking of cutting body and intersecting body

6. Problems needing attention in dimensioning

7. Examples of dimensioning

1. The dimensions shall be complete, and the shape and size of the object shall be completely determined without omission or repetition.

2. The dimensions shall comply with the provisions of national standards, that is, strictly abide by national standards

3. The dimensions shall be reasonable and the arrangement shall be clear.

1. Dimension datum

The starting point of dimensioning is the dimension datum.

2. Setting size

Determine the size of the shape and size of each component of the assembly.

3. Positioning dimension

Determine the relative position and size between the basic shapes.

4. Overall dimensions

Total length, total width and total height of each body.

1). Dimension datum

2). Setting size

3). Positioning dimension

4). Overall dimensions

Legend to dimension the overall dimension

Legend without direct overall dimension

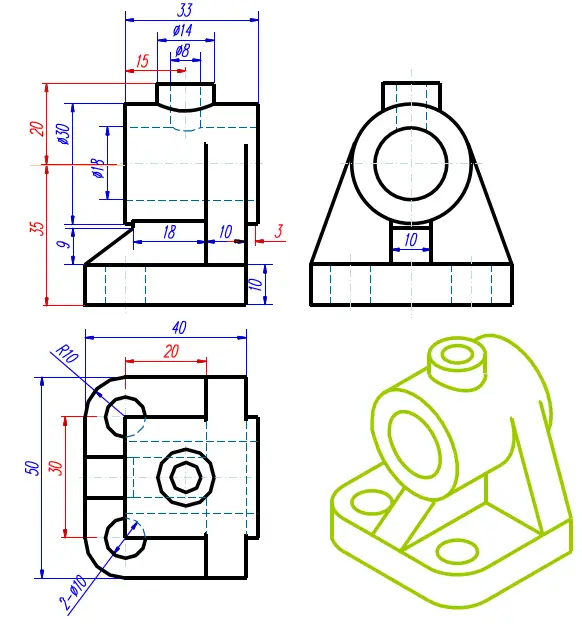

Steps to dimensioning:

1. Conduct shape analysis. The assembly can be divided into five basic parts: bottom plate, cylinder, support plate, rib plate and small cylinder.

2. Mark the fixed size of the shape one by one.

3. Select the dimension datum, select the bottom surface of the bottom plate as the datum in the height direction, select the symmetrical plane passing through the cylinder axis as the dimension datum in the length direction, and select the rear end face of the cylinder as the dimension datum in the width direction.

4. Mark the positioning dimension.

5. Adjust and mark the overall dimension.

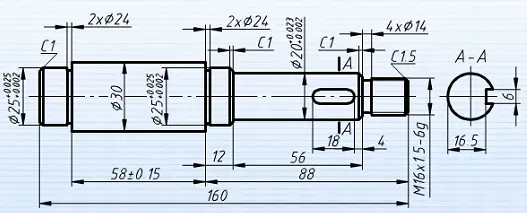

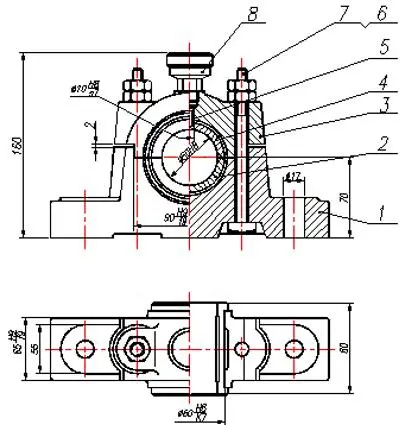

Shaft parts shall conform to the processing sequence and inspection method

Machining sequence of shaft:

The dimensions shall be complete, but there shall be no redundant dimensions.

Consider the requirements of convenient measurement and inspection.

The marked dimensions are convenient for measurement and inspection.

It is not necessary to note all dimensions of parts on the assembly drawing.

It is only necessary to further describe the performance, working principle, assembly relationship and required dimensions of the machine.

1. Specifications and dimensions

Also known as performance dimension, it reflects the specifications and working performance of components or machines.

This dimension should be determined first in the design. It is the basis for designing, understanding and selecting machines.

2. Assembly dimensions

The dimensions indicating the assembly relationship and working accuracy between parts generally include the following:

1. Fitting dimensions refer to some important dimensions with fitting requirements between parts.

2. Relative position dimension indicates the important distance and clearance between parts to be ensured during assembly.

3. Machining dimensions during assembly. Some parts can be machined only after they are assembled together. The machining dimensions during assembly shall be marked on the assembly drawing.

3. Installation dimension

The dimensions that need to be determined to install the components on the machine or the machine on the foundation.

4. Overall dimension

Indicates the total length, width and height of the machine or part.

It enables the required dimensions for packaging, transportation, installation and plant design.

5. Other important dimensions

It does not belong to the above dimensions, but the dimension should be guaranteed during design or assembly.