What makes galvanized sheet metal a preferred choice for various industries? This article dives into the properties, types, and applications of galvanized sheet metal, revealing its effectiveness in rust prevention and durability. From hot-dip to electro-galvanized sheets, discover the different methods of galvanization and their specific advantages. Learn how this versatile material is crucial in construction, agriculture, and automotive sectors, ensuring longevity and cost-effectiveness. By the end, you’ll understand why galvanized sheet metal is indispensable in modern manufacturing and engineering.

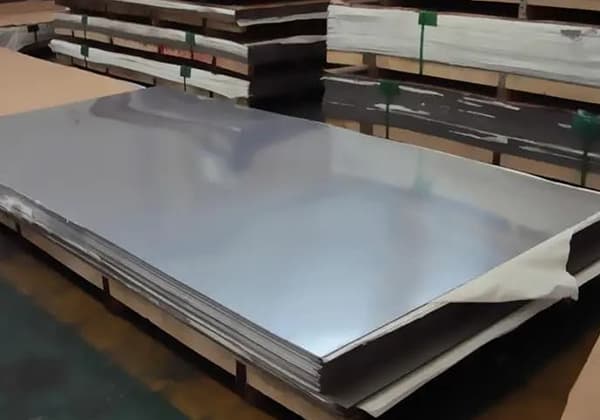

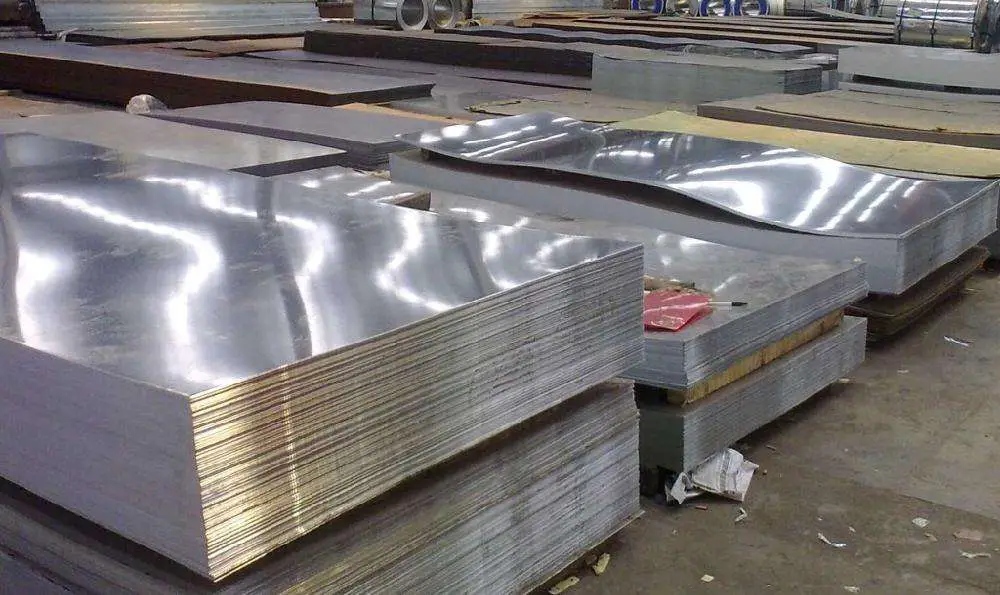

Galvanized sheet refers to the steel plate with a layer of zinc on its surface.

Galvanizing is an economic and effective rust prevention method often used.

About half of the world’s zinc production is used in this process.

Galvanized sheet metal is used to prevent the surface of steel plate from corrosion and prolong its service life.

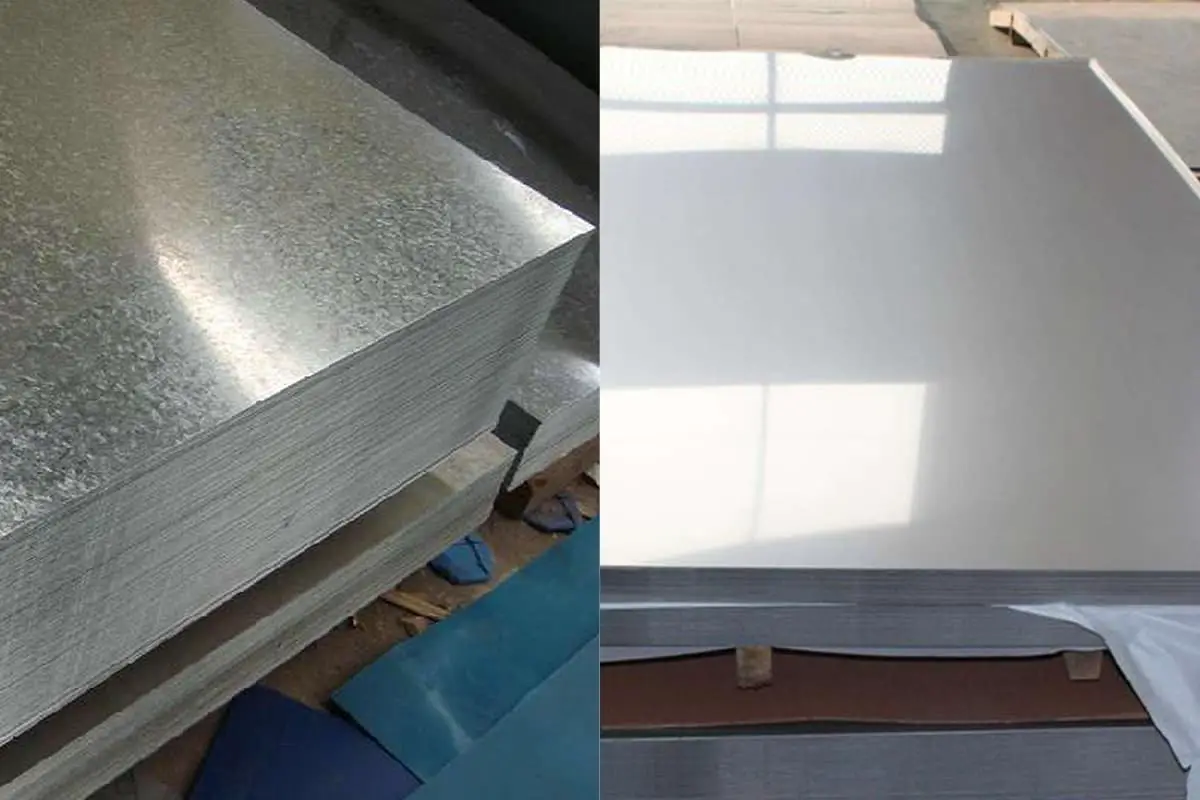

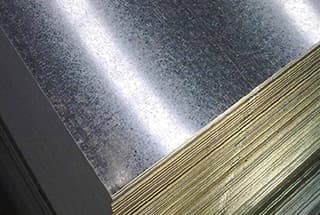

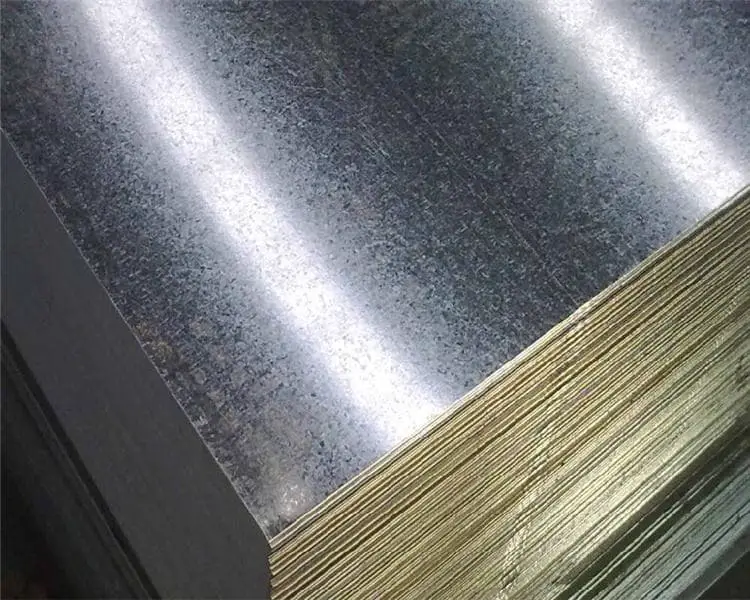

Due to different treatment methods in the coating process, the surface state of galvanized sheet is also different, such as ordinary zinc flower, fine zinc flower, flat zinc flower, non zinc flower and phosphated surface.

The German standard also specifies the surface grade.

The galvanized sheet shall have a good appearance and shall not have any defects harmful to the use of the product, such as no plating, holes, cracks, dross, over plating thickness, scratches, chromic acid dirt, white rust, etc.

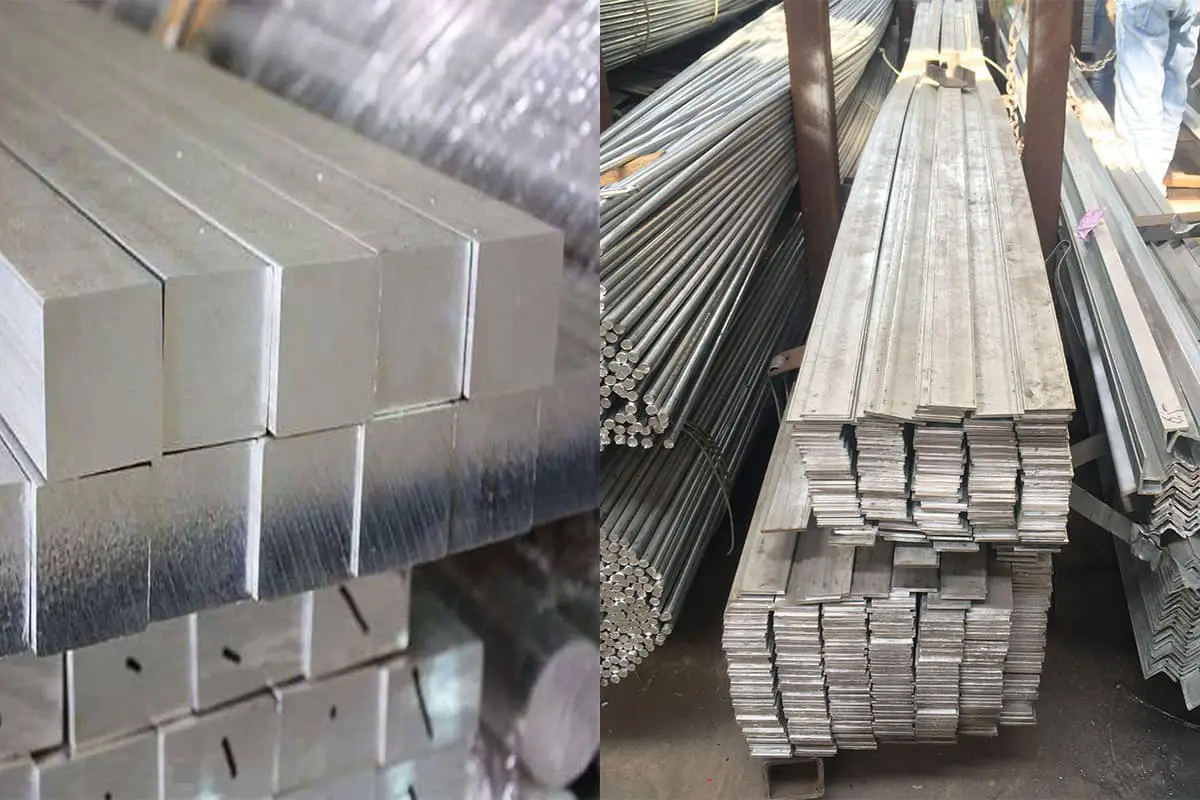

Galvanized sheet can be divided into the following categories according to production and processing methods:

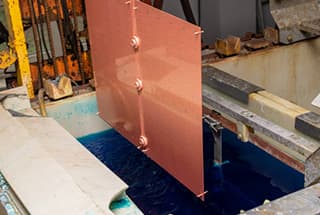

The steel sheet is immersed in the molten zinc bath, and a layer of zinc is adhered to its surface.

At present, the continuous galvanizing process is mainly used for production, that is, the rolled steel plate is continuously immersed in the zinc melting bath to make galvanized steel plate;

This kind of steel plate is also made by hot-dip method, but it is heated to about 500 ℃ immediately after being grooved to form an alloy film of zinc and iron.

This galvanized sheet has good adhesion and weldability of coating;

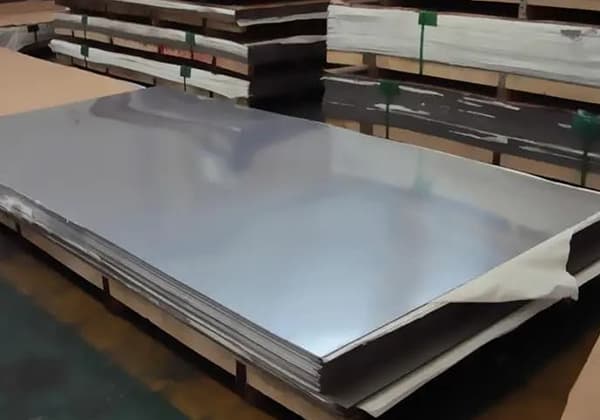

The galvanized steel sheet produced by electroplating has good processability.

However, the coating is thin and the corrosion resistance is not as good as that of hot-dip galvanized sheet;

Single side galvanized steel plate, that is, products galvanized only on one side.

It has better adaptability than double-sided galvanized sheet in welding, coating, rust prevention treatment and processing.

In order to overcome the disadvantage of one side not coated with zinc, there is also a galvanized sheet coated with a thin layer of zinc on the other side, that is, a double-sided difference galvanized sheet;

It is a steel plate made of zinc and other metals, such as aluminum, lead and zinc, and even composite plating.

This kind of steel plate not only has excellent rust prevention performance, but also has good coating performance;

In addition to the above five kinds, there are color galvanized steel plate, printed galvanized steel plate, PVC laminated galvanized steel plate, etc.

But at present, the most commonly used is still hot-dip galvanized plate.

1. Cold and hot-dip galvanized sheet is mainly used in agricultural machinery, grain storage, high-speed guardrail and other industries in life.

Its prominent feature is low cost and high added value.

2. Galvanized sheet is also used in building materials, household appliances, automobiles and other industries, because these industries are more or less involved in the support of steel structures.

The emergence of galvanized sheet cleverly solves this problem. I believe that its demand will continue to increase in the future.

3. In addition to being widely used in industrial production, galvanized sheet also plays an important role in modern buildings, factories, spatial structures, transportation energy, etc.

The application of galvanized sheet in these fields mainly plays the role of protective film, which weakens the corrosive effect of the outside world on objects.

As the name implies, galvanized steel plate is plated with a layer of zinc on the surface of the steel plate, which can play an anti-corrosion role to a certain extent.

This production method can also reduce the consumption of zinc in the world.

1. Non alloy hot galvanized steel strip

DC5XD series:

It can be used for general use, deep drawing and biting.

The higher the zinc content on the surface, the better the anticorrosion performance;

The smaller the amount of zinc plating on the surface, the better the processing performance.

SXXXGD series:

It can be used as a structure and has good processing performance and corrosion resistance.

HXXXPD + Z series:

It includes low alloy steel, phosphorus containing steel and hardened steel, which have excellent processing properties and corrosion resistance.

2. Alloyed hot galvanized steel strip

DCXXD + ZF series:

It can be used for structure, stamping and cold forming.

The galvanized sheet of this material has better welding performance and coating performance, but it is very easy to peel off in the process of processing.

Galvanized sheet is rust proof, and stainless steel is resistant to weak corrosive media such as air, steam and water.

The differences between stainless steel and galvanized steel are as follows:

Galvanizing refers to coating a layer of metal zinc on the surface of the steel plate in order to prevent corrosion on the surface of the steel plate and prolong its service life.

This zinc coated thin steel plate is called galvanized plate.

Stainless steel refers to the steel that is resistant to weak corrosive media such as air, steam and water and chemical corrosive media such as acid, alkali and salt, also known as stainless acid resistant steel.

Galvanizing is mainly to coat a layer of dense zinc on the surface of steel.

Stainless steel is the addition of other metal elements inside the steel.

It is the internal structural change that makes the product not rusty.

Galvanized steel strip products are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery, commerce and other industries.

Such as for building roof panels, roof grilles, etc;

Kitchen utensils, etc;

Storage and transportation of materials, packaging equipment, etc.

Stainless steel is mainly used in the construction field, which is one of the highest strength building metal materials.

It is also used in food processing, catering, brewing, chemical industry and other fields with high sanitary requirements.

In comparison, stainless steel is better.

First of all, galvanized pipes are rarely used. China has banned galvanized pipes since 2000.

At present, galvanized pipes are rarely used for cold water pipes in new residential areas, and galvanized pipes are used for hot water pipes in a few residential areas.

Galvanized pipes are used as water pipes. After several years, a large amount of rust and scale will be generated in the pipes.

The yellow water flowing out will not only pollute the sanitary ware, but also be mixed with bacteria growing on the unsmooth inner wall.

The rust will cause the heavy metal content in the water to be too high, which will seriously harm human health.

Galvanized sheet refers to the steel plate with a layer of zinc on its surface.

Galvanizing is an economic and effective anti-corrosion method often used.

About half of the world’s zinc output is used in this process.

The surface of the aluminized zinc steel plate is smooth, flat and gorgeous, and the primary color is silver white.

The special coating structure makes it have excellent corrosion resistance.

The normal service life of the aluminized zinc plate can reach 25 years, and the heat resistance is very good.

It can be used in the high temperature environment of 315 ℃;

The coating has good adhesion to the paint film and good processing performance, which can be used for stamping, shearing, welding, etc;

The surface conductivity is very good.

The coating is composed of 55% aluminum, 43.4% zinc and 1.6% silicon by weight.

The production process of aluminized zinc steel plate is similar to that of galvanized rigid plate and aluminized plate, which is a continuous melting plating process.

The aluminum zinc plated steel sheet with 55% aluminum zinc alloy coating has better corrosion resistance than the galvanized steel sheet with the same thickness when both sides are exposed to the same environment.

The 55% aluminum zinc alloy coated aluminum zinc steel plate not only has good corrosion resistance, but also has excellent adhesion and flexibility.

The difference between galvanized sheet and aluminized zinc sheet mainly lies in the difference of coating.

A layer of zinc material is evenly distributed on the surface of the galvanized sheet, which plays an anodic protection role for the base metal.

In other words, the alternative corrosion of zinc material protects the use of the base metal.

Only when the zinc is completely corroded can the base metal inside be damaged.

The surface coating of the aluminized zinc plate is composed of 55% aluminum, 43.5% zinc and a small amount of other elements.

The surface of the aluminized zinc coating has a honeycomb structure under the microscope, and the “honeycomb” composed of aluminum contains zinc.

In this case, although the aluminum zinc coating also plays the role of anode protection, on the one hand, due to the reduction of zinc content and on the other hand, because the zinc material is wrapped by aluminum and is not easy to electrolyze, the role of anode protection is greatly reduced.

Therefore, once the aluminum zinc plated plate is cut, it will soon rust when the cut edge is basically unprotected.

Therefore, the aluminized zinc plate should be cut as little as possible.

Once cut, the edges should be protected with antirust paint or zinc rich paint, so as to prolong the service life of the plate.

The surface of aluminized zinc plate is more beautiful than that of galvanized plate.

At the same time, the cost of aluminized zinc plate is higher than that of galvanized plate, and the cost of small zinc flower is higher than that of large zinc flower.

In cities with humid air and heavy rain, once a certain point of the aluminum zinc plated plate is rusted, if measures are not taken in time, the slowly rusted place will become larger and larger, and eventually even the whole plate surface;

The corrosion of galvanized sheet will not spread even if there is corrosion at a certain point.

The thickest zinc coating is 80 grams per square meter, which means 160 grams on both sides.

The most common is 50 grams, which means 100 grams on both sides.

In this way, we can know a simple relationship.

The density of galvanized sheet is 7.85 tons/m³, that is to say, the weight of 1.0mm plate per square meter is 7.85kg, and the weight of 0.75mm plate per square meter is 5.8875kg.

Zinc plate density calculation method = iron plate weight + zinc coating weight

For example:

1 mm thick galvanized sheet, the weight of the sheet is 7.85 kg, and the weight of the galvanized layer is 2 × 0.05kg, the weight per square meter is 7.95kg, and other specifications are also calculated in the same way.

The weight of galvanized sheet is slightly heavier than that of ordinary iron sheet, and the increase of coating thickness is different.

The price should be different for different coating thicknesses.

The function of galvanizing is to prevent steel from rusting, which is easy to be rusted in the natural atmosphere.

While zinc is not easy to change in dry air, in wet environment, a dense zinc carbonate protective film will be formed on the surface, which can effectively protect steel.

Generally, there are three types of galvanizing processes and methods: mechanical galvanizing, hot galvanizing and cold galvanizing:

Mechanical zinc plating process is a more traditional zinc plating process, which makes zinc powder adhere to the plated parts through mechanical collision and chemical adsorption to form a coating.

It is also called hot-dip galvanizing.

First, the plated part is pickled to remove the oxide layer on the surface of the plated part, so as to provide conditions for the firm attachment of the plating layer.

After cleaning with ammonium chloride or zinc chloride plating aid, the impurities on the surface of the plated part are further removed, and then it is put into the zinc solution of the hot-dip tank to make the zinc solution uniformly and tightly adhere to the plated part through immersion to form a plating layer.

It is also called electro galvanizing.

After removing the oil dirt and dust on the surface, pickling and cleaning to remove the impurities on the surface of the plated parts, the plated parts are put into the zinc salt solution. At the same time, the zinc plate is placed on the opposite side of the plated parts, and then the plated parts are connected to the negative electrode of the electrolytic equipment.

The zinc plate is connected to the positive electrode of the electrolytic equipment, and the power is connected.

Through the electrolytic reaction, the zinc layer is attached to the plated parts.

With the continuous maturity of new processes, mechanical plating has been eliminated.

The commonly used processes are hot-dip galvanizing and cold galvanizing.

The main producers of galvanized steel sheets are China, Japan, Germany, Russia, France, South Korea, etc.

| Defects | Characteristics | Causes |

| Exposed steel (missing plating) | If there are black spots or black blocks on the galvanized steel strip that expose the original steel, it is called exposed steel. These black spots or blocks are not plated with zinc, and they are variable in shape and size. Sometimes they are spread all over the upper and lower surfaces of the steel strip. | 1. Due to the corrosion of the original plate, the yellow rust cannot be fully reduced after entering the annealing furnace; 2. There are defects on the surface of the original plate, such as pressed iron oxide scale, serious corrosion, inclusions, etc; 3. The steel strip enters the preheating section of the annealing furnace for reoxidation, and then enters the reduction section for reduction; 4.The protective gas is impure, with high dew point and low hydrogen content (< 15% =, the steel strip is oxidized again); 5. The pipes in the furnace are broken and leaking; 6. insufficient pickling; 7. The composition of plating aid is unqualified;8. Excessive baking of plating aid. |

| Zinc layer falling off | When the mechanical bite or ball impact test is conducted on the galvanized sample, the serious separation between the zinc layer and the substrate on the surface is called the zinc layer falling off. It can also be seen directly on the production line that the zinc layer is locally separated from the substrate in blocks and the zinc layer falls. | 1. Poor furnace temperature; 2. The annealing furnace leaks air, water or the reduction conditions are not good, leaving oxides on the surface of the steel strip that have not been reduced well; 3. The original plate has high silicon content; 4. Poor operating conditions, such as high galvanizing temperature, long galvanizing time and improper control of aluminum content; 5. The original coil is seriously rusted. |

| Zinc particle (zinc scar) | The surface is raised in dots and blocks, with different sizes. The particles are like sesame and rice grains, and the surface is rough and uneven.It is called zinc granule in granular form and zinc scar in massive form on the surface. | 1. The bottom slag is too much and is stirred and floated, accompanying with the zinc liquid adhering to the surface of the galvanized steel strip or being pressed onto the surface of the steel strip by the submerged roller; 2. The temperature of molten zinc is too high (> 470 ℃) to float the bottom slag; 3. The high content of aluminum in the molten zinc reduces the solubility of iron in the molten zinc, resulting in more scum. |

| Poor zinc flower | The size of zinc flower is uneven and there is no zinc flower. | Poor temperature rise in furnace area. |

| Gray plating zinc bump | The surface is matte and grey without galvanized layer. | 1. Slow cooling of the original plate; 2. Scratch in semi solidified state. |

| Air knife stripe (stripe) | The galvanized steel strip presents dendritic stripe or strip convex stripe along the rolling direction. | 1. Zinc is too thick and zinc temperature is low; 2. High aluminum content increases melting point; 3. Low position or pressure of air knife; 4. The gap of the air knife is partially blocked; 5. Local notch or damage of air knife; 6. Poor shape. |

| Edge thickness (pattern) | The zinc layer on the edge of the galvanized steel strip is thicker than the zinc layer in the middle or other parts, which is called edge thickness. Generally, the edge is in a stripe pattern. | 1. Poor adjustment of air knife angle; 2. Fast edge cooling; 3. When the speed of steel strip is lower than 30m / min, part of the air flow at both ends of the nozzle is dissipated outward, which reduces the air flow impulse at the edge, resulting in less zinc scraping at the edge than in the middle; 4. The shape of the original plate is not good, and there is edge wave; 5. The edge of the original plate is seriously rusted. |

| Zinc ripple (zinc wave) | Wavy pattern | 1. High temperature of molten zinc; 2. Zinc silk, less aluminum. |

| Shell pattern | Shell pattern, zinc undulation. | High aluminum content and low temperature. |

| Watermark | White band shaped groove or dot shaped pit on the surface of small zinc flower plate. | The cooling water drops are too large or the water flow shoots, causing pits in the non solidified zinc flowers. |

| Dithering streak | Periodic stripes on the surface. | 1. Sinking roller slagging and shaft corrosion; 2. The finishing roller is worn. |

| Finishing and embossing (flower) | There are zinc particles or marks after finishing. | 1. Zinc sticking on the finishing roll; 2. Mechanical wear of the finishing machine. |

| C poor handling | The surface is yellowish. | The extrusion drying effect of post-treatment is poor, and chromium liquid remains. |

| Bell mouth | The steel coil is bell mouth shaped. | The air knife is blocked, the edge of the steel strip is over galvanized, and a bell mouth is generated during coiling. |

| Scratch | scratch | 1. Scratch on the original plate; 2. The immersion roller is in poor working condition. |

| Side wave and medium wave | The side or middle part is wavy. | 1. The original plate is poor; 2. The stabilization roll is in poor working condition. |

| White rust | 1. The surface is white in different degrees;The surface of Zn (OH) 2 shows white oxide powder and precipitate, which is mainly composed of zinc oxide ZnO and zinc hydroxide Zn (OH) 2. | 1. Poor oil coating and passivation; 2. Poor workshop environment; 3. Contaminated with plating aid and floating ash; 4. Smoke of plating aid; 5. Poor oil coating and passivation on the surface; 6. The storage and transportation time is too long under humid conditions; 7. Rain (sea water) immersion during storage and transportation; 8. The temperature of the storage warehouse is lower than the dew point temperature, and condensed water appears, corroding the board surface; 9. Contact or store with other corrosive media such as acid, alkali and salt. |

| Stratification | The layered inspection is unqualified. | The steel plate has inclusions. |

| Coating is too thin | The amount of zinc plating is less than the specified standard. | 1. Poor adjustment of air knife; 2. The temperature of molten zinc is too high and the speed is too slow (too fast when using air knife). |

| Uneven coating | The copper sulfate test is unqualified. | 1. Improper adjustment of both sides of air knife; 2. The plating roller is eccentric; 3. Serious buckling. |

| Folding performance is unqualified. | The folding test is unqualified and the zinc layer falls off. | 1. The temperature of molten zinc is too high; 2. The aluminum content is too high or too low; 3. Zinc dipping time is too long (shutdown). |

| Scratch | The coil is scratched. | Poor lifting and damaged package. |

| Surface black spot | There are black spots and dark spots on the surface. | Plate surface friction during storage and transportation. |

| Black rust | Black rust spots on the surface. | 1. Extended storage; 2. Poor oil coating and passivation; 3. Adhesion dye plating aid; 4. Immersion in water (sea water) during storage and transportation; 5. Long term contact with the industrial atmosphere. |