Ever wondered how lasers can cut through metal like a hot knife through butter? This article dives into the fascinating world of laser cutting, focusing on the crucial role of focus position. Discover how adjusting this key factor can change everything, from the precision of cuts to the quality of the final product. Get ready to learn the secrets behind achieving perfect cuts every time!

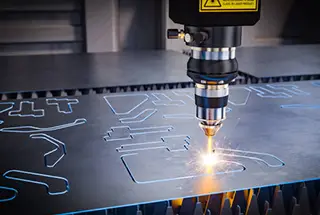

Laser cutting is a critical application of laser technology in metal fabrication. This process utilizes a high-power laser beam, typically CO2 or fiber laser, focused through a precision lens onto the material surface. The intense, concentrated energy rapidly heats the material to its melting or vaporization point, creating a localized cut zone.

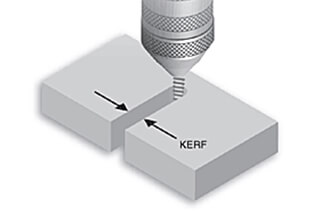

Concurrently, a coaxial stream of high-pressure assist gas (such as nitrogen, oxygen, or compressed air, depending on the material and desired outcome) is directed at the cut zone. This gas serves multiple purposes: it expels molten material from the kerf, prevents oxidation in some cases, and provides additional cooling. The choice of assist gas significantly influences cut quality, speed, and edge characteristics.

The cutting process is achieved through the synchronized movement of the laser beam and workpiece relative to each other, following a predetermined path. This movement is typically controlled by CNC (Computer Numerical Control) systems, enabling the creation of complex, precise geometries with minimal material waste. Advanced laser cutting machines can achieve tolerances as tight as ±0.1 mm and cutting speeds up to 20 m/min for thin sheet metal, making this technology indispensable for high-precision, high-volume manufacturing applications.

Laser cutting is a complex process involving the synergistic operation of the motion mechanism, control system, laser source, and cutting head. The quality and efficiency of the cutting process are influenced by various parameters originating from these four key components.

The primary factors affecting cutting performance include:

Beam characteristics:

Laser parameters:

Focusing optics:

Cutting dynamics:

Material properties:

Among these factors, the focus position is particularly critical. Adjusting the focus position alters both the beam diameter incident on the workpiece surface and the beam’s incident angle within the kerf. These changes significantly impact kerf formation, beam reflection within the cut, and ultimately, the kerf width.

The kerf width is a crucial parameter that influences numerous cutting quality metrics, including:

Optimizing these factors requires a comprehensive understanding of their interdependencies and their effects on the specific material being processed. Advanced laser cutting systems often employ adaptive control algorithms to dynamically adjust these parameters in real-time, ensuring consistent cutting quality across varying material thicknesses and compositions.

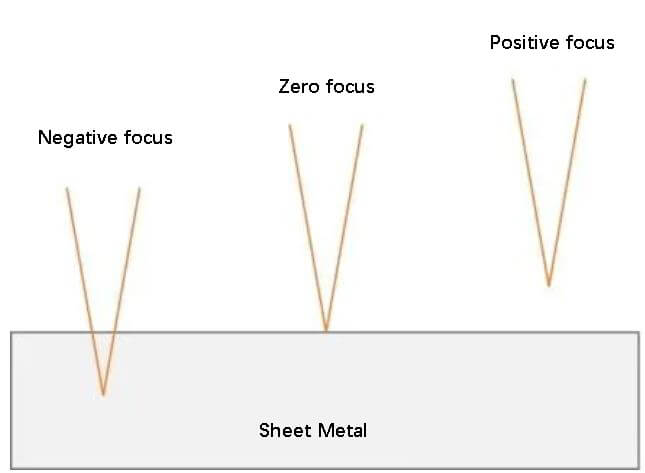

The focus position (Z) is a critical parameter in laser cutting that defines the distance between the focal point of the laser beam and the upper surface of the material being cut. This positioning significantly influences the cutting process’s efficiency, quality, and overall performance.

In laser cutting terminology:

The optimal focus position varies depending on factors such as material type, thickness, cutting speed, and desired cut quality. Proper focus adjustment is crucial for achieving clean, precise cuts and maximizing the laser’s cutting capability.

A schematic diagram illustrating these focus positions is presented below:

Understanding and controlling the focus position is essential for optimizing laser cutting operations, as it directly affects beam intensity at the cutting zone, kerf width, and overall cut quality.

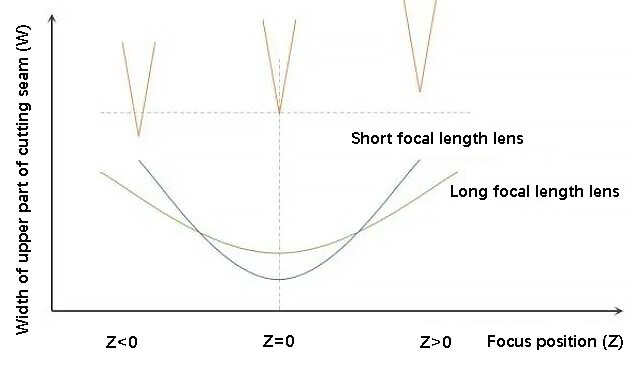

The following figure shows the variation relationship between the focus position (Z) and the width (W) of the upper part of the cutting seam of the processing material.

When the focus is on the plate surface, the width of the cut is the narrowest.

As the focus position changes, whether it is a positive or negative defocus, the width of the cut will widen.

The degree to which the width of the cut widens varies depending on the focal length of the cutting head lens and the focal depth. In general, the shorter the focal length and the smaller the focal depth, the greater the variation in the width of the cut with the focal position.

Before cutting any material, it is necessary to adjust the distance between the focus and the material.

Typically, the choice of the focus position will differ depending on the type of material being cut, so it is crucial to select it appropriately.

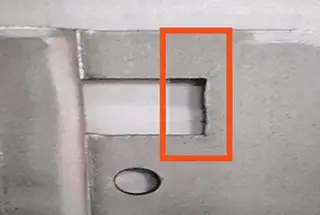

When the focus is positioned above the cutting material, the light beam will spread out and diffuse in the cutting seam after reaching the material surface. This will cause the lower part of the cut to be larger than the upper part.

This type of focus is suitable for oxidative cutting, such as oxygen cutting of carbon steel, as it allows oxygen to reach the bottom of the workpiece and participate in a sufficient oxidation reaction. Additionally, the larger cut at the bottom also helps to remove slag.

For oxygen cutting of carbon steel, a larger positive defocus within a certain range will result in a larger spot size on the material surface, as well as a brighter and smoother cutting surface. However, beyond a certain range, the energy of the lower part may not be sufficient, which can result in impervious cutting or slag hanging at the bottom.

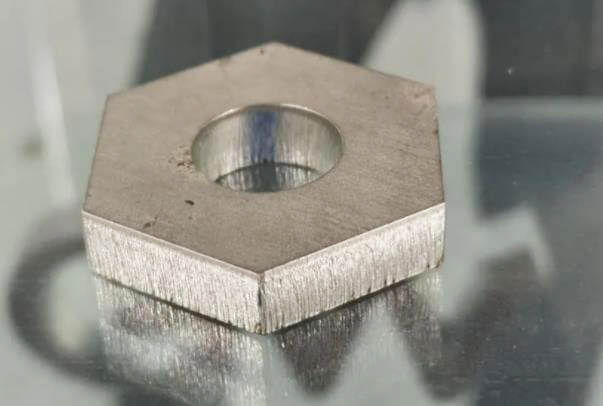

2KW laser – positive focus cutting 15mm carbon steel with oxygen

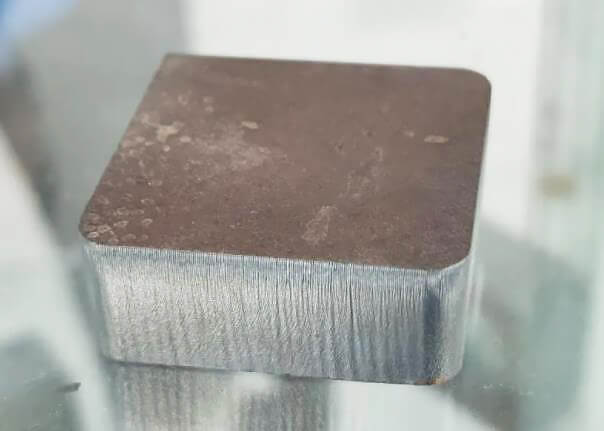

Negative focus cutting involves positioning the focus inside the plate, thereby ensuring that the lower part of the cut has sufficient energy density.

The cut is wider at the top and narrower at the bottom, with the upper part experiencing a larger cutting amplitude, which improves the fluidity of the melt. However, the lower part has a smaller cut width and requires a greater airflow.

Negative defocus is typically used when cutting with air or nitrogen.

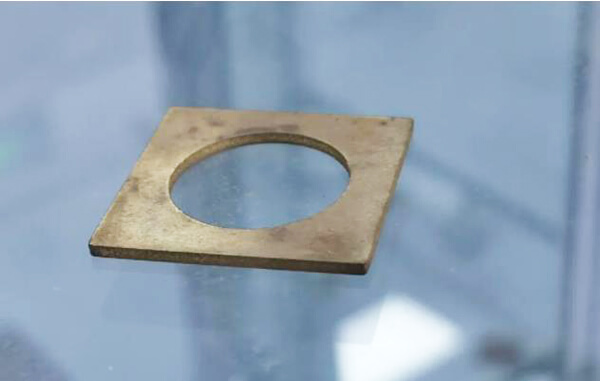

6kW laser – negative focus cutting 10mm stainless steel with nitrogen

During zero focus cutting, the smallest spot size can be obtained on the plate surface. This results in a relatively narrow melting range and a smaller cut, making it suitable for high-precision cutting of thin materials.

2KW laser – zero focus cutting 1mm brass with nitrogen

Cutting characteristics and application scope of different focus positions

|

Focus position | Cutting characteristics |

Scope of application |

Positive focus | The slit at the bottom of the plate is larger than that at the top, which helps the bottom participate in full oxidation reaction and slag discharge. | Oxygen cutting of carbon steel |

Negative focus | The focus is inside the plate, and the cutting seam of the upper part of the plate is larger, which ensures that the lower part has sufficient energy density. | Nitrogen/air cutting of stainless steel, carbon steel, galvanized steel, aluminum and copper |

Zero focus | The slit is the narrowest and the machining precision is high | Sheet/foil cutting

Precision cutting |

In recent years, the power range of fiber lasers has been increasing annually, and laser cutting applications have changed from kilowatts to 10,000 watts.

Our laser factory has been continuously exploring the application of high-power lasers and has developed a unique HBF (high brightness flat mode) laser output. This output ensures excellent cutting quality for thick plates while also accounting for the need for efficient thin plate cutting.

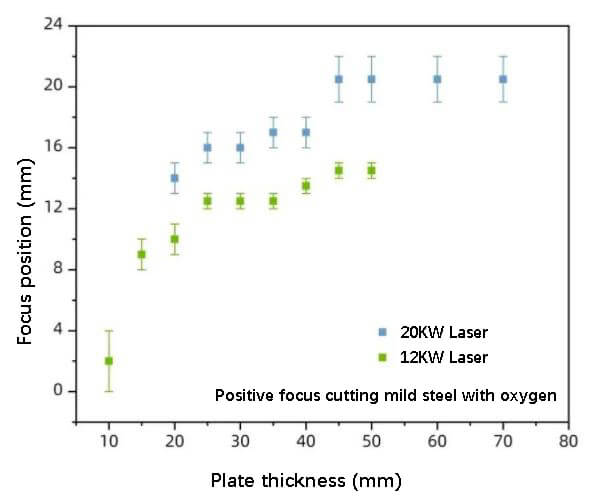

Positive focus on cutting mild steel with oxygen

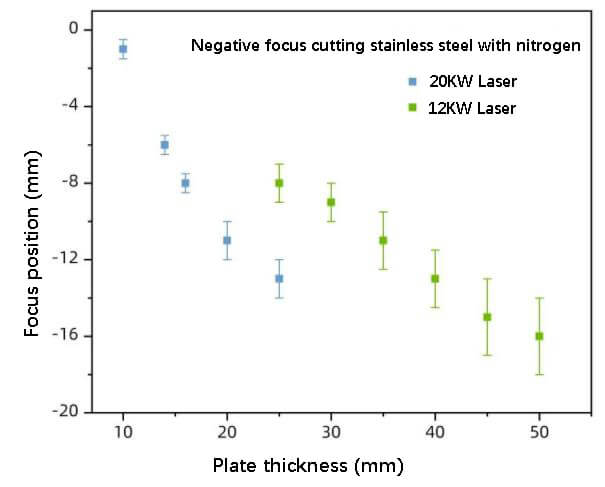

Negative focus on cutting stainless steel with oxygen

In actual cutting applications, it is necessary to select the appropriate focus position according to specific cutting requirements.