Have you ever wondered how to weld extremely thick metal pieces without multiple passes? Electroslag welding (ESW) offers an efficient solution, using molten slag to generate the necessary heat for welding. This technique is ideal for welding thick sections in a single pass, saving time and materials. In this article, you’ll learn about the process, equipment, applications, and benefits of ESW, equipping you with the knowledge to understand its advantages and potential drawbacks in various industrial applications.

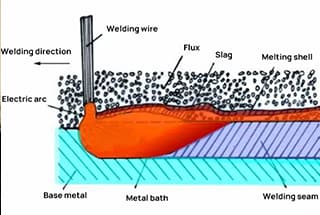

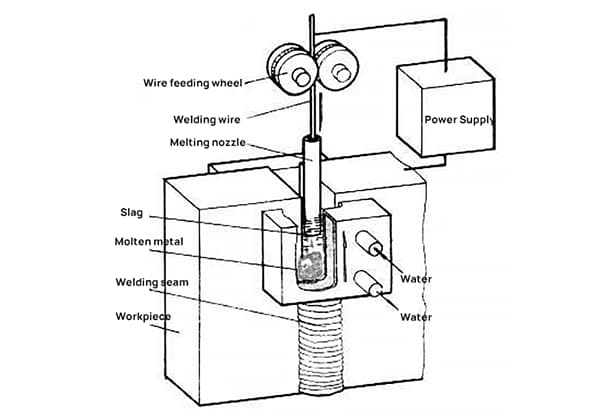

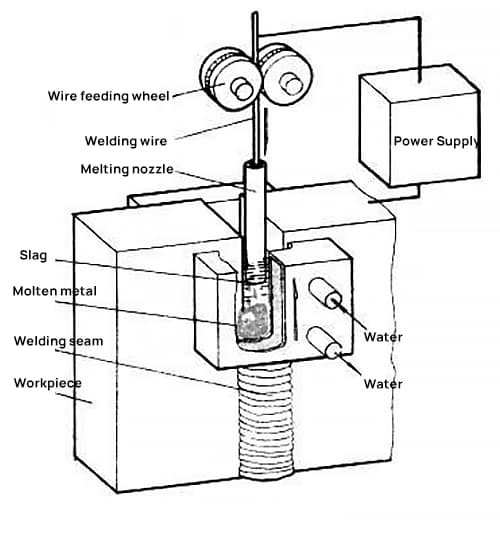

Electroslag welding uses the resistance heat generated by current passing through slag as a heat source to melt the filler metal and base metal, which then solidifies to form a firmly connected structure between metal atoms.

When starting the welding process, short-circuit the welding wire with the welding groove and continuously add a small amount of solid flux.

Use the heat of the electric arc to melt it and form a liquid slag.

When the slag reaches a certain depth, increase the speed of wire feeding and reduce the voltage so that the wire is inserted into the slag pool and the arc is extinguished, thus entering the electroslag welding process.

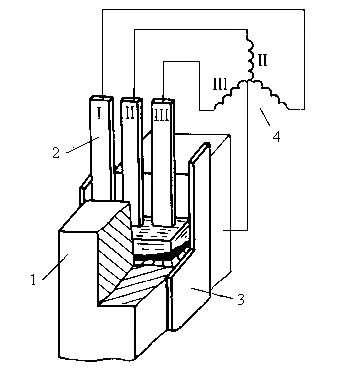

Electroslag welding mainly includes fusion nozzle electroslag welding, non fusion nozzle electroslag welding, wire electrode electroslag welding, plate electrode electroslag welding, etc.

Its drawback is that the input heat is large, the joint stays at high temperatures for a long time, and the area near the weld is prone to overheating, resulting in coarse crystal cast structures in the weld metal, low impact toughness, and generally requiring post-welding annealing and tempering heat treatment.

Backing plate: It is used to draw the part of the weld metal that forms the slag pool and often produces shrinkage holes and cracks when welding stops, out of the workpiece.

Starting groove: In addition to forming the slag, it is also used to leave the part of the start of the electric arc process that is unstable and has a low temperature and is prone to unmelted defects inside the starting groove.

After welding, the backing plate and starting groove are removed.

Electroslag welding has the following characteristics in its process:

Compared with other fusion welding methods, electroslag welding has the following advantages:

(1) It can weld very thick workpieces at one time, thereby increasing welding productivity.

(2) Thick workpieces do not need to be grooved, as long as there is a certain assembly gap between the two workpieces, which can save a lot of filler metal and processing time.

(3) Due to the vertical welding position, there is always a high-temperature slag pool with a certain volume on the metal melt pool, which makes it easier for gas and impurities in the melt pool to precipitate.

Therefore, defects such as pores and slag inclusion are generally less likely to occur.

Moreover, due to the slow welding speed and the weaker concentration of heat source compared to arc welding, the heating and cooling speeds of the near seam area are slower.

This reduces the possibility of quenching cracks in the near seam area for steel grades that are easy to quench. Preheating is not required when welding carbon steel and low-alloy steel.

(4) Because the depth of fusion of the base metal is relatively easy to adjust and control, the proportion of filler metal and base metal in the weld metal can be adjusted over a wide range.

This is of particular significance for adjusting the chemical composition of the weld metal and reducing harmful impurities.

Due to the characteristics of the heat source and slow welding speed of electroslag welding, its disadvantages are:

The weld metal and near-seam area stay at high temperatures (above 1000℃) for a long time, which is prone to coarse grains, overheated structures, and reduced impact toughness of the welded joint.

Therefore, post-weld annealing or tempering heat treatment is generally required for some steel grades, which is relatively difficult for large workpieces.

It is necessary to improve the impact toughness of the welded joint during the welding state of electroslag welding.

There are three types of Electroslag welding methods according to the shape of the electrode:

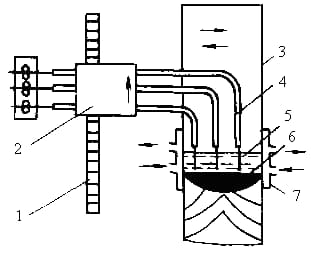

1 – Guide rail

2 – Welding machine head

3 – Weldment

4 – Electrical nozzles

5 – Slag tank

6 – Metal melt pool

7 – Water cooled forming slider

Electroslag welding is mainly used for welding steel or iron-based alloys.

Low-carbon steel and medium-carbon steel are easy to weld. Due to slow cooling, it is also suitable for welding high-carbon steel and cast iron.

With appropriate measures, low-alloy steel, stainless steel, and nickel-based alloys can also be welded.

In general, it is advisable to weld plate thicknesses of 30mm or more.

Generally, it is advisable to weld plates with a thickness of over 30mm, while plates with a thickness of less than 30mm are not as economical as submerged arc welding and gas electric vertical welding.

Although there is no upper limit on the thickness of electroslag welding, due to equipment limitations, wire electrode electroslag welding can generally weld plates up to 400mm thick.

For larger thicknesses, plate electrode electroslag welding and melt nozzle electroslag welding can be used, with a thickness of up to 1m.

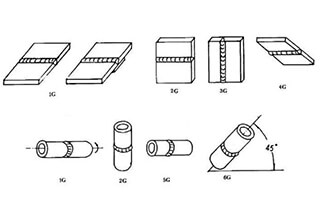

Butt joints between plates of equal thickness are the easiest to weld and the most commonly used. Next are T-joints, corner joints, and cross joints.

The most widely used structure is a thick-plate structure, followed by large-section structures, cylindrical structures, and variable-section structures (including structures with curved or curved surface welds).

These structures are frequently encountered in industrial sectors such as machine manufacturing, heavy machinery, boiler pressure vessels, ships, and high-rise buildings.

Function: Melts into slag to convert electrical energy into heat:

(1) Melts filling metal and base metal;

(2) Preheats the welded part;

(3) Extends the time of existence of the molten pool and slows the cooling of the welded part;

(4) No alloying effect.

Requirements for Welding Flux:

(1) It must be able to easily and quickly form slag. The slag should have an appropriate conductivity, but not too high conductivity, otherwise it will increase the current diversion around the welding wire, weaken the convection effect of the liquid flow in the high-temperature zone, and cause the molten width to decrease or even produce incomplete penetration.

(2) The liquid slag should have an appropriate viscosity. When the viscosity is too high, it is easy to produce slag inclusion and undercutting in the welded metal. When the viscosity is too low, the slag is easy to leak from the gap between the workpiece and the backing plate, which may lead to welding interruption.

During the electroslag welding process, alloying of the weld metal is generally not accomplished through the flux, but mainly by adjusting the alloy composition of the electrode material to control the chemical composition and mechanical properties of the weld metal.

When selecting an electroslag welding electrode, the dilution effect of the base metal on the weld should be considered.

When welding carbon steel and low-alloy steel:

(1) The sulfur and phosphorus content of the electrode material should be controlled.

(2) The carbon content of the electrode should generally be lower than that of the base metal, typically controlled at around 0.10% W(C).

(3) The resulting decrease in the mechanical properties of the weld can be compensated for by increasing the content of manganese, silicon, and other alloy elements.

Table for selecting commonly used electroslag welding wires for steel materials.

| Variety | Steel grade | Welding wire |

| Steel plate | Q235A Q235B Q235C Q235D | H08A H08MnA |

| 20g 22g 25g Q345 (16Mn) Q295 (09Mn2) | H08Mn2Si H10MnSi H10Mn2 H08MnMoA | |

| Q390 (15Mnv, 15MnTi,16MnNb) | H08Mn2MoVA | |

| Q420 (15MnVN, 14MnVTiRE) | H10Mn2MoVA | |

| 14MnMoV 14MnMoVN 15MnMoVN 18MnMoNb | H10Mn2MoVA H10MdNiMo | |

| Cast and forged parts | 15 20 25 35 | H10h4n2 H10MnSj |

| 20MnMo 20MnV | H10Mn2 H10MnSi | |

| 20MnSi | H10MnSi |

The basic requirements of electroslag welding for welding power supply are as follows:

1. Maintain a stable electric arc process.

During the welding process, there should be no occurrence of arc discharge or mixed process of slag and arc, otherwise normal welding process parameters will be destroyed.

The electric arc power supply should be selected with flat characteristics (low no-load voltage and small inductance).

2. Maintain a stable welding current and voltage.

During electroslag welding, the welding wire is fed at a constant speed, and the current-voltage characteristics in the slag pool are rising curves.

Therefore, when the network voltage changes and the wire feeding speed changes, the welding current and voltage changes caused by the flat characteristic welding power source are small, and its self-regulation effect is strong.

3. Electroslag welding requires sufficient power, low no-load voltage, and also a flat characteristic welding power source.

AC power sources are commonly used for electroslag welding, with models like BP1-3×1000 and BP1-3×3000 (arc welding transformers with flat characteristics). If there is no welding power source with flat characteristics available, an arc welding power source with downward characteristics can also be temporarily used as a substitute.

Electroslag welding:

(1) Arc process: Firstly, an arc is generated between the welding wire and the electrode plate. The arc heat melts the welding flux around the arc. When the liquid slag reaches a certain depth, the wire feeding speed is increased, and the arc voltage is lowered to insert the welding wire into the molten pool. The arc is extinguished, and the next process begins.

(2) Slag process: When the current flows through the slag pool towards the workpiece, the welding wire and the workpiece are melted by the resistance heat generated by the slag pool. The melted metal deposits on the bottom of the slag pool due to its weight greater than the density of the slag, forming a molten pool. As the electrode continues to melt and feed, the molten pool and slag pool continue to rise. The cooled and solidified metal at the bottom of the molten pool far away from the heat source forms the weld.

1. Gases and slag in the molten pool are easy to precipitate, so it is not easy to produce pores or slag inclusion.

2. The metallurgical reaction is sufficient, and the chemical composition of the weld is uniform.

3. It can reduce the quenching tendency of the weld and prevent cold cracks, which is especially beneficial for medium and high carbon steel.

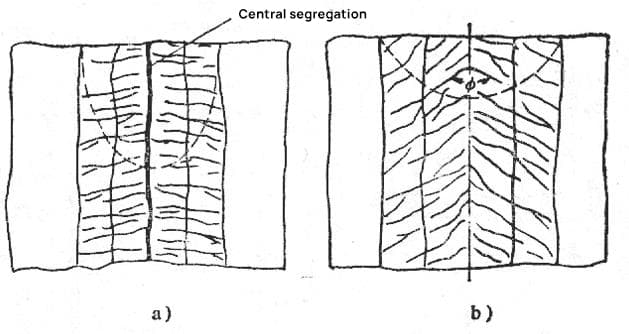

4. The heat-affected zone is wide, the grain size is coarse, and the toughness index decreases. The weld has a zigzag crystallization characteristic, forming a junction angle φ. The larger the junction angle φ, the greater the tendency for segregation and inclusions to form in the middle of the weld, resulting in cracks. To prevent this, the forming coefficient (ψ=B/H) should be increased, thereby reducing the junction angle φ.

a) Shape factor ψ = 0.8, large intersection angle Φ, severe center segregation.

b) Shape factor ψ = 3.0, small intersection angle Φ.

5. It has good protection for the molten metal.

6. It can weld large and thick workpieces at once without beveling, and the advantage becomes more obvious as the thickness increases.

7. It has low cost.

8. The melting ratio is small, generally 10-20%, and the weld composition can be easily adjusted through the welding wire.

9. Preheating is not required, but post-weld heat treatment is needed to improve toughness (usually annealing or tempering).

10. The slag pool has a large heat capacity and is not sensitive to short-term changes in current.

Cracks:

Hot cracks at the center of the welding joint interface.

End of the weld: solidification cracks (reduce wire feeding speed, and locally heat the lower part).

Heat affected zone: cold cracks (preheat, post-heat);

Porosity: H2; CO

Slag inclusion: specification change or unstable electric slag process.

Incomplete penetration: unstable electric slag process or inappropriate specification parameters.

Wide heat affected zone with coarse grain size: post-welding normalization and tempering heat treatment can be carried out, as well as measures such as reducing clearance, adding filler metal, and increasing welding speed.