Imagine a critical component failing unexpectedly, leading to catastrophic consequences. This is where fracture mechanics comes into play. This article explores the basics of fracture mechanics, highlighting how understanding crack propagation and material resistance can prevent such failures. By examining the stages of component fracture and the classification of fracture mechanics, readers will gain insights into designing safer, more reliable products. Discover the science behind why materials break and how engineers can mitigate these risks.

(1) In 1969, a catastrophic incident occurred during a U.S. F-111 aircraft’s flight training exercise. While performing a bomb dropping recovery maneuver, the aircraft’s left wing suddenly detached, resulting in a crash. This failure was particularly alarming as the aircraft was operating well within its design parameters, with flight speed, total weight, and g-force loads significantly below the specified limits.

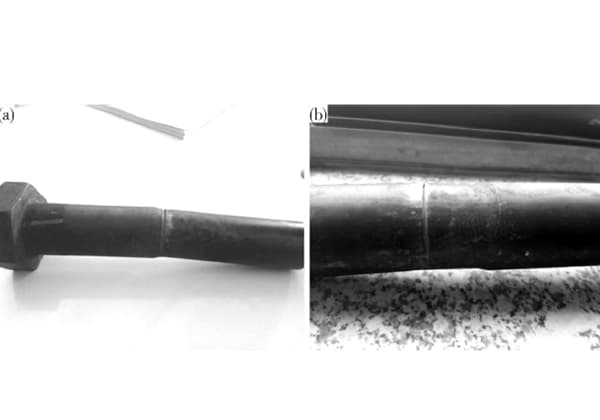

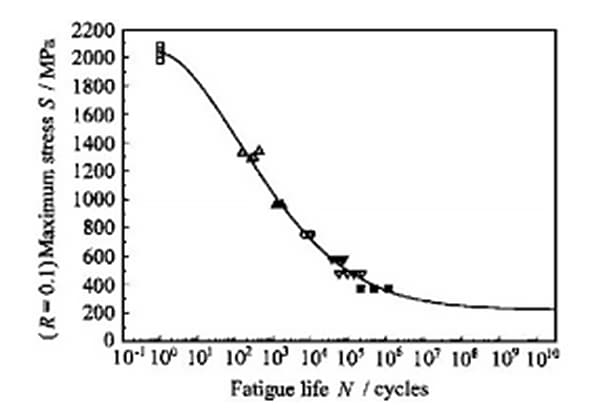

Subsequent forensic analysis revealed a critical defect in the wing pivot, traced back to improper heat treatment during the manufacturing process. This metallurgical flaw created a stress concentration point, initiating a fatigue crack. Despite routine inspections, the crack propagated insidiously under cyclic loading conditions, eventually leading to a low-stress brittle fracture. This incident underscores the critical importance of stringent quality control in heat treatment processes and the need for advanced non-destructive testing methods in aerospace manufacturing.

(2) During World War II, the United States embarked on an ambitious shipbuilding program, producing 2,500 Liberty ships. However, this rapid production was marred by a series of structural failures: 700 vessels suffered serious damage, and 145 experienced catastrophic hull fractures, splitting into two sections. Most alarmingly, some of these failures occurred in calm seas, despite the use of high-strength steel in construction.

A comprehensive failure analysis revealed two primary factors contributing to these incidents:

These findings led to significant advancements in naval architecture, welding techniques, and material science, including the development of notch-tough steels and improved welding procedures to mitigate stress concentrations.

(3) The Hasselt Bridge, colloquially known as the “feline bridge” due to its distinctive arch shape, collapsed catastrophically in 1938 in Belgium. The bridge, which spanned the Albert Canal, fractured into three sections, highlighting a critical failure in structural engineering and material selection.

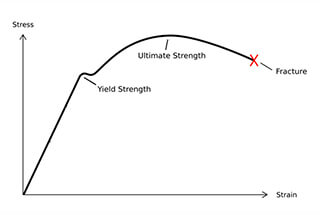

Fracture mechanics is a critical field of study that investigates the behavior of materials containing cracks or flaws. Extensive research has consistently demonstrated that brittle fractures in materials and structures are primarily initiated by macroscopic cracks. The presence of such defects is often unavoidable in real-world engineering applications due to manufacturing processes, environmental factors, or in-service loading.

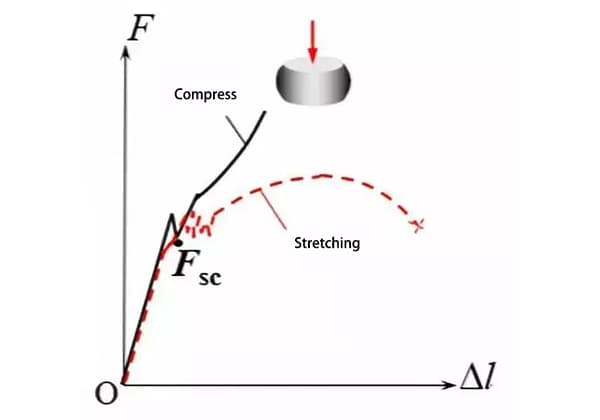

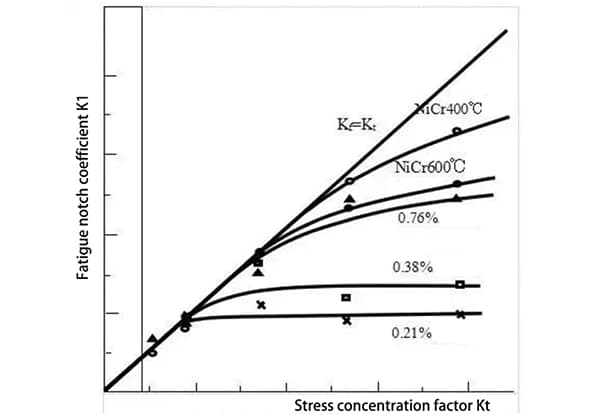

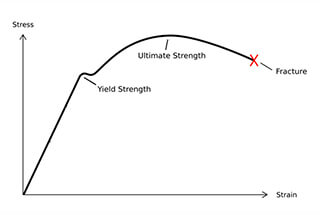

The strength and integrity of a material containing cracks are fundamentally linked to its inherent resistance to crack propagation. This resistance is governed by various intrinsic material properties, including fracture toughness, yield strength, and microstructural characteristics. Understanding these properties is crucial for predicting material behavior under different loading conditions and designing structures with improved fracture resistance.

Fracture mechanics employs advanced analytical techniques, combining elastic and plastic theories with cutting-edge experimental methodologies. This approach enables researchers and engineers to quantitatively analyze the stress and strain fields surrounding crack tips, which are critical regions where fracture initiation and propagation occur. Additionally, fracture mechanics investigates crack growth laws, providing insights into how cracks evolve under various loading scenarios.

Key aspects of fracture mechanics include:

(1) Crack Initiation:

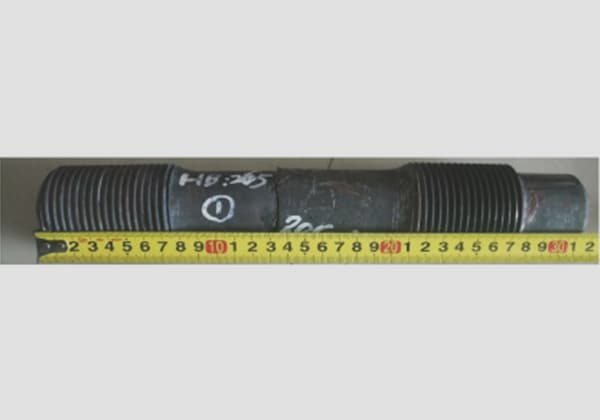

Macro and microscopic cracks originate at stress concentration points within a structure due to various environmental factors, including cyclic loading (fatigue), corrosive environments, applied stresses, and temperature fluctuations.

Inherent material defects, such as inclusions, voids, or grain boundary imperfections, can serve as nucleation sites for cracks.

Manufacturing processes and fabrication techniques may inadvertently introduce flaws or residual stresses that lead to crack formation.

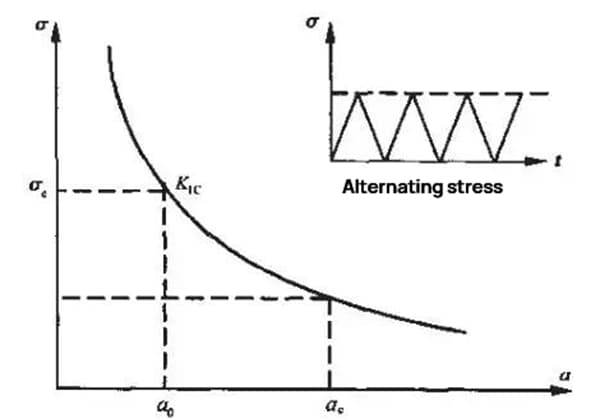

(2) Subcritical Crack Growth:

During the component’s service life, macro and microscopic cracks gradually propagate under the combined influence of environmental factors and applied stresses. This stage is characterized by slow, stable crack growth, often governed by mechanisms such as stress corrosion cracking or fatigue crack propagation.

(3) Critical Crack Length:

As the crack continues to grow, it approaches a critical length specific to the material and loading conditions. At this point, the stress intensity at the crack tip reaches a critical value (fracture toughness), and the component becomes unstable.

(4) Rapid Crack Propagation:

Once the critical crack length is exceeded, unstable crack growth occurs. The crack propagates at extremely high velocities, typically ranging from 0.2 to 0.4 times the material’s speed of sound. This phase is characterized by rapid energy release and often accompanied by audible sounds.

(5) Crack Arrest or Complete Fracture:

The final stage of fracture can result in two outcomes:

a) Complete Fracture: The unstable crack propagates through the entire structure, leading to catastrophic failure and separation of the component.

b) Crack Arrest: Under certain conditions, such as encountering regions of higher fracture toughness, reduced stress intensity, or energy-absorbing features, the crack may decelerate and stop before complete separation occurs.

Fracture mechanics can be broadly categorized into two main branches: macroscopic fracture mechanics and microscopic fracture mechanics. This classification is based on the scale at which fracture phenomena are analyzed and the underlying principles applied.

Macroscopic fracture mechanics, which deals with observable crack behavior at the structural level, can be further subdivided into several specialized fields:

Microscopic fracture mechanics, on the other hand, investigates fracture processes at the microstructural level, considering factors such as grain boundaries, dislocations, and atomic bonds. This approach is essential for understanding the fundamental mechanisms of crack initiation and propagation, and it often employs advanced techniques like molecular dynamics simulations and in-situ electron microscopy.

Fracture mechanics is a specialized branch of materials science and engineering that investigates the complex processes involved in material failure due to crack initiation and propagation. This discipline systematically analyzes the behavior of materials containing pre-existing flaws or cracks under various loading conditions. Through rigorous experimental methodologies and theoretical modeling, fracture mechanics quantifies a material’s resistance to fracture, known as fracture toughness, and elucidates the fundamental laws governing the entire fracture process.

The primary objectives of fracture mechanics include:

By bridging the gap between theoretical concepts and practical applications, fracture mechanics provides invaluable tools for engineers to design products with enhanced safety margins, optimize maintenance schedules, and develop more efficient non-destructive testing methods. This field continues to evolve, incorporating advanced computational techniques and addressing emerging challenges in new materials and complex loading scenarios.