Have you ever wondered if the laser power rating on your handheld welding device is accurate? This article dives into the rampant issue of false labeling in the handheld laser welding market, exposing the discrepancies between claimed and actual power outputs. By reading on, you’ll learn about the impacts of these inaccuracies on welding quality, understand the reasons behind this practice, and discover how to choose reliable equipment amidst widespread exaggeration.

In recent years, handheld laser welding equipment has rapidly emerged as one of the most significant directions in the industry, showing explosive growth and attracting many companies throughout the industrial chain.

As the hottest product, how has the domestic handheld laser welding market grown? What are the urgent issues that still need to be addressed? What is the future development trend?

Recently, we conducted a comparative evaluation of three 1500W fiber laser machines that are widely used for handheld welding in the market, creating a significant impact in the industry.

Laser industry observers obtained specific evaluation results and communicated with handheld welding equipment manufacturers to explore the actual state of the domestic handheld laser welding market together.

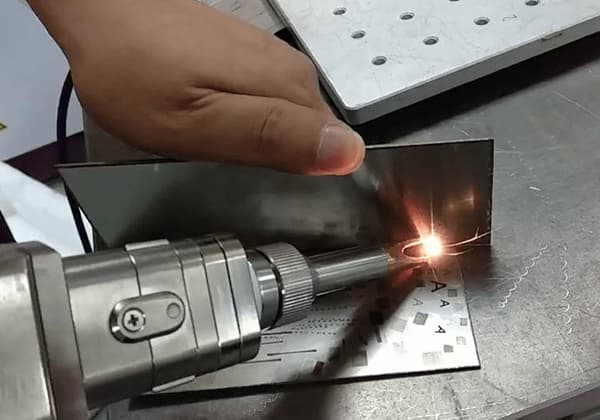

As a new generation of welding methods, handheld laser welding has significant advantages in the speed, welding quality, and post-processing (smooth and flat without manual polishing) of welding thin stainless steel plates, iron plates, aluminum plates, and other metal materials.

Moreover, it is more energy-efficient and meets the current industry trends.

Handheld laser welding began to gradually popularize in the second half of 2018, succeeding in major exhibitions and attracting many light source and equipment manufacturers to enter the market. Its compound growth rate exceeds 100% annually.

As of 2021, there are about 500 manufacturers of handheld laser welding equipment actively operating in the market, presenting an explosive growth in just two to three years.

Compared to applications such as marking and cutting, laser welding has a higher level of difficulty and requires higher demands for laser and processing technology.

Laser welding equipment is highly customized and mostly used in high-precision manufacturing fields, such as the new energy vehicle and power battery industries.

The emergence of handheld laser welding equipment can be said to have subverted the traditional product form, becoming more portable and flexible, making mass production of laser welding possible, and bringing it to ordinary households.

Thus, a large number of manufacturers have joined in, igniting the handheld laser welding market.

At an early stage, handheld laser welding equipment mainly used water cooling for heat dissipation, and enterprises were mainly assembling-based. Laser, welding heads, wire feeders, and other components were basically purchased externally and did not require deep R&D capabilities.

On the other hand, domestic fiber laser manufacturers successively released medium to high-power laser sources such as 500W, 1000W, and 1500W.

Fiber lasers have good beam quality, small size, low energy consumption, stable equipment compatibility, and other characteristics, providing ideal light sources for handheld welding equipment.

Equipment manufacturers can quickly launch new products to seize the market.

As the upstream and downstream industry chains mature, handheld laser welding products are continuously iterated and innovated towards high reliability, more portability, and affordability.

According to relevant data statistics, the number of handheld laser welding manufacturers in the market has grown to nearly 800 in 2022, with extremely surprising growth.

However, beneath the prosperous appearance, the handheld laser welding market also hides potential risks. Currently, there are many brands in the domestic handheld laser welding market, but many of them are counterfeit and the quality is not guaranteed.

In order to grab the market at low prices, they often exaggerate the welding effect and even falsely label the power. Consumers have to blindly trust the quality of the purchased products, becoming a game of luck.

As one of the core components of handheld laser welding equipment, the power of the laser has a significant impact on welding quality and capability. If the laser’s power is insufficient or falsely labeled, it can easily lead to defects such as false welding, shallow or deep melting, and unclear welding marks, seriously affecting processing results.

Due to different laser brands, power exaggeration has become a severe issue in the quality of handheld laser welding equipment.

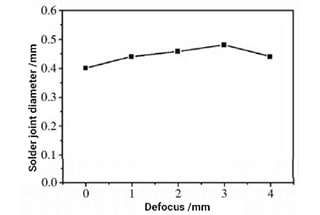

According to the testing data, we found that the phenomenon of “lack of weight” has invaded the laser industry. Many lasers have the issue of “false labeling” of power. Here are the specific power test results.

| Products | Test of 800W | Test of 1500W |

| A | 667W | 1152W |

| B | 858W | 1180W |

| C | 814W | 1530W |

From the above table, among the three commonly used brands A,B,C chosen for comparison, both A and B have power loss issues at high power levels, with A exaggerating by 23%.

A persistently exhibits this issue even at medium power levels, with a false labeling of nearly 17%. B displays power consistent with actual output below 1200W but fluctuates around 1180W above 1200W, exaggerating by 21%.

Only brand C reaches 1530W at full power, and displays power levels consistent with actual output at middle power levels among the three brands.

In order to further test the actual welding capabilities of the three fiber laser welder products, we chose 1mm aluminum, 4mm aluminum, 1mm stainless steel, and 4mm stainless steel for testing and comparison. The following are the actual welding results:

| Products | 1mm Aluminum | 4 mm Aluminum | 1mm Stainless steel | 4mm Stainless steel |

| A | 800W was sufficient to achieve full penetration, and the backside was transparent. | 800W was sufficient to achieve full penetration, and the backside was transparent. | ||

| 1500W was sufficient to achieve full penetration, but it did not weld through. | 1500W was sufficient to achieve full penetration, but it did not weld through. | |||

| B | 350W was sufficient to achieve full penetration, and the backside was transparent. | |||

| 1500W was sufficient to achieve full penetration, but it did not weld through. | 1500W was sufficient to achieve full penetration, but it did not weld through. | |||

| C | 500W was sufficient to achieve full penetration, and the backside was transparent. | 600W was sufficient to achieve full penetration, and the backside was transparent. | ||

| 1500W was sufficient to achieve full penetration, and the backside was slightly transparent. | 1500W was sufficient to achieve full penetration, and it almost welded through. |

Through the above comparison, it was found that all three products were able to complete the welding of 1mm aluminum and 1mm stainless steel. However, as the material thickness increased, due to the different degrees of power exaggeration of Brands A and B in high-power, they were unable to weld through 4mm aluminum and 4mm stainless steel, while the fully powered Brand C did not have this problem.

This shows that power exaggeration has almost become a common phenomenon in the field of handheld laser welding, which also reflects the real situation of the industry.

For the handheld laser welding market, although it has been developed for several years, the industry is still in the “barbaric growth” stage. The industry lacks unified norms and standards, which also leads to mixed industry, low-quality competition, one-time deals, poor after-sales service, and safety hazards, which are often seen.

For fiber laser welders, after breakthroughs in upstream key materials and components, the entry threshold is further reduced.

In addition, with the increasing internal circulation of the industry in recent years, the trend of domestic fiber laser welder replacement has arisen, attracting upstream and downstream of the industrial chain and cross-border transformation of other fields to independently develop fiber laser welders.

Due to differences in technology accumulation and R&D capability, in order to quickly launch products to seize the market, product quality naturally cannot be guaranteed, which has been a persistent problem in the laser industry.

Specifically for the field of handheld laser welding, the phenomenon of power exaggeration in laser equipment is naturally inevitable. This has also led to the unique phenomenon in the field of handheld laser welding, where manufacturers are betting on laser equipment, causing end customers to suffer.

How to break through the current situation of handheld laser welding?

Currently, there is no technological barrier or leading manufacturer in the field of handheld laser welding, and there are many new entrants. There are also many brands of handheld fiber laser welding machines in the market, but the quality is uneven, and the prices vary from tens of thousands to hundreds of thousands of yuan, making it a challenge to choose the right one.

With this issue in mind, we have had discussions with downstream equipment manufacturers.

One manufacturer stated that “the biggest problem now is price competition. We started earlier, and more and more brands have entered the market, gradually making low prices an important means of competition.

This has led to user confusion, similar to the situation with laser marking machines where prices continued to drop.

In addition, as an integrated equipment manufacturer, the quality of core components such as fiber laser and welding head greatly affects our product quality and after-sales service.

Although there are many brands of laser available now, small brand products are not very stable, and the quality of welding is not guaranteed.

Therefore, we tend to choose domestic major brand manufacturers or foreign brands. Although they have higher prices, the quality is guaranteed.”

Handheld laser welding equipment generally consists of laser, welding system, handheld laser gun, and cooling system, and is widely used in cabinets, kitchens and bathrooms, stairs and elevators, shelves, ovens, stainless steel doors and windows, electrical boxes, and stainless steel home furnishings.

For consumers, when choosing handheld welding equipment, they need to consider the key components in an all-round way, not blindly focusing on product prices while ignoring product performance and quality.

For enterprises in the handheld laser welding industry chain, they should also break away from previous patterns and continuously improve product quality and grades to pursue long-term benefits.

According to data from the Laser Industry Association, it is expected that the market size of handheld laser welding will exceed 30 billion yuan, which has a very large market space for traditional welding to be replaced. The handheld laser welding market is transitioning from assembly to branding, with more and more powerful fiber laser companies beginning to focus on this market.

In addition to strategic cooperation with equipment manufacturers, many laser companies have also introduced whole machine products, hoping for a new upgrade in product quality and after-sales service. This will further promote the development of the domestic handheld laser welding market towards standardization.

As one of the key components, domestic fiber laser manufacturers should focus on product quality in a down-to-earth manner, providing downstream with more stable and high-quality lasers. Starting from user needs, continuous technological innovation and iterative products are the key to ensuring the healthy development of the industry and further expanding the handheld welding market.