Have you ever wondered how a laser can cut through metal like a hot knife through butter? In this fascinating article, we’ll explore the science behind fiber laser cutting technology. Our expert mechanical engineer will guide you through the fundamental concepts, shedding light on how this cutting-edge technology is revolutionizing manufacturing. Get ready to dive into the world of laser cutting and discover its immense potential!

“The laser cuts through iron as though it were mud,” this statement is not an exaggeration.

Let’s examine the laser in more detail.

What is a Laser?

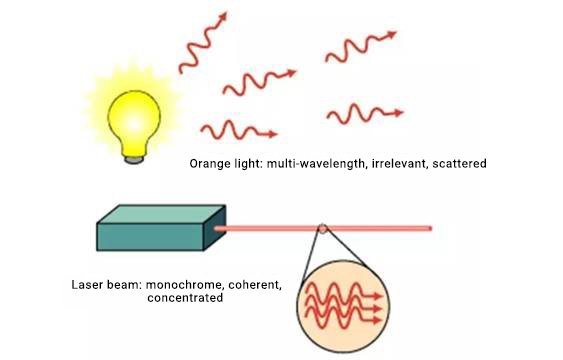

A laser is a type of enhanced light produced through stimulated radiation.

Its key features include:

When the laser beam is directed onto the surface of the workpiece, the light energy is absorbed and transformed into heat energy.

This causes the temperature at the point of irradiation to rapidly increase, melt, and vaporize, forming a small pit.

The metal surrounding the pit melts due to thermal diffusion. The vapor in the small pit expands rapidly, causing a micro-explosion, and the molten material is expelled at high speed, generating a highly directional anti-shock wave.

This results in the formation of a hole with a large upper side and small lower side on the surface being processed.

Comparison of Ordinary Light and Laser:

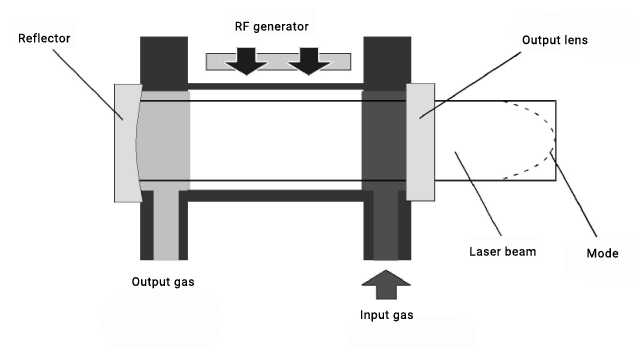

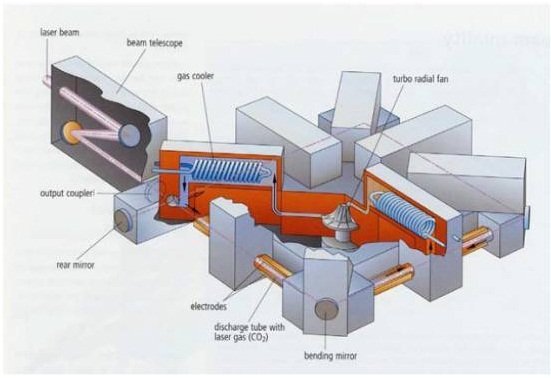

The Generation of Laser

Laser Generating Gas

Laser generating gas is different from cutting gas.

Laser generating gas composition:

The proportional relationship between the above mentioned three gas is:

N2:CO2:He = 1:4:5

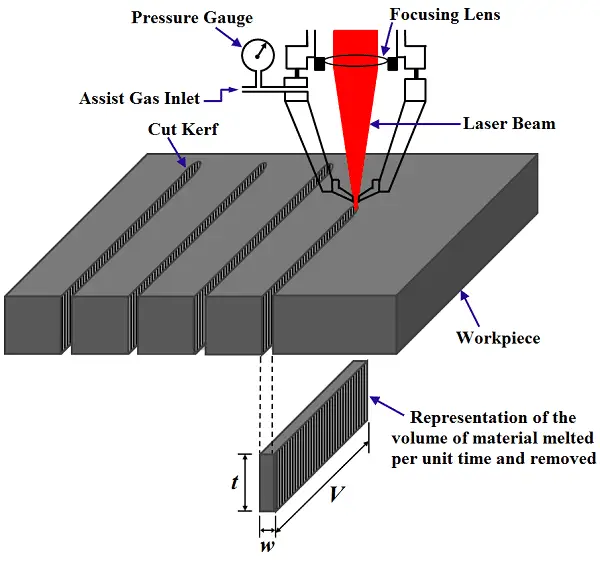

Fiber Laser Cutting is a hot cutting method that utilizes a focused high-power density laser beam as the main heat source. This causes the irradiated materials to rapidly melt, evaporate, ablate, or reach ignition point.

At the same time, the use of high-speed airflow that is coaxial with the laser beam helps blow away the molten material, enabling cutting of the workpiece.

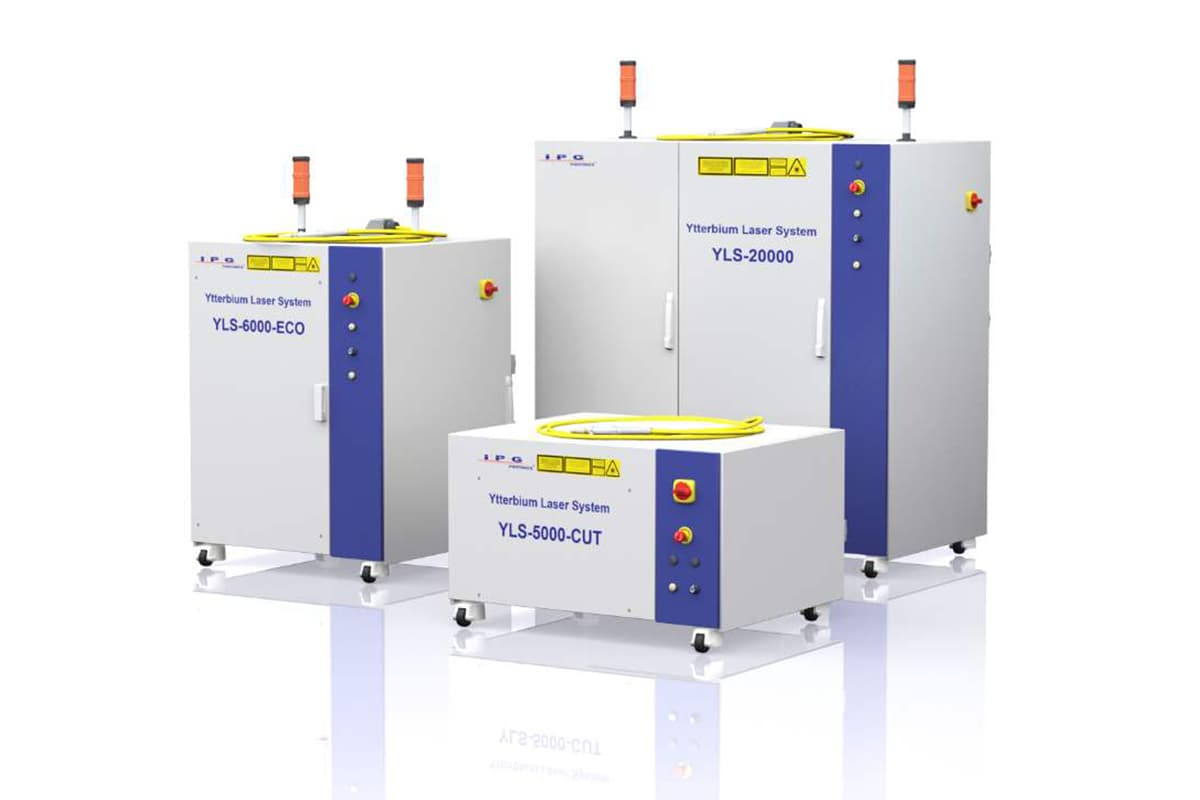

In recent years, the technology behind high-power fiber laser generators has matured and improved, leading to a continuously expanding range of applications.

The fiber laser cutting machine has become a popular focus of industrial research and development.

In the realm of thin plate cutting, fiber laser generators are gradually replacing traditional CO2 lasers and YAG lasers for several reasons:

(1) Lower Cost:

The photoelectric conversion efficiency of fiber lasers is around 30%, while the photoelectric conversion efficiency of CO2 lasers is 6-10%, and the photoelectric conversion efficiency of YAG lasers is only 3%. In addition, fiber laser generators have no vulnerable parts, so there is no cost associated with late maintenance.

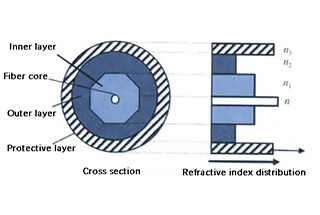

(2) Compact and Flexible Design:

Fiber lasers have a small size, light weight, and offer a flexible and movable working position.

(3) Improved Cutting Quality:

The use of a flexible light-guiding system in fiber lasers and a constant beam transmission distance avoids poor cutting quality caused by changes in the light path length of CO2 laser generators.

This ensures consistent cutting quality throughout the cutting width, making it ideal for large-format laser processing systems.

(4) Cost Savings:

The beam of a fiber laser travels along an optical fiber, so there is no need for an external reflected light path system, saving the cost of reflection lenses and organ shields.

There is also no need for external optical path adjustments, which reduces the risk of light path pollution from dirt and reduces the weight of moving parts.

(5) Improved Performance for Metal Cutting:

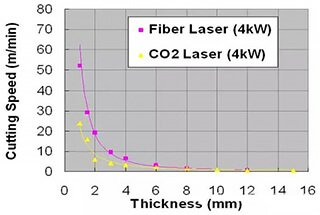

The wavelength of a fiber laser is 1.06 μm, which is more easily absorbed by metal materials compared to the wavelength of CO2 (10.6 μm).

This is particularly beneficial for sheet metal cutting, with cutting speeds 2-4 times faster than CO2.

Fiber lasers also have a better cutting effect for high-reflective materials such as aluminum alloys, copper, and copper alloys.

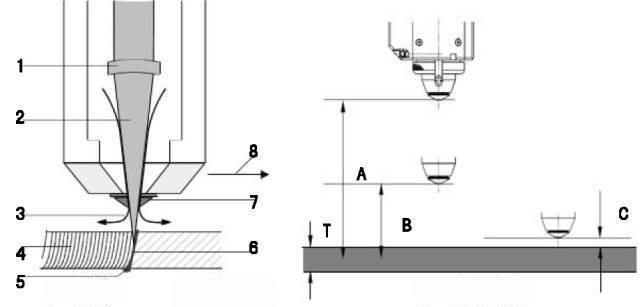

See also:

(1) lens

(2) the laser beam

(3) airflow

(4) the line

(5) molten material

(6) cutting surface

(7) nozzle

(8) cutting direction

A: Empty height

B: Puncture height

C: Cutting height

T: Sheet thickness

The world’s first laser cutting machine was invented in the 1970s. In the past thirty years, the application of laser cutting machines has expanded continuously, and the technology has constantly improved.

Many companies now manufacture various types of laser cutting machines to meet market demand, including 2D plate laser cutting machines, 3D space laser curve cutting machines, and pipe laser cutting machines.

Some of the top laser cutting machine companies include: Trumpf (Germany), Prima (Italy), Bystronic (Switzerland), Amada (Japan), MAZAK (Japan), NTC (Japan), and HGLaserLab (Australia).

A list of the top laser cutting machine manufacturers worldwide is available for reference.

Fiber laser cutting equipment can effectively cut stainless steel that is less than 4mm thick. If oxygen is added, it can even cut stainless steel up to 8 to 10mm thick using a laser beam.

However, when oxygen is used, a thin oxide film forms on the cutting surface. The maximum cutting thickness can be increased to 16mm, but the size tolerance of the cut part becomes greater.

While fiber laser cutting equipment is expensive, it is still economically viable for large production runs due to the lower cost of subsequent processing.

Additionally, since there is no tooling cost, the laser cutting equipment is also suitable for small batches of parts that were previously unprocessable.

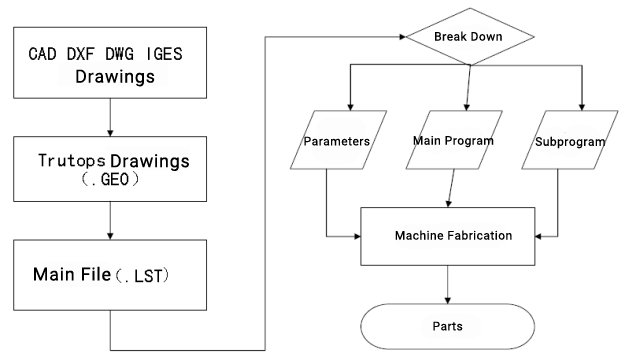

Fiber laser cutting equipment typically utilizes a computerized numerical control (CNC) system. With this technology, cutting data can be received from a computer-aided design (CAD) workstation.

See also:

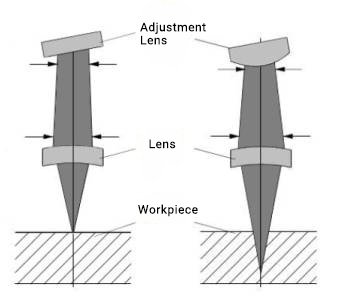

The adaptive optical system, a core component of modern laser cutting machines, dynamically adjusts the curvature of the focusing lens through precise hydraulic pressure control. This modification alters the divergence angle of the laser beam, enabling fine-tuned vertical positioning of the focal point.

Moreover, this sophisticated system compensates for focal shifts that occur due to varying spot diameters across different working positions of the machine. This automatic adjustment ensures consistent cutting quality and precision, regardless of the workpiece’s position or the cutting head’s location within the working envelope.

The adaptive optics not only optimize the beam’s focus for different material thicknesses but also maintain cutting performance during high-speed operations, where rapid acceleration and deceleration can affect beam characteristics. This technology significantly enhances cutting efficiency, reduces kerf width variations, and improves overall part quality, particularly in complex contour cutting and high-precision applications.

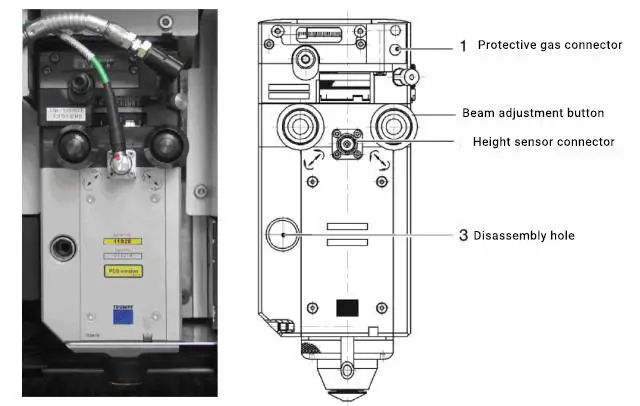

The fiber laser cutting head is a critical component in modern laser cutting systems, designed to focus and direct the high-power laser beam onto the workpiece with precision. It consists of several key elements that work in synergy to achieve optimal cutting performance:

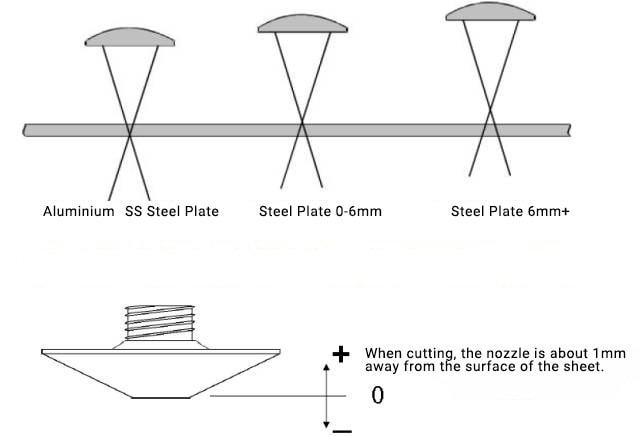

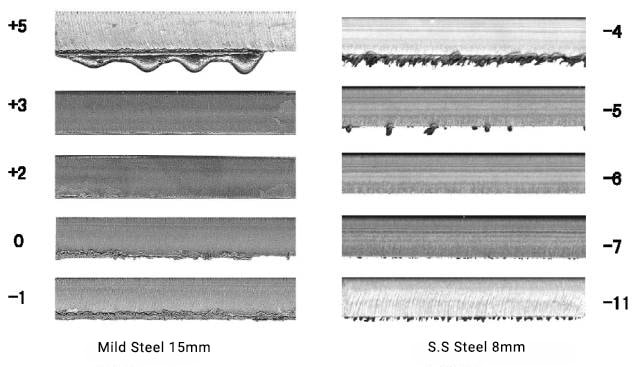

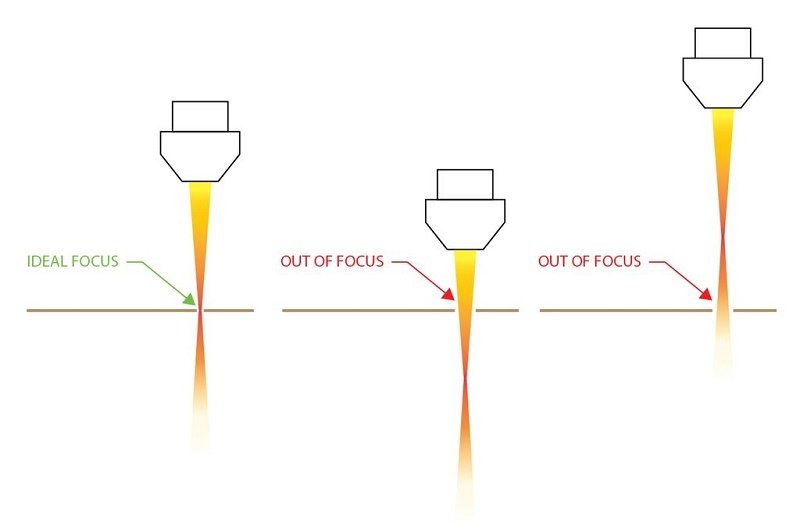

In practical applications, the height of the focus varies with the material and the cutting machine.

Focus position selection

In laser cutting, the position of the laser focus greatly impacts the quality of the surface finish of the cut parts, and different materials have different focus requirements.

For instance, when cutting carbon steel, the focus should be on the top surface of the plate; when cutting stainless steel, the focus should be approximately halfway through the thickness of the plate; when cutting aluminum alloy, the focus should be close to the bottom surface of the plate.

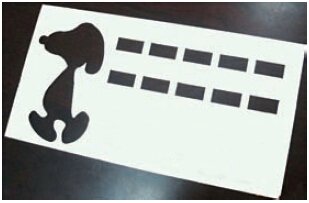

In the case of cutting a 2mm stainless steel sample, as shown in the figure below, the focus position should be about 0.8 to 1.2mm below the surface of the plate.

Fig. Laser cutting sample

During the cutting process, the uneven surface of the material can cause changes in the laser’s focal position, thereby impacting the cutting quality.

To address this issue, a highly sensitive capacitive sensor is placed on the cutting head to provide real-time feedback on the distance between the nozzle and the panel to the CNC system.

Based on this feedback, the height of the cutting head is adjusted in real time through a transmission mechanism, creating a closed-loop control system with a high dynamic response that helps prevent defects caused by changes in the focus position during plate cutting.

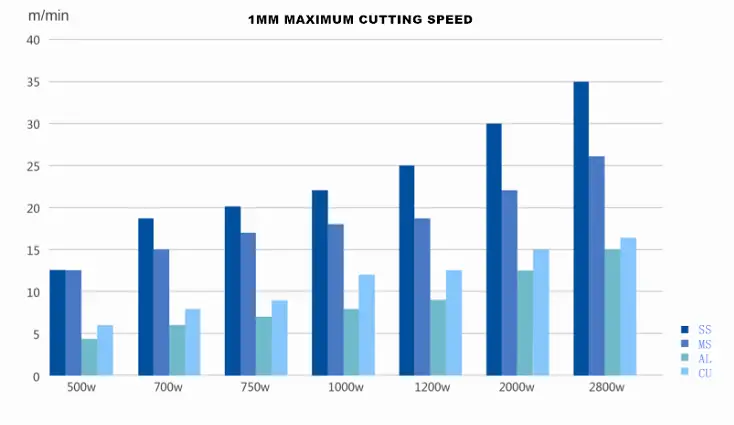

The laser power is a critical parameter that significantly influences cutting thickness, speed, kerf width, and overall quality in laser cutting operations. Generally, higher laser power enables cutting of thicker materials at faster speeds. However, the relationship between these variables is more nuanced and requires careful optimization.

For each combination of material thickness and cutting speed, there exists an optimal laser power range that minimizes surface roughness and maximizes cut quality. Deviating from this optimal range leads to increased surface roughness, reduced processing efficiency, and higher operational costs. Excessive power can cause burning or heat-affected zone (HAZ) issues, while insufficient power may result in incomplete cuts or increased dross formation.

It’s crucial to note that when laser power and assist gas pressure are held constant, cutting speed and kerf width exhibit a nonlinear inverse relationship. As cutting speed increases, kerf width decreases, and vice versa. This relationship is essential for achieving precise dimensional control in laser-cut parts.

The correlation between cutting speed and surface roughness of the cut edge follows a parabolic curve. Starting from zero, increasing cutting speed initially reduces surface roughness. This improvement continues until reaching an optimal speed where surface roughness is minimized. Beyond this point, further speed increases lead to incomplete cuts and deteriorating surface quality.

Modern CNC laser cutting systems employ adaptive control algorithms to dynamically adjust laser power based on cutting speed and geometry. For instance, when negotiating small radii or sharp corners where the cutting speed must be reduced, the system automatically decreases laser power to maintain optimal energy input and prevent overheating or excessive kerf width.

This adaptive power control is particularly crucial for achieving high precision and excellent edge quality in complex parts with varying feature sizes. It allows for consistent cut quality across straight sections, curves, and intricate details without manual intervention.

Understanding and optimizing these interrelated parameters – laser power, cutting speed, material thickness, and assist gas dynamics – is essential for achieving high-quality, cost-effective laser cutting operations across a wide range of materials and applications.

See also:

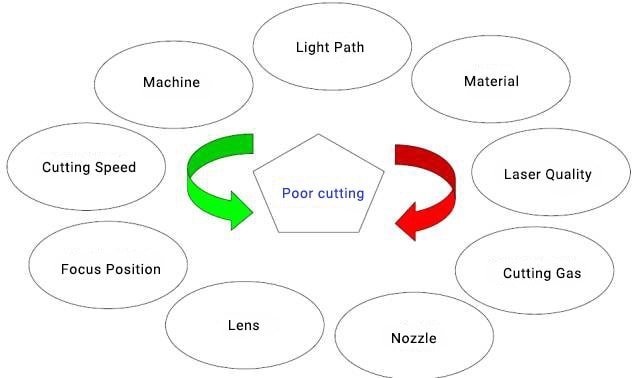

As a novice in the field of laser cutting, do you often feel overwhelmed during the process? It can be confusing to experiment with different plates, gases, air pressures, and powers and still not achieve the desired results.

Have you wondered about choosing the right auxiliary gas and what factors affect cutting quality? Which auxiliary gas should be used for different materials? How is the pressure of the auxiliary gas controlled and what is the requirement for its purity?

It’s important to understand the role of the auxiliary gas in laser cutting. It is used to blow away the slag in the cutting kerf, cool the surface of the material being processed to reduce the heat-affected zone, cool the protective lens to prevent contamination, and in some cases, protect the base metal.

Auxiliary gas types and characteristics

The auxiliary gases commonly used in laser cutting are nitrogen, oxygen and air.

Auxiliary gas is crucial in laser cutting as it helps to remove the melted and vaporized material from the cut and also blows away the smoke generated during the cutting process, reducing any hindrance to the cutting process.

The pressure and flow rate requirements for the auxiliary gas vary depending on the thickness and type of material being cut.

When cutting low carbon steel plates, oxygen is typically used. The purpose of using oxygen in cutting carbon steel is to ignite and remove the melted material.

As a novice in the laser cutting field, do you often encounter difficulties during the laser cutting process? Despite trying various plates, gases, air pressures, and powers, you may still be unsure about the optimal combination.

To choose the best auxiliary gas, it is essential to understand its role and the factors that affect cutting quality, such as pressure and flow, as well as the purity of the gas.

For cutting low carbon steel plates, oxygen is typically used. Oxygen’s role in the cutting process is to fuel and remove the molten material.

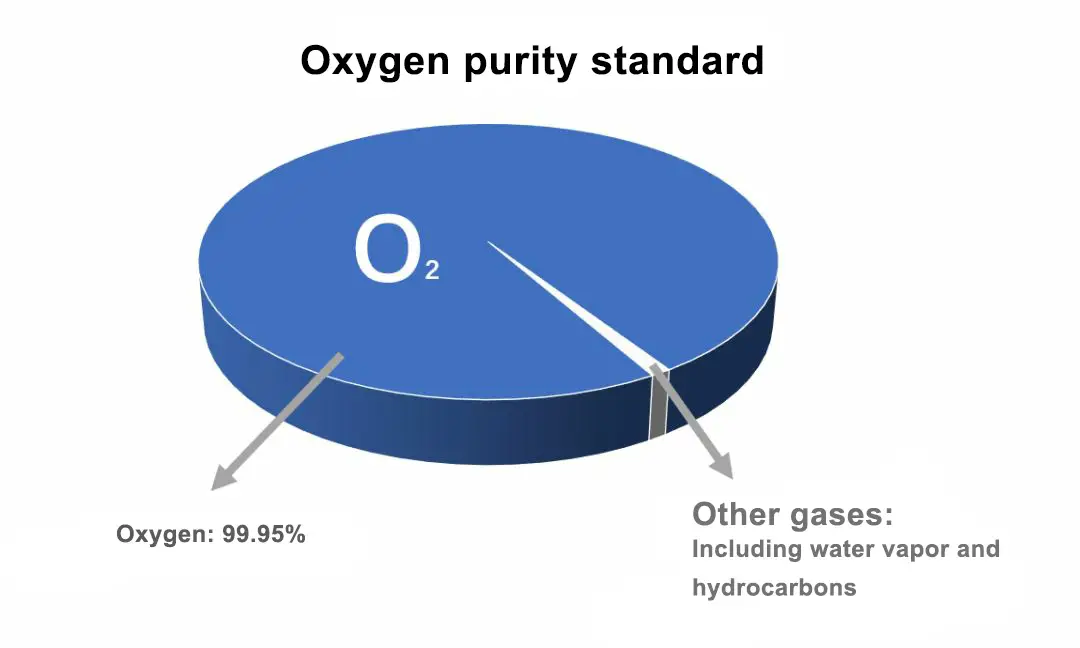

The purity of oxygen should be higher than 99.5%, with a higher purity resulting in a brighter cutting surface.

However, impurities such as water can have a significant impact on the cutting quality of the plate. If the oxygen purity is not high enough, or if the parts have higher surface quality requirements, it may be necessary to improve the purity through oxygen drying or other methods.

Nitrogen is usually used for cutting stainless steel and aluminum alloy materials. Nitrogen’s role is to eliminate oxidation and remove the melt.

The pressure of nitrogen increases with the thickness of the plate.

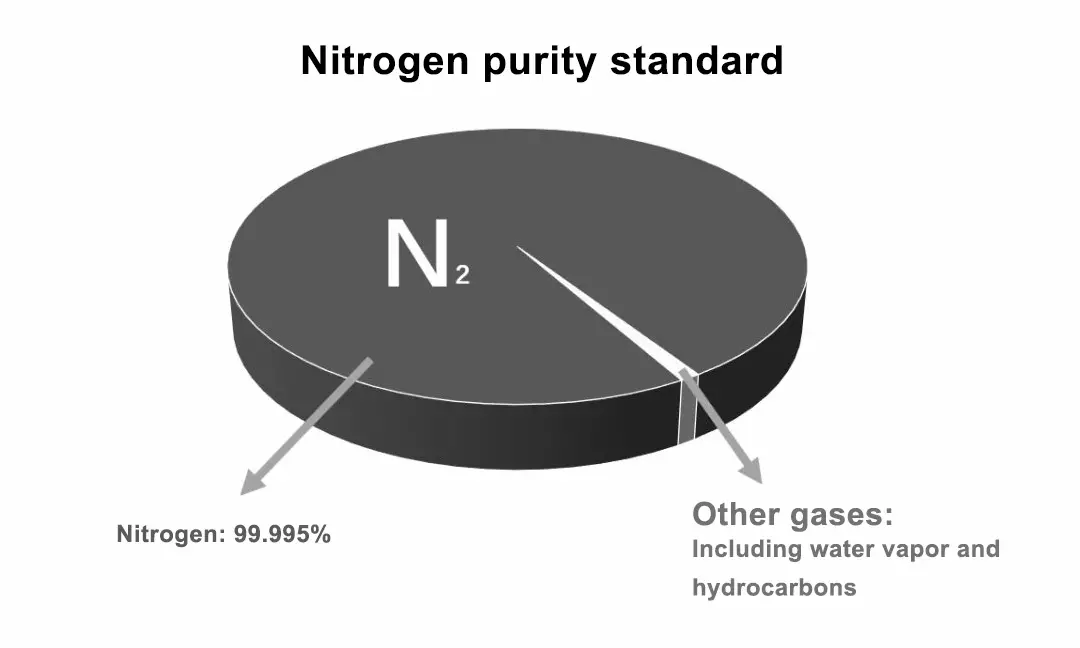

For cutting stainless steel, the purity of nitrogen should be higher than 99.999%. Low-purity nitrogen can result in yellowing of the cutting surface and decreased brightness.

A sample in the laser cutting figure was cut with high-purity (99.99%) liquid nitrogen, with a gas pressure of 0.8 to 1.0 MPa.

Auxiliary gas purity standard

The use of matching auxiliary gases is required for laser processing of different materials.

Impurities in the auxiliary gas can have detrimental effects on the lens, resulting in fluctuations in cutting power and inconsistencies on the front and back cutting surfaces.

Auxiliary gas pressure standard

The amount of air pressure that can be used for various types of auxiliary gases is different. Based on the characteristics of the gas, such as flammability and combustion, experience has shown that the auxiliary gas can prevent slag from returning during the cutting process, thus protecting the internal lens of the laser head.

In other words, with the same processing power, material, and sheet thickness, the higher the gas pressure, the more smoke and dust that can be blown off at the unit speed.

Therefore, a higher air pressure value results in a faster laser cutting speed, which is why nitrogen is used for cutting thin sheets.

It can be concluded that the general rule for the cutting speed of thin plates is: Oxygen < Air < Nitrogen. This rule can be used as a starting point for selecting auxiliary gases by novice users.

Note: The above general rule does not apply to laser cutting of thick plates. The type of cutting gas used should be selected based on the individual sheet characteristics.

After reading this, you should have a basic understanding of the characteristics of the three auxiliary gases. Let’s take a closer look.

Oxygen

Oxygen is mainly used for cutting carbon steel. The oxygen reaction heat is used to increase cutting efficiency, but the resulting oxide film increases the beam spectral absorption factor of the reflective material.

This results in the end of the slit appearing black or dark yellow.

Oxygen is mainly used for cutting rolling steel, rolled steel for welding structures, carbon steel for mechanical construction, high-tension plates, tool plates, stainless steel, electroplated steel sheets, copper, copper alloys, etc.

The purity requirement for oxygen is generally 99.95% or higher. Its main function is to help burn and blow off the cut melt.

The pressure and flow rate required are different and are determined by the size of the nozzle model and the thickness of the cutting material. In general, the required pressure is 0.3-1Mpa, and the flow rate varies based on the thickness of the cutting material.

For example, when cutting 22mm carbon steel, the flow rate should be 10m3/h, including the protection oxygen of the double-nozzle.

Nitrogen

Some metals require the use of nitrogen to prevent oxidation during cutting and to maintain the quality of the cutting surface. This results in a whitish end face of the slit and a high resistance to welding, smearing, and corrosion.

The main materials that can be cut with nitrogen are stainless steel, plated steel, brass, aluminum, and aluminum alloys. The goal of using nitrogen is to prevent oxidation and to blow off the melt.

For high-quality cutting, a high purity of nitrogen is necessary (99.999% is often required for stainless steel with a thickness of 8mm or more). The pressure requirement is relatively high, usually around 1.5 MPa. For thicker stainless steel (12mm or more, up to 25mm), a pressure of 2 MPa or higher may be needed.

The flow rate of nitrogen varies based on the type of nozzle being used, but it is generally quite high. For example, cutting 12mm stainless steel requires a flow rate of 150 m3/h, while cutting 3mm stainless steel requires only 50 m3/h.

Air

The use of air as an auxiliary gas in laser processing is cost-effective as it can be directly obtained from an air compressor. Although it contains 20% oxygen, the cutting efficiency is low compared to oxygen and is similar to nitrogen.

A trace of oxide film may appear on the cut surface, but it can also help prevent the coating from falling off. The end of the cut has a yellowish appearance.

Mainly used for cutting materials such as aluminum, stainless copper, brass, electroplated steel sheets, and non-metals. However, when high-quality products are required, air is not suitable for cutting aluminum, aluminum alloy, and stainless steel as it will oxidize the base material.

The selection of the auxiliary gas depends on the cost of cutting and the requirements for the product. For instance, when cutting stainless steel for low-quality products that will undergo further processing, air can be used to reduce cost.

On the other hand, when the cut product is the final product, a protective gas such as nitrogen must be used, such as in craft products.

Therefore, it is necessary to choose the auxiliary gas based on the characteristics of the product in the cutting process.

See also:

Using a high-energy density laser beam to heat the workpiece, the temperature rapidly rises and reaches the boiling point of the material in a very short time, causing the material to vaporize and form steam.

This fast-moving steam creates an incision in the material while also evaporating.

The heat of vaporization of materials is usually high, requiring a large amount of power and high power density for laser vaporization.

This technique is used to cut thin metal materials and non-metallic materials such as paper, cloth, wood, plastic, and rubber.

During the vaporization process, the steam carries away the melted material and debris, forming a hole.

About 40% of the material is dissolved into steam while 60% is expelled in the form of droplets by the flow during the vaporization process.

When the power density of the incoming laser beam exceeds a certain threshold, the material at the beam’s irradiation point begins to evaporate and form a hole. The hole absorbs all of the incoming beam energy, acting as a black body.

The holes are surrounded by molten metal walls, and the auxiliary air flow, along the beam axis, carries away the molten material surrounding the hole.

As the workpiece moves, the hole is synchronized horizontally, forming a cut in the cutting direction. The laser beam continues to irradiate along the edge of the seam, causing the melting material to continuously or periodically be blown away through the cracks.

Laser fusion cutting does not require the full vaporization of the metal, using only 1/10 of the energy required for vaporization.

This method is mainly used for cutting non-oxidizable materials or active metals such as stainless steel, titanium, aluminum, and alloys.

The principle of laser oxygen cutting is similar to that of oxyacetylene cutting. It utilizes the laser as the preheating source and employs oxygen and other active gases as the cutting gas.

On one hand, the gas reacts with the metal being cut and causes an oxidation reaction, releasing a significant amount of heat.

On the other hand, the molten oxide and the molten metal are expelled from the reaction area, forming a cut in the metal.

Due to the high amount of heat generated during the oxidation reaction, laser oxygen cutting requires only half the energy needed for melting cutting and has a faster cutting speed compared to laser vaporization cutting and melting cutting.

This method is mainly used for cutting carbon steel, titanium steel, heat-treated steel, and other easily oxidized metal materials.

The process of laser oxygen cutting can be described as follows:

For brittle materials that are prone to heat damage, cutting through laser beam heating with high speed and control is known as controlled fracture cutting.

The key aspect of this cutting process is that the laser beam heats a small area of the brittle material, leading to a large thermal gradient and significant mechanical deformation in the region, causing the material to crack.

As long as the heating gradient is maintained in balance, the laser beam can guide the cracks in any desired direction.

It’s important to note that this type of cutting is not suitable for cutting sharp angles or corners. It is also challenging to achieve success when cutting a large and closed shape.

The cutting speed of controlled fracture cutting is fast and does not require excessive power, otherwise it will cause the surface of the workpiece to melt and break the cutting edge.

The main control parameters are laser power and spot size.

Laser cutting classified by cutting gas:

| Flame burning cutting | Melt cutting | |

|---|---|---|

| Cutting Gas | Oxygen | Nitrogen |

| Features | Large cutting thickness | Cutting section without oxide layer |

| Fast cutting speed | Less cutting burrs | |

| Has oxidized layer | Cutting gas is expensive | |

| Cutting section with a rear tow line | Slow cutting speed | |

| Part of the material requires oxygen to participate in the puncture | ||

| Applicable material | Carbon steel | Stainless steel, aluminum, galvanized sheet |

Compared to other thermal cutting methods, laser cutting stands out for its high cutting speed and superior quality.

Specifically, the following aspects can be summarized:

Laser cutting provides better cutting quality due to its small laser spot, high energy density, and fast cutting speed.

The laser beam is focused on a small point, resulting in a high power density at the focal point.

The heat input from the beam is significantly higher than that reflected, transmitted, or diffused by the material.

This leads to rapid heating and vaporization of the material, creating a pore through evaporation.

With the relative linear movement of the beam and the material, the hole is continuously formed into a narrow slit.

The cutting edge is affected very small by the heat, and there is no deformation of the workpiece.

In the cutting process, the auxiliary gas suitable for the cut material is added.

When the steel is cut, oxygen is used as the auxiliary gas and molten metal to produce exothermic chemical reaction oxidation material, while helping to blow away the slag in the slit.

When cutting plastics such as polypropylene, compressed air is been used.

When cutting flammable materials such as cotton, paper, the inert gas is been used.

The auxiliary gas entering the nozzle can also cool the focus lens, prevent the dust from entering the lens seat to contaminate the lens and cause the lens to overheat.

Most organic and inorganic materials can be cut by laser.

The heavy metal processing industry which means a lot to the industrial manufacturing system, many metal materials, no matter how hard it is, can be cut without deformation.

Of course, for high-reflectance materials such as gold, silver, copper, and aluminum, they are also good heat transfer conductors, so laser cutting is difficult and can’t even be cut.

Laser cutting without burr, wrinkle. It’s in high precision, better than plasma cutting.

For many mechanical and electrical manufacturing industry, due to modern laser cutting system controlled by the microcomputer program can easily cut workpieces in different shapes and sizes, it often is preferable than blanking, mold forming process;

Although its processing speed is still slower than the die punch, it has no mold consumption, no need to repair the mold, and also saves the time of replacing the mold, thus saving the processing cost and reducing the production cost. Therefore, it’s much more economical generally.

① The laser cutting incision is narrow, the slits are parallel and perpendicular to the surface, and the dimensional accuracy of the cutting parts can reach ±0.05mm.

② The cutting surface is smooth and beautiful, the surface roughness is only a few tens of micrometers, and even laser cutting can be used as the last process. No machining is required, and the parts can be used directly.

③ After laser cutting, the width of the heat-affected zone is small, the performance of the material near the slit is almost unaffected, and the deformation of the workpiece is small, the cutting precision is high, the geometry of the slit is good, and the shape of the slit cross-section is relatively regular rectangular.

The comparison of laser cutting, oxyacetylene cutting and plasma cutting methods is shown in Table 1.

The cutting material is low carbon steel plate with 6.2mm thickness.

Table 1 laser cutting vs. oxyacetylene cutting vs. plasma cutting

| Cutting Methods | Slit Width /mm | Heat Affected Zone Width /mm | Slit Form | Cutting Speed | Equipment Cost |

|---|---|---|---|---|---|

| Laser cutting | 0.2-0.3 | 0.04-0.06 | Parallel | Fast | High |

| Oxyacetylene cutting | 0.9-1.2 | 0.6-1.2 | Relatively Parallel | Slow | Low |

| Plasma cutting | 3.0-4.0 | 0.5-1.0 | Wedge & Tilt | Fast | Medium |

Due to its transmission characteristics, laser cutting machines typically feature multiple numerical control worktables, allowing for full numerical control over the cutting process.

During operation, different shapes of parts can be cut simply by changing the numerical control program. This allows for both two-dimensional and three-dimensional cutting.

Cutting a 2mm low carbon steel plate with a 1200W fiber laser cutting machine can result in a cutting speed of 600cm/min.

When cutting a 5mm polypropylene resin plate, the cutting speed can reach 1200cm/min.

The material does not need to be clamped or fixed during laser cutting, saving time on fixture preparation and the loading and unloading process.

The laser beam is focused to create a highly concentrated point of energy, which has several key advantages for cutting applications.

First, the laser beam can be transformed into intense thermal energy in a very small area, resulting in:

(1) a narrow, straight cut slit;

(2) a minimal thermal impact zone near the cutting edge;

(3) minimal local deformation.

Second, the laser beam operates without physical contact with the workpiece, making it a non-contact cutting tool, providing the benefits of:

(1) no mechanical deformation of the workpiece;

(2) no tool wear or breakage issues;

(3) the ability to cut any material, regardless of its hardness.

Finally, the laser beam is highly controllable and flexible, leading to:

(1) ease of integration with automation equipment, making it simple to automate the cutting process;

(2) unlimited ability to repeat cuts on the same workpiece;

(3) the ability to optimize material usage by arranging cuts on the entire plate with the help of a computer.

Materials that can be cut using a laser cutting machine include metal matrix composites, leather, wood, and fiber.

However, each material exhibits different levels of adaptability to laser cutting due to its unique thermophysical properties and absorption rates of laser light.

The laser cutting performance of different materials using a CO2 laser source is illustrated in the following table.

| Materials | Ability to absorb laser light | Cutting performance | ||

|---|---|---|---|---|

| Metal | Au, Ag, Cu, Al | Low absorption of laser light | In general, it is more difficult to process, and 1-2mm Cu and Al sheets can be cut by laser. | |

| W,Mo,Cr,Ti | Large absorption of laser light | If low-speed processing is used, the thin plate can be cut, and metals such as single Ti and Zr need to use air as the auxiliary gas. | ||

| Fe,Ni,Pb,Sn | Easier to process | |||

| Non-metal | Organic material | Acrylic, polyethylene, polypropylene, polyester, PTFE | Permeate to incandescence light | Most materials can be cut with a small power laser. Because these materials are flammable, the cut surface is easily carbonized. Acrylic acid and polytetrafluoroethylene are not easily carbonized. Generally, nitrogen or dry air can be used as an auxiliary gas. |

| Leather, wood, cloth, rubber, paper, glass, epoxy, phenolic plastic | Can’t permeate to incandescence light | |||

| Inorganic material | Glass, fiberglass | Large thermal expansion | Glass, ceramics, porcelain, etc. are prone to cracking during or after processing, and quartz glass with a thickness of less than 2 mm has good cutting properties. | |

| Ceramic, quartz glass, asbestos, mica, porcelain | Small thermal expansion | |||

Compared to other traditional machining methods, laser cutting has greater versatility.

Firstly, other thermal cutting methods are unable to cut in such a small area as the laser beam can, leading to wider cuts, larger heat-affected zones, and significant deformation.

Secondly, lasers can cut non-metallic materials, which is not possible with other hot cutting methods.

Cutting with the aid of oxygen results in better outcomes for the material.

When oxygen is utilized as the processing gas, a slight oxidation occurs at the cutting edge. For plates with a thickness of up to 4mm, high-pressure cutting can be performed using nitrogen, resulting in no oxidation of the cutting edge.

For plates with a thickness greater than 10mm, the use of a special plate in conjunction with the laser and applying oil to the surface of the workpiece can enhance the cutting quality.

Oxygen can be used when oxidation at the cutting edge is acceptable. The use of nitrogen results in a non-oxidized cutting edge with no burrs that don’t require further processing.

The application of a coating oil film on the surface of the plate can improve the piercing effect without sacrificing processing quality.

Aluminum, despite its high reflectivity and thermal conductivity, can be cut with a thickness less than 6mm, depending on the alloy type and the laser generator’s capability.

When cutting with oxygen, the cutting surface is rough and hard. Using nitrogen results in a smooth cutting surface.

Pure aluminum is difficult to cut due to its high level of purity.

Only when the system is equipped with a “reflective absorption” device can aluminum be cut, as without it, the optical component will be damaged by reflection.

Titanium plates are cut using argon and nitrogen as processing gases. The other parameters for cutting can be referred to those used for nickel-chrome steel.

Both brass and copper have high reflectivity and excellent thermal conductivity. Brass plates with a thickness of 1mm can be cut using nitrogen as the processing gas.

Copper plates with a thickness of less than 2mm can be cut using oxygen as the processing gas.

However, it’s essential to have a “reflective absorption” device installed on the system, otherwise, the reflection will cause damage to the optical components.

Compared to other thermal cutting methods, laser cutting stands out for its fast cutting speed and high-quality cuts. Some of its key advantages include:

Excellent cutting quality:

Laser cutting has a narrow incision width (typically 0.1-0.5mm), high precision (with a hole center distance error of 0.1-0.4mm and a profile size error of 0.1-0.5mm), and a smooth surface roughness (with a Ra value of 12.5-25μm). Cut seams typically do not require additional processing before welding.

Rapid cutting speed:

For example, a 2KW laser cutter can cut through 8mm thick carbon steel at a speed of 1.6m/min, and 2mm thick stainless steel at a speed of 3.5m/min, with minimal thermal influence and deformation.

Clean, safe, and environmentally friendly:

Laser cutting improves the working environment for operators, as it is clean, safe, and does not create pollution.

See also:

It is summarized as follows:

(1) Good cutting quality.

Because of its small laser light spot and high energy density, laser cutting can achieve better cutting quality.

(1) The laser cutting incisions are narrow, with cutting edges that are parallel and perpendicular to the surface, and the size accuracy of the cut parts can reach + 0.05mm.

(2) The cutting surface is clean and smooth, with a surface roughness of just a few tens of microns. In some cases, laser cutting can even be used as the final step, allowing the parts to be used directly without further machining.

(3) After laser cutting, the area affected by heat is very small, and the properties of the material near the cut are largely unaffected. Additionally, there is minimal workpiece deformation, resulting in high cutting precision and a regular rectangle shape in the cross-section of the cut.

(2) High cutting efficiency.

Due to the characteristics of laser transmission, laser cutting machines typically feature multiple CNC workstations, allowing the entire cutting process to be performed using CNC alone.

In operation, different shaped parts can be cut simply by changing the NC program, and both 2D and 3D cutting can be performed.

(3) Fast cutting speed.

The cutting speed for 2mm mild steel with a 1200W laser cutter can reach 600cm/min, while for a 5mm polypropylene resin plate, the cutting speed can reach 1200cm/min.

The material does not need to be clamped in laser cutting, which not only saves tooling but also reduces the time needed for loading and unloading materials.

(4) Non-contact cutting.

In laser cutting, the cutting torch does not come into contact with the workpiece and there is no tool wear. No replacement of the “cutter” is required for machining parts with different shapes.

The only necessary change is in the output parameters of the laser. Additionally, the laser cutting process is low noise, low in vibration, and does not result in any pollution.

(5) Numerous varieties of cutting materials.

Compared to oxyacetylene and plasma cutting, laser cutting is capable of cutting a wider variety of materials, including metals, non-metals, metal-based and non-metal matrix composites, leather, wood, and fibers.

However, the suitability of laser cutting for these materials varies due to their distinct thermal and physical properties, as well as their differing rates of laser absorption.

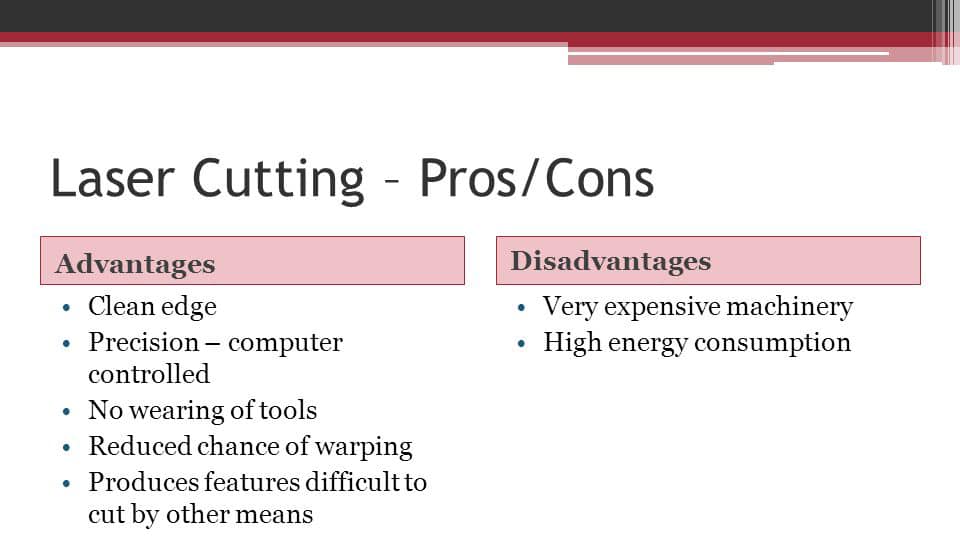

Due to limitations in laser power and equipment size, laser cutters are limited in their ability to cut thicker plate and pipe materials.

As the thickness of the workpiece increases, the cutting speed decreases significantly.

Additionally, laser cutting equipment is expensive, resulting in a high initial investment.

Laser cutting technology has revolutionized metal fabrication, offering a high-precision alternative to conventional cutting methods. With its superior cutting speed and exceptional edge quality, laser cutting has become indispensable in modern manufacturing processes.

In recent years, the advent of fiber laser cutting machines has further enhanced the efficiency and versatility of metal laser cutting operations. These systems offer improved beam quality, higher power outputs, and reduced maintenance requirements compared to their CO2 counterparts.

Assessing the quality of a laser cutter is crucial for ensuring optimal performance and product quality. The cutting quality of the machine serves as a primary indicator of its overall capabilities. Drawing from extensive industry experience and best practices, we have identified nine key criteria that customers can use to evaluate laser cutters effectively. These benchmarks provide a comprehensive framework for assessing machine performance, edge quality, and overall cutting precision.

See also:

Hardware Factors

Parameter Factors

By systematically optimizing these hardware and parameter factors, you can significantly enhance laser cutting quality, achieving cleaner cuts, improved edge finish, and higher overall precision in metal fabrication processes.

Most laser cutting machines are controlled by CNC programs or integrated into cutting robots. As a high-end machining method, laser cutting can cut a wide range of materials, including the 2D or 3D cutting of thin metal sheets.

In the automobile manufacturing industry, laser cutting technology is widely used to cut complex body sheets and various curved parts, such as car roof windows.

For example, Volkswagen AG uses a 500W laser to cut these components. In the aerospace industry, laser cutting technology is mainly used to cut special aviation materials such as titanium alloys, aluminum alloys, nickel alloys, chrome alloys, stainless steel, cerium oxide, composite materials, plastics, ceramics, and quartz.

Aerospace components processed by laser cutting include engine flame tubes, thin-walled titanium alloys, aircraft frames, titanium alloy skins, wing long sterns, tail sidings, helicopter main rotors, and space shuttle ceramic heat insulation tiles.

Laser cutting is also widely used in the non-metallic materials industry. It can cut both hard and brittle materials, such as silicon nitride, ceramics, quartz, as well as flexible materials, such as cloth, paper, plastic sheets, and rubber.

For example, laser cutting can be used in the clothing industry to save 10% to 12% of material and increase efficacy by more than three times.

Products suitable for laser cutting can be generally classified into three categories:

Recent advancements in laser cutting technology include:

See also:

Below are answers to some frequently asked questions:

Fiber laser cutters are highly versatile and capable of cutting a broad range of materials with high precision and efficiency. These materials primarily include various metals and some plastics.

For metals, fiber laser cutters excel in cutting stainless steel up to 0.75 inches (19 mm) thick, carbon steels up to 0.6 inches (15 mm) thick, and galvanized steel up to 0.5 inches (13 mm) thick. They can also handle aluminum and aluminum alloys up to 0.4 inches (10 mm), copper and its alloys up to 0.2 inches (5 mm), titanium up to 0.3 inches (7.6 mm), and nickel alloys up to 0.4 inches (10 mm). The use of assist gases like nitrogen, oxygen, or argon helps manage the cutting process, especially for reflective metals like aluminum and copper.

In terms of plastics, fiber laser cutters can effectively cut materials such as acrylic (PMMA), polyoxymethylene (POM), polypropylene, polyethylene, nylon, and ABS (Acrylonitrile Butadiene Styrene). Each plastic type requires careful power management to prevent issues like melting, warping, or the release of harmful fumes, ensuring a smooth cutting process.

Certain materials are unsuitable for fiber laser cutting, including glass, polyvinyl chloride (PVC), polycarbonate, polystyrene foam, and fiberglass or coated carbon fiber, due to issues like poor wavelength absorption, toxic fume release, and flammability.

Overall, fiber laser cutters offer high precision, fast processing speeds, a low heat-affected zone, and reduced tool wear, making them highly efficient for cutting a variety of metal and some plastic materials.

Fiber laser cutting is highly precise compared to other cutting methods due to several key factors. Fiber laser cutting machines can achieve extremely tight tolerances, often around ±0.003 inches (±0.076 mm) or even as precise as ±0.0005 inches (±0.013 mm) under optimal conditions. This precision is largely attributed to the small beam spot size of fiber lasers, which can be as tiny as 10-30 microns. This results in narrower slits and smaller heat-affected zones, enhancing the accuracy and quality of the cuts.

When compared to other laser cutting technologies, fiber lasers outperform YAG and CO2 lasers in terms of precision. YAG lasers typically offer a process accuracy of around ±0.05 mm, while CO2 lasers have an accuracy of about ±0.1 mm. The superior beam quality of fiber lasers, which approaches the diffraction limit, contributes to smoother and more precise cuts that are not matched by YAG or CO2 lasers.

In contrast to traditional cutting methods like plasma cutting or mechanical tools, fiber laser cutting stands out significantly. Plasma cutting, for instance, generally has a tolerance of ±0.020 inches, which is less precise than fiber laser cutting. The precision of fiber lasers is further enhanced by the use of fiber optic lenses to guide the laser beam, computer-guided systems often integrated with CAD software, and the consistent, intense energy beam produced by fiber lasers.

Fiber lasers are particularly effective for cutting thin to medium-thick metal plates (up to 8 mm) with high speed and accuracy. They are especially favored in industries requiring exacting standards, such as aerospace, electronics, and automotive manufacturing, due to their ability to handle intricate designs and fine details with high precision. Overall, fiber laser cutting is renowned for its superior precision and is a preferred choice for applications where accuracy and quality are critical.

Fiber laser cutting offers several significant advantages over traditional cutting methods. One of the primary benefits is its high precision and accuracy, which allows for extremely fine and detailed cuts with tight tolerances, making it ideal for intricate designs and complex geometries. This precision also ensures minimal material wastage and high-quality finishes, reducing the need for additional processing.

In terms of speed and efficiency, fiber laser cutters operate much faster than traditional methods, significantly increasing productivity and reducing production times. This high-speed capability is particularly evident when cutting thin materials, where fiber lasers can outperform other cutting technologies by a substantial margin.

Energy efficiency is another key benefit. Fiber lasers convert a higher percentage of electrical energy into laser light, resulting in lower power consumption and operational costs. This energy efficiency also translates into a smaller environmental footprint, making fiber laser cutting a more sustainable option.

Fiber laser cutting machines are also known for their versatility, effectively cutting a wide range of materials, including highly reflective metals like aluminum, copper, and brass, which can be challenging for other laser types. This versatility makes them suitable for various industrial applications.

Maintenance and operational costs are lower with fiber lasers due to their solid-state design, which involves fewer moving parts and consumables. This leads to reduced downtime and lower maintenance expenses, further enhancing their cost-effectiveness.

The compact design of fiber laser cutting machines saves valuable floor space in manufacturing environments, making them an ideal choice for facilities with space constraints. Additionally, the stable and advanced technology used in fiber lasers ensures consistent performance and reliability.

Overall, fiber laser cutting provides superior precision, speed, energy efficiency, versatility, and lower operational costs, making it an advantageous choice over traditional cutting methods for many industrial applications.

The cost of fiber laser cutting machines generally tends to be higher compared to other types of laser cutting machines due to their advanced technology and superior capabilities. Fiber laser cutters, optimized for cutting metals with high precision and speed, typically range from $20,000 to $500,000. This price variation is influenced by factors such as power output (ranging from 500W to over 20kW), size of the cutting bed, and specific features tailored for industrial applications.

In contrast, CO2 laser cutting machines, which are more commonly used for non-metal materials like wood, acrylic, and fabric, have a lower price range of approximately $8,000 to $50,000. Entry-level CO2 machines can be found for less than $5,000, while high-end models reach up to $50,000.

Diode laser cutters, suitable for both beginner and intermediate operations, are more affordable, with prices ranging from $5,000 to $20,000. Nd: YAG laser cutters, known for their versatility in cutting various materials including metals and plastics, have a price range between $40,000 and $300,000.

When considering operating and maintenance costs, fiber laser machines generally offer lower operating expenses compared to CO2 lasers. For example, a 4kW fiber laser system has an average per-hour cost of $6.24, compared to $12.73 per hour for a 4kW CO2 laser cutter. Additionally, fiber lasers typically require less maintenance due to fewer moving parts, further reducing long-term costs.

Overall, while fiber laser cutters have a higher initial investment, their efficiency, precision, and lower operating costs can provide significant long-term value, especially for businesses focused on cutting metals.

The latest trends in fiber laser cutting technology are marked by significant advancements in power, precision, automation, and sustainability. High-power fiber lasers, capable of operating at up to 80 kW, allow for faster cutting speeds and the handling of thicker materials with exceptional accuracy, making them ideal for demanding industries such as aerospace and heavy manufacturing. Beam-shaping technology has also improved, focusing the laser beam on smaller diameters to minimize heat-affected zones and material distortion, resulting in cleaner cuts.

Adaptive optics are another trend, enabling real-time adjustments to the laser beam for variations in material thickness and environmental conditions, thus enhancing cutting accuracy and speed. Automation and integration are becoming more prevalent, with smart software packages and dynamic cutting algorithms streamlining workflows and optimizing performance. The incorporation of robotics is increasing productivity and reducing labor costs by automating loading systems and production processes.

Artificial intelligence and machine learning are poised to revolutionize fiber laser cutting by allowing machines to optimize settings based on historical data and predict the most efficient cutting paths. This technology promises to reduce waste and increase output. The versatility of fiber lasers is expanding as well, with the ability to cut a variety of high-tech materials like composites and alloys, crucial for advanced manufacturing sectors.

Sustainability is a growing focus, with energy-efficient machines that consume less power while maintaining high performance, aligning with environmental goals. The market for laser cutting machines is expected to grow significantly, driven by the adoption of fiber laser technology and the demand for precision engineering solutions. Overall, these trends highlight the continuous evolution of fiber laser cutting technology towards greater efficiency, adaptability, and environmental responsibility.