Have you ever wondered about the differences between galvanized iron and galvanized steel? In this article, we’ll dive into the intricacies of these two materials, exploring their unique properties, applications, and corrosion resistance. Our expert mechanical engineer will guide you through the key distinctions, providing valuable insights to help you make informed decisions for your projects.

Galvanized iron and galvanized steel exhibit some differences in material properties, areas of application, and processing capabilities.

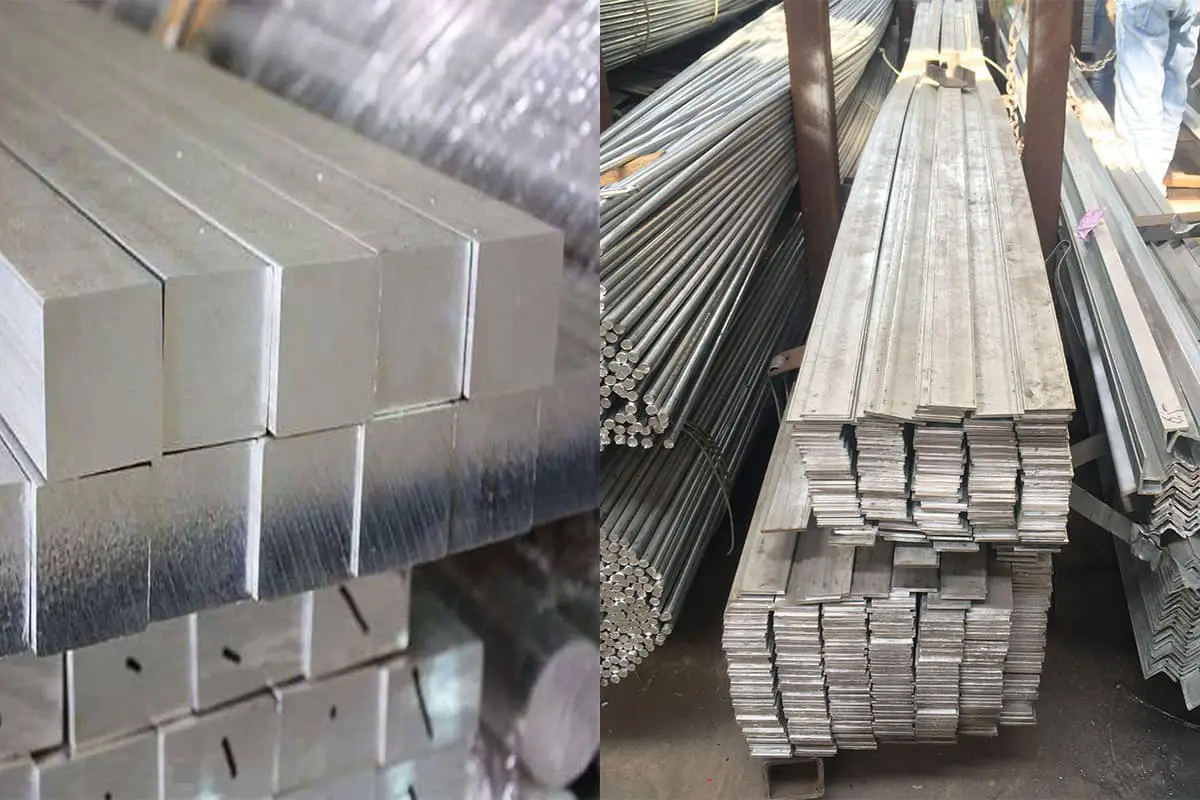

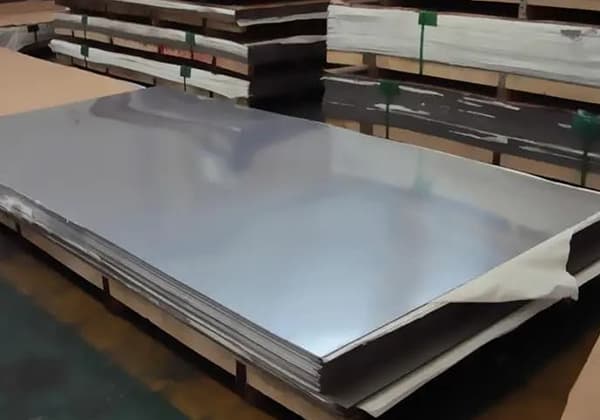

First, in terms of material composition, galvanized iron is a low-carbon steel sheet coated with zinc on the surface; its thickness generally ranges between 0.44 to 1.2 millimeters, with a zinc layer thicker than 0.02 millimeters.

Galvanized steel, on the other hand, is a welded steel plate with a surface hot-dip galvanized or electroplated zinc layer, which can be divided into ordinary electrolytic plates and fingerprint-resistant electrolytic plates. This indicates that galvanized iron is primarily made of low-carbon steel, while galvanized steel may incorporate different types of steel, such as ordinary steel or steel treated in a specific manner.

Second, in terms of corrosion resistance and ductility, galvanized iron is virtually rust-resistant and has strong corrosion resistance and ductility. Galvanized steel plates can effectively prevent steel corrosion, extending their lifespan, and they exhibit excellent paintability, decorativeness, and good formability. This implies that while both have good rust-proof capabilities, galvanized steel plates perform better in terms of decorativeness and formability.

Finally, looking at carbon content, galvanized steel wire holds a carbon content of 0.40-0.80%, while galvanized iron has a carbon content of 0.05-0.25%. This difference results in variations in their strength; due to its higher carbon content, galvanized steel wire possesses relatively higher strength.

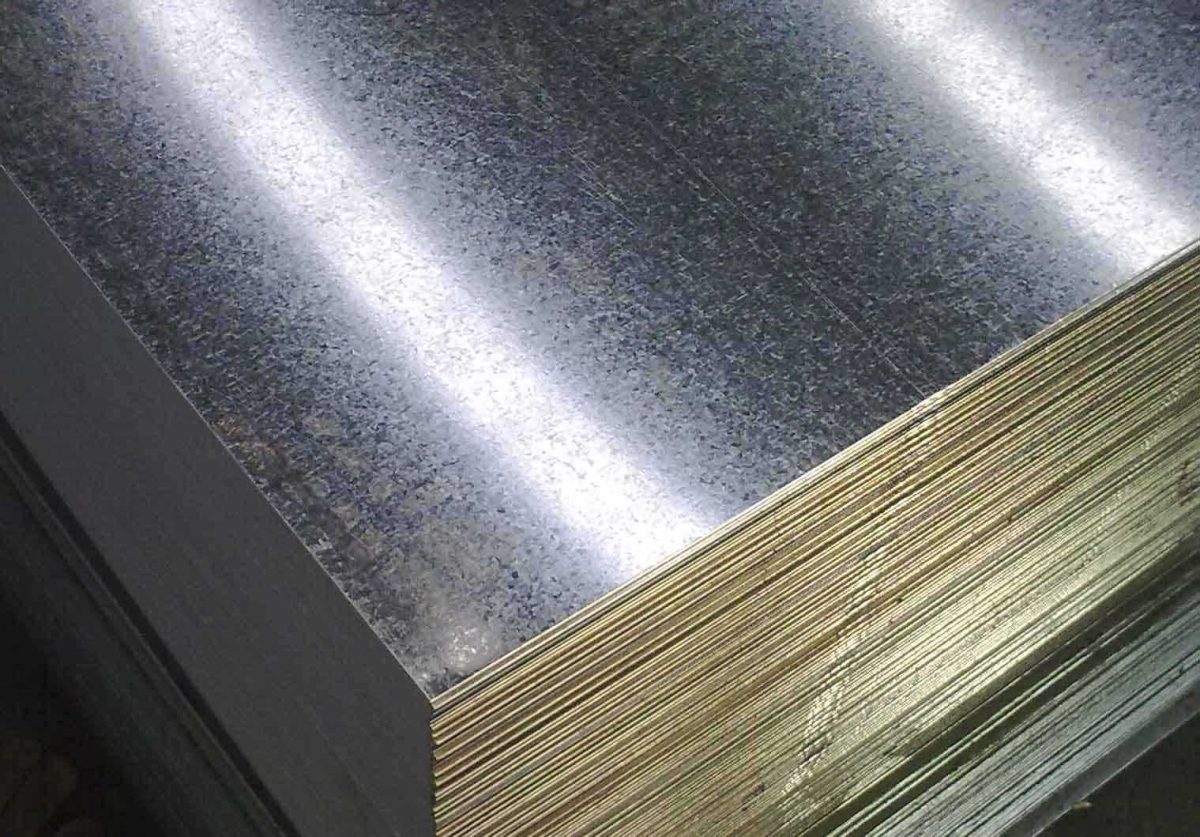

Galvanized steel is a type of steel that has been coated with a layer of zinc to enhance its corrosion resistance and durability. This protective zinc layer prevents the steel, which primarily consists of iron, from rusting when exposed to moisture or humidity. The process of galvanization provides a barrier against environmental elements, extending the lifespan of the steel and making it suitable for various applications.

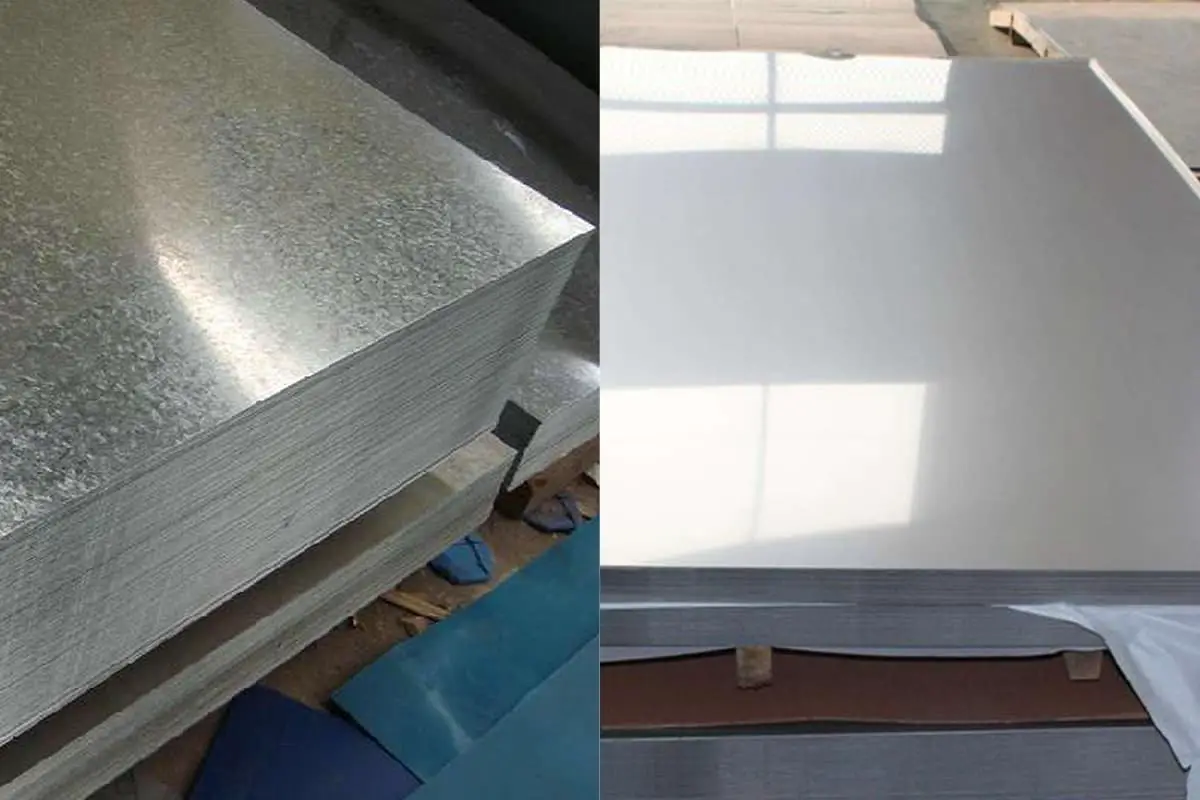

The most common method of applying the zinc coating to steel is through hot-dip galvanization. In this process, the steel is immersed in a bath of molten zinc at a temperature of approximately 860°F (460°C). The interaction between the molten zinc and the steel forms a metallurgical bond. This bond occurs as the zinc reacts with the iron in the steel, creating a series of zinc-iron alloy layers. Once exposed to the atmosphere, a zinc oxide layer forms on top, further enhancing the protective qualities.

Other methods of galvanization include:

The zinc coating acts as both a barrier and a sacrificial anode. A sacrificial anode is a metal that corrodes preferentially, protecting the underlying steel from rust even if the coating is damaged.

Galvanized steel is widely used across multiple sectors due to its enhanced properties:

The combination of its protective zinc coating, durability, and versatility makes galvanized steel an essential material in numerous applications, providing long-term benefits and reliability.

Galvanized iron is a type of iron that has been coated with a protective layer of zinc to enhance its resistance to corrosion and extend its durability. This zinc coating serves as a barrier against environmental elements that can cause rust and degradation, thereby preserving the integrity of the iron underneath.

Galvanizing iron primarily aims to protect it from corrosion. Iron is highly susceptible to rust when exposed to moisture and oxygen. Coating it with zinc shields the iron from direct exposure to these elements, significantly reducing the rate of corrosion. The zinc layer also provides sacrificial protection; even if the coating is damaged, the zinc will corrode preferentially, protecting the iron.

The most common method of galvanizing iron is through hot-dip galvanizing. This process involves several key steps:

Apart from hot-dip galvanizing, other methods are also used to coat iron with zinc. These alternative methods might be chosen based on specific application requirements or cost considerations.

Galvanized iron boasts several advantages over untreated iron:

Galvanized iron is utilized in a variety of industries and applications due to its enhanced properties:

In summary, galvanized iron combines the strength of iron with the protective qualities of zinc, making it a versatile and reliable material suitable for numerous applications across various industries.

Galvanization is a critical process in the manufacturing of metals, aimed at enhancing their durability and resistance to corrosion. By applying a protective zinc coating, metals such as steel and iron gain significantly improved performance in various environmental conditions. This chapter delves into the composition and manufacturing processes of galvanized steel and iron, highlighting their differences, applications, and benefits.

Galvanized steel consists primarily of carbon steel coated with a layer of zinc. The zinc coating provides enhanced corrosion resistance, making galvanized steel ideal for various applications, including construction, automotive, and infrastructure. The typical composition includes:

Galvanized iron is similar to galvanized steel, featuring a zinc coating to prevent rust and increase durability. The key components are:

Galvanized steel and iron are used in various applications due to their enhanced durability. Galvanized steel is commonly used in construction (e.g., roofing, beams), automotive parts, and outdoor structures due to its strength and longevity. Galvanized iron is often used in smaller-scale applications such as piping, wiring, and some types of fencing.

The steel surface is prepared by thoroughly cleaning it to remove impurities, ensuring proper adhesion of the zinc coating:

The cleaned steel is dipped into a flux solution containing zinc ammonium chloride, preventing oxidation before galvanization and ensuring a better bond between the zinc and steel.

The steel is submerged in a bath of molten zinc, heated to around 860°F (460°C). The zinc reacts with the steel, forming a series of zinc-iron alloy layers with a pure zinc outer layer.

The coated steel is removed from the zinc bath and allowed to cool, solidifying the zinc coating. The steel is inspected for uniformity and thickness, with any imperfections corrected to ensure coating integrity.

The iron surface is cleaned to remove impurities that could interfere with the zinc coating adhesion:

The cleaned iron is dipped into a flux solution containing zinc ammonium chloride, preventing oxidation before galvanization and ensuring a strong bond between the zinc and iron.

The fluxed iron is immersed in a bath of molten zinc, heated to around 860°F (460°C). The zinc reacts with the iron, forming a series of zinc-iron alloy layers topped with a pure zinc layer.

After coating, the iron is removed from the zinc bath and allowed to cool. The zinc coating solidifies, and the iron is inspected to ensure a consistent and uniform coating.

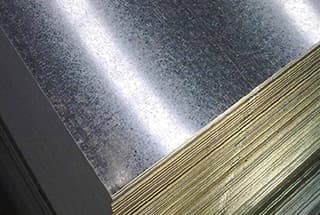

Zinc coatings significantly enhance the lifespan of steel and iron by providing a protective barrier against corrosion. Studies show that galvanized steel can last up to 50 years in rural environments and 20-25 years in coastal or industrial settings. This extended lifespan reduces maintenance costs and increases the overall value of galvanized materials.

Using galvanized steel and iron offers notable environmental and economic benefits. The extended lifespan of these materials reduces the need for frequent replacements, conserving resources and reducing waste. Additionally, the reduced maintenance costs contribute to overall economic savings for various industries.

Apart from hot-dip galvanizing, other methods apply zinc coatings to both steel and iron:

These alternative methods may be chosen based on specific application requirements, cost considerations, or desired coating characteristics.

This chapter explores the corrosion resistance of galvanized steel and galvanized iron. It delves into the mechanisms behind their corrosion resistance, compares their performance in various environments, and discusses their durability and maintenance requirements. The aim is to provide a comprehensive understanding of how these materials perform under different conditions, supported by real-world examples and specific data.

The corrosion resistance of galvanized steel and galvanized iron is primarily due to their zinc coatings. Zinc acts as a barrier, preventing moisture and oxygen from reaching the underlying metal. Additionally, zinc provides sacrificial protection, meaning it corrodes in place of the base metal if the coating is damaged.

Galvanized steel is known for its robust corrosion resistance due to several factors:

Galvanized iron also benefits from a zinc coating, though its performance can vary:

The effectiveness of galvanized steel and galvanized iron can vary based on environmental conditions.

In rural areas with low pollution and humidity, both galvanized steel and galvanized iron can last several decades without significant corrosion. The zinc coating remains largely intact, providing long-term protection.

In urban and industrial areas with higher pollution levels, the corrosion resistance of both materials is challenged by acidic compounds and particulate matter. Galvanized steel, with its thicker zinc coating and additional alloy layers, typically performs better under these conditions.

Coastal and marine environments pose the greatest challenge due to high salt content and humidity. In these settings, galvanized steel, especially grades with thicker zinc coatings or additional alloying elements (such as galvannealed steel), offers superior protection compared to standard galvanized iron. The presence of salt accelerates corrosion, making the thickness and quality of the zinc coating crucial.

Examples of real-world applications illustrate the performance of these materials:

Specific data from corrosion tests and industry standards highlight the durability of these materials:

In summary, both galvanized steel and galvanized iron offer significant corrosion resistance due to their zinc coatings. However, galvanized steel generally provides superior performance and longevity, especially in harsh or highly corrosive environments. The choice between the two materials should consider specific application requirements, environmental conditions, and desired maintenance levels.

Galvanized steel and iron are materials coated with a layer of zinc to protect them from corrosion and rust. This galvanization process extends their lifespan and enhances their durability, making them ideal for various industrial, commercial, and residential applications. Below is a detailed exploration of their uses across different sectors.

Galvanized steel is a cornerstone in the construction industry due to its robustness and resistance to environmental factors.

The automotive sector relies heavily on galvanized steel for manufacturing components that are both durable and corrosion-resistant.

In infrastructure projects, galvanized steel provides long-lasting and maintenance-free solutions.

Galvanized steel is also prevalent in various consumer products, offering durability and aesthetic appeal.

Galvanized iron is widely used in construction for its cost-effectiveness and corrosion resistance.

In the agricultural sector, galvanized iron is valued for its robustness and resistance to rust.

Galvanized iron is used in the automotive and transportation industries for various components.

Galvanized iron is employed in decorative and architectural applications, combining functionality with aesthetic appeal.

Both galvanized steel and galvanized iron offer versatile and practical solutions across various industries. Galvanized steel is preferred for its superior strength and wider range of applications, while galvanized iron provides a cost-effective alternative for specific uses. The choice between the two materials depends on environmental conditions, required durability, and budget considerations.

When deciding between galvanized steel and galvanized iron, cost is a significant factor. The cost differences arise from the base materials, the galvanization process, and the end-use requirements.

The cost of galvanization also varies depending on the method used:

The practicality of using galvanized steel or galvanized iron depends on several factors, including the specific application, environmental conditions, and maintenance requirements.

When evaluating cost and practicality, it is essential to consider not just the initial purchase price but also the long-term cost implications.

In conclusion, both galvanized steel and galvanized iron offer distinct advantages in terms of cost and practicality. The choice between the two should be based on a careful assessment of the specific application requirements, environmental conditions, and long-term cost implications.

Technical specifications are detailed documents that outline the requirements, guidelines, and instructions for designing, developing, and implementing a product, system, or process. They provide a clear and comprehensive description of the features, functionalities, and performance characteristics of a technical solution, ensuring that all stakeholders understand the project’s goals and requirements.

Effective technical specifications for galvanized steel and galvanized iron typically include several key components:

This section provides an overview of the project, outlining the goals, objectives, and intended outcomes of using galvanized materials. It defines the extent of the work, the materials involved, and the standards that must be adhered to.

This section describes the features and functionalities the galvanized product must include. For galvanized steel and iron, this might involve specifying the thickness of the zinc coating, the type of galvanization process used, and the expected performance benchmarks in terms of corrosion resistance and durability.

This section outlines the design specifications for the galvanized product, including dimensions, tolerances, and any specific design elements. It may also cover the visual appearance, such as the finish and coating uniformity.

This section specifies the industry standards and protocols that must be followed. Common standards for galvanized steel and iron include:

This section details the testing and validation procedures to ensure the galvanized product meets the specified requirements. It includes test plans, test cases, and acceptance criteria. Common tests for galvanized materials include:

This section provides information on delivery dates, packaging, and handling requirements. It ensures that the galvanized materials are delivered in good condition and ready for installation or further processing.

This section outlines the warranties, maintenance agreements, and technical support available for the galvanized product. It ensures that the product will be supported throughout its lifecycle, with clear guidelines for maintenance and repair.

In military procurement, technical specifications for galvanized materials can be categorized into several types:

These documents establish uniform technical requirements for military-unique or substantially modified commercial processes. Types of defense standards include:

In the construction industry, technical specifications for galvanized materials are often organized into 50 divisions or broad categories of work types and work results. Each section is subdivided into “general,” “products,” and “execution” parts. Specifications can be performance-based, prescriptive, or proprietary, and they may allow for substitutions or be closed to specific products and vendors.

Standard Technical Specifications (STS) are published for various types of nuclear reactors and include criteria for improving technical specifications based on policy statements and federal regulations. These specifications are continuously updated with approved generic changes known as “Travelers.”

Technical specifications can also approach the level of detail and completeness of international standards but may not have passed through all approval stages. These are known as Technical Specifications (TS) and are developed according to consensus procedures. Publicly Available Specifications (PAS) are used to speed up standardization in rapidly evolving technologies and respond to urgent market needs.

Technical specifications and standards are crucial for ensuring that projects involving galvanized steel and iron are completed on time, within budget, and to the highest quality standards. They help in:

Hot-dip galvanizing involves immersing steel or iron in molten zinc, creating a robust and durable coating. The advantages include strong corrosion resistance and a long lifespan. However, the process can be more costly and requires handling of molten zinc.

Electro-galvanizing involves applying a zinc coating using an electric current. This method allows for a thinner and more uniform coating. It is less expensive and suitable for smaller items. However, it offers lower corrosion resistance compared to hot-dip galvanizing.

Technical specifications must address potential challenges such as:

In a large infrastructure project, specifying ASTM A123/A123M for hot-dip galvanized steel ensured the bridge components met stringent corrosion resistance requirements, extending the structure’s lifespan.

Using electro-galvanized steel in vehicle manufacturing provided a cost-effective solution for corrosion protection, meeting industry standards while maintaining product quality.

Detailed guidelines for long-term care include:

By adhering to these comprehensive technical specifications and standards, projects involving galvanized steel and iron can achieve superior quality, reliability, and longevity.

Galvanized steel is known for its exceptional resistance to corrosion. The zinc coating serves as a protective barrier, preventing moisture and oxygen from reaching the underlying steel. This makes it ideal for outdoor applications like fencing, roofing, and gutters, which are constantly exposed to the elements. For example, galvanized steel is often used in the construction of highway guardrails due to its ability to withstand harsh weather conditions and resist rusting.

The galvanization process greatly enhances the durability and longevity of steel. Galvanized steel can last over 50 years in rural environments and more than 25 years in urban and coastal areas, which are more corrosive. This extended lifespan is due to the zinc coating’s resistance to wear and tear, making it a reliable choice for long-term projects such as bridges, street lighting poles, and agricultural structures like grain silos.

Galvanized steel requires minimal maintenance compared to untreated steel. Beyond occasional cleaning to remove dirt and debris, the material needs little upkeep. The smooth surface of the zinc coating makes it easy to inspect and maintain, and any damage to the coating is usually visible, allowing for quick and effective repairs. This low maintenance requirement makes galvanized steel an economical option for infrastructure projects where regular maintenance is challenging.

While the initial cost of galvanized steel may be higher than untreated steel, it proves to be cost-effective over time. The extended lifespan and reduced need for maintenance result in significant long-term savings. Additionally, the galvanization process is generally less labor-intensive compared to other protective methods, further reducing costs. For instance, in the construction of water treatment plants, galvanized steel is often chosen for its durability and cost-effectiveness over the structure’s lifespan.

Inspecting galvanized steel is straightforward and efficient. The zinc coating can be visually examined for uniformity and integrity, and its thickness can be tested using non-destructive methods like magnetic gauges or X-ray fluorescence. This ease of inspection ensures that any potential issues can be identified and addressed promptly, maintaining the material’s protective qualities.

Galvanized steel has a smooth, rust-free finish that is both aesthetically pleasing and protective. The zinc coating, combined with advanced chemical processing, results in a smooth appearance that enhances the material’s visual appeal while protecting it from contamination by other chemicals and harmful substances. This makes it a popular choice for architectural elements where both appearance and durability are important.

One of the primary drawbacks of galvanized steel is its higher initial cost compared to untreated steel or other coated metals such as aluminum. This higher cost can be prohibitive for projects with limited budgets or for short-term applications where long-term durability is not a priority. For example, in temporary construction projects, the added expense of galvanized steel might not be justified.

While the zinc coating effectively prevents external rusting, it does not protect the steel from internal corrosion. Over time, the zinc barrier can deteriorate, leading to internal corrosion, which can cause leaks or failures in structures such as pipes and tanks. In plumbing systems, this internal corrosion can lead to significant issues if not properly managed.

As galvanized pipes corrode, minerals and lead from the exposed metal can leach into the water supply, potentially contaminating it. This can result in the formation of plaques that restrict water flow and pose health risks. In residential plumbing, this is a significant concern, leading to a preference for alternative materials like copper or plastic in modern installations.

The galvanization process involves the use of toxic chemicals and can produce hazardous waste, raising environmental concerns. This is particularly relevant during the production and disposal phases of galvanized steel, necessitating proper handling and disposal methods to mitigate environmental impact. Sustainable practices and recycling are essential to address these concerns.

Galvanized steel has a distinctive look that may not be suitable for all design schemes. In projects where aesthetics are a priority, the appearance of galvanized steel might be a drawback, prompting the need for additional coatings or treatments to achieve the desired look. For instance, in high-end architectural projects, the industrial appearance of galvanized steel may not meet the desired aesthetic standards.

If the galvanization process is not conducted correctly, it can result in inadequate protection and premature corrosion. Ensuring that the process is carried out by credible and experienced providers is crucial to achieving the desired protective qualities. Poor-quality galvanization can lead to significant structural issues, undermining the material’s benefits.

While galvanized steel generally requires less maintenance than untreated steel, it still needs regular care to ensure the longevity of the zinc coating. Damage to the coating can compromise its protective properties, making periodic inspections and maintenance essential to maintain its effectiveness. In industrial applications, regular maintenance schedules are critical to ensure the material’s continued performance.

Galvanized iron is known for its durability, significantly extending the lifespan of iron structures. The zinc coating, applied through the galvanization process, acts as a protective layer. For example, galvanized iron can last up to 50 years in rural environments and 20 to 25 years in urban and coastal areas. This makes it a reliable choice for long-term applications such as highway guardrails and utility poles.

The zinc coating on galvanized iron serves as a sacrificial layer, which means it corrodes before the underlying iron. This sacrificial protection is particularly effective because zinc corrodes at a slower rate than iron. The zinc layer reacts with environmental elements like moisture, forming a patina that further protects the iron beneath. This property is beneficial in construction and agricultural settings, where exposure to moisture and chemicals is common.

Galvanized iron is often more affordable than other protective methods like painting or powder coating. The initial cost is relatively low, and the long-term savings on maintenance and replacement can be substantial. For example, using galvanized iron for fencing or roofing in agricultural projects can save farmers from frequent replacements and repairs, reducing overall costs.

The smooth finish of the zinc coating on galvanized iron allows for easy inspection for damage or corrosion. The zinc layer can be visually examined, and its thickness tested with simple, non-destructive methods. This ease of inspection helps in identifying and addressing any issues promptly, ensuring the integrity of the iron remains intact. For instance, a visual inspection of galvanized iron pipes can quickly reveal areas needing attention.

Galvanized iron is versatile and suitable for a wide range of applications, from construction and agriculture to automotive and decorative uses. Its balance of durability, corrosion resistance, and cost-effectiveness makes it a preferred material in many industries. For example, it is commonly used in the automotive industry for parts like frames and chassis due to its strength and resistance to rust.

While the zinc coating protects the iron from external corrosion, it does not prevent internal corrosion. Over time, the zinc barrier can degrade, allowing the iron to corrode from the inside out. This internal corrosion can lead to leaks or failures in structures such as pipes and tanks, posing significant risks in certain applications.

As galvanized iron pipes corrode, they can release minerals and lead into the water supply, causing contamination and reducing water flow over time. This issue is particularly problematic in plumbing applications, where the release of harmful substances can affect water quality and pose health risks.

Although galvanized iron is cost-effective in the long run, the initial cost can be higher than some other materials like cold-rolled steel or untreated iron. This can be a disadvantage for short-term projects where the higher upfront cost may not be justified.

Galvanized iron pipes and components are rigid and can be difficult to work with in applications that require flexibility. This limitation makes them less suitable for installations where pipes need to navigate around obstacles or fit into tight spaces. In such cases, more flexible materials like plastic or copper may be preferred.

While galvanized iron is durable, it still requires regular maintenance to ensure its longevity. Internal rust and mineral buildup can occur, necessitating frequent inspections and upkeep. Replacing sections of galvanized iron pipes or components can also be costly and labor-intensive.

The quality of the galvanization process can vary depending on the method and the company providing the service. Incorrect processing can lead to a less effective zinc coating, reducing the overall durability and corrosion resistance of the iron. Ensuring that the galvanization process is carried out by reputable providers is crucial to achieving the desired protective qualities.

Galvanized iron is not lightweight, which can make it more difficult to handle, transport, and install compared to lighter materials like aluminum. This added weight can increase labor and transportation costs, particularly in large-scale projects.

When choosing galvanized iron for your projects, ensure you select reputable galvanization providers to guarantee the quality of the zinc coating. Regularly inspect the zinc coating for signs of wear or damage, and address any issues promptly to maintain the integrity of the iron. Consider the specific requirements of your application, such as the need for flexibility or weight constraints, to determine if galvanized iron is the most suitable material.

Below are answers to some frequently asked questions:

The main differences between galvanized steel and galvanized iron are based on their base materials, properties, and typical applications.

Galvanized steel is steel that has been coated with a protective layer of zinc. Steel itself is an alloy primarily composed of iron and carbon, with additional elements like manganese, chromium, and vanadium. This zinc coating provides enhanced corrosion resistance without significantly altering the steel’s inherent strength and physical properties. Galvanized steel is widely used in industries such as construction, aerospace, automotive, and oil & gas, where both structural integrity and resistance to environmental degradation are essential.

Galvanized iron, on the other hand, is iron that has been coated with zinc. Unlike steel, iron is predominantly composed of the metal element iron with minimal or no carbon content. This zinc coating also imparts corrosion resistance to iron. However, iron is generally softer and more malleable than steel, lacking the added strength and durability that carbon provides. Galvanized iron is often used in applications where high strength is not critical, but corrosion resistance is important. Common uses include nails, bolts, framing components, plumbing, and infrastructure exposed to moisture.

Both materials undergo the hot-dip galvanization process, where they are submerged in molten zinc, but their base material differences result in varying properties and applications. While both gain significant corrosion resistance from the zinc coating, the underlying material’s properties influence the overall durability and lifespan.

Galvanized steel is generally more resistant to corrosion compared to galvanized iron. Both materials gain their corrosion resistance from a zinc coating applied through the galvanization process, which acts as a protective layer against rust and corrosion. However, the underlying base material plays a significant role in their overall performance.

Galvanized steel, being a type of carbon steel, has higher tensile strength and durability. This makes it more suitable for applications that require both high strength and resistance to wear and tear. The zinc coating on galvanized steel can provide long-lasting protection, especially in less aggressive environments, with a potential lifespan of up to 70 years.

On the other hand, galvanized iron, while still benefiting from the protective zinc coating, does not offer the same level of inherent strength and durability as galvanized steel. It is typically used in applications where high strength is not the primary requirement, such as pipes, stakes, sheeting, and wire.

The corrosion resistance of both materials is influenced by the thickness of the zinc coating and the environmental conditions they are exposed to. In highly corrosive environments, such as those with high humidity or exposure to acidic substances, the zinc coating can degrade more quickly.

In summary, galvanized steel tends to be more resistant to corrosion and more durable overall due to its stronger base material and the enhanced properties provided by the galvanization process. However, both galvanized steel and galvanized iron can offer excellent corrosion resistance when properly coated and maintained.

Yes, galvanized iron, particularly in the form of galvanized steel, is extensively used in construction projects due to its numerous benefits and versatile applications. Its primary advantage lies in its durability and corrosion resistance, which is achieved through a protective zinc coating. This coating ensures that the material remains strong and intact even in harsh environmental conditions, making it an ideal choice for building structures.

Galvanized steel is commonly used for structural support in framing buildings such as apartments, office buildings, stadiums, and museums. It provides a robust and corrosion-free framework, especially when used in conjunction with concrete. Additionally, it is employed in reinforcing roads and bridges, where its ability to withstand harsh conditions and maintain integrity over time is crucial.

For outdoor applications, galvanized steel is used in fencing, gutters, rails, tubing, poles, and other structural elements due to its resistance to weathering and corrosion. Its aesthetic appeal also makes it popular in modern architectural designs for features like balconies, verandahs, staircases, and walkways.

In industrial processes, galvanized steel is utilized for forming complex machinery and reinforcing concrete structures, ensuring stability and safety. It also offers environmental and economic benefits, being made from recycled steel and requiring less maintenance due to its long-lasting nature.

Specific applications include creating strong barriers and fences with galvanized iron wire and reducing damage and maintenance needs in telecommunications through the use of galvanized steel in phone wiring and equipment boxes.

In summary, galvanized iron is a highly versatile and beneficial material in construction projects, providing durability, corrosion resistance, aesthetic appeal, and economic advantages.

Galvanized steel, known for its enhanced corrosion resistance and durability, finds widespread use across various industries. In construction, it is utilized for structures like bridges, train lines, balconies, staircases, and other outdoor elements, as well as highway guardrails, structural framing, roofing, and cladding. The automotive industry employs galvanized steel for car body panels, chassis components, and exhaust systems, with electrogalvanized steel favored for its smooth finish and paint adherence. In aerospace, its durability and corrosion resistance make it suitable for outdoor and harsh environments. The solar and wind energy sectors use it for mounting structures, wind turbine towers, and solar panel systems due to its ability to withstand continuous exposure to environmental elements. In telecommunications, galvanized steel is essential for cell towers, cable support systems, and equipment enclosures. Agriculture benefits from its use in farm buildings, livestock equipment, and irrigation systems, where resistance to corrosion is crucial. HVAC systems rely on galvanized steel for ductwork, ventilation systems, air handling units, and other components. Outdoor structures and fittings, such as ladders, walkways, fences, and sidings, also utilize galvanized steel for its durability in environmental exposure. Additionally, it is used for hardware and fasteners like nuts, bolts, tools, and wires, extending their lifespan by preventing rust and corrosion. Industrial and consumer products, including lighting fixtures, grain bins, metal fans, and fuel tanks, benefit from the material’s longevity and resistance to corrosion. Overall, the versatility and protective properties of galvanized steel make it a preferred material for applications demanding durability and longevity.

The cost of galvanized steel and galvanized iron is generally comparable, primarily because the main expense is associated with the zinc coating process used to protect against corrosion. The initial galvanizing cost for both materials is similar, focusing more on the zinc than the base metal itself. Production costs for galvanized steel are competitive due to efficiencies in the hot-dip galvanizing process, which is commonly used for both steel and iron.

Considering life-cycle costs, both materials benefit from the durable zinc coating, though galvanized steel is often noted for its longer service life and lower maintenance costs, which can offer long-term savings. Specific applications, location, and market conditions can affect the cost, but these factors typically influence both materials similarly.

Overall, there is no significant difference in the cost structure between galvanized steel and galvanized iron. Both materials are cost-effective for corrosion protection, with galvanized steel sometimes having an edge due to its potential for longer-term cost benefits.

When comparing the long-term use costs of galvanized iron and galvanized steel, several factors need to be considered, including initial costs, maintenance expenses, lifespan, and the impact of environmental factors on corrosion rates.

Firstly, looking at the initial costs, the choice of material (iron or steel) in the galvanizing process may lead to some cost differences. However, this discrepancy isn’t significant enough to represent the overall expenditure.

Secondly, maintenance costs are another crucial consideration. Evidence suggests that the maintenance costs for galvanized systems can vary significantly depending on the system. Specifically, hot-dip galvanizing corrosion protection projects excel in long-term economic benefits, especially with rising wages, painting and repair costs will continually escalate, demonstrating the excellence of hot-dip galvanizing.

Thirdly, the lifespan is also a critical measure for assessing cost-effectiveness. Hot-dip galvanizing is more expensive than cold galvanizing because it requires higher energy consumption to form a layer of zinc-iron alloy, which results in a longer lifespan. Furthermore, the lifespan of galvanized steel plates can be affected by environmental factors like sulfur dioxide gas or salt, particularly in industrial areas or coastal regions where corrosion rates are accelerated.

Lastly, the impact of environmental factors on corrosion rates cannot be ignored. For instance, during the rainy season, coatings subjected to long-term exposure to rainwater may accelerate corrosion rates, thereby affecting lifespan.

Although there may be differences in the initial costs of galvanized iron and galvanized steel, from a long-term use cost perspective, hot-dip galvanizing, due to its superior corrosion resistance and longer lifespan, has an advantage in maintenance costs and overall economic benefits. Therefore, considering long-term use costs, hot-dip galvanizing may be a more economical choice. However, the specific selection should still be made based on the actual application scenario and environmental conditions.