Imagine transforming dull, lifeless metal surfaces into shining, polished masterpieces. This is the magic of electrolytic polishing, a technique that uses electric current to dissolve metal at microscopic levels, creating ultra-smooth and glossy finishes. This article delves into the principles, advantages, and necessary equipment for electrolytic polishing, offering insights into how it enhances durability and corrosion resistance. Discover the science behind achieving that perfect metallic sheen and learn how this process can revolutionize the quality and efficiency of your metalworking projects.

Electrolytic polishing is a process wherein the workpiece to be polished acts as the anode, an insoluble metal serves as the cathode, and both are simultaneously immersed in an electrolytic bath.

Direct current is applied to selectively dissolve the anode, thereby enhancing the brightness of the workpiece’s surface.

There is much debate worldwide about the underlying principle of electrolytic polishing, with the commonly acknowledged explanation being the Membrane Theory.

According to this theory, the metal ions detaching from the workpiece form a layer of phosphate film on the workpiece’s surface by combining with the phosphoric acid in the polishing liquid.

This membrane is thinner at protruding areas and thicker at recessed spots. Since the current density is higher at the protrusions, they dissolve rapidly. With the flow of the membrane, the uneven surface is gradually smoothed out.

(1) Uniform color and luster inside and out, which is durable; even unreachable recesses can be smoothed.

(2) High production efficiency and low cost.

(3) Enhanced corrosion resistance of the workpiece surface, suitable for all stainless steel materials.

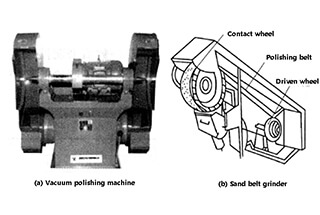

Either dual-phase 220V or three-phase 380V power supply can be chosen.

The requirements for power source waveform in electrolytic polishing are not too strict. Silicon-controlled rectifiers or high-frequency rectifiers can be used.

If the working voltage drops below 6V, the polishing speed slows down and the brightness is insufficient.

Rectifier current: Determined based on the size of the customer’s workpiece.

The cell can be made from welded rigid polyvinyl chloride (PVC) boards.

It is equipped with three electrode rods, with the movable anode rod in the center, connected to the power supply anode (or positive pole), and the cathode rods on either side, connected to the power supply cathode (negative pole).

① Quartz heating tubes or titanium heating tubes can be used for heating.

② Serpentine tubes can be used for cooling, which can also facilitate heating.

Titanium fixtures are preferred due to their high corrosion resistance and long lifespan, and they do not affect the bath solution.

It is advisable to avoid using copper fixtures as copper ions can deposit a layer of poorly adherent copper on the surface of stainless steel, which can affect the polishing quality.

Exposed copper parts can be baked into a film with PVC glue and the insulating film can be scraped off at the contact points.

Lead sheets can be used for the cathode material, while copper can be used for the anode material. The anode-to-cathode ratio should be between 1:2. The optimal distance between the cathode and the anode should be 10–30 centimeters.

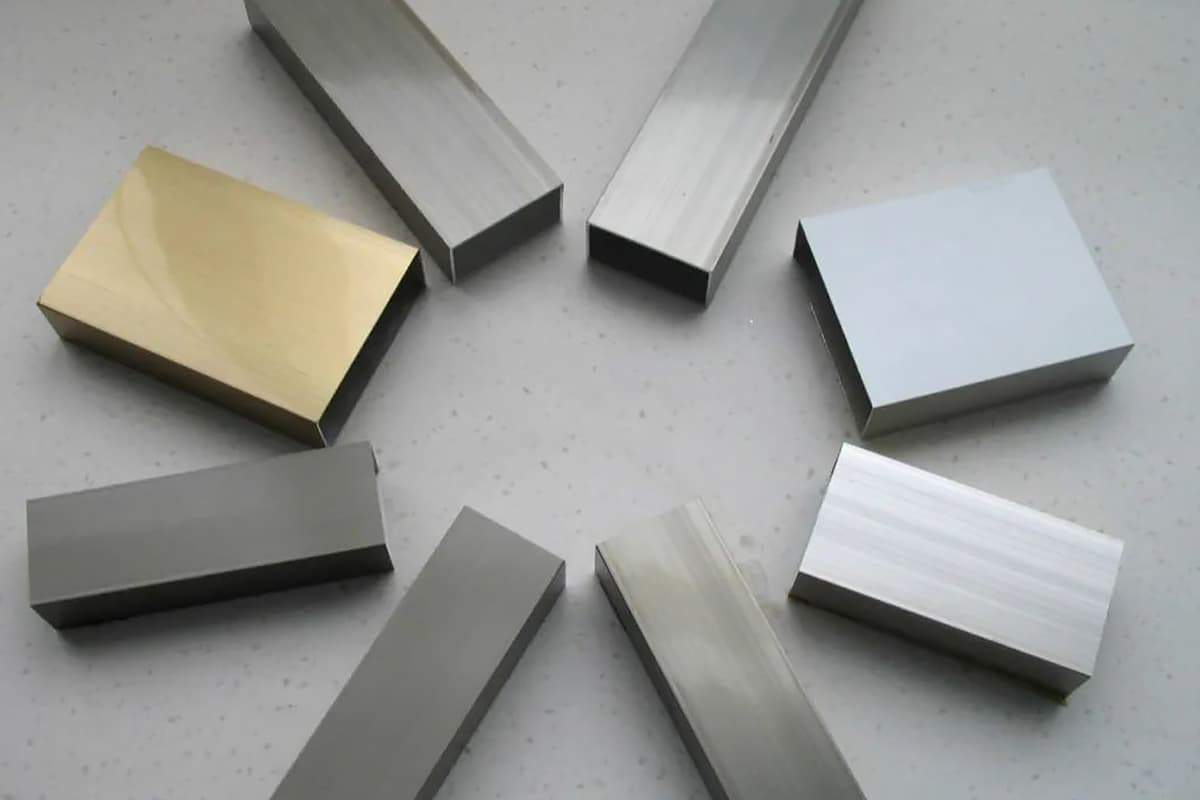

Currently, electrolytic polishing is mainly used for the surface brightening of stainless steel workpieces. Stainless steel workpieces can be divided into the 200 series, 300 series, and 400 series materials, each requiring a specific electrolytic polishing solution.

For example, stainless steel from the 200 series must use the 200 series formula, which cannot be adapted to the 300 or 400 series of stainless steel materials.

This has always been a major problem domestically, as some manufacturers use composite workpieces that include materials from the 200, 300, and 400 series of stainless steel.

In December 2007, a senior engineer from Weihai Yunqing Chemical Development Institute developed a universal electrolyte for stainless steel.

This electrolyte is suitable for all types of stainless steel. It integrates all the advantages of the original electrolyte, with the optimal specific gravity, and achieves mirror-like brightness.

It also has new advantages, such as enhancing the original brightness, reducing the current density by half, saving 50% on electricity costs during production, and extending the lifespan by 40%. This electrolyte has always been at the forefront of domestic technology.

Electrolytic Polishing Process: Degreasing — Water Washing — Rust Removal — Water Washing — Electrolytic Polishing — Water Washing — Neutralization — Water Washing — Packaging

The main types of electrolytic polishing solutions currently used in production include:

1. Polishing solution composed of sulfuric acid, phosphoric acid, and chromic anhydride;

2. Polishing solution composed of sulfuric acid and citric acid;

3. Mixed polishing solution composed of sulfuric acid, phosphoric acid, hydrofluoric acid, and glycerol or similar compounds.

Electrochemical Polishing of Steel Parts

1. Influence of Material Type: There are many types of steel materials, and different polishing solutions should be used for different steels.

2. Influence of Various Factors: Phosphoric acid is the main component of the polishing solution. The phosphate it forms adheres to the anode surface and plays an important role during the polishing process. Sulfuric acid can increase the polishing speed, but the content must not be too high to avoid causing corrosion. Chromic anhydride can improve the polishing effect and make the surface bright.

The current density has a great impact on the quality of polishing. Different current densities should be used for different solutions. If the current density is too low, the leveling effect is poor, and if it is too high, it will cause over-corrosion. Temperature has a certain impact on the quality of polishing, but it is not the main factor.

3. Operation Precautions:

(1) The newly prepared solution should be subjected to electrification treatment under the condition of a large cathode area (the cathode area is several times larger than the anode area), so that part of the hexavalent chromium is reduced. If the amount of trivalent chromium increases too much during use, the opposite is true, that is, the electrification treatment is carried out under the condition of a large anode and a small cathode.

(2) Frequently measure the density of the solution and add water or concentrate the solution by heating in a timely manner. The content of phosphoric acid, sulfuric acid, chromic anhydride, and trivalent chromium in the solution should be analyzed and adjusted regularly.

(3) During use, the content of iron dissolved from the anode gradually increases. When the content of iron (calculated as Fe2O3) reaches 7-8%, the solution should be partially or completely replaced.

(4) Preparation: First, mix phosphoric acid and sulfuric acid, dissolve chromic anhydride in water, then pour the mixed acid solution into the chromic anhydride aqueous solution and heat it to 80°C. Slowly add gelatin under constant stirring (the reaction is intense at this time). After the reaction ends (about 1 hour later), the solution becomes a uniform green.

Electrolytic Polishing of Metals

Electrolytic polishing of copper and its alloys commonly utilizes phosphoric acid electrolytes. For aluminum and its alloys, a solution with phosphoric acid, sulfuric acid, and chromic acid is used for electrolytic polishing.

Electrolytic polishing of aluminum and its alloys is extensively applied in production. If the polished parts undergo a short subsequent treatment, not only can they achieve a smooth and shiny appearance, but a complete oxidation film can also be formed, enhancing their corrosion resistance and maintaining their surface gloss for a long time.

For the preparation method of the solution, one can refer to the relevant content on the electrolytic polishing of steel parts.

When the aluminum content in the solution exceeds 5%, a partial or complete replacement of the solution should be considered. If the chloride ion content exceeds 1%, spot corrosion may easily occur on the surface of the parts. The chloride ion content in the water used for preparing the solution should be less than 80mg/L.