What makes the right electrode and welding wire so crucial for a perfect weld? This guide delves into the specifics of various electrode and welding wire models, including their applications and performance characteristics. Discover how choosing the correct type can significantly enhance the quality and durability of your welds, particularly in challenging environments. From general-purpose to heat-resistant and stainless steel options, this article equips you with the essential knowledge to select the best materials for your welding needs.

General-purpose welding wires:

Heat-resistant steel series flux-cored welding wires:

Gas shielded welding wires for stainless steel:

Gas shielded overlay welding flux-cored wires:

Submerged Arc Overlay Welding Flux-Cored Wires:

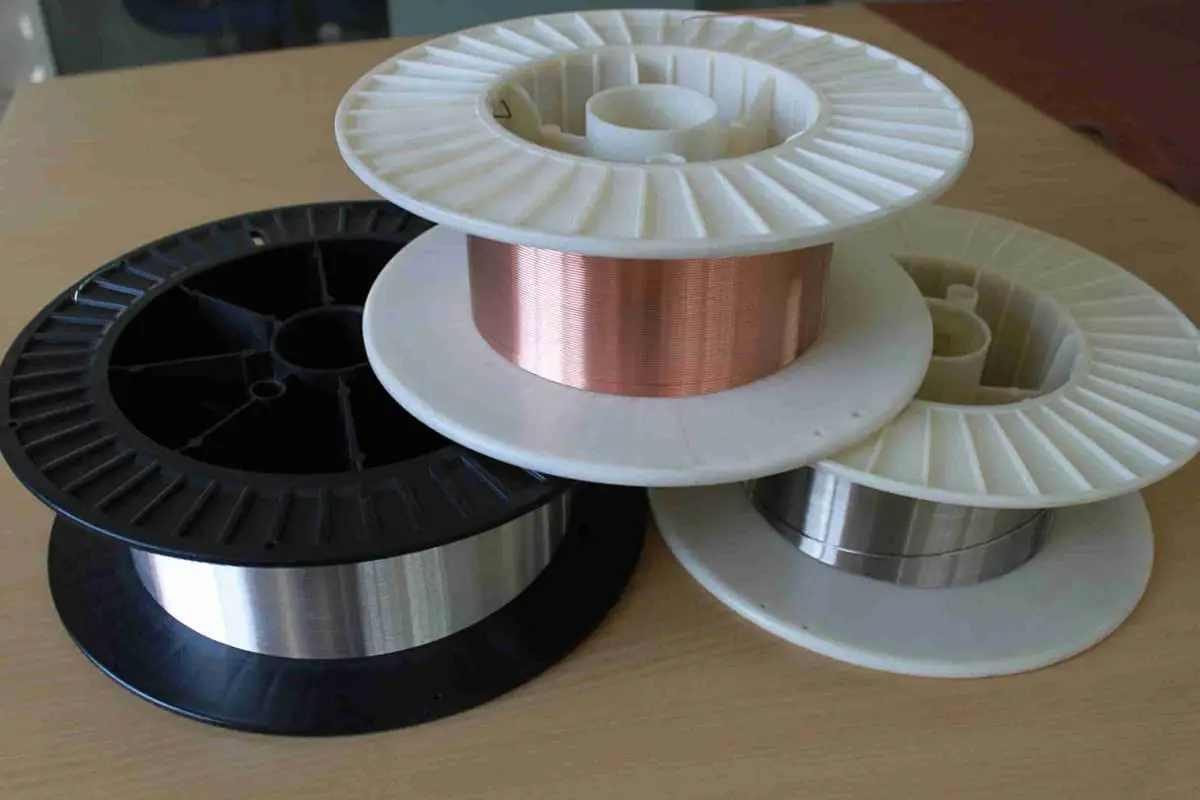

Stainless Steel Solid Core Welding Wires:

Stainless steel solid core welding wires can be used for both inert gas shielded welding (TIG, MIG) and submerged arc welding. MIG welding with stainless steel wires can achieve high-efficiency welding and is easily automated, making it widely used in overlay welding and thin plate joints. The chemical composition of MIG welding wires for stainless steel is the same as TIG welding wires.

However, for certain stainless steel grades, there are MIG welding wires with higher silicon (Si) content, such as ER308Si and ER309Si corresponding to ER308 and ER309 welding wires. The high Si content (around 0.8%) reduces the surface tension of the molten metal, resulting in finer droplet particles and easier droplet transfer, making the arc more stable.

Stainless Steel Spring Wires:

Stainless steel hydrogen relief wires:

Important notes:

| Types | Grade | China GB | America AWS | Types | Grade | China GB | America AWS |

| Carbon steel welding rods | THJ422 | E4303 | — | Stainless steel welding rods | THA002 | E308L-16 | E308L-16 |

| THJ426 | E4316 | E6016 | THA022 | E316L-16 | E316L-16 | ||

| THJ427 | E4315 | E6015 | THA102 | E308-16 | E308-16 | ||

| THJ506 | E5016 | E7016 | THA107 | E308-15 | E308-15 | ||

| THJ507 | E5015 | E7015 | THA132 | E347-16 | E347-16 | ||

| Low alloy steel welding rods | THJ506R | E5016-G | E7016-G | THA137 | E347-15 | E347-15 | |

| THJ507RH | E5015-G | E7015-G | THA202 | E316-16 | E316-16 | ||

| THJ557R | E5MoV-15 | — | THA207 | E316-15 | E316-15 | ||

| THJ606 | E6016-D1 | E9016-D1 | THA212 | E318-16 | E318-16 | ||

| THJ607 | E6015-D1 | E9015-D1 | THA242 | E317-16 | E317-16 | ||

| THW707Ni | E5515-C1 | — | THA302 | E309-16 | E309-16 | ||

| THR207 | E5515-B1 | E8015-B1 | THA307 | E309-15 | E309-15 | ||

| THR307 | E5515-B2 | E8015-B2 | THG202 | E410-16 | E410-16 | ||

| THR317 | E5515-B2-V | — | — | — | — | ||

| THR407 | E6015-B3 | — | Gas shielded solid core welding wire | THQ-G2Si | EN440 G38 4MG2Si | ||

| THR507 | E5MoV-15 | — | THQ-50CG4 | EN440 G38 3CG4Si1 | |||

| Grade | ModelGB | Category | Main applications: |

| THT49-1 | ER49-1 | Carbon steel welding wire | Used for butt and fillet welding of high-pressure pipes in shipbuilding, petrochemical, nuclear power, etc. |

| THT-10MnSi | ER50-G | Used for welding thin plates and backing welding structures. | |

| THT50-6(TIG-J50) | ER50-6 | Used for welding of pipes, flat plates, etc. requiring precise polishing. | |

| THT55-B2 | ER55-B2 | Pearlitic heat-resistant steel welding wire | Used for welding of boiler heating surface tubes, steam pipes, high-pressure vessels, and structures of petroleum refining equipment operating below 550℃. |

| THT55-B2V | ER55-G | Used for welding of boiler heating surface tubes, steam pipes, high-pressure vessels, and structures of petroleum refining equipment operating below 550℃. | |

| THT-307THS-307 | H09Cr21Ni9Mn4Mo | Stainless steel welding wire | Used for welding of bulletproof steel, cladding stainless steel, and dissimilar materials of carbon steel. |

| THT-307SiTHS-307Si | H10Cr21Ni10Mn6Si1 | Used for welding of high manganese steel, hardened wear-resistant steel, and non-magnetic steel. | |

| THT-308THS-308 | H08Cr21Ni10Si | Used for welding of stainless steel structures such as 308, 301, 304, etc. | |

| THT-308LTHS-308L | H03Cr21Ni10Si | Used for welding of stainless steel structures such as 304L, 308L, etc. | |

| THT-308LSiTHS-308LSi | H03Cr21Ni10Si1 | Used to improve the processability, weldability, and fluidity of the filler metal. | |

| THT-309THS-309 | H12Cr24Ni13Si | Used for welding dissimilar steels, such as carbon steel, low alloy steel, and stainless steel. | |

| THT-309MoTHS-309Mo | H12Cr24Ni13Mo2 | Used for welding of Cr22Ni12Mo2 composite steel and dissimilar steels. | |

| THT-309LTHS-309L | H03Cr24Ni13Si | Used for welding of 309S, 1Cr13, 1Cr17, low-carbon stainless steel, low-carbon cladding steel, and dissimilar steels. | |

| THT-309LSiTHS-309LSi | H03Cr24Ni13Si1 | Used for welding of 309 stainless steel and 304 stainless steel with carbon steel. | |

| THT-309LMoTHS-309LMo | H03Cr24Ni13Mo2 | Used for welding of dissimilar steels or low toughness martensitic and ferritic stainless steels. | |

| THT-310THS-310 | H12Cr26Ni21Si | Used for welding of heat-resistant steels operating at high temperatures and for welding of 1Cr5Mo, 1Cr13, etc. that cannot be preheated or post-heat treated. | |

| THT-312THS-312 | H15Cr30Ni9 | Used for welding of dissimilar cladding stainless steel, hardened low alloy steel, and in cases where welding is difficult or porosity is prone to occur. | |

| THT-316THS-316 | H08Cr19Ni12Mo2Si | Used for welding of structures in phosphoric acid, sulfuric acid, acetic acid, and salt corrosion media. | |

| THT-316LTHS-316L | H03Cr19Ni12Mo2Si | Used for welding of chromium stainless steels and composite steels in urea, synthetic fibers, and other structures that cannot undergo heat treatment. | |

| THT-316LSiTHS-316LSi | H03Cr19Ni12Mo2Si1 | Used for welding of the same type of stainless steel and composite steel structures. | |

| THT-317THS-317 | H08Cr19Ni14Mo3 | Used for welding of important corrosion-resistant chemical containers. | |

| THT-317LTHS-317L | H03Cr19Ni14Mo3 | Used for welding of important corrosion-resistant chemical containers. | |

| THT-321THS-321 | H08Cr19Ni10Ti | Used for welding of 304, 321, 347 stainless steels and heat-resistant steels. | |

| THT-347THS-347 | H08Cr20Ni10Nb | Used for welding of 304, 321, 347 stainless steels and heat-resistant steels. | |

| THT-410THS-410 | H12Cr13 | Used for overlay welding of 410, 420 stainless steels and corrosion-resistant and wear-resistant surface overlays. | |

| THT-420THS-420 | H31Cr13 | Used for overlay welding of corrosion-resistant materials for Cr13 martensitic stainless steels. | |

| THT-430THS-430 | H10Cr17 | Used for overlay welding on surfaces of corrosion (nitric acid) and heat-resistant stainless steels. | |

| THT-2209THS-2209 | H03Cr22Ni8Mo3N | Used for welding of duplex stainless steels containing 22% Cr. |

| Grade | ModelGB | Chemical composition of deposited metal (%)(≤) | Mechanical properties of deposited metal (≥) | Characteristics and applications | ||||||||

| C | Mn | Si | S | P | Others | Rel/RP0.2MPa | RmMPa | A% | AKVJ | |||

| J421 | E4313 | 0.10 | 0.32/0.55 | 0.30 | 0.030 | 0.035 | — | 355 | 440/570 | 22 | 0℃47 | Welding of low carbon steel structures, especially suitable for intermittent welding and fillet welding of thin plates and small components. Can be welded in all positions. |

| THJ421X | E4313 | 0.10 | 0.32/0.55 | 0.30 | 0.035 | 0.040 | — | 330 | 420 | 17 | 0℃27 | Welding of low carbon steel and galvanized plates, especially suitable for vertical-down welding and intermittent welding of thin plates. |

| THJ421Fe18 | E4324 | 0.12 | 0.30/0.60 | 0.35 | 0.035 | 0.040 | — | 330 | 420 | 17 | 0℃47 | Suitable for flat welding and fillet welding of ship structures made of low carbon steel and other corresponding grades of common low carbon steel. |

| THJ422 | E4303 | 0.10 | 0.32/0.55 | 0.25 | 0.035 | 0.040 | — | 330 | 420 | 22 | 0℃27 | Welding of low carbon steel structures and low alloy steel structures of equivalent strength grade, such as 09Mn2. Can be welded in all positions. |

| THJ422GM | E4303 | 0.10 | 0.32/0.55 | 0.25 | 0.035 | 0.040 | — | 330 | 420 | 22 | 0℃27 | Suitable for welding surface decorative seams of offshore platforms, ships, vehicles, and construction machinery. |

| THJ423 | E4301 | 0.10 | 0.32/0.55 | 0.30 | 0.035 | 0.040 | — | 330 | 420 | 22 | -20℃27 | Similar applications as THJ422, but its vertical welding operability is slightly inferior to THJ422, and it is more affordable in price compared to THJ422. |

| THJ425X | E4310E4311 | 0.20 | 0.32/0.60 | 0.30 | 0.035 | 0.040 | — | 330 | 420 | 22 | -30℃27 | Suitable for butt welding of low carbon steel pipes and low alloy steel pipes, with vertical-down welding in all positions. Easy to perform single-sided welding and double-sided formation during bottom layer welding. |

| THJ426 | E4316 | 0.10 | 1.25 | 0.90 | 0.035 | 0.040 | — | 330 | 420 | 22 | -30℃27 | Welding of important low carbon steel and low alloy steel structures, with welds having good mechanical properties and crack resistance. Can be welded in all positions. |

| THJ427 | E4315 | 0.10 | 1.25 | 0.90 | 0.035 | 0.040 | — | 330 | 420 | 22 | -30℃27 | Same applications and characteristics as THJ426, using a power source with reverse polarity. |

| THJ501Fe15 | E5024 | 0.12 | 1.25 | 0.90 | 0.035 | 0.040 | — | 400 | 490 | 17 | 0℃27 | Welding of carbon steel and low alloy steel structures with corresponding strength, suitable for flat welding and fillet welding. The deposition efficiency is 150%. |

| THJ501Fe18 | E5024 | 0.12 | 1.25 | 0.90 | 0.035 | 0.040 | — | 400 | 490 | 17 | 0℃27 | The application is similar to THJ501Fe15, with a deposition efficiency of around 180%. |

| THJ502 | E5003 | 0.12 | 1.25 | 0.30 | 0.035 | 0.040 | — | 400 | 490 | 20 | 0℃27 | Welding of important carbon steel and low alloy steel structures with corresponding strength, can be welded in all positions. |

| THJ505X | E5010E5011 | 0.20 | 0.50/1.00 | 0.30 | 0.035 | 0.040 | — | 400 | 490 | 20 | -30℃27 | Welding of carbon steel and low alloy steel pipe circumferential seams with corresponding strength, using vertical-down welding in all positions. It is easy to perform single-sided welding and achieve double-sided formation during bottom layer welding. |

| THJ506 | E5016 | 0.12 | 1.60 | 0.75 | 0.035 | 0.040 | — | 400 | 490 | 20 | -30℃27 | Suitable for all-position welding of medium carbon steel and low alloy steel structures, with welds exhibiting good mechanical and crack resistance properties. |

| THJ506-1 | E5016-1 | 0.12 | 1.60 | 0.75 | 0.030 | 0.030 | — | 400 | 490 | 20 | -46℃27 | Suitable for all-position welding of low-temperature high-toughness materials. |

| THJ506Fe-1 | E5018-1 | 0.10 | 1.60 | 0.65 | 0.030 | 0.030 | — | 420 | 500/640 | 22 | -50℃47 | The application is similar to THJ506-1, with the addition of iron powder in the flux coating to improve the deposition efficiency of the welding rod and enhance its process performance. |

| THJ506D | E5016 | 0.12 | 1.60 | 0.75 | 0.035 | 0.040 | — | 400 | 490 | 22 | -30℃27 | Specifically designed for bottom layer backing welding of medium carbon steel and low alloy steel structures, with easy single-sided welding and double-sided formation. |

| THJ506X | E5016 | 0.12 | 1.60 | 0.75 | 0.035 | 0.040 | — | 400 | 490 | 20 | -30℃47 | Particularly suitable for vertical-down fillet welds and lap welds, with aesthetically pleasing weld formation. Specifically designed for vertical-down welding with low hydrogen flux coating. |

| THJ506Fe | E5018 | 0.12 | 1.60 | 0.75 | 0.035 | 0.040 | — | 400 | 490 | 22 | -30℃27 | The application is similar to THJ506, suitable for all-position welding. The flux coating contains iron powder, which can improve the deposition rate. |

| THJ506Fe13 | E5028 | 0.12 | 1.60 | 0.90 | 0.035 | 0.040 | — | 400 | 490 | 22 | -20℃27 | The application is the same as THJ506, suitable for flat welding and fillet welding. The flux coating contains iron powder, which can improve the deposition efficiency. |

| THJ506Fe16 | E5028 | 0.12 | 1.60 | 0.90 | 0.035 | 0.040 | — | 400 | 490 | 22 | -20℃27 | The application is the same as THJ506, suitable for flat welding and fillet welding. The deposition efficiency of the welding rod is around 160%. |

| THJ507 | E5015 | 0.10 | 0.85/1.40 | 0.65 | 0.030 | 0.035 | — | 400 | 490 | 22 | -30℃47 | Suitable for all-position welding of medium carbon steel and low alloy steel structures, using a power source with reverse polarity. The welds exhibit good mechanical properties and crack resistance. |

| THJ507-1 | E5015-1 | 0.12 | 1.60 | 0.75 | 0.030 | 0.030 | — | 400 | 490 | 22 | -46℃ 27 | Suitable for important structures made of carbon steel or low alloy steel, as well as shipbuilding grade A, B, C, D, E steels. |

| Grade | ModelGB | Chemical composition of deposited metal (%) (≤) | Mechanical properties of deposited metal (≥) | Characteristics and applications: | ||||||||

| C | Mn | Si | S | P | Other | Rel/RP0.2MPa | RmMPa | A% | AKVJ | |||

| THJ502WCu | E5003-G(TB) | 0.12 | 0.30/0.90 | 0.40 | 0.030 | 0.030 | Cu0.20/0.50W0.20/0.50 | 425(Example values) | 540(Example values) | 27(Example values) | -40℃35(Example values) | Weathering steel dedicated welding rods, used for welding of weather-resistant vehicles in railways. |

| THJ502NiCu | E5003-G(TB) | 0.12 | 0.30/0.90 | 0.40 | 0.030 | 0.030 | Cu0.20/0.50Ni0.20/0.50 | 420(Example values) | 535(Example values) | 27(Example values) | -40℃36(Example values) | Special welding rods for weathering steel, used for welding weathering vehicles in railways. |

| THJ502NiCrCu | E5003-G(TB) | 0.12 | 0.30/0.90 | 0.40 | 0.030 | 0.030 | Cr0.20/0.50Ni0.20/0.50Cu0.20/0.50 | 420(Example values) | 530(Example values) | 27(Example values) | -40℃36(Example values) | Mainly used for welding weather-resistant railway locomotives and vehicles. |

| THJ506NiCu | E5016-G(TB) | 0.12 | 1.25 | 0.70 | 0.025 | 0.030 | Cu0.20/0.40Ni0.20/0.50 | 390 | 490 | 22 | -40℃27 | Used for welding of carbon steel and 50Kg grade weathering steel. |

| THJ506NiCrCu | E5016-G(TB) | 0.10 | 1.25 | 0.60 | 0.020 | 0.025 | Cu0.20/0.40Cr0.30/0.80Ni0.20/0.50 | 400 | 500 | 22 | -40℃60 | Used for welding of 50Kg grade weathering steel. |

| THJ506NH | E5016-G | 0.10 | 0.50/1.30 | 0.40 | 0.020 | 0.030 | Cu0.20/0.35Mo0.30/0.50 | 390 | 490 | 20 | -20℃47 | This welding rod is a special welding rod designed for 50kg grade weather-resistant steel, mainly used for welding important steel structures that require fire and weather resistance. |

| 230(600℃) | — | ≥25(600℃) | — | |||||||||

| THJ506R | E5016-G | 0.10 | 1.00/1.50 | 0.50 | 0.025 | 0.030 | Ni0.45/0.80 | 390 | 490 | 22 | -40℃47 | Suitable for welding important structures such as oil platforms, ships, and high-pressure vessels. |

| THJ506RK | E5016-G | 0.10 | 1.00/1.50 | 0.50 | 0.025 | 0.030 | Ni0.45/0.80 | 390 | 490 | 22 | -40℃47 | Can be used for welding low-temperature high-toughness materials. |

| THJ507R | E5015-G | 0.10 | 1.00/1.50 | 0.50 | 0.025 | 0.030 | Ni0.45/0.80 | 390 | 490 | 22 | -40℃47 | Suitable for welding important structures such as oil platforms, ships, and high-pressure vessels. |

| THJ507RH | E5015-G | 0.10 | 1.60 | 0.50 | 0.025 | 0.025 | Ni0.45/0.80 | 390 | 490 | 22 | -40℃47 | Used for welding of ships, bridges, high-pressure pipelines, pressure vessels, boilers, offshore platforms, and other important structures. |

| THJ507CuP | E5015-G | 0.12 | 0.80/1.30 | 0.50 | 0.035 | 0.06/0.12 | Cu0.20/0.50 | 390 | 490 | 22 | -30℃27 | Used for welding of steel structures that are resistant to atmospheric and seawater corrosion in the copper-phosphorus series. |

| THJ507MoNb | E5015-G | 0.12 | 0.60/1.20 | 0.65 | 0.025 | 0.030 | Mo0.30/0.60Nb0.03/0.15 | 390 | 490 | 22 | At room temperature 47 | Used for welding of steels resistant to hydrogen sulfide, hydrogen, nitrogen, ammonia, and hydrogen medium corrosion, such as 12SiMoVNb, 15MoV, etc. |

| THJ507MoWNbB | E5015-G | 0.10 | 0.85/1.30 | 0.45 | 0.025 | 0.030 | Nb0.01/0.04B0.0005/0.0015Mo0.40/0.60 | 390 | 490 | 22 | At room temperature 47 | Used for welding in medium-temperature, high-pressure, and hydrogen-resistant, ammonia-corrosive environments, such as 12SiMoVNb. |

| THJ556 | E5516-G | 0.12 | ≥1.00 | 0.30/0.70 | 0.025 | 0.030 | — | 440 | 540 | 17 | -30℃27 | Used for welding of medium carbon steel and low alloy steel structures with corresponding strength grades, such as 15MnV. |

| THJ556R | E5516-G | 0.12 | 1.00/1.80 | 0.30/0.70 | 0.025 | 0.030 | Ni0.85 | 440 | 540 | 17 | -40℃47 | Used for welding of low-temperature high-toughness materials and low alloy steels with corresponding strength grades. |

| THJ556RH | E5516-G | 0.12 | 1.00/1.80 | 0.60 | 0.020 | 0.020 | Ni0.60/1.20 | 440 | 540 | 17 | -40℃54 | Used for welding of low-temperature high-toughness materials and low alloy steels with corresponding strength grades. |

| THJ556NiCrCu | E5516-G(TB) | 0.10 | 1.60 | 0.60 | 0.025 | 0.020 | Cu0.20/0.40Cr0.30/0.90Ni0.20/0.60 | 440 | 550 | 22 | -40℃60 | Used for welding of 55kg grade weathering steel. |

| THJ557R | E5515-G | 0.10 | 1.00/1.80 | 0.30/0.70 | 0.025 | 0.030 | Ni0.85 | 440 | 540 | 17 | -40℃47 | Used for welding of carbon steel and some low alloy steel structures. |

| THJ557 | E5515-G | 0.12 | 1.00 | 0.30/0.70 | 0.025 | 0.030 | — | 440 | 540 | 17 | -30℃47 | Used for welding of medium carbon steel and some low alloy steels. |

| THJ557RH | E5515-G | 0.12 | 1.00/1.80 | 0.60 | 0.020 | 0.020 | Ni0.60/1.20 | 440 | 540 | 17 | -40℃57 | Used for welding of medium carbon steel and some low alloy steels. |

| THJ606 | E6016-D1 | 0.12 | 1.25/1.75 | 0.60 | 0.025 | 0.030 | Mo0.25/0.45 | 490 | 590 | 15 | -30℃27 | Welding of medium carbon steel and low alloy steel with corresponding strength grades. |

| THJ606NiCrCu | E5016-G(TB) | 0.10 | 2.0 | 0.60 | 0.020 | 0.025 | Cu0.20/0.40Cr0.30/0.90Ni0.20/0.90 | 550 | 600 | 20 | -40℃60 | Used for welding of 60Kg grade weathering steel, as well as welding of vehicles, near-shore engineering structures, bridges, etc. |

| THJ607 | E6015-D1 | 0.12 | 1.25/1.75 | 0.60 | 0.025 | 0.030 | Mo0.25/0.45 | 490 | 590 | 15 | -30℃27 | Used for welding of medium carbon steel and low alloy steel structures with corresponding strength grades, such as 15MnVN. |

| THJ607Ni | E6015-G | 0.10 | ≥1.00 | 0.80 | 0.025 | 0.030 | Ni1.20 | 490 | 590 | 15 | -40℃34 | Used for welding of steel structures with corresponding strength grades and susceptibility to reheat cracking. |

| THJ607RH | E6015-G | 0.10 | 1.00/1.65 | 0.60 | 0.025 | 0.025 | Ni0.65/1.20Mo0.10/0.40 | 490 | 590 | 15 | -40℃47 | Used for welding of pressure vessels, bridges, hydroelectric station penstocks, and marine engineering and other important structures. |

| THJ657RH | E6015-G | 0.12 | 1.20/1.80 | 0.60 | 0.020 | 0.020 | Ni0.80/1.40Mo0.20/0.40 | 540 | 640 | 15 | -40℃54 | Used for welding of X80 grade pipeline steel and low alloy steel structures with the same strength grade. |

| THJ707 | E7015-D2 | 0.15 | 1.65/2.00 | 0.60 | 0.025 | 0.030 | Mo0.25/0.45 | 590 | 690 | 15 | -30℃27 | Used for welding low alloy steel structures with corresponding strength grades, such as 15MnMoVNd. |

| THJ707RH | E7015-G | 0.10 | 1.20/1.60 | 0.30/0.60 | 0.020 | 0.025 | Ni1.40/2.00Mo0.25/0.50 | 590 | 690 | 15 | -50℃34 | Used for welding of ship structures, as well as welding of important structures such as high-strength steel. |

| THJ807 | E8015-G | 0.20 | 2.00 | 0.75 | 0.025 | 0.030 | Mo0.60/1.00 | 690 | 780 | 13 | At room temperature 27 | Used for welding low alloy steels with corresponding strength grades such as 14MnMoVN. |

| THJ807RH | E8015-G | 0.10 | 1.30/1.80 | 0.50 | 0.020 | 0.025 | Mo0.30/0.60Ni2.00/2.70 | 685 | 785 | 17 | -40℃69 | Used for welding important structures made of low alloy steel with corresponding strength grades. |

| THJ807A | E8015-G | 0.09 | 2.00 | 0.40 | 0.020 | 0.025 | Mo0.80/1.10 | 690 | 780 | 13 | -40℃34 | Welding of corresponding low-strength low alloy steel structures. |

| THJ857 | E8515-G | 0.20 | 2.00 | 0.75 | 0.020 | 0.025 | Mo0.60/1.00 | 740 | 830 | 12 | At room temperature 27 | Used for welding low alloy steel structures with a tensile strength equivalent to 830MPa. |

| THJ857Ni | E8515-G | 0.10 | 2.10 | 0.75 | 0.015 | 0.020 | Ni2.50/3.00 | 740 | 830 | 12 | -40℃27 | Used for welding of low alloy steel structures with tensile strength equivalent to 830MPa. |

| THJ857Cr | E8515-g | 0.15 | 1.00 | 0.60 | 0.035 | 0.035 | Cr0.70/1.10V0.05/0.15 Mo0.50/1.00 | 740 | 830 | 12 | -40℃27 | Used for welding of low alloy steel structures with tensile strength equivalent to 830MPa. |

| THJ857R | E8515-G | 0.09 | 0.80/1.60 | 0.50 | 0.015 | 0.015 | Ni2.00/2.80Mo0.30/0.80Cr0.50/1.00 | 740 | 830 | 14 | -50℃27 | Used for welding important structures made of low alloy steel with corresponding strength grades. |

| THJ857RH | E8515-G | 0.09 | 0.80/1.60 | 0.50 | 0.015 | 0.015 | Ni2.00/2.80Mo0.30/0.80Cr0.50/1.00 | 740 | 830 | 14 | -50℃27 | Used for welding important structures made of low alloy steel with corresponding strength grades. |

| THJ907 | E9015-G | 0.20 | 1.40/2.00 | 0.40/0.80 | 0.020 | 0.025 | Mo0.80/1.20 | 780 | 880 | 12 | At room temperature 27 | Used for welding of low alloy high-strength steel structures with tensile strength equivalent to 880MPa. |

| THJ907R | E9015-G | 0.10 | 1.20/1.60 | 0.40 | 0.020 | 0.025 | Ni2.40/2.80Mo0.50/0.80Cr0.70/1.00V0.03/0.12 | 780 | 880 | 12 | -30℃27 | Used for welding of low alloy high-strength steel with tensile strength equivalent to 880MPa, as well as welding of pressure vessels and other components. |

| THJ907Cr | E9015-G | 0.15 | 1.40/2.00 | 0.50 | 0.020 | 0.025 | Cr0.70/1.10Mo0.50/1.10V0.05/0.15 | 780 | 980 | 12 | At room temperature 27 | Used for welding of low alloy high-strength steel structures with tensile strength equivalent to approximately 880MPa. |

| THJ957R | E9515-G | 0.10 | 1.40/1.80 | 0.50 | 0.020 | 0.025 | Ni2.40/3.00Mo0.50/0.80Cr0.70/1.00V0.03/0.12 | 830 | 930 | 12 | -30℃27 | Used for welding of low alloy high-strength steel with tensile strength equivalent to 880MPa, as well as pressure vessels and other structures. |

| THJ107 | E1005-G | 0.20 | 1.50/2.30 | 0.30/0.80 | 0.020 | 0.025 | Mo0.80/1.40 | 880 | 980 | 12 | At room temperature 27 | Used for welding of low alloy high-strength steel structures with tensile strength equivalent to 980MPa. |

| THJ107Cr | E1005-G | 0.15 | 1.40/2.00 | 0.30/0.70 | 0.020 | 0.025 | Cr1.50/2.20Mo0.40/0.80V0.08/0.16 | 880 | 980 | 12 | At room temperature 27 | Used for welding of low alloy high-strength structures with tensile strength greater than 980MPa. |

| THJ107R | E10015-G | 0.10 | 1.40/2.00 | 0.50 | 0.020 | 0.025 | Ni2.40/3.20Mo0.50/0.80Cr0.70/1.00V0.03/0.12 | 880 | 980 | 12 | -30℃27 | Used for welding of low alloy high-strength steel with tensile strength equivalent to 980MPa, as well as pressure vessels and other structures. |

| V840 | E9015-G | 0.09 | 0.08/1.60 | 0.50 | 0.015 | 0.015 | Mo0.30/0.80Ni2.00/2.80Cr0.50/1.00 | 785 | _ | 15 | -50℃27 | Used for welding of important engineering structures with high strength, high toughness, and yield strength greater than 800MPa. |

| Grade | ModelGB | Chemical composition of deposited metal (%) (≤) | Mechanical properties of deposited metal (≥) | Characteristics and applications: | ||||||||

| C | Mn | Si | S | P | remains | Rel/RP0.2MPa | RmMPa | A% | AKVJ | |||

| THR106Fe | E5018-A1 | 0.05/0.12 | 0.90 | 0.50 | 0.035 | 0.035 | Mo0.40/0.65 | 390 | 490 | 22 | At room temperature 47 | Used for welding of heat-resistant ferritic steels such as 15Mo with operating temperatures below 510°C, as well as for welding of general low alloy steels. |

| THR107 | E5015-A1 | 0.12 | 0.90 | 0.50 | 0.035 | 0.035 | Mo0.40/0.65 | 390 | 490 | 22 | At room temperature 47 | Used for welding of heat-resistant ferritic steels such as 15Mo with operating temperatures below 510°C. |

| THR202 | E5503-B1 | 0.05/0.12 | 0.90 | 0.50 | 0.035 | 0.035 | Mo0.40/0.65 Cr0.40/0.65 | 440 | 540 | 16 | — | Used for welding of 15Mo and boiler pipelines with operating temperatures below 510°C. |

| THR207 | E5515-B1 | 0.05/0.12 | 0.90 | 0.60 | 0.030 | 0.030 | Mo0.40/0.65 Cr0.40/0.65 | 440 | 540 | 17 | At room temperature 34 | Used for welding of heat-resistant ferritic steels such as 12CrMo with operating temperatures below 510°C. |

| THR307 | E5515-B2 | 0.05/0.12 | 0.90 | 0.60 | 0.020 | 0.030 | Mo0.40/0.65Cr0.80/1.50 | 440 | 540 | 17 | At room temperature 47 | Used for welding of heat-resistant ferritic steels such as 15CrMo with operating temperatures below 520°C. |

| THR307A | E5515-B2 | 0.05/0.12 | 0.90 | 0.60 | 0.015 | 0.020 | Mo0.40/0.65Cr0.80/1.50 | 440 | 540/640 | 20 | -20℃55 | Used for welding of heat-resistant ferritic steels such as 12CrMo with operating temperatures below 540°C. |

| THR317 | E5515-B2-V | 0.05/0.12 | 0.90 | 0.60 | 0.020 | 0.035 | Mo0.40/0.65Cr0.80/1.50V0.10/0.35 | 440 | 540 | 17 | At room temperature 47 | Used for welding of heat-resistant ferritic steels such as 12CrMo with operating temperatures below 540°C. |

| THR317L | E5515-B2-V | 0.05/0.12 | 0.90 | 0.60 | 0.015 | 0.020 | Mo0.40/0.65Cr0.80/1.50V0.10/0.35 | 440 | 540 | 20 | At room temperature 47 | Can be welded without post-heat treatment and used for welding of heat-resistant ferritic steels such as 12CrMo with operating temperatures below 540°C. |

| THR317B20 | E6015-G | 0.05/0.15 | 0.70/1.50 | 0.80 | 0.025 | 0.030 | Mo0.90/1.30Cr0.90/1.50V0.10/0.35 | 440 | 590 | 15 | At room temperature 47 | Used for welding of heat-resistant ferritic steels with Cr-Mo-V composition, such as GS17CrMov511 low alloy cast steel, with operating temperatures below 600°C. |

| THR337 | E5515-B2-VNb | 0.05/0.12 | 0.90 | 0.60 | 0.025 | 0.030 | Mo0.70/1.00Cr1.00/1.50Nb0.10/0.25V0.15/0.40 | 440 | 540 | 17 | At room temperature 47 | Used for welding of heat-resistant ferritic steels such as 15CrMo with operating temperatures below 570°C. |

| THR347 | E5515-B3-VWB | 0.05/0.12 | 1.00 | 0.60 | 0.030 | 0.035 | Mo0.30/0.80Cr1.50/2.50W0.20/0.60B0.001/0.003 | 440 | 540 | 17 | At room temperature 47 | Used for welding of corresponding heat-resistant steels with operating humidity below 620°C. |

| THR407 | E6015-B3 | 0.05/0.12 | 0.90 | 0.60 | 0.035 | 0.035 | Cr2.00/2.50Mo0.90/1.20 | 490 | 590 | 15 | At room temperature 47 | Used for welding of heat-resistant Cr2.5Mo ferritic steels. |

| THR417 | E5515-B3-VNb | 0.05/0.12 | 1.00 | 0.60 | 0.035 | 0.035 | Cr2.40/3.00Mo0.70/1.00W0.25/0.50Nb0.35/0.65 | 440 | 540 | 17 | At room temperature 27 | Used for welding of corresponding heat-resistant steels with operating humidity below 620°C. |

| THR507 | E5MoV-15 | 0.12 | 0.50/0.90 | 0.50 | 0.030 | 0.035 | Cr4.50/6.00Mo0.40/0.70V0.10/0.35 | — | 520 | 14 | — | Used for welding of heat-resistant Cr5Mo ferritic steels. |

| THR717B9 | — | 0.08/0.13 | 1.25 | 0.30 | 0.01 | 0.01 | V0.15/0.30Nb0.02/0.10N0.02/0.07Cr8.0/10.5Mo0.85/1.20 | 530 | 620 | 17 | 20℃27 | Used for welding of heat-resistant steel for T91/P91 pipelines and for welding of ZG1Cr10MoVNbN and other steels for supercritical turbines. |

| THR727 | E6015-G | 0.08/0.14 | 0.40/1.00 | 0.40 | 0.01 | 0.01 | Cr8.0/10.0Mo0.30/0.70V0.15/0.30Nb0.02/0.07N0.02/0.07 | 530 | 620 | 15 | 20℃27 | Used for the construction of supercritical and ultra-supercritical coal-fired power plants, such as the welding of heat-resistant steel and steel pipes for T92/P92 pipelines. |

| THW607 | — | 0.07 | 1.20/1.70 | 0.50 | 0.035 | 0.035 | Ni0.60/1.00Ti0.03B0.003 | 390 | 490 | 22 | -60℃27 | Used for welding of low-temperature steel structures, such as 09MnNiN6, which are designed for applications operating at -60℃. |

| THW707Ni | E5515-C1 | 0.12 | 1.25 | 0.60 | 0.035 | 0.035 | Ni2.00/2.75 | 440 | 540 | 17 | -70℃27 | Used for welding of 09Mn2v06MnVA1 and 3.5Ni steel, which are used for applications operating at -70°C. |

| THW107Ni | — | 0.08 | ≈0.5 | 0.30 | 0.020 | 0.020 | Ni4.00/5.50Mo≈0.30Cu≈0.50 | 340 | 490 | 16 | -100℃27 | Welding of 06A1NbCuN06NnNb and 3.5Ni steel, which are used for applications operating at -100°C. |

| Grade | ModelGB | Chemical composition of deposited metal (%)(≤) | Mechanical properties of deposited metal (≥) | Characteristics and applications: | ||||||||||

| C | Mn | Si | S | P | Cr | Ni | Mo | Other | RmMPa | A% | ||||

| THG202 | E410-16 | 0.12 | 1.0 | 0.90 | 0.030 | 0.040 | 11.0/13.5 | 0.7 | 0.75 | Cu0.75 | 450 | 20 | Used for welding of OCr13 and ICr13 stainless steel structures, and can also be used for overlay welding of corrosion and wear-resistant surfaces. (The deposited and heat-treated samples are heated to 860°C for 2 hours, followed by slow cooling to 600°C, and then air-cooling.) | |

| THG207D | E410-15 | 0.12 | 1.0 | 0.90 | 0.030 | 0.030 | 11.0/13.5 | 0.7 | 0.75 | Cu0.75 | 520 | 35 | Mainly used for overlay welding of valve sealing parts. | |

| THA002 | E308L-16 | 0.04 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 18.0/21.0 | 9.0/11.0 | 0.75 | Cu0.75 | 520 | 35 | Used for welding of ultra-low carbon 00Cr9Ni11 stainless steel and 00Cr18Ni9 steel structures, such as synthetic fiber, fertilizer, and petroleum equipment. | |

| THA002R | E308L-17 | 0.04 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 18.0/21.0 | 9.0/11.0 | 0.75 | Cu0.75 | 520 | 35 | Mainly used in the manufacturing of equipment for synthetic fibers, fertilizers, petroleum, and other industries. | |

| THA022 | E316L-16 | 0.04 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 17.0/20.0 | 11.0/14.0 | 2.0/3.0 | Cu0.75 | 490 | 30 | Primarily used in the manufacturing of equipment for synthetic fiber, fertilizer, and petroleum industries.Also used for welding of equipment for urea and synthetic fiber production, as well as stainless steel structures of the same type. | |

| THA022Used for applications in cryogenic environments. | E316L-16 | 0.04 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 17.0/20.0 | 11.0/14.0 | 2.0/3.0 | Cu0.75 | 490 | 30 | Used for welding of equipment for urea and synthetic fiber production, as well as stainless steel structures of the same type. It can also be used for stainless steel structures used at cryogenic temperatures. | |

| THA022R | E316L-17 | 0.04 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 17.0/20.0 | 11.0/14.0 | 2.0/3.0 | Cu0.75 | 490 | 30 | Used for welding of equipment for urea and synthetic fiber production, as well as stainless steel structures of the same type. | |

| THA032 | E317MoCuL-16 | 0.04 | 0.5/2.5 | 0.90 | 0.030 | 0.035 | 18.0/21.0 | 12.0/14.0 | 2.0/2.5 | Cu0.20 | 540 | 25 | Used for welding of equipment for synthetic fiber production, such as welding of stainless steel structures of the same type with ultra-low carbon content, which work in dilute to medium concentration sulfuric acid media. | |

| THA042 | E309MoL-16 | 0.04 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 22.0/25.0 | 12.0/14.0 | 2.0/3.0 | Cu0.75 | 540 | 25 | Used for welding of stainless steel structures of the same type with ultra-low carbon content, as well as for welding of dissimilar steels. | |

| THA052 | — | 0.04 | 2.00 | 1.00 | 0.030 | 0.040 | 17.0/22.0 | 22.0/27.0 | 4.0/5.0 | Cu2.0 | 490 | 25 | Used for welding reactors, separators, and other equipment that are chemically resistant to sulfuric acid, acetic acid, phosphoric acid, as well as for welding of corrosion-resistant steel used in seawater environments. | |

| THA062 | E309L-16 | 0.04 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 22.0/25.0 | 12.0/14.0 | 0.75 | Cu0.75 | 520 | 25 | Used for welding stainless steel structures of the same type, composite steel, and dissimilar steels in the manufacturing of equipment for synthetic fiber, petroleum, chemical, and other industries. | |

| THA072 | — | 0.04 | 1.0/2.0 | 0.80 | 0.030 | 0.030 | 27.0/29.0 | 14.0/16.0 | — | — | 540 | 25 | Used for welding of 00Cr25Ni20Nb steel, such as nuclear fuel equipment, and so on. | |

| THA092 | E385-16 | 0.03 | 1.0/2.5 | 0.75 | 0.020 | 0.030 | 19.5/21.5 | 24.0/26.0 | 4.2/5.2 | Cu1.2/2.0 | 520 | 30 | Mainly used in the manufacturing of towers, tanks, pipelines, heat exchangers, and other equipment. It has excellent resistance to pitting corrosion in various strong acids and hot acids. | |

| THA102 | E308-16 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 18.0/21.0 | 9.0/11.0 | 0.75 | Cu0.75 | 550 | 35 | Used for welding of corrosion-resistant stainless steel structures such as Cr19Ni9 and OCr19Ni11Ti, which operate at temperatures below 300℃. | |

| THA102Used for applications in cryogenic environments. | E308-16 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 18.0/21.0 | 9.0/11.0 | 0.75 | Cu0.75 | 620(Example values:) | 42(Example values) | Used for welding of corrosion-resistant stainless steel structures such as Cr19Ni9 and OCr19Ni11Ti, which operate at temperatures below 300°C. It can also be used for stainless steel structures used in cryogenic environments. | |

| -196℃(Example values)AKJ45J | ||||||||||||||

| THA102B(Example values) | E308-16 | 0.05 | 2.50 | 0.80 | 0.015 | 0.016 | 18.50 | 10.50 | 0.15 | — | 560 | 38 | Mainly used for welding of structures with low magnetic permeability or non-magnetic steel. | |

| THA102R | E308-16 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 18.0/21.0 | 9.0/11.0 | 0.75 | Cu0.75 | 550 | 35 | Used for welding of corrosion-resistant stainless steel structures such as 0Cr19Ni9 and 0Cr19Ni11Ti, which operate at temperatures below 300°C. | |

| THA107 | E308-15 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 18.0/21.0 | 9.0/11.0 | 0.75 | Cu0.75 | 550 | 35 | Used for welding of corrosion-resistant 0Cr19Ni9 stainless steel structures operating at temperatures below 300°C. It can also be used for welding some steels with poor weldability and for overlay welding of stainless steel surface layers. | |

| THA112 | — | 0.12 | 2.50 | 1.50 | 0.035 | 0.040 | 17.0/22.0 | 7.0/11.0 | — | — | 540 | 25 | Used for welding of Cr19Ni9 stainless steel structures with general corrosion resistance requirements. | |

| THA117 | — | 0.12 | 2.50 | 1.50 | 0.030 | 0.040 | 17.0/22.0 | 7.0/11.0 | — | — | 540 | 25 | Used for welding of Cr18Ni9 stainless steel structures with general corrosion resistance requirements. | |

| THA122 | — | 0.08 | 2.50 | 1.50 | 0.030 | 0.040 | 20.0/24.0 | 7.0/11.0 | — | — | 540 | 25 | Used for welding of OCr19Ni9 stainless steel structures with high resistance to cracking and corrosion, operating at temperatures below 300°C. | |

| THA132 | E347-16 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 18.0/21.0 | 9.0/11.0 | 0.75 | Cu0.75 Nb8×C- 1.00 | 520 | 25 | Used for welding of important corrosion-resistant OCr19Ni11Ti stainless steel structures containing titanium stabilizer. | |

| THA132R | E347-17 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 18.0/21.0 | 9.0/11.0 | 0.75 | Cu0.75Nb8×C- 1.00 | 520 | 25 | Used for welding of important corrosion-resistant 0Cr19Ni11Ti stainless steel containing titanium stabilizer. | |

| THA137 | E347-15 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 18.0/21.0 | 9.0/11.0 | 0.75 | Cu0.75 Nb8×C- 1.00 | 520 | 25 | Used for welding of important corrosion-resistant OCr19Ni11Ti stainless steel structures containing titanium stabilizer. | |

| THA 146 | — | 0.12 | 4.0/7.0 | 0.90 | 0.035 | 0.040 | 19.0/22.0 | 8.0/11.0 | — | — | 540 | 20 | Used for welding of important corrosion-resistant OCr20Ni10Mn6 stainless steel containing titanium stabilizer. | |

| THA172 | E307-16 | 0.04/0.14 | 3.30/4.75 | 0.90 | 0.030 | 0.040 | 18.0/21.5 | 9.0/10.7 | 0.5/1.5 | Cu0.75 | 590 | 30 | Suitable for welding of ASTM307 steel and other dissimilar steels. It can also be used for overlay welding of impact-resistant corrosion-resistant steel and transition layers. | |

| THA202 | E316-16 | 0.08 | 0.5/2.5 | 0.09 | 0.030 | 0.040 | 17.0/20.0 | 11.0/14.0 | 2.0/3.0 | Cu0.75 | 520 | 30 | Used for welding of OCr18Ni2Mo2 stainless steel structures and dissimilar steel structures that work in organic and inorganic acid media. | |

| THA202R | E316-17 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 17.0/20.0 | 11.0/14.0 | 2.0/3.0 | Cu0.75 | 520 | 30 | Used for welding of 0Cr18Ni12Mo2 stainless steel that works in organic and inorganic acid media or as a dissimilar steel weld. | |

| THA207 | E316-15 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 17.0/20.0 | 11.0/14.0 | 2.0/3.0 | Cu0.75 | 520 | 30 | Used for welding of low carbon OCr18Ni12Mo2 stainless steel structures, high-chromium acid-resistant steel, and dissimilar steels. | |

| THA 212 | E318-16 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 17.0/20.0 | 11.0/14.0 | 2.0/3.0 | Nb6×C/1.00 | 550 | 25 | Used for welding of critical components of stainless steel equipment such as urea synthesis towers and vinyl equipment, which are in contact with strong corrosive media. | |

| THA222 | E317MoCu-16 | 0.08 | 0.5/2.5. | 0.90 | 0.030 | 0.035 | 18.0/21.0 | 12.0/14.0 | 2.0/2.5 | Cu2.0 | 540 | 25 | Used for welding of stainless steel structures of the same type containing copper, such as 0Cr18Ni12Mo2Cu. | |

| THA232 | E318V-16 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.035 | 17.0/20.0 | 11.0/14.0 | 2.0/2.5 | Cu0.5V0.30/0.70 | 540 | 25 | Used for welding of general heat-resistant and corrosion-resistant stainless steel structures, such as Cr19Ni10 and Cr18Ni12Mo2. | |

| THA237 | E318V-15 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.035 | 17.0/20.0 | 11.0/14.0 | 2.0/2.5 | Cu0.5V0.30/0.70 | 540 | 25 | Used for multi-layer welding of general heat-resistant and corrosion-resistant stainless steel structures, such as Cr19Ni10 and Cr18Ni12Mo2. | |

| THA242 | E317-16 | 0.08 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 22.0/25.0 | 12.0/14.0 | 3.0/4.0 | Cu0.75 | 550 | 25 | Used for welding of stainless steel materials of the same type, as well as composite steel and dissimilar steels. | |

| THA302 | E309-16 | 0.15 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 22.0/25.0 | 12.0/14.0 | 0.75 | Cu0.75 | 550 | 25 | Used for welding of stainless steel structures of the same type, as well as dissimilar steels, high-chromium steel, high-manganese steel, and others. | |

| THA302R | E309-17 | 0.15 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 22.0/25.0 | 12.0/14.0 | 0.75 | Cu0.75 | 550 | 25 | Used for welding of stainless steel of the same type, stainless steel cladding, dissimilar steels, as well as high-alloy steel and high-manganese steel. | |

| THA307 | E309-15 | 0.15 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 22.0/25.0 | 12.0/14.0 | 0.75 | Cu0.75 | 550 | 25 | Used for welding of stainless steel structures of the same type, as well as for welding of dissimilar steels such as high-chromium steel and high-manganese steel. | |

| THA312 | E309Mo-16 | 0.12 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 22.0/25.0 | 12.0/14.0 | 2.0/3.0 | Cu0.75 | 550 | 25 | Used for welding of stainless steel containers of the same type that are resistant to sulfuric acid media (sulfur-ammonia) corrosion, as well as for welding of composite steel dissimilar steels. | |

| THA402 | E310-16 | 0.08/0.20 | 1.0/2.5 | 0.75 | 0.030 | 0.030 | 25.0/28.0 | 20.0/22.5 | 0.75 | Cu0.75 | 550 | 25 | Used for welding of heat-resistant stainless steels of the same type operating under high-temperature conditions. It can also be used for welding of high-hardness chromium steels (Cr13) and dissimilar steels. | |

| THA407 | E310-15 | 0.08/0.20 | 1.0/2.5 | 0.75 | 0.030 | 0.030 | 25.0/28.0 | 20.0/22.5 | 0.75 | Cu0.75 | 550 | 25 | Used for welding of heat-resistant stainless steels of the same type operating under high-temperature conditions. It can also be used for welding of high-hardness chromium steels and dissimilar steels. | |

| THA412 | E310Mo-16 | 0.12 | 1.0/2.5 | 0.75 | 0.030 | 0.030 | 25.0/28.0 | 20.0/22.0 | 2.0/3.0 | Cu0.75 | 550 | 25 | Used for welding of heat-resistant stainless steels of the same type and dissimilar steels, as well as stainless steel cladding, operating under high-temperature conditions. | |

| THA502 | E16-25MoN-16 | 0.12 | 0.5/2.5 | 0.90 | 0.030 | 0.035 | 140./18.0 | 22.0/27.0 | 5.0/7.0 | Cu0.50N≥0.1 | 420 | 30 | Used for welding of low alloy, medium alloy, and dissimilar steels in a quenched state, such as 30CrMnSi, as well as stainless steel and carbon steel welding. | |

| THA507 | E16-2MoN-15 | 0.12 | 0.5/2.5 | 0.90 | 0.030 | 0.035 | 14.0/18.0 | 22.0/27.0 | 5.0/7.0 | Cu0.50N≥0.1 | 420 | 30 | Used for welding of low alloy, medium alloy, and dissimilar steels in a quenched state, such as 30CrMnSi, as well as stainless steel and carbon steel welding. | |

| THA802 | — | 0.10 | 2.5 | 1.00 | 0.030 | 0.035 | 18.0/21.0 | 17.0/19.0 | 3.0/5.0 | Cu1.5/2.5 | 540 | 25 | Used for welding pipelines of synthetic rubber manufactured with a sulfuric acid concentration of 50% and certain working temperatures and pressures, as well as steel grades such as Cr18Ni18Mo2Cu2Ti. | |

| THAF312 | E312-16 | 0.15 | 0.5/2.5 | 0.90 | 0.030 | 0.040 | 28.0/32.0 | 8.0/10.5 | 0.75 | Cu0.75 | 660 | 22 | Can be used for welding of high carbon steel, tool steel, high temperature steel, armor steel, dissimilar steels, and more. | |

| THAF2209 | E2209-16 | 0.04 | 0.5/2.0 | 0.90 | 0.030 | 0.040 | 21.5/23.5 | 8.5/10.5 | 2.5/3.5 | N0.08/0.20Cu0.75 | 690 | 20 | Suitable for welding of super low carbon stainless steel materials in the petrochemical and chemical industries. | |