Have you ever wondered how to shape metal plates into cones, spheres, or tubes with precision? This article delves into the four-roller plate bending machine, an essential tool in metalworking. We’ll explore its structure, from the fixed upper roller to the hydraulically-driven lower and side rollers, and discuss crucial precautions for safe operation. By the end, you’ll understand how to use this machine effectively while ensuring safety and accuracy. Read on to discover more about this fascinating process.

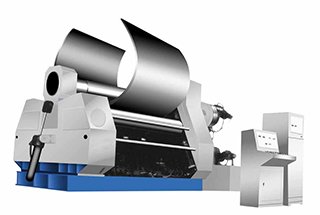

The Plate Rolling Machine is a commonly used forging equipment that can shape metal plates into cone, spherical, or tubular forms, among other shapes.

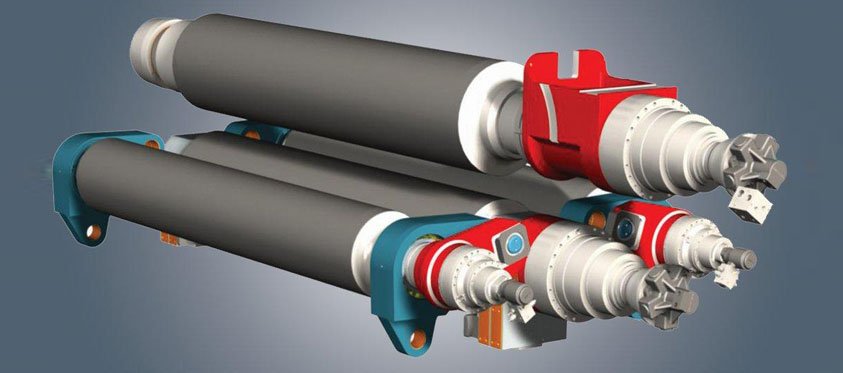

The machine is called “four rolls” due to its four rolls.

What is the structure of the Four Rolls Plate Rolling Machine?

What precautions should be taken when using the machine?

Let’s explore these topics further.

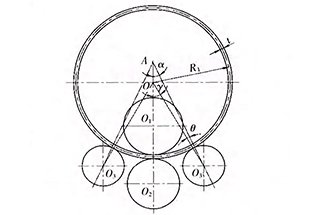

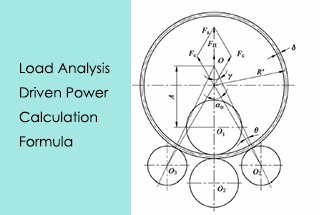

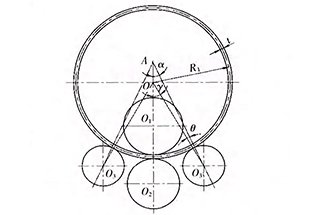

The upper roller of a four-roller plate bending roll is a drive roller, while the lower roller and the side roller are slave-driven rollers.

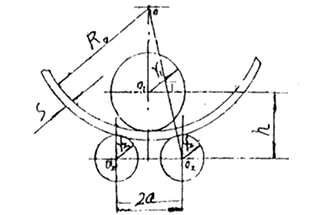

The position of the upper roller is fixed, while the bottom and side rollers can be lifted and moved.

The upper roller is driven by a hydraulic motor, while the rotation of the lower and side rollers is driven by the friction between the steel plate and the rollers.

Both the lower roller and the side roller are lifted through the oil cylinders on both ends.

The reversal of the front bearing body of the upper roller is carried out by a reverse oil cylinder. Both the roller bearing bodies and oil cylinders are mounted on the left and right ends of the frame.

The left and right frame are the main body of the four-roll machine and the entire base is installed with a welding structure.

As for the pushing device, after the workpiece has been rolled, the overturned oil cylinder pushes it out when it is turned into place.

The machine’s entire operation is conducted on the operating table.

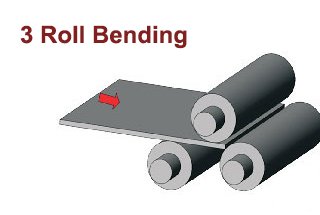

The rollers of the four-roller rolling machine can clamp the steel plate to prevent sliding during bending.

The side roller can position the steel plate, allowing it to be calibrated during feeding. This makes it easy to bend tapered, elliptical, and other shapes.

The steel plate cannot be reversed during pre-bending and circular rolling on the four-roll bending machine.

If abnormal machine noise, shock, vibration, electrical leakage, or high temperature (>60℃) is detected in the hydraulic oil, motor, or bearings, the machine must be immediately stopped for inspection.

When checking the roundness with a sample, it must be done after the rolling machine has stopped.

It is strictly prohibited to extend one’s head while rolling the steel plate.

Machine operators must stand on the sides of the rolling steel plate and must not stand in front of or behind the plate bending rolls (upper roller’s effective working surface). No one should stand on the plate during the rolling process to prevent the steel plate from stretching out or falling off and causing harm to people.

The specifications of the rolled sheet must not exceed the limits specified in the equipment specifications and capacity chart.

The pressure of the roller must not be adjusted without proper authorization.

The operator must constantly monitor the operating conditions.

All rolled sheets must be rolled in the center of the roller and skidding is not allowed during the rolling process.

During the rolling process, the operator must constantly observe various operating conditions and the sheet must not slip out of the roller. The worksite must not be entered by outsiders.

When tipping the frame, the horizontal direction of the upper roller must be in the middle position, and it can be overturned when the vertical direction is at the highest point. The upper roller must not be moved horizontally when it is in contact with the lower roller.

When initial welding is performed on the cylinder of the rolling machine, the ground wire of the welding machine must be in good contact with the cylinder body.