Imagine coordinating the transport of massive equipment through cramped subway tunnels—it’s a logistical challenge requiring precision and careful planning. This article outlines the comprehensive strategies used for safely and efficiently moving heavy machinery in underground projects, specifically focusing on Harbin Metro Line 1. From using cranes to manual forklifts, it covers each step necessary to ensure the equipment reaches its destination without a hitch. By reading further, you’ll gain insights into the meticulous processes and safety measures essential for such complex operations.

The transportation of equipment in the subway engineering project involves the transportation of equipment from the ground to the installation location inside the station.

Therefore, the problem of equipment transportation becomes particularly important, and it is necessary to prepare a special plan for equipment and material handling and lifting.

Low headroom and narrow construction site are prominent characteristics of underground railway engineering. In the AFC system engineering of Harbin Metro Line 1, the transportation of ticket machines and check-in machines is highly difficult.

Therefore, before transporting the equipment, a scientifically reasonable and operationally strong plan for equipment transportation must be prepared to ensure the safety and efficiency of equipment transportation.

All 18 stations of Harbin Metro Line 1 are underground. The equipment installation position is located in the middle of the station hall on the mezzanine level, and the equipment is bulky and can only be lifted.

According to the construction schedule, there are a total of 18 stations for AFC equipment and material transport, which is a relatively heavy task with a short cycle.

From the perspective of actual supply, products from the same manufacturer will be concentrated in a certain period of time, so all equipment transportation will be completed within this period.

Based on the understanding of the transportation conditions of subway stations and the experience accumulated in equipment transportation during AFC construction, our project team has developed the following four steps for equipment transportation:

Step One: Transport the equipment by ground vehicle to the location of the equipment lifting hole at each station. This is a necessary procedure in the equipment transportation process.

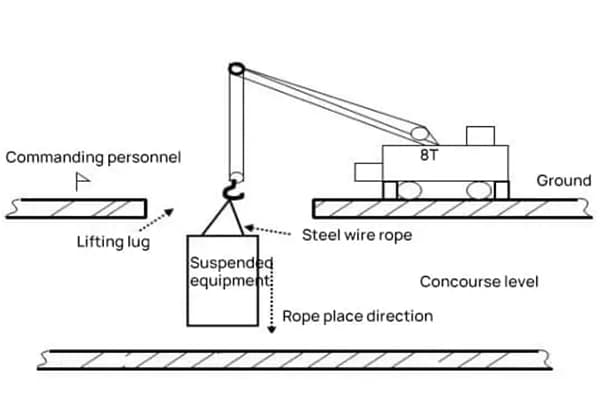

Step Two: Use a crane to lower the equipment through the hole that reaches the ground. This is an effective method for equipment transportation.

Step Three: Use a crane to lower the equipment to the floor of the station hall through the hole.

When the crane cannot reach the lifting point, vertical transportation of equipment is used. This method is used when AFC equipment is transported from the ground to the mezzanine level of the station hall.

Step Four: Use manual forklifts to move the equipment horizontally and accurately position it. Manual transportation is used when the equipment cannot be transported to the mezzanine level of the station hall by a crane.

All AFC equipment and materials can be transported to the required locations using combinations of the above steps.

1. Personnel Organization

| Serial number | Personnel category and type of work | Quantity | Main responsibilities |

| 1 | Group leader | Organizational command | |

| 2 | Deputy team leader | technical guidance | |

| 3 | Safety supervisor | Safety monitoring | |

| 4 | Loading and unloading workers | 10 | Equipment loading and unloading, handling |

| 5 | Crane driver | 1 | Crane driving and operation |

2. Preparation of Main Machinery and Tools

| Serial number | Item | Specifications | Unit | Quantity | Remarks |

| 1 | Crane | 8T | Set | 1 | |

| 2 | Crowbar | L=1500mm | Pcs | 4 | |

| 3 | Walkie-talkie | Set | 3 | ||

| 4 | Wire rope | φ 10~ φ 16 | Meter | Quantity according to actual needs | |

| 5 | U-shaped ring | 5T | Pcs | 1 | |

| 6 | Sleeper | 300X200 | Pcs | Quantity according to actual needs | |

| 9 | Protective equipment | Quantity according to actual needs |

3. Other Preparation Work

(1) Check whether the size, strength and equipment foundation of the equipment entry channel meet the requirements for equipment transportation and installation. If there is a problem, deal with it first.

(2) Check whether the unloading site for AFC equipment meets the operational requirements, and whether it needs to be flattened or reinforced.

(3) If working at night, sufficient lighting equipment should be prepared for the unloading site, transport channels, and entrance platforms.

(4) Before picking up the goods, carefully check the name, model, specifications, quantity, box number, etc. of the equipment to be extracted based on the construction drawings, equipment list and other information, and make a pick-up list. Complete the procedures with the equipment supplier and arrange the delivery time.

4. Transportation Process

(1) Based on the weight, volume and quantity of the transformed AFC equipment, lift the equipment onto the highway trailer with a crane and secure it with straps. When loading the equipment, remove its chassis, wheels, etc., and lay wooden boards under the bottom of the equipment as pads.

(2) Drive the trailer to the equipment at a speed below 20km/h. When passing through a curved road, slow down to ensure safety.

(3) Lift the equipment smoothly onto the entrance platform. Install the chassis and wheels of the equipment, and use wedges to fix the wheels in place.

5. Safety Precautions

(1) Before lifting the equipment, a trial lift should be carried out to observe the force and balance of the equipment. Only after confirming that it is safe and reliable can formal lifting be performed. The lifting capacity of the crane should have sufficient margin, and the strength and length of the wire rope should be checked and confirmed to meet the usage requirements.

(2) The falling speed of the equipment should be slow and steady. The operators should cooperate with each other under the unified command of the commander. Before the equipment is about to land, support and adjustment should be made to ensure that the landing point of the equipment is correct and accurate.

(3) When loading the equipment, pay attention to the bearing capacity of the transport vehicle, place the equipment in a suitable position, and secure it firmly with special ropes in four directions.

(4) During the transportation of equipment, control the speed according to the road conditions to avoid accidents.

(5) Pay attention to listening and watching weather forecast programs and avoid working in thunderstorm weather.

(1) Check whether the station meets the operational requirements. The entrance platform and the station hall level should be prepared with sufficient lighting equipment.

(2) Check whether the air duct opening is unobstructed and whether it can accommodate equipment passing through.

(3) Prepare wood and other materials for temporary coverage of the lifting holes at the station hall mezzanine level.

(1) Place the equipment where the crane can reach it.

(2) After stabilizing the crane outriggers, follow the general lifting operating procedures.

(3) Once the equipment reaches the station hall mezzanine level, immediately move the lifting position to ensure the continuity of crane operations.

(1) Understand and confirm that the load-bearing capacity of the transportation channel meets the transportation requirements.

(2) When using lifting equipment, conduct a trial lift first, observe the force and balance of the equipment, and confirm that it is safe and reliable before officially starting the lift. The lifting capacity of the crane should have sufficient margin, and the strength and length of the wire rope should be inspected to confirm that they meet the usage requirements.

(3) The falling speed of the equipment should be slow and steady. The operators should cooperate with each other under the unified command of the commander. Before the equipment is about to land, support adjustment should be carried out to ensure that the landing point and direction of the equipment are correct. Pay attention to weather forecasts and avoid working in thunderstorm weather.

(1) Check whether the station concourse floor meets the operational requirements. And prepare enough lighting equipment.

(2) Prepare wood or other materials for temporarily covering the lifting hole at the station concourse level.

(3) Check and confirm that the strength of the reserved lifting ring and concrete ceiling meets the lifting requirements (if necessary, tension tests are required). If the strength of the lifting ring or concrete ceiling cannot meet the lifting requirements, reinforcement treatment or temporary lifting frames can be built. Install lifting devices, wire ropes, etc.

(1) Cover the lifting hole at the station concourse level with temporary wooden boards.

(2) Use a manual forklift to drag the equipment to the lifting hole on the station concourse level, connect the wire rope to the equipment through a fixed pulley, then tighten the wire rope through the crane. Let the equipment hang slightly off the ground and observe whether the lifting status is normal. Remove the temporary sealing of the lifting hole at the station concourse level, and continue to synchronize the operation of the crane to make the equipment descend evenly.

When the bottom of the equipment reaches the station concourse level, stop descending. Quickly drag the equipment away from the lifting hole.

(1) Each component of the lifting facility, such as wire ropes and chains, must pass the strength inspection, and the stress of each part must be carefully calculated and analyzed, leaving a certain margin.

(2) When using lifting equipment, conduct a trial lift first, observe the force and balance of the equipment, and confirm that it is safe and reliable before officially starting the lift. The strength and length of the wire rope should be inspected to confirm that they meet the usage requirements.

(3) The falling speed of the equipment should be slow and steady. The operators should cooperate with each other under the unified command of the commander. Before the equipment is about to land, support adjustment should be carried out to ensure that the landing point and direction of the equipment are correct.

(4) A designated person must command and supervise the lifting of the equipment, and closely observe the lifting situation of the equipment to prevent accidents.

(5) When the equipment falls to the station concourse level, ensure that it is placed in the correct direction. It may need to turn several times from the entrance of the equipment to the equipment foundation. If the initial direction is incorrect, it will cause a lot of trouble.

(6) When sealing the lifting hole at the station concourse level, pay attention to stability. The wooden board should be strong and densely laid, and its strength should be able to withstand the weight of the equipment and have sufficient margin to prevent the danger of falling.

Check whether the site of the station concourse floor meets the operational requirements and prepare enough lighting equipment.

Clear obstacles on the transportation channel. If there is a large height difference in the stairs in the transportation channel, build a relatively flat transition section with wood or sleepers.

Lift the equipment with a jack, insert the manual forklift into the bottom of the equipment, and release the jack.

When the ground is relatively flat, the manual forklift can be directly pulled. When the ground is uneven and the manual forklift is difficult to roll, place wooden boards in the direction of the manual forklift’s movement and then pull the manual forklift.

After arriving at the destination, use a jack to lift the equipment, remove the manual forklift, and release the jack.

The transportation schematic is as follows:

A dedicated person must command and supervise the transportation of equipment, closely observe the equipment situation to prevent unexpected phenomena such as equipment side slip and free sliding along slopes.

When encountering a move with a certain slope, anti-free sliding measures must be taken, and triangle wedges and other anti-slip articles should be prepared. When the slope is large, sleeper platforms can be used to reduce the slope.

Pay attention to the effective braking system of the manual forklift.

Due to the professional characteristics of the project and the actual on-site situation, it is not possible to use a crane to lift the equipment.

The general contractor and our company jointly establish a special equipment transportation team, consisting of a team leader, deputy team leader, safety supervisor, and loading and unloading workers.

The team leader should frequently inspect the handling work, the deputy team leader should always be at the forefront during the handling process, and participate in the command of on-site handling work throughout the entire process.

The safety supervisor supervises the handling work at each station on-site throughout the entire process, and is directly responsible to the team leader. If any safety hazards are found, the safety supervisor has the right to stop the work and issue a work-stop order.

| Serial number | Personnel category and type of work | Position | Main responsibilities |

| 1 | group leader | Organizational command | |

| 2 | Deputy team leader | Technical guidance | |

| 3 | safety supervisor | Safety monitoring | |

| 4 | Loading and unloading worker | 10 | Equipment handling |

| Name | Specification and model | Quantity | Company | Remarks |

| Hydraulic forklift | 3T | 1 | Set | |

| Crowbar | L=1500mm | 4 | Pcs | |

| Hand hammer | 5 pounds | 2 | Pcs | |

| Punch | 2 | Pcs | ||

| Protective equipment | Quantity according to actual needs |

| Name | Specification and model | Weight | Quantity | Unit | remarks |

| TVM | 1806*920*850 | 400kg | 1 | Set | |

| AG | 1078*1992*300 | 175kg | 2 | Set |

To ensure that there is a designated unloading area and that the equipment can be transported to the site in a timely manner after arrival, our company will conduct a detailed investigation with the general contractor before the equipment arrives at the station.

The investigation includes the decoration of the concourse floor, confirming that the ground and ceiling of the equipment area in the concourse have been completed, and that there is a storage area for the equipment in the concourse that does not affect the construction of other units.

The investigation also includes ensuring that there are conditions for transporting the equipment from outside the station to the concourse, and that the equipment can be transported downwards from the entrance and exit; ensuring the safety of the personnel and equipment during transportation; and investigating whether there is a temporary storage area for the equipment after it is unloaded outside the station.

(1) Investigate the unloading environment, handling route, and placement position of equipment in the concourse before unloading and handling to make sufficient preparations.

(2) Ensure that there are enough handling personnel, and prevent overloading work. Protective personnel must participate throughout the entire process.

(3) The load capacity of the forklift used for unloading must meet the weight requirements of the equipment and should not be operated while diseased.

(4) The ropes and lifting bars must be firm and securely tied.

(5) Sufficient lighting tools should be provided to meet the needs of the construction.

(6) Safety protective equipment must be worn.

(7) All obstacles along the handling route must be cleared before construction.

(8) During the lifting process, the equipment must be lifted and placed gently to prevent damage to the equipment and other professional products.

(9) The command must be unified and orderly during the handling process.

(1) Unloading:

First, organize the handling personnel to ensure that the unloading work is unified and organized. At the same time, the unloading personnel should wear work gloves and take effective safety measures.

During unloading, every step (including equipment landing and shifting) must be ensured to have no safety hazards before proceeding to avoid personnel being crushed, bumped, or hit and prevent damage to the equipment.

During unloading, the team leader or deputy team leader must participate in the command throughout the process, and the safety supervisor must be responsible for safety supervision. If any unsafe factors are found, work should be stopped immediately.

(2) Handling:

Before handling the equipment, the handling route should be well inspected, and obstacles along the route should be cleared. The lifting ropes must be checked for no broken wires and can fully bear the weight of the equipment.

The firmness of the binding must also be confirmed before lifting. Additionally, the stability of the lifting bar should be checked for any security risks. Multiple persons should be used for lifting during the handling process.

Two individuals should stand beside the equipment to provide protection, while one person is responsible for commanding.

The command must be unified. During lifting, the equipment must be lifted and placed gently to prevent damage to the equipment and other professional products. When placing the equipment, attention must be paid to the feet to prevent leg injuries.

Only after a unified command can the personnel bend down to place the equipment.

Construction methods, technical requirements

(1) The appearance of the equipment should not have any damage such as paint peeling, impacts, etc., and there should be no damage to equipment, modules, meters, etc.

(2) Equipment loading and unloading operations must be strictly in accordance with national regulations.

(3) Product transportation and loading and unloading should strictly follow the installation and usage instructions of the product.

(4) During the lifting of the equipment, no one or other equipment is allowed under the equipment.

(5) The equipment must be securely tied with steel wire ropes and shrink clamps during transportation.

(6) There should be anti-theft measures for the storage of equipment and materials, and a dedicated person should be set up to guard or protective fences should be installed.

(7) Contractors are required to notify station supervisors and construction units to pay attention to equipment protection.

(1) After the equipment installation is completed, protect it with the original packaging wooden box or plastic sheet.

(2) Install warning protection strips around the equipment after the installation is complete.

(3) Send personnel to conduct daily inspections after the equipment installation is completed, check for any damage or theft, and promptly deal with any issues found.