Have you ever wondered what keeps precision machining parts securely in place during processing? Fixture clamps play a crucial role in ensuring stability and accuracy. This article highlights ten essential types of fixture clamps used in machining, from the traditional chuck to advanced pneumatic cylinder clamps. By the end, you’ll understand how each type of clamp works and its unique benefits, enabling you to choose the right one for your specific needs.

This particular type of fixture clamp was once very popular but has now declined in popularity due to the advent of indexing spindle. Consequently, it is now ranked tenth in terms of usage.

The pneumatic fixture clamp is considered the essence of automatic clamping fixtures and is highly favored by workers among the many types of fixture clamps available.

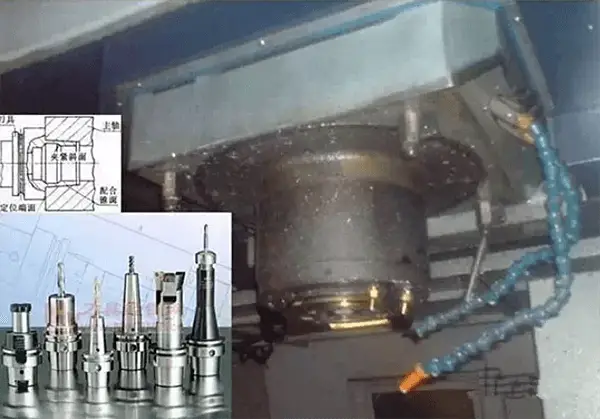

If you are facing the challenge of clamping various tools with fewer handles, here are some possible solutions you can consider.

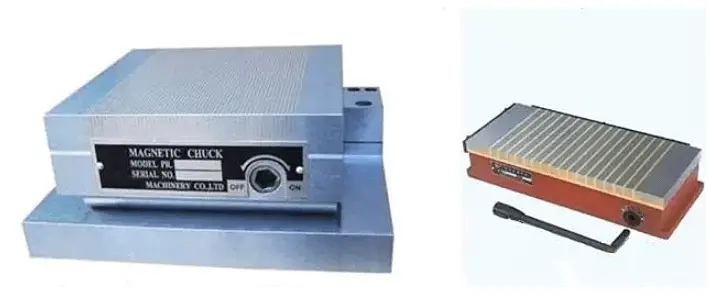

If you need to process parts that don’t have a specific clamping position on the workbench, there are some techniques you can use to make it easier. Let’s take a look at how it can be done.

The spindle and tool holder represent the pinnacle of human ingenuity and cutting-edge technology.

If a workpiece cannot be securely held down by the pressure plate, it may be necessary to consider clamping it using a vise or a custom fixture designed for maximum stability.

This device ensures a repeat positioning accuracy of ±0.002mm, making it indispensable for electrode work, four-axis machining, and even more so for five-axis machining.

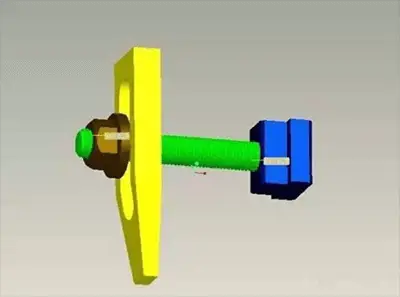

While you may be able to enhance other fixtures, installing them on a milling machine or machining center without utilizing a combination of T-blocks, screws, pressure plates, and nuts can be quite challenging. If you’re skeptical, give it a try.

It may seem unimportant in everyday situations, but if you suddenly discover that your machine tool lacks a T-shaped worktable, you may find yourself in a difficult situation.

The century-old fixture still finds use in mechanical workshops, and its classic status is undeniable. In fact, there are more chucks than lathes in many workshops, as without a chuck, lathes are rendered useless.