Imagine if you could enhance your machining efficiency while ensuring high precision and versatility. Flexible positioning fixtures might be the game-changer you’re looking for. These modular components offer unparalleled flexibility, allowing you to quickly adapt to various workpieces and reduce downtime significantly. In this article, you’ll discover how these fixtures work, their benefits, and practical applications. Dive in to see how you can streamline your machining processes and boost productivity.

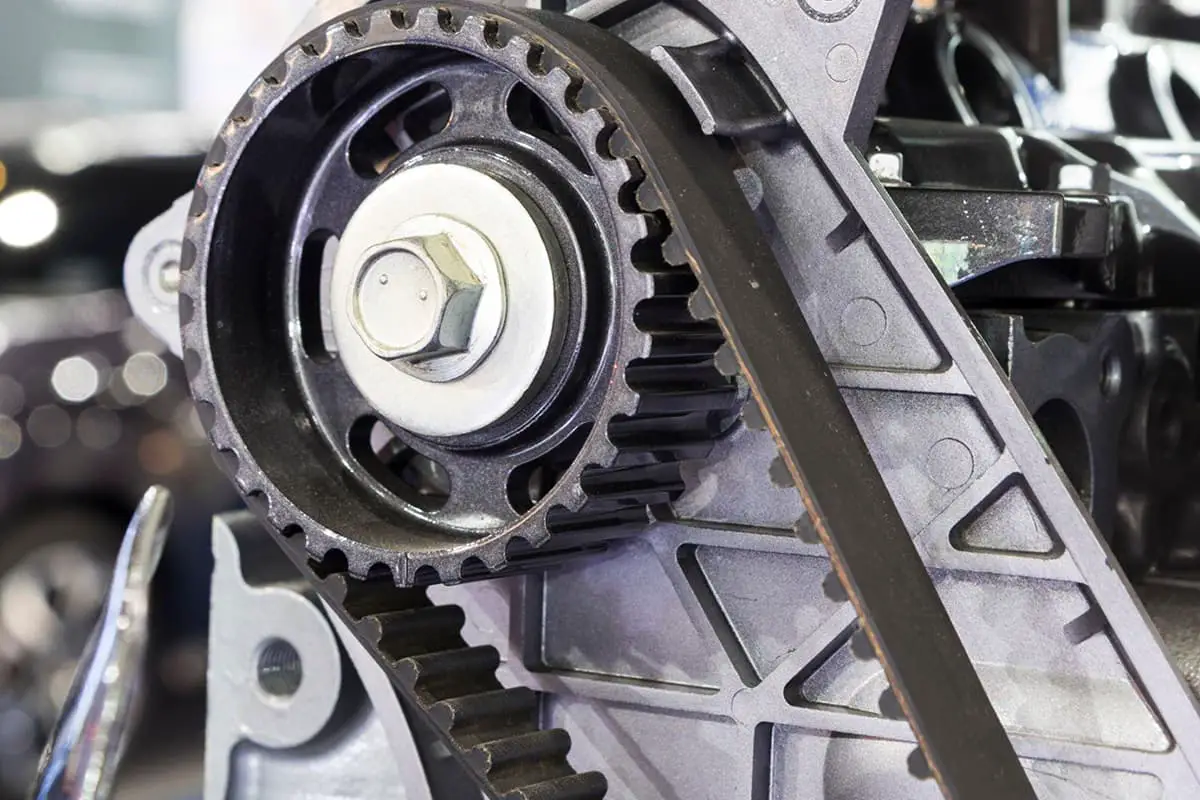

A flexible positioning fixture is a system assembled from a pre-manufactured set of serialized, standardized components and parts of various shapes, sizes, and functionalities.

These flexible fixture components and parts possess good interchangeability, high precision, and durability.

Flexible positioning fixtures can be used individually or in combination with other components, and the proportion of their multi-functional modular units will continue to increase.

For example, the various positioning and clamping seats, positioning and pressure support, precision vices, and other modular units currently in use have comprehensive functions of positioning, clamping, and adjustment.

They can be used individually or assembled together. T-shaped bases and square boxes can assemble into flexible fixtures that can clamp multiple identical or different workpieces at once.

Using these fixtures can reduce the downtime of machine tools and maximize the high efficiency of CNC and machining center machine tools.

To improve labor productivity and shorten processing time for workpieces, machining has progressed towards high speed and large cutting volume, with highly concentrated processes. After a workpiece is positioned and clamped, it needs to sequentially complete multiple processes such as milling, drilling, and boring.

The size and direction of the cutting force are constantly changing, which requires the flexible positioning fixture itself to have high usage strength and rigidity to meet the machining precision of the workpiece.

The multifunctionality of modern processing equipment necessitates a highly concentrated technological process, where a workpiece can complete multiple operations after being fixed and positioned once. This requires a universal, reusable, and adjustable welding fixture system.

This system consists of a series of uniform and standardized components and parts, which can be assembled into various forms, structures, and reusable fixtures for single-piece or small and medium batch production.

This fixture system maintains the various advantages of combinational fixtures, with assembly as simple and reliable as dedicated fixtures, and adjustable components preserving the benefits of group fixtures.

For easy flexible positioning of the fixture and machine tool, the fixture base has a standardized positioning connection location, promoting the development towards integration and combination of dedicated, combinational, and group fixtures to meet the needs of modern processing equipment.

To reduce auxiliary time in workpiece processing and lessen worker’s labor intensity, the installation and disassembly of workpieces require mechanization and automation.

Workpiece clamping has evolved from single-function compression and fastening components to adjustable modules for quick assembly and clamping. For large-batch workpiece processing, hydraulic and pneumatic fixtures can achieve automated rapid clamping.