Have you ever wondered how the tiny shift of a laser’s focal point can transform a weld? In laser welding, defocus—the distance between the workpiece and the laser’s focal point—plays a crucial role in determining weld quality. This article delves into how positive and negative defocus affect weld penetration, shape, and overall effectiveness. By understanding these impacts, you’ll learn how to optimize welding settings for different materials and achieve precise results.

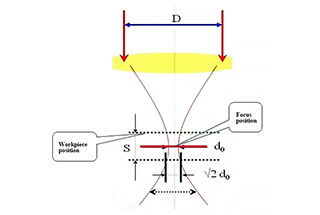

Defocus is the term used to describe the distance between the surface of a workpiece and the focal point.

When the focal point is above the workpiece, it is referred to as positive defocus. On the other hand, when the focal point is located below the workpiece, it is called negative defocus.

The power density at the center of the laser focus is too high, making it susceptible to evaporating into holes. The power density distribution is relatively uniform on each plane away from the laser focus.

In theory, when the distance between the positive and negative defocus planes and the welding plane is equal, the power density on the corresponding plane should be approximately the same.

However, in practice, this results in different weld penetrations and shapes. During negative defocus, the internal power density of the material is higher than that of the surface, which leads to stronger melting and vaporization. This allows light energy to penetrate deeper into the material, resulting in greater penetration.

The defocus amount should be negative 1-2mm.

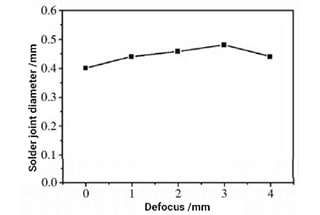

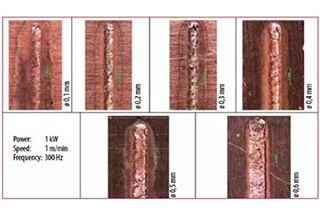

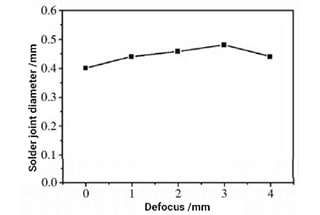

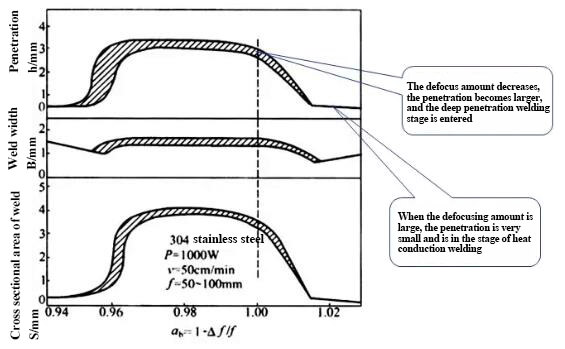

Effect of defocus on weld shape

The material to be welded is 6mm thick stainless steel, with a power of 5kW and a welding speed of 96cm/min. As the defocus amount decreases, the penetration increases and enters the deep penetration welding stage.

On the other hand, when the defocus amount is large, the penetration is minimal and the welding is in the heat conduction stage.

Effect of defocus on weld penetration, weld width and cross section

The defocus amount refers to the distance between the focus and the surface of the workpiece. If the focus is positioned above the workpiece, it is considered positive defocus. If the focus is positioned below the workpiece, it is considered negative defocus. Negative defocus is advantageous in increasing weld penetration.

Influence on the welding quality.

Laser welding typically requires a specific defocus amount as the power density at the center of the laser focus is too high, making it susceptible to evaporating into holes. The power density distribution is more uniform on each plane away from the laser focus.

According to geometrical optics theory, when the distance between the positive and negative defocus planes and the welding plane is equal, the power density on the corresponding plane should be approximately the same.

However, in reality, the shape of the molten pool is different. When using negative defocus, deeper penetration can be achieved due to the formation process of the molten pool. Experimentally, negative defocus is used when a deep penetration depth is desired, while positive defocus is used when welding thin materials.