Have you ever wondered about the hidden mathematics behind the steel structures that shape our world? In this captivating article, an experienced mechanical engineer takes you on a journey to uncover the intricacies of equal angle steel bars. Discover how these unassuming components play a vital role in construction and learn how to calculate their weight with precision. Get ready to gain valuable insights that will change the way you look at steel forever!

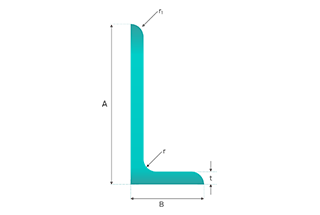

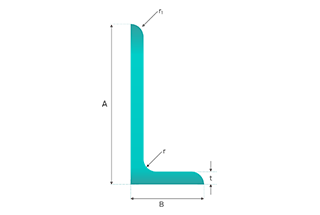

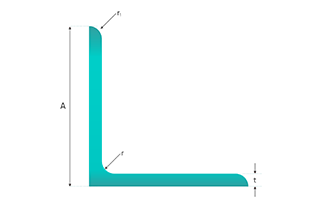

Equal angle steel bar, often referred to simply as “angle iron,” is a long strip of steel with a cross-section in the shape of an “L.” Unlike unequal angle steel, where the two sides of the “L” are of different lengths, equal angle steel has sides of equal length. This makes it a versatile structural component used in various construction and engineering applications.

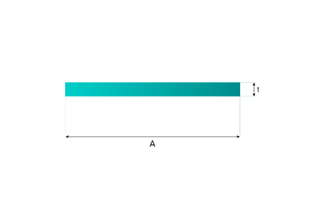

The specifications of equal angle steel are typically expressed in millimeters, indicating the length of each side and the thickness of the steel. For example, “L30 * 30 * 3” refers to an equal angle steel bar with each side measuring 30mm and a thickness of 3mm.

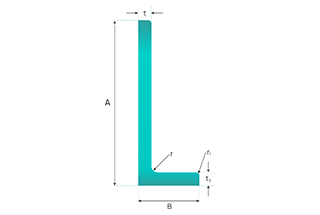

It can also be expressed by a model number, which is expressed as a fraction. The numerator represents the centimeters of the long side width, while the denominator represents the centimeters of the short side width. For example, “L3 / 2 #” means that the long side is 3 centimeters, and the short side is 2 centimeters.

The specification range for unequal angle steel is from 2.5 / 1.6 # to 20 / 12.5 #.

Equal angle steel bars are widely used in:

Their uniformity in dimensions makes them ideal for applications where symmetry and balance are crucial.

According to the dimension, shape, weight, and allowable deviation of hot-rolled section steel (GB/T 706-2008), the length of a hot-rolled equal angle steel bar typically ranges from 4 meters to 19 meters. The weight of an equal angle steel bar can be delivered based on either its actual weight or theoretical weight in the market.

The deviation between the theoretical weight and actual weight of an equal angle steel bar should not exceed -5% to 3%. This means that the actual weight can be slightly less or more than the theoretical weight, but within the specified tolerance range.

Related Tool: Steel Weight Calculator

Below is a weight chart for equal angle steel bars, showing the weight per meter for various dimensions:

| Spec.(Length*Thickness) mm | Weight (kg/m) |

| 20*3 | 0.89 |

| 20*4 | 1.15 |

| 25*3 | 1.12 |

| 25*4 | 1.46 |

| 30*3 | 1.37 |

| 30*4 | 1.79 |

| 36*3 | 1.66 |

| 36*4 | 2.16 |

| 36*5 | 2.65 |

| 40*3 | 1.85 |

| 40*4 | 2.42 |

| 40*5 | 2.98 |

| 45*3 | 2.09 |

| 45*4 | 2.74 |

| 45*5 | 3.37 |

| 45*6 | 3.99 |

| 50*3 | 2.33 |

| 50*4 | 3.06 |

| 50*5 | 3.77 |

| 50*6 | 4.46 |

| 56*3 | 2.62 |

| 56*4 | 3.45 |

| 56*5 | 4.25 |

| 56*8 | 6.57 |

| 63*4 | 3.91 |

| 63*5 | 4.82 |

| 63*6 | 5.72 |

| 63*8 | 7.47 |

| 63*10 | 9.15 |

| 70*4 | 4.37 |

| 70*5 | 5.4 |

| 70*6 | 6.41 |

| 70*7 | 7.4 |

| 70*8 | 8.37 |

| 75*5 | 5.82 |

| 75*6 | 6.91 |

| 75*7 | 7.98 |

| 75*8 | 9.03 |

| 75*10 | 11.09 |

| 80*5 | 6.21 |

| 80*6 | 7.38 |

| 80*7 | 8.53 |

| 80*8 | 9.66 |

| 80*10 | 11.87 |

| 90*6 | 8.35 |

| 90*7 | 9.66 |

| 90*8 | 10.95 |

| 90*10 | 13.48 |

| 90*12 | 15.94 |

| 100*6 | 9.37 |

| 100*7 | 10.83 |

| 100*8 | 12.28 |

| 100*10 | 15.12 |

| 100*12 | 17.9 |

| 100*14 | 20.61 |

| 100*16 | 23.26 |

| 110*7 | 11.93 |

| 110*8 | 13.53 |

| 110*10 | 16.69 |

| 110*12 | 19.78 |

| 110*14 | 22.81 |

| 125*8 | 15.5 |

| 125*10 | 19.13 |

| 125*12 | 22.7 |

| 125*14 | 26.19 |

| 140*10 | 21.49 |

| 140*12 | 25.52 |

| 140*14 | 29.49 |

| 140*16 | 33.39 |

| 160*10 | 24.73 |

| 160*12 | 29.39 |

| 160*14 | 33.99 |

| 160*16 | 38.52 |

| 180*12 | 33.16 |

| 180*14 | 38.38 |

| 180*16 | 43.54 |

| 180*18 | 48.63 |

| 200*14 | 42.89 |

| 200*16 | 48.68 |

| 200*18 | 54.4 |

| 200*20 | 60.06 |

| 200*24 | 71.17 |

For a comprehensive weight chart, you can download the PDF file of the Equal Angle Bar Weight Chart.