How does a machine achieve high precision and efficiency in metal bending? Discover the secrets behind the Electro-Hydraulic Servo Press Brake. This article delves into the intricate mechanics, setup procedures, and operational guidelines of this advanced machine, providing essential knowledge for maximizing performance and safety. Learn how to maintain and troubleshoot this equipment to ensure optimal operation in various industrial applications.

The Electro-Hydraulic Servo Numeric-Control Press Brake is known for its high efficiency and precision in bending sheet metal.

The size of the V-groove on the lower die should be adjusted according to the thickness of the sheet. It is typically larger than 8 times the thickness of the sheet.

By using different types of upper and lower dies, a wide range of workpieces can be bent.

For desired bending force, refer to the Sheet Metal Bending Chart on the body of the press brake machine or use the bending formula to calculate it.

One pass of the slider results in a bend in the sheet, and complex shapes can be achieved by bending the workpiece multiple times.

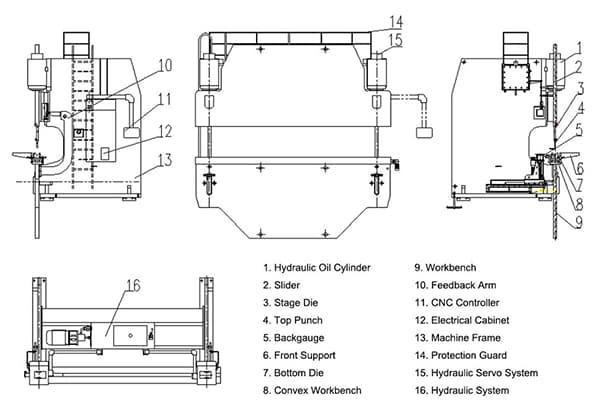

The Hydraulic Press Brake is constructed with steel plates, providing the necessary strength and rigidity.

Its hydraulic drive prevents the machine from experiencing serious overload accidents, even with changes in sheet thickness or incorrect lower die selection.

In addition, this press brake is known for its stability during operation, ease of use, and reliable safety features.

The connection to the upper die includes a compensation device, which compensates for any deflection in the worktable and slider during bending, ensuring high precision.

It is equipped with hydraulic electric control and adjustable slider travels, making it convenient for trial and adjustment purposes.

This press brake machine is advanced in technology and reliable in performance, making it an ideal shaping tool.

It is widely used in the plane, automobile, shipbuilding, and machinery industries due to its high production efficiency.

Hoisting

Due to its high center of gravity, the bending brake is heavy in the front and light in the rear. Therefore, care must be taken to ensure the stability of the machine and prevent it from tipping over.

In order to maintain consistency, silk ropes should be used at a narrow angle of incidence.

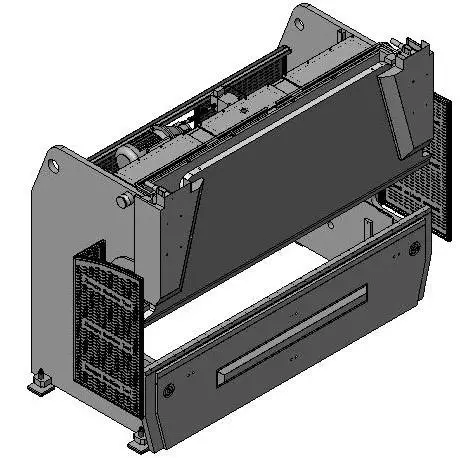

Fig.1

Fig.2

Clear up

Before running the hydraulic press brake, you must get rid of the rust protection oil on the following moving parts.

Note: Permit to use gasoline and coal oil to clean, prohibit using the dissolvent wash.

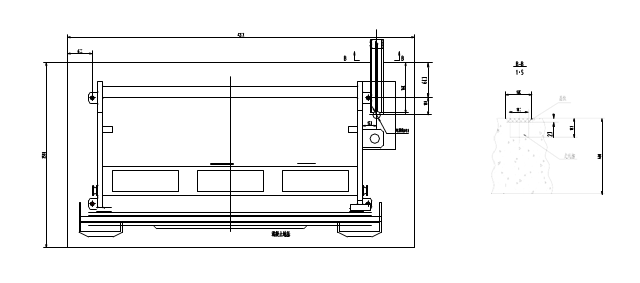

Leveling

Note: The machine should be placed on a level surface before performing precision adjustments. Ensure that all parts of the machine, including electrical components, are properly connected before proceeding.

The process is as follows:

And in all this process, the bottom screw must be connected well.

Note: The level must be check and adjust again after using for 30-50 hours.

The connections of electric

After connecting the main switch (power phases: R, S, T, PE), check the orientation of the hydraulic pump by performing a short test start. If the orientation is incorrect, immediately turn off the power and switch the two phase lines (refer to the hydraulic pump’s directional arrow).

The cable entry can be located at the bottom of the electrical box.

Note:

(1) Ensure that the voltages are consistent.

(2) It is recommended that a trained electrician or someone who is knowledgeable of the manual perform the electrical connection of the machine.

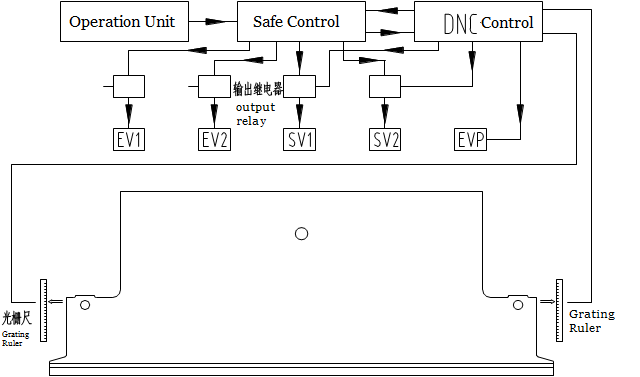

The Electro-Hydraulic Servo Press Brake integrates numerical technology, servo, and hydraulic systems. The movement of the control valve causes the upper crossbeam to move up and down periodically, with the movement measurement taken by the rasters on both sides of the machine.

The DNC controls the opening and closing of the two valves in the left and right oil cylinders. If necessary, the servo can reallocate the flow in the oil cylinder, causing the upper crossbeam to move vertically. The movement measurement is determined by the new pulse count. (Figure 3)

Fig.3

The signal from the DNC controller is transmitted to the servo valve, which converts it into a hydraulic pressure signal and controls the movement of the valve. Each cylinder in the hydraulic system has its own independent control loop, which includes the servo valve and the filling valve.

The DNC controls the following axes:

Note: The position of the slider block can be programmed using the absolute value equation and the angle size.

Manual adjustments or controller control can be applied to the Z1, Z2, R1, and R2 axes.

The position and character of each axis

| Axis | Zero position | Actual numerical value |

|---|---|---|

| Y1 left slider block(up or

(up or down) |

Surface of worktable | Distance between the surface of the worktable and mold of the slider block |

| Y2 right slider block(up or

(up or down) |

Surface of worktable | Distance between the surface of the worktable and mold of the slider block |

| X、X1、X2 back gauge

〔front and back〕 |

The center of lower die | Max distance between the center of upper

die and back gauge |

| R、R1、R2 back gauge

(up and down) |

Surface of worktable(and the lowest spot of back gauge) | The distance between the surface of the worktable and the lowest spot of back gauge |

| Z1 the left of the back gauge

〔left to right〕 |

Left of machine body | The distance between the most left side of the machine body and left the end of the back gauge |

| Z2 the right of the back gauge

〔right to left〕 |

Left of machine body | The distance between the most left side of the machine body and left the end of the back gauge |

Note:

(1) Follow the instructions in the DNC manual to program the axes.

(2) The terms “left” and “right” in the table refer to the front of the machine when facing it.

Warning:

(1) The operator should be cautious of the position of the back gauge. If it moves into the area of the mold, it may cause damage to the machine.

(2) When adjusting the Z-axis manually, only do so from the back of the machine.

(3) Take care when adjusting the back gauge to avoid hitting the lower die.

The back gauge is composed of a beam that extends from one side of the machine to the other, supported by straight-line guides and ball bearing lead screws. The guides for the back gauge are located on both sides of the machine body, leaving ample room for movement. The X axis controls the movement of the back gauge through the DNC control, and it is driven by a servo motor.

The hydraulic pressure oil tank is welded inside the body of the machine. The intake is located within the tank, while the motor, oil pump, high-pressure valve, control valve, and electronic system are located outside. The filtering core and valve pedestal are placed at the top, and the oil discharge screw is located at the bottom of the tank.

3-phase four-grade motor

The high-pressure gear pump and the main motor are connected by a flexible coupling shaft.

The level of filtration is 10μm and the maximum pressure is 400 bar. If the filter becomes clogged or if the oil needs to be changed, the filter must be replaced.

The servo valve is mounted on the top of the oil cylinder. Its flow is regulated by the DNC numerical control system and servo amplifier, allowing for control of the slider block’s speed throughout its entire travel range. The position and manner of control are as follows:

The servo valve is located on top of the oil cylinder. When the slider moves quickly, oil flows into the cylinder from the oil box through the fill-in valve. The valve is closed during the bending process.

The pressure valve is in the servo valve, back pressure when adjustable return travels.

The overtravel protection is controlled by the DNC. At startup, the DNC checks the time and pressure of the oil path for overtravel, also known as oil pressure leak checking.

Note:

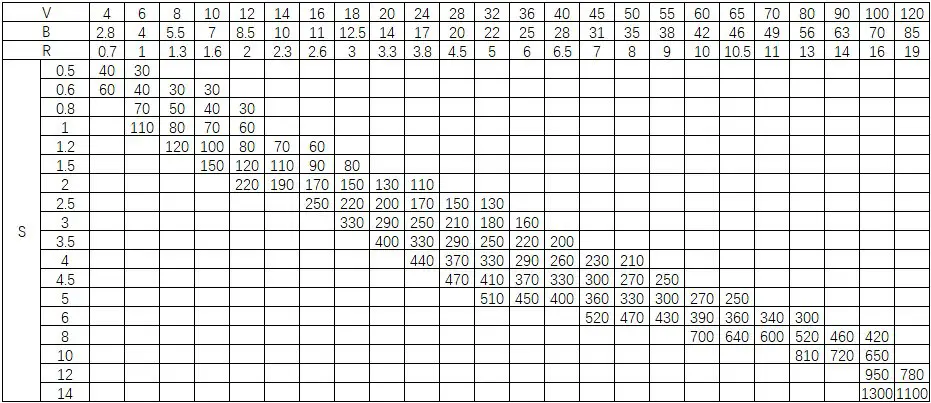

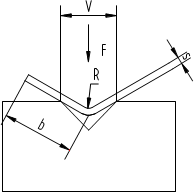

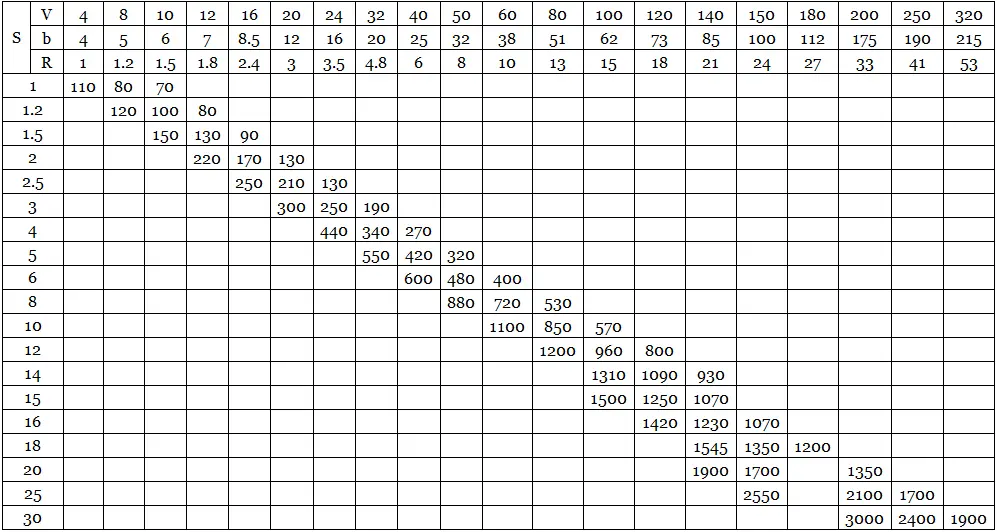

The selection of lower die (See Picture 4)

Fig. 4 The sketch map o the lower die

F: The requiring bending force (KN/m) of per meter when the material tensile strength is 400 N/mm.

If the material tensile strength is 800N/mm, the requiring bending force (KN/m) of per meter doubles. S: Plate thickness (mm)

S<3mm V=(6~8) ×S

S>3mm V=(8~12) ×S

Only by changing the minimum bending width and bending angle can the overall dimension of the lower die’s limit be scientifically determined.

| S | V | F | R | B |

|---|---|---|---|---|

| 0.5 | – | – | – | – |

| – | – | – | – | |

| -8 | -28 | -1 | -4 | |

| 1 | 8 | 110 | 1 | 4 |

| 8 | 80 | 1.2 | 5 | |

| 10 | 70 | 1.5 | 6 | |

| 1.2 | 8 | 120 | 1.2 | 5 |

| 10 | 100 | 1.5 | 6 | |

| 12 | 80 | 1.8 | 7 | |

| 1.5 | 10 | 150 | 1.5 | 6 |

| 12 | 130 | 1.8 | 7 | |

| 16 | 90 | 2.4 | 9.5 | |

| 2 | 12 | 220 | 1.8 | 7 |

| 18 | 170 | 2.4 | 9.5 | |

| 20 | 130 | 3 | 12 | |

| 2.5 | 18 | 250 | 2.5 | 9.5 |

| 20 | 210 | 3 | 12 | |

| 24 | 130 | 3.6 | 15 | |

| 3 | 20 | 300 | 3 | 12 |

| 24 | 250 | 3.6 | 15 | |

| 32 | 190 | 4.8 | 20 | |

| 4 | 24 | 440 | 3.6 | 15 |

| 32 | 340 | 4.8 | 20 | |

| 40 | 270 | 6 | 25 | |

| 5 | 32 | 550 | 4.8 | 20 |

| 40 | 420 | 6 | 25 | |

| 50 | 320 | 7.5 | 32 | |

| 6 | 40 | 600 | 6.5 | 25 |

| 50 | 480 | 8 | 32 | |

| 60 | 400 | 9.5 | 38 | |

| 8 | 50 | 880 | 8 | 32 |

| 60 | 720 | 10 | 38 | |

| 80 | 530 | 12.5 | 51 | |

| 10 | 60 | 1100 | 10 | 38 |

| 80 | 850 | 13 | 51 | |

| 100 | 570 | 16 | 62 | |

| 12 | 80 | 1200 | 13 | 51 |

| 100 | 960 | 16 | 62 | |

| 120 | 800 | 19 | 73 | |

| 14 | 100 | 1310 | 15 | 62 |

| 120 | 1090 | 18 | 73 | |

| 140 | 980 | 21 | 85 | |

| 15 | 100 | 1500 | 15 | 62 |

| 120 | 1250 | 18 | 73 | |

| 140 | 1070 | 21 | 85 | |

| 16 | 120 | 1420 | 18 | 68 |

| 140 | 1230 | 21 | 79 | |

| 160 | 1070 | 24 | 90 | |

| 18 | 140 | 1545 | 21 | 87 |

| 160 | 1350 | 24 | 100 | |

| 180 | 1200 | 27 | 112 | |

| 20 | 140 | 1900 | 25 | 85 |

| 180 | 1700 | 28 | 98 | |

| 200 | 1350 | 38 | 121 | |

| 25 | 180 | 2550 | 28 | 100 |

| 200 | 2100 | 38 | 121 | |

| 250 | 1700 | 41 | 131 | |

| 30 | 200 | 3000 | 38 | 125 |

| 250 | 2550 | 41 | 131 | |

| 300 | 2100 | 53 | 143 |

During the bending process, the bending force is concentrated on the worktable surface and acts on the tooling at the same time. Therefore, the load that the tooling can bear should not exceed its capacity.

For example:

When selecting the lower die, the options are V12, V16, and V20. When choosing V16, it is best to take the thickness of the plate into consideration.

Relatively speaking, the radius is not very significant, and when the bending width (b) is greater than the minimum bending radius, different thickness plates can be processed with the same lower die.

V16 S= 1.5mmm, 2mm, 2.5mm

Note: If it’s a molding tool, the bending force must be two or three times greater.

FP= (2….3)Fb

You can also calculate the required press brake tonnage by Press Brake Bending Force Calculator.

The selection of the upper die must also be based on the bending force and the load capacity should not be exceeded. Additionally, customers can choose special tooling, but they should be aware of the differing load capacity compared to standard tooling.

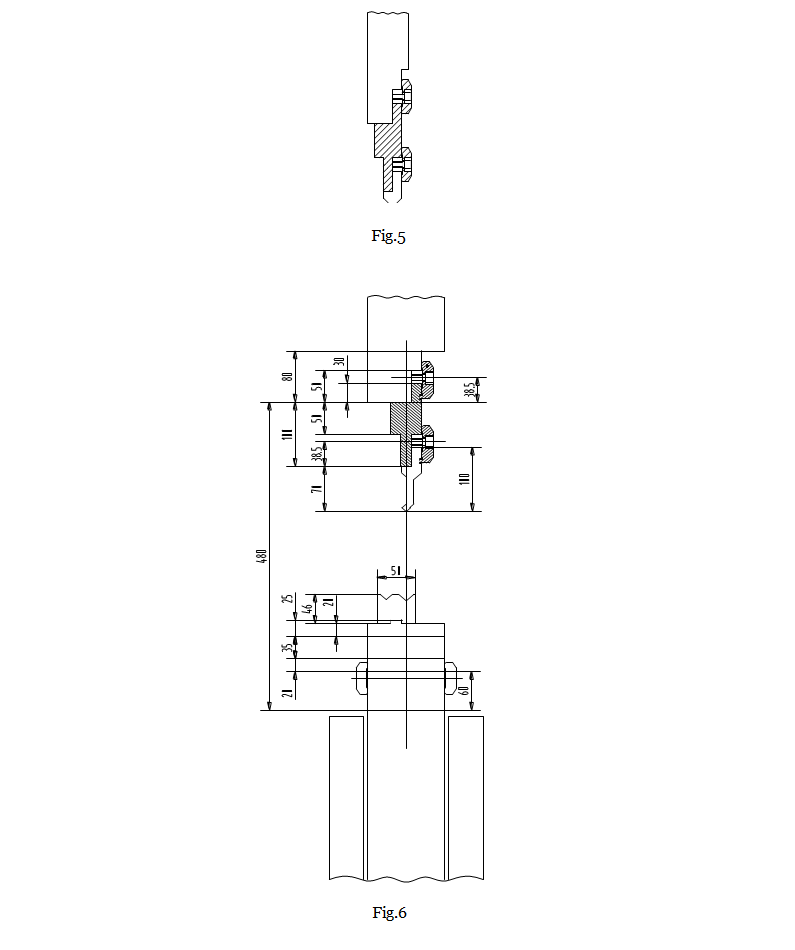

Note: The operator must follow safety principles in dangerous areas of the machine, as shown in Figures 5 and 6.

A. It is forbidden to pass through the tooling.

B. To prevent accidents, before installing the upper and lower dies, the starting button should be set to the second control position and the NC driving button should be set to “axis stop”.

The table below is for reference only. If there are any questions, please refer to the processing material.

| Type | Tensile strength Kg/mm2 | |

|---|---|---|

| Aluminum | Soft rigidity | 10.5 |

| Middling | 13.3 | |

| High | 19.6 | |

| Brass | Soft | 32.9 |

| Mennir high strength resists corrosion the constantan | Middling | 42 |

| High | 59.5 | |

| Copper | Rolled | 25.9 |

| Chromeplate Aluminum | Soft | 24.5 |

| Heat treatment | 38.5 | |

| Iron | Wrought iron | 35 |

| Steel | 0.25%c | 46.9 |

| 0.5%c | 66.5 | |

| 0.75%c | 80.5 | |

| 1.0%c | 91 | |

| 1.2%c | 105 | |

| 1# Volume steel | 52.5 | |

| Stainless steel 18-8 | 66.5 | |

Note:

Before starting, ensure that it will not cause any harm.

The machine tool must be in a safe and suitable condition to run, with all protective measures and safety devices in place.

Avoid any dangerous operations and follow safety precautions.

If a fault occurs, immediately stop the machine and address the issue.

Fault resolution must be carried out under the supervision of a qualified technician or expert.

Regularly inspect the exterior of the machine for damage or faults and stop it if necessary.

The operator must thoroughly read the operation manual.

| Failure | Reasons |

| Press engine can not move quickly | Guide rail move spang, exchange valve EV1/2 damaged, control valve SV1/2 damaged |

| Press engine can not produce pressure | Exchange EV1/2 didn’t work, filling in valve V5/6 opened, pressure adjustment damaged, pump wear and tear |

| The press engine stop at the stopping position for 5-10 seconds then do slow movement | Filling in valve EV5/6 closed, oil position is too low in the oil cylinder |

| The press head moving back slightly first then start slowly | Single valve V11/V12 opened, the setting parameters wrong |

| Bending not correct | Control valve failure, basic setting wrong, transducer doesn’t adjust well, or transducer damaged. |

| The press head can not go back, the press head go back slowly | Control valve SV1/2 damaged, exchange valve Ev1/2 have no response, filling in valve jammed at the closing position, single valve EV9/8 at the closing position, pressure adjustment valve EVP damaged, wrong parameter setting, guide rail move spang, stroke pressure is too low. |

| The press head stopped at the high position, up to 2-3mm go back, slowly move down and the speed does not exceed 2mm/min | Single-way V7/8 opened, exchange EV1/2 leak or plug |

Note: A qualified individual is required to resolve any potential failures and comply with inspection and maintenance procedures. During the warranty period, notify the maintenance personnel. If the failure is due to incorrect operation, the maintenance personnel will not be held responsible.

Note:

Two ways of stop:

—Move the slider block to the center of the lower dead spot

—Close the main motor switch

—Set the operation selection switch to “0”

—Set the main switch to “0”

—Place the two pieces of wood on the work table

—Turn the “operation selection” key switch to “2” (for adjustment)

—Operate in “manual” mode

After the machine stopped, move the slider block down manual until it connecting the wood slightly.

—Turn off the main motor

—Change the operation selection switch to “0”

—Set the main switch to “0”

When activating this button, all axes will stop and the pump will shut down, but the control system will remain active. To restart the machine:

—Release the emergency button

—Press the green “main motor run” button. There is no need to restart the machine tool.

In the event of a stop, if one side of the slider block is tilted or lower than the level position, it can be manually adjusted, but the machine must be turned off and restarted under normal conditions.

Note: If the slider block cannot be corrected or the positioning function fails repeatedly, this may indicate a failure in the control system or hydraulic system.

The person responsible for maintenance and testing must thoroughly read the operation manual and have ample experience.

It is recommended to have the manufacturer of this machine conduct a check.

The machine operator should perform a daily inspection for any potential leaks or loose parts.

If the user is unable to resolve a malfunction, they should immediately notify the manufacturer.

Weekly Maintenance Checklist:

Hydraulic Oil Refilling:

T = V /Q* 5

Filter Core Replacement Schedule:

Note: If the yellow “replace filter” indicator light illuminates, the core must be replaced within 8 hours of operation.

If necessary, the zero position of all axes on the machine (without a back gauge locator) must be checked weekly or receive compensation from DNC.

Regular Inspection Items:

Valve Inspection Schedule:

Valves V7, V8, V9, and V10 must be inspected every six months using the following procedures:

Note: The check valves mentioned above are part of the safety system. Do not start the machine tool before replacing any potentially damaged valves.

Pressure Adjustment Valve Inspection:

The mechanical pressure adjustment valve’s safety seal ring must be inspected annually.

Note: If the above adjustment cannot be performed, any claims for compensation for quality issues during the warranty period will be void.

Hydraulic Oil Replacement Schedule:

Recommending hydraulic oil and lubricant

| Manufacturer | Hydraulic oil | Grease |

|---|---|---|

| ESSO | NUTO H46 | BEACON EP2 |

| SHELL | TELLUS 46 | ALVANIA EP2 |

| GULF | HARMONY 46 AW | CROWN EP2 |

| BP | HLP 46 | LS2 |

| FEXACO | RANDO OIL 46 | MUTIFAX EP2 |

| MOBIL OIL | MOBIL DTE 25 | MOBIL LUX EP2 |

Here are the drawings: