Have you ever thought about the precision required in tightening flange bolts? Proper technique can prevent leaks and ensure safety in high-pressure systems. This article delves into essential methods for inspecting and fastening flange bolts correctly. By following these guidelines, you’ll learn how to achieve a secure and efficient flange connection, crucial for maintaining system integrity and avoiding costly failures. Read on to discover the key steps in achieving optimal bolt tensioning and enhancing your mechanical installations.

● Gasket: When installing, make sure that the gasket is new and clean, and check whether the gasket has defects or damage.

Old gaskets cannot be reused. Before installation, confirm that the size and grade of the gasket used are consistent with the identification of the flange.

● Flange: Check whether the flange surface is damaged before installation, such as scratches, inscriptions, mud, corrosion, and burrs.

When the depth of dents or scratches that pass through the radial sealing surface watermark line of the flange exceeds 0.2mm and the covering surface exceeds half the sealing surface width of the gasket, the flange must be replaced or the sealing surface needs to be re-machined and repaired.

The back nut support surface position of the flange should be parallel and smooth. Check whether the flange is centered, and the inspection method should follow the pipeline installation requirements in SH3501-2011.

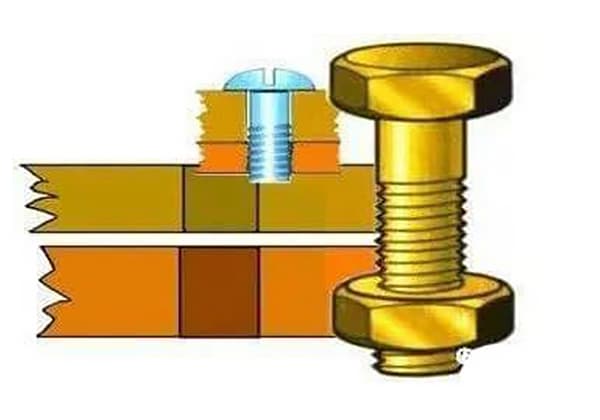

● Bolts and nuts: Check whether the bolts and nuts are used correctly according to the equipment and pipeline design requirements.

The threads and contact surfaces shall not have external substances such as dirt, rust, heavy skin, inscriptions, burrs, debris, and others that affect torque during tightening.

Welding or machining methods are not allowed to repair bolts. After the flange is installed and tightened, at least two threads should be exposed outside the nut.

Bolts and nuts must be lubricated before use to reduce the friction coefficient during bolt tightening, and to improve the anti-slip and anti-corrosion properties of bolts and nuts.

The threads of stud bolts, nut threads, and contact surfaces must be degreased and dried before using lubricating oil.

The bolt threads, nut threads, nut bearing surfaces, washers, and nut support surfaces on flanges should use the same lubricating oil properly. High-temperature anti-seizing agents should be used as needed.

● Non-torque spanner or striking spanner: Suitable for general equipment and pipeline flange tightening. Select according to bolt size and flange pressure level.

The fastening requirements are as follows:

Tighten the two bolts that are radially opposite to the predetermined hammering load of the bolts.

Tighten another pair of bolts that are about 90 degrees from the previous two bolts along the circumference.

Continue to tighten until all remaining bolts are tightened to the predetermined hammering load.

● Torque wrench: Suitable for important equipment and pipeline flanges with high temperature, high pressure, flammable and explosive properties, etc.

The fastening requirements are as follows:

Tighten the two bolts that are radially opposite to the predetermined torque of the bolts.

Tighten another pair of bolts that are about 90 degrees from the previous two bolts along the circumference.

Continue to tighten until all remaining bolts are tightened to the predetermined torque.

● Bolt tensioner: Suitable for important equipment and pipeline flanges with high temperature, high pressure, flammable and explosive properties, etc.

The fastening requirements are as follows:

(1) Perform thermal tightening according to the temperature in Table 1.

Table 1: Temperature for Thermal and Cold Tightening of Equipment and Pipeline, Unit: ℃

| Working temperature | Primary hot and cold tightening temperature | Secondary hot and cold tightening temperature |

| 250~350 | working temperature | / |

| >350 | 350 | working temperature |

| -70~-29 | working temperature | / |

| <-70 | -70 | working temperature |

Note: The hot and cold tightening cannot be carried out for working temperature between -29~250℃.

(2) Hot or cold tightening should be carried out after the equipment and pipeline temperature has stabilized. Use explosion-proof tools and do not perform operations such as heating and pressurizing during tightening.

(3) For tightening, it is recommended to start from the largest gap between flanges and tighten symmetrically. If there is leakage, first tighten the leak.

(4) During the equipment and pipeline temperature rising process, it is necessary to carry out quality inspection for tightening. Use torque wrench according to 100% torque value or use explosion-proof hammer to check whether the nut is loose in the tightening direction.