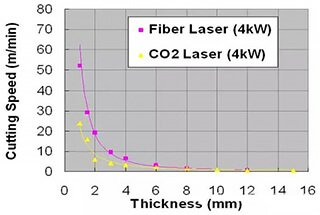

Imagine cutting through metal as effortlessly as slicing through butter. Fiber laser technology has revolutionized metalworking, offering unmatched precision and speed. This article explores the cutting speeds of various metals using IPG fiber laser sources, from 1000W to 6000W. Readers will gain insights into optimal settings for different materials and thicknesses, ensuring efficiency and quality in their cutting processes. Dive into the specifics to elevate your metal fabrication skills!

Remarks:

Note: The following chart provides approximate cutting speeds based on material type and thickness. Actual performance may vary depending on specific machine configurations, material properties, and desired cut quality.

| Material | Thickness (mm) | IPG 1000 | IPG 1500 | IPG 2000 | IPG 2000 | IPG 3000 | IPG 4000 | IPG 6000 |

|---|---|---|---|---|---|---|---|---|

| Core Dia | ||||||||

| 50um | 100um | 50um | 100um | 100um | 100um | 100um | ||

| (m/min) | ||||||||

| Carbon Steel (O2) | 1 | 7.0-9.0 | 7.0-11.0 | 7.0-12.0 | 7.0-12.0 | 7.0-12.0 | 8.0-12.0 | 8.0-12.0 |

| 2 | 5.0-6.0 | 5.0-6.5 | 5.0-6.5 | 5.0-6.5 | 5.0-7.0 | 5.0-7.5 | 5.0-7.5 | |

| 3 | 2.5-3.0 | 2.8-3.8 | 3.0-4.6 | 3.0-4.6 | 3.5-5.0 | 3.8-5.0 | 3.8-5.0 | |

| 4 | 2.0-2.4 | 2.5-3.2 | 2.8-4.0 | 2.8-4.0 | 3.0-4.2 | 3.5-4.5 | 3.5-4.5 | |

| 5 | 1.5-1.8 | 1.8-2.5 | 2.2-3.2 | 2.2-3.2 | 2.5-3.6 | 3.0-3.8 | 3.0-3.8 | |

| 6 | 1.4-1.6 | 1.6-2.2 | 2.0-2.8 | 2.0-2.8 | 2.4-3.0 | 2.6-3.2 | 2.6-3.2 | |

| 8 | 1.0-1.2 | 1.1-1.5 | 1.4-2.0 | 1.4-2.0 | 1.8-2.4 | 2.0-2.5 | 2.0-2.5 | |

| 10 | 0.75-0.85 | 1.0-1.2 | 1.1-1.4 | 1.1-1.4 | 1.2-1.8 | 1.8-2.1 | 1.8-2.1 | |

| 12 | 0.6-0.7 | 0.9-1.0 | 0.9-1.2 | 0.9-1.2 | 1.0-1.5 | 1.0-1.5 | 1.0-1.5 | |

| 16 | 0.60-0.75 | 0.60-0.75 | 0.7-0.85 | 0.7-0.85 | 0.7-0.85 | |||

| 20 | Can’t Cutting | 0.4-0.5 | 0.6-0.75 | 0.6-0.75 | 0.6-0.75 | |||

| 22 | 0.50-0.65 | 0.55-0.65 | 0.55-0.65 | |||||

| 25 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | |||||

| Stainless Steel (N2) | 1 | 15-18 | 10.0-15.0 | 35.0-50.0 | 20.0-28.0 | 35.0-50.0 | 45.0-55.0 | 45.0-55.0 |

| 2 | 4.5-6.0 | 5.0-7.0 | 10.0-15.0 | 9.0-13.0 | 15.0-23.0 | 18.0-27.0 | 20.0-35.0 | |

| 3 | 2.0-2.4 | 3.0-4.0 | 5.0-7.0 | 4.0-6.5 | 7.0-11.0 | 10.0-15.0 | 15.0-20.0 | |

| 4 | 1.0-1.5 | 2.0-2.8 | 3.5-4.5 | 3.0-4.5 | 4.0-6.0 | 5.0-7.5 | 10.0-14.0 | |

| 5 | 0.75-0.85 | 1.2-1.7 | 1.8-2.5 | 1.8-2.5 | 2.5-4.0 | 4.0-5.0 | 8.0-12.0 | |

| 6 | 0.7-1.0 | 0.7-0.8 | 1.2-1.8 | 2.0-3.2 | 3.0-4.0 | 6.0-8.0 | ||

| 8 | 0.5-0.7 | 0.5-0.6 | 0.7-1.0 | 1.2-1.8 | 1.5-2.6 | 3.5-4.0 | ||

| 10 | 0.5-0.6 | 0.7-0.9 | 0.7-1.3 | 1.8-2.2 | ||||

| 12 | 0.3-0.4 | 0.4-0.6 | 1.2-1.5 | |||||

| 14 | 0.3-0.5 | 0.8-1.2 | ||||||

| 16 | 0.3-0.5 | 0.6-0.8 | ||||||

| 20 | 0.3-0.4 | |||||||

| Aluminum Alloy (N2) | 1 | 10.0-15.0 | 30.0-45.0 | 13.0-25.0 | 30.0-38.0 | 35.0-40.0 | 45.0-55.0 | |

| 2 | 5.0-6.0 | 10.0-15.0 | 7.0-10.0 | 12.0-16.0 | 13.0-22.0 | 20.0-30.0 | ||

| 3 | 2.5-3.5 | 5.0-7.0 | 4.0-6.0 | 6.5-8.0 | 7.0-13.0 | 13.0-18.0 | ||

| 4 | 1.4-2.0 | 3.5-5.0 | 2.5-3.5 | 3.5-5.0 | 4.0-5.5 | 10.0-12.0 | ||

| 5 | 0.8-1.0 | 2.0-3.0 | 1.4-1.8 | 2.5-3.5 | 3.0-4.0 | 5.0-8.0 | ||

| 6 | 0.5-0.6 | 1.5-2.0 | 0.8-1.2 | 1.8-3.0 | 2.2-3.5 | 4.0-6.0 | ||

| 8 | 0.5-0.6 | 0.6-0.8 | 0.9-1.3 | 0.9-1.6 | 2.0-3.0 | |||

| 10 | 0.4-0.7 | 0.55-1.0 | 1.0-1.9 | |||||

| 12 | 0.3-0.45 | 0.4-0.6 | 0.8-1.4 | |||||

| 16 | 0.3-0.4 | 0.6-0.9 | ||||||

| Copper (N2) | 1 | 8.0-12.0 | 12.0-18.0 | 10.0-16.0 | 20.0-32.0 | 25.0-30.0 | 45.0-55.0 | |

| 2 | 3.5-5.0 | 6.0-8.5 | 6.0-8.0 | 9.0-11.0 | 10.0-13.0 | 25.0-35.0 | ||

| 3 | 1.5-2.2 | 2.5-4.0 | 2.5-4.0 | 4.0-6.0 | 5.0-6.5 | 12.0-18.0 | ||

| 4 | 1.0-1.2 | 1.5-1.8 | 1.6-2.2 | 3.0-4.5 | 3.0-5.2 | 8.0-10.0 | ||

| 5 | 0.6-0.8 | 0.8-1.2 | 0.9-1.2 | 1.5-2.0 | 2.0-3.0 | 4.5.0-6.0 | ||

| 6 | 0.4-0.5 | 0.4-0.7 | 1.0-1.6 | 1.4-2.0 | 3.0-4.0 | |||

| 8 | 0.5-0.6 | 0.7-0.8 | 1.6-2.2 | |||||

| 10 | 0.2-0.3 | 0.8-1.2 | ||||||

| Stainless Steel (High pressure air) | 1 | 35.0-50.0 | 20.0-28.0 | 35.0-50.0 | 45.0-55.0 | 45.0-55.0 | ||

| 2 | 10.0-15.0 | 9.0-12.0 | 15.0-23.0 | 18.0-27.0 | 20.0-35.0 | |||

| 3 | 5.0-7.0 | 4.0-6.0 | 7.0-11.0 | 10.0-15.0 | 15.0-20.0 | |||

| 4 | 3.5-4.5 | 3.5-4.0 | 4.0-6.5 | 5.0-6.5 | 10.0-14.0 | |||

| 5 | 1.8-2.5 | 1.5-2.0 | 2.5-4.0 | 3.5-5.0 | 8.0-12.0 | |||

| 6 | 0.7-0.8 | 1.0-1.2 | 2.0-3.2 | 3.0-4.5 | 6.0-8.0 | |||

| 8 | 1.2-1.8 | 1.5-2.6 | 3.5-4.0 | |||||

| 10 | 0.7-0.9 | 0.6-1.2 | 1.8-2.2 | |||||

| 12 | 1.2-1.5 | |||||||

| Aluminum Alloy (Air) | 1 | 30.0-45.0 | 13.0-25.0 | 35.0-50.0 | 45.0-55.0 | 45.0-50.0 | ||

| 2 | 10.0-16.0 | 7.0-12.0 | 12.0-20.0 | 18.0-27.0 | 20.0-30.0 | |||

| 3 | 5.0-7.0 | 4.0-6.0 | 6.5-9.0 | 9.0-14.0 | 13.0-18.0 | |||

| 4 | 3.5-5.0 | 2.5-4.0 | 4.0-5.5 | 4.5-6.5 | 10.0-12.0 | |||

| 5 | 2.0-3.0 | 1.4-1.8 | 2.5-3.5 | 3.5-5.0 | 5.0-8.0 | |||

| 6 | 1.2-2.0 | 0.8-1.5 | 1.8-3.0 | 3.0-4.0 | 4.0-6.0 | |||

| 8 | 0.9-1.3 | 1.5-2.0 | 2.0-3.0 | |||||

| 10 | 0.7-0.8 | 0.5-0.8 | 1.0-1.9 | |||||

| Copper (Air) | 1 | 18-28.0 | 13.0-22.0 | 25.0-36.0 | 18.0-35.0 | 35.0-45.0 | ||

| 2 | 8-12.0 | 6.0-10.0 | 7.0-10.0 | 10.0-15.0 | 15.0-30.0 | |||

| 3 | 1.5-2.5 | 2.5-5.0 | 5.0-6.0 | 6.0-7.5 | 10.0-15.0 | |||

It’s crucial to optimize cutting parameters for each specific application, considering factors such as material composition, surface condition, and required edge quality. Regular maintenance of the laser system, including proper alignment and lens cleaning, is essential for consistent cutting performance.