Have you ever wondered how bearings stay clean and efficient in harsh environments? This article explores the secrets behind rolling bearing sealing, revealing the methods and materials that protect them from contamination. Learn how different seals work and what makes them essential for smooth, reliable operations.

This question, put another way, asks: How is a bearing’s inherent pollution protection achieved? Since the question doesn’t specify which type of bearing, my response will cover most scenarios.

Not all rolling bearings possess inherent protection against pollution. Most bearings operate within a bearing housing, and thus, the environment of the bearing housing defines the working environment of the bearing. Protection against pollution is accomplished through the sealing of the bearing housing.

The primary method of sealing the bearing housing involves introducing a seal between the bearing cover and the rotating shaft. Various types of seals can be used, such as labyrinth seals, rubber skeleton seals, felt seals, and more. Detailed guidance can be found in specialized seal design manuals.

Regarding the bearing itself, some bearing designs incorporate pollution protection features. Bearings with built-in protection are primarily small to medium-sized deep groove ball bearings and some types of self-aligning roller bearings.

The sealing design of a rolling bearing involves placing a seal (or dust cover) between the outer and inner ring of the bearing. A common design is to affix the seal to the outer ring of the bearing, and design a sealing structure between the seal lip and the inner ring of the bearing.

The reason for positioning the seal design of rolling bearings between the lip and inner ring is to reduce the relative linear speed between the sealing lip and sealing surface.

For bearings at the same rotational speed, the linear speed of the outer surface of the inner ring is less than that of the inner surface of the outer ring (due to different rotation radii), so choosing the outer surface of the inner ring is more beneficial to reduce wear on the sealing lip.

Standard bearing seal structures often include dust covers and sealing caps.

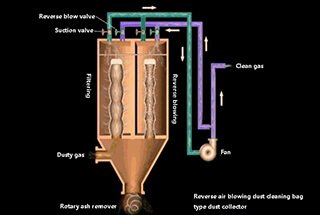

The dust cover design typically involves mounting a metal protective cover on the inner side of the bearing’s outer ring. A minimal gap is left between the inner side of the dust cover and the outer surface of the inner ring to prevent larger contaminant particles from entering. As illustrated in the figure below:

It’s evident from the bearing structure with a dust cover that such bearing seals can only protect against solid contaminants of a certain size. They do not provide adequate sealing protection against liquid contaminants and very small solid particles. These bearings are typically suitable for relatively clean operating environments. Bearings with seals often use skeleton seals.

A skeleton seal consists of an internal metal frame coated with other seal materials. The seal material typically used is nitrile rubber. Nitrile rubber possesses good wear resistance and its operating temperature range is suitable for general conditions. As shown in the following figure:

The design of bearing seal structures with seal components varies among different brands. Specific design details and pros and cons depend on the particular structure; consult with the corresponding supplier for more information.

However, generally, rolling bearings with seal components have good protective capabilities due to the contact (which may be light or heavy) between the seal lip and the sealed surface, providing a certain level of liquid contamination prevention.

But concurrently, the friction between the lip and the sealed surface can generate additional heat. A balance between seal friction heat and sealing effectiveness should be considered when choosing a type.

The nitrile rubber used as seal material also has a specific range of wear resistance. The maximum linear speed tolerated by the lip surface is usually 15 m/s. For higher relative rotation speeds, more wear-resistant seal materials are required.

The general operating temperature range for nitrile rubber is -30°C to 120°C, covering most industrial applications. The exact temperature range may slightly vary depending on the formula; bearing users can provide specific values to the supplier.

Below this temperature range, the material becomes hard and brittle, leading to easy damage. Above this range, the material softens and carbonizes, ultimately causing premature failure and damage.