Ever wondered how to draw precise bend lines on sheet metal using CAD? This article simplifies the process, covering everything from determining bend allowance to modifying line types for fabrication. By the end, you’ll know how to create accurate flat patterns for efficient metalworking. Ready to master the art of sheet metal bending? Let’s get started!

Sheet metal flat patterns are an essential aspect of sheet metal processing. Today, let’s discuss how to draw bend lines for CAD sheet metal flat patterns in sheet metal fabrication drawings.

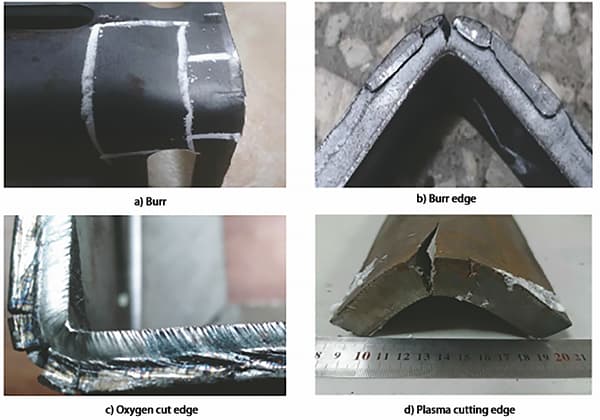

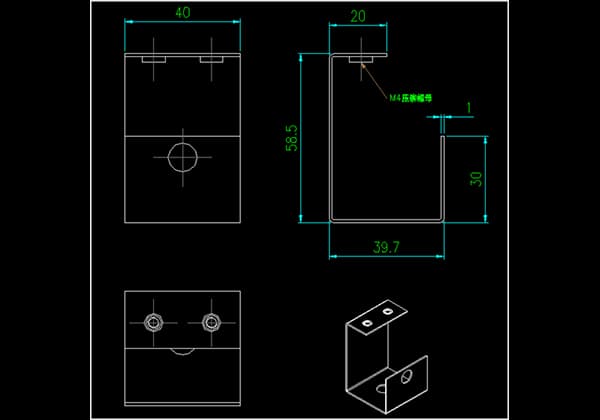

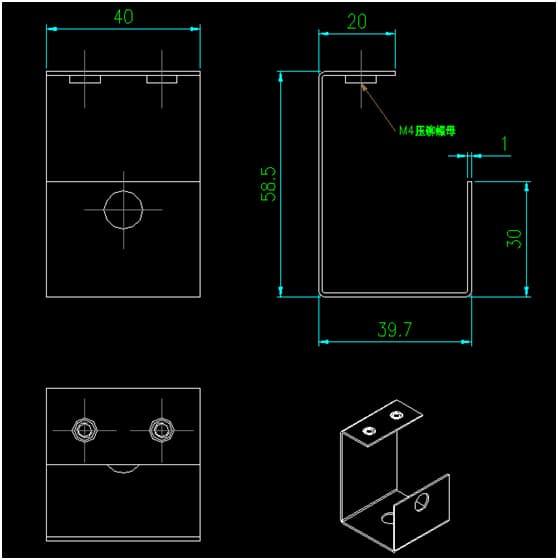

In the example below, we have a standard CAD sheet metal fabrication drawing of a component we need to process. We must convert the orthographic views into a flat pattern, which is the sheet metal flat pattern.

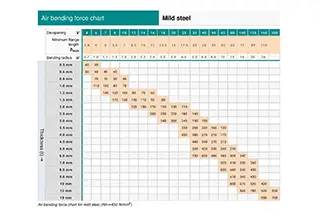

To draw sheet metal bend lines, first determine the sheet metal bend allowance. The bend line position is determined based on the bend allowance. In the illustration below, the bend allowance is calculated using the formula: inner dimension + inner dimension + compensation factor.

Related reading: Bend Allowance Formula

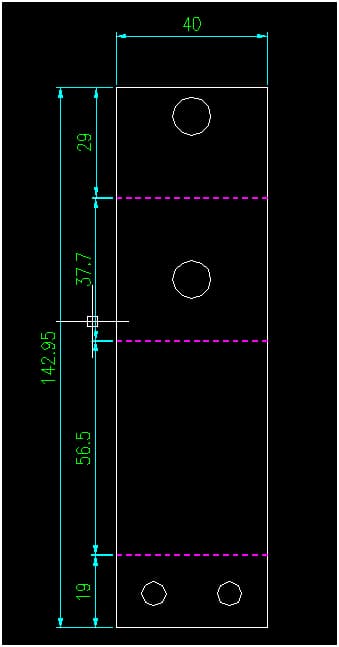

The sheet metal thickness is 1 millimeter, and the compensation factor is 0.25. Determine this value, offset the bend size by subtracting 1 (sheet metal thickness), then offset by 0.25 (compensation factor). Continue offsetting the adjacent bend sizes, and so on, until the final line segment.

Measure each value to ensure it conforms to the inner dimensions and compensation factor.

Modify the CAD line type to dashed lines, and set the color according to preferences or company requirements.

At this point, the CAD sheet metal flat pattern bend lines are complete. Production workers can now process and bend the sheet metal based on the fabrication drawings.

The calculation of bend allowance varies among companies; the example above is just one approach.