Choosing between an electric and hydraulic press brake can significantly impact your business efficiency and costs. Electric press brakes offer superior energy savings, environmental benefits, and faster operation speeds, while hydraulic press brakes are known for their reliability and slightly lower initial costs. This article will help you understand the differences, advantages, and potential drawbacks of each type, guiding you to make an informed decision that aligns with your operational needs. Discover the key factors that could transform your manufacturing process and elevate productivity.

With the increasing development of technology, modern sheet metal processing, especially the bending process, requires higher and higher standards. There are different technical requirements for equipment and processing efficiency, and both companies and countries have strict control over environmental protection and energy conservation.

Therefore, compared to hydraulic press brakes, press brakes controlled by pure electric servo systems are becoming increasingly accepted by major manufacturers.

In recent years, the maturity and cost reduction of high-power and high-torque electric motors and drive technologies have driven the increasing application of related electric drive devices.

The CNC press brake widely used in the sheet metal industry has opened up a new trend of pure electric servo main drive replacing hydraulic main drive, and the tonnage and production of pure electric servo CNC press brake are increasing.

This article describes the advantages of pure electric servo press brakes compared to hydraulic press brakes in terms of energy saving, environmental protection, processing efficiency, bending accuracy, and maintenance costs.

One of the advantages of pure electric servo drive technology is that the input power of the motor is proportional to the load power, resulting in high power consumption during bending, low power consumption when the ram moves up without load, and virtually no power consumption when the ram is stopped.

However, in a hydraulic servo press brake, the main motor and hydraulic pump continue to run even when the slide is not working, consuming energy.

In addition, the mechanical main transmission efficiency of a pure electric servo press brake is over 95%, while the hydraulic transmission efficiency of a valve-controlled hydraulic servo press brake is below 80%, and its efficiency decreases further after aging and wear of hydraulic system components.

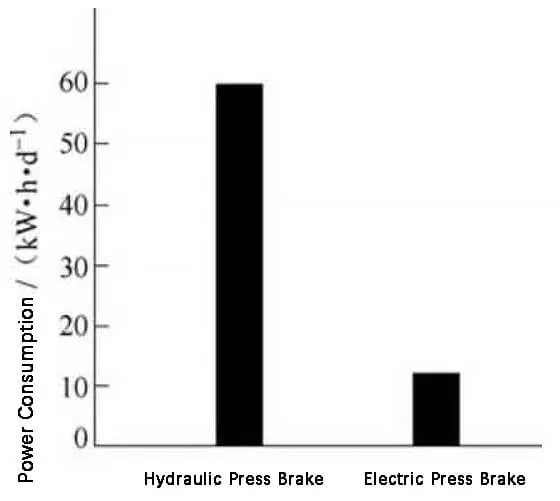

Taking a 100-ton press brake as an example and based on an 8-hour workday, the power consumption of the main unit of a pure electric servo press brake is about 12 kW·h/day, while the power consumption of the hydraulic system of a hydraulic press brake is about 60 kW·h/day.

Therefore, the pure electric servo press brake can save approximately 80% energy compared to a hydraulic press brake.

The pure electric servo press brake does not use hydraulic oil, which eliminates the need for oil replacement and component replacement. As a result, there is no need to deal with the hassles associated with oil replacement.

Additionally, there are no hydraulic oil leaks during the disassembly process or in the hydraulic system during regular use, which means there is no need for waste oil treatment and pollution control.

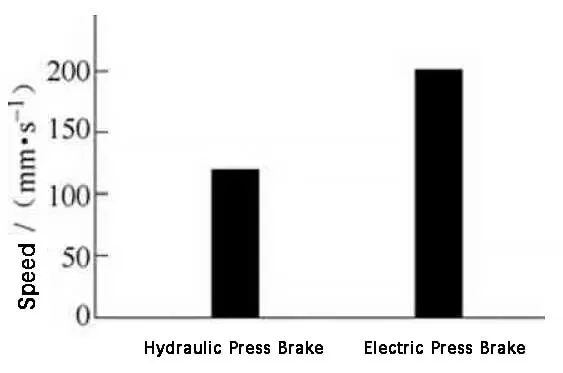

The response speed of the servo motor is faster than that of the hydraulic servo.

Taking the 100t pure electric servo press brake machine as an example, the ram return and fast down speeds are as high as 200mm/s, and the working speed is 0-20mm/s;

Most hydraulic press brakes with the same tonnage have ram return and fast down speeds below 120mm/s, and a working speed of 10mm/s.

The hydraulic servo press brake needs to be started for preheating or stopped for heat dissipation due to the influence of the environment and the heating of the hydraulic system;

Once there is a fault in the hydraulic system, the technical requirements for troubleshooting are high and the time is long.

The pure electric servo press brake machine has few components and a low failure rate, which fundamentally eliminates these problems.

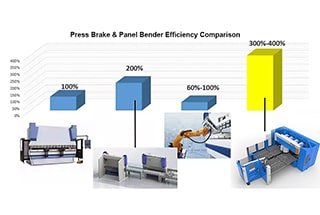

Therefore, the processing efficiency of a pure electric servo press brake is nearly twice as high as that of a hydraulic press brake of the same tonnage.

A pure electric servo press brake has an adjustable bending speed, which can be set to a more appropriate speed for different thicknesses, materials, and bending lengths, improving bending accuracy and ensuring high productivity.

The deflection compensation axis of the pure electric servo press brake uses a VILA structure compensation device, resulting in higher bending accuracy.

The bending angle error of a hydraulic press brake is within ±1 degree, while the main drive of a servo press brake is driven by a servo motor through a ball screw, resulting in higher transmission accuracy.

By measuring the bending angles of various sizes of sheets, the bending angle error can be controlled within ±0.5 degree.

The hydraulic oil of a hydraulic press brake needs to be replaced regularly, and the pump, valve, and sealing components are prone to failure and damage.

The hydraulic system is also prone to pollution, and finding and eliminating faults can be difficult. Once the hydraulic system is polluted, cleaning the system can be challenging and can lead to environmental pollution.

In contrast, the transmission system of a pure electric servo press brake is simple and has almost no maintenance costs, except for regular lubrication.

The design and manufacturing of a pure electric servo press brake aims for high bending precision, high operating efficiency, and high reliability.

Finite element analysis is performed on the bed and slide, and the performance of these components is optimized and strengthened.

Based on the analysis of energy consumption, environmental protection, processing efficiency, processing accuracy, and cost of pure electric servo press brakes and hydraulic press brakes, the conclusions are shown in the attached table.

Comparison Table of Hydraulic Press Brake and Pure Electric Servo Press Brake

| Comparison category | Hydraulic press brake | Pure electric servo press brake |

| Energy Consumption (based on a 100-ton press brake and an 8-hour workday) | Power consumption: about 60kWh/d | Power consumption: about 12kWh/d |

| Environment protection | Possibility of contamination | No pollution possibility |

| Processing Efficiency (based on a 100-ton press brake) | The return speed and fast down speed of the ram are below 120 mm/s, and the upward speed is 10 mm/s. | The return speed and fast down speed of the ram are as high as 200 mm/s, and the working speed ranges from 0 to 120 mm/s. |

| Bending accuracy | Bending angle error is within ± 1 ° | Bending angle error is within ± 0.5 ° |

| Cost | Slightly lower | Slightly higher |

The improvement in bending efficiency of an full-electric servo press brake is mainly reflected in the following aspects:

First, the rapid traverse speed of an all-electric servo press brake is generally faster than that of an electro-hydraulic servo press brake.

Second, the working speed of an all-electric servo press brake is more than twice that of an electro-hydraulic servo press brake.

Third, the acceleration and deceleration capabilities of an all-electric servo press brake are far superior to those of an electro-hydraulic servo press brake, saving time during speed changes.

Comparison analysis of bending efficiency between full-electric servo press brake and electro-hydraulic servo press brake

Processing conditions: Fast downward stroke of 80mm, working stroke of 10mm, and fast upward return stroke of 90mm.

| Universal electro-hydraulic servo press brake | High speed electro-hydraulic servo press brake | Universal all-electric servo press brake | High-speed fully electric servo press brake | |

| Y-axis fast forward speed (mm/s) | 100-120 | 150-160 | 100-130 | 200 |

| Y-axis working speed (mm/s) | 10 | 10 | 20 | 20 |

| Motion time (s) | About 4 | About 3.5 | About 2.8 | About 2.2 |

| Material change time (s) | 0.8 | 0.8 | 0.8 | 0.8 |

| Single bending time (s) | 4.8 | 4.3 | 3.6 | 3 |

| Number of bending cycles per day | 7500 | 8372 | 10000 | 12000 |

| Improvement in efficiency relative to conventional electro-hydraulic servo press brakes. | 100% | 112% | 133% | 160% |

| Increase in daily bending cycles relative to conventional electro-hydraulic servo press brakes. | 0 | 872 | 2500 | 4500 |

Number of bending cycles per day: Assuming a total work time of 10 hours per day, or 36,000 seconds.

The oil cylinder, pump valve, and seals of traditional hydraulic servo bending machines are prone to failure and damage. Troubleshooting requires high technical skills and takes a long time. Additionally, the hydraulic system is easily contaminated, and once contaminated, it is difficult to clean and can cause environmental pollution.

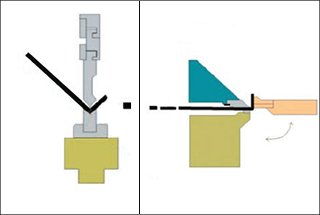

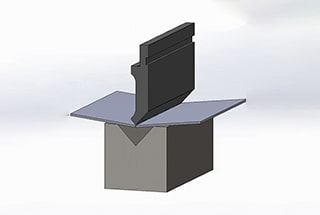

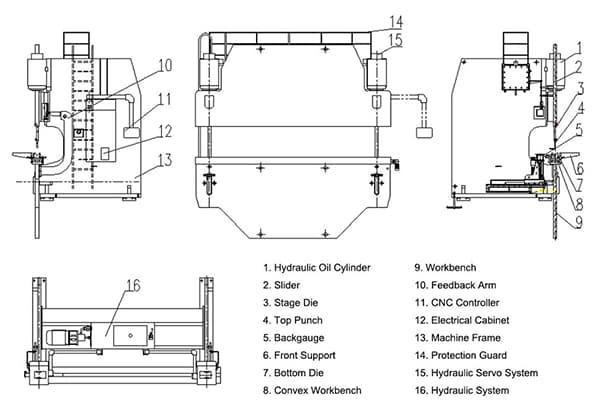

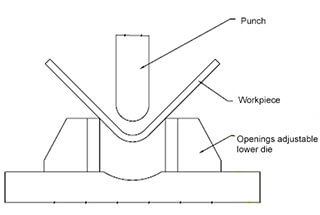

As shown in Figure 1, the all-electric servo press brake has a simple transmission system, eliminating components such as cylinders, pump valves, seals, and oil pipes. This results in a very low failure rate and virtually no maintenance costs, requiring only periodic lubrication. It ensures high bending precision, high operational efficiency, and high reliability. A performance comparison between the same tonnage all-electric servo press brake and the hydraulic servo press brake is shown in Table 1.

Table 1 Performance comparison between the same tonnage all-electric servo press brake and hydraulic servo press brake

| Item | 35 tons 1.3 meters | 100 tons 3.1 meters | ||

| All-electric servo press brake | Hydraulic servo press brake | All-electric servo press brake | Hydraulic servo press brake | |

| Idle speed/(mm/s) | 200 | 160 | 180 | 160 |

| Working speed/(mm/s) | 50 | 10 | 50 | 10 |

| Return speed/(mm/s) | 200 | 140 | 180 | 130 |

| Y-axis positioning accuracy/mm | ±0.01 | ±0.03 | ±0.01 | ±0.03 |

| Power consumption/(kW·h) | 0.9 | 2.2 | 1.5 | 7 |

The response speed of the servo motor of the all-electric servo press brake is faster than that of the hydraulic servo. For example, the 100-ton 3.1-meter all-electric servo press brake has a slider return and fast down speed of up to 140mm/s, and a working speed of 0-50mm/s. In contrast, most hydraulic servo press brakes of the same tonnage have a slider return and fast down speed below 120mm/s, and a working speed of only 10mm/s. Hydraulic servo press brakes are prone to failures due to environmental and hydraulic system heating issues, requiring preheating or cooling, whereas the all-electric servo press brake has fewer components and a very low failure rate, fundamentally avoiding these problems.

The processing efficiency of the all-electric servo press brake is nearly twice that of the hydraulic servo press brake of the same tonnage. For example, the 100-ton 3.1-meter press brake can bend up to 34 times per minute (with an opening height of 10mm) and at least 29 times per minute (with an opening height of 140mm), significantly improving production efficiency. For a fast down stroke of 140mm, the all-electric servo press brake can bend 29 times per minute, while the hydraulic servo press brake can only bend 12 times per minute. For a fast down stroke of 10mm, the all-electric servo press brake can bend 34 times per minute, while the hydraulic servo press brake can bend 21 times per minute.

The all-electric servo press brake uses a servo motor to directly drive the screw rod, adding a magnetic scale and forming a fully closed-loop control with the system, improving transmission accuracy with a positioning accuracy of ±0.01mm. In contrast, the hydraulic servo press brake uses a motor to drive the oil pump, which inputs oil to the proportional valve, and the proportional valve controls the oil volume for operation, resulting in lower accuracy with a positioning accuracy generally of ±0.03mm.

One of the advantages of all-electric servo drive technology is that the input power of the motor is proportional to the load power. The motor does not rotate in standby mode, consuming almost no electrical energy, and the noise during operation is much lower than that of hydraulic servo press brakes. For example, the 100-ton 3.1-meter servo press brake consumes 1.5kW·h, while the hydraulic servo press brake consumes 7kW·h.

The mechanical main transmission efficiency of the all-electric servo press brake is over 95%, while the hydraulic transmission efficiency of the hydraulic servo press brake is below 80%, and the efficiency decreases further as hydraulic system components age and wear. For example, the 100-ton 3.1-meter press brake consumes about 12kW·h/d for the main machine when working 8 hours a day, while the hydraulic system of the hydraulic servo press brake consumes about 56kW·h/d, saving about 80% energy with the all-electric servo press brake.

The all-electric servo press brake does not use hydraulic oil (saving about 5000 yuan annually on average), avoiding the hassle of replacing hydraulic oil and hydraulic components, as well as the issues of hydraulic oil leakage and waste oil disposal and pollution.