Have you ever wondered about the weight of galvanized sheets? In this blog post, we’ll dive into the fascinating world of galvanized sheet weight calculation. As an experienced mechanical engineer, I’ll share insights on how factors like density and thickness affect the weight. You’ll gain a deeper understanding of the complexities involved and learn practical tips for accurate weight measurement. Get ready to expand your knowledge and discover the intricacies of galvanized sheet weight!

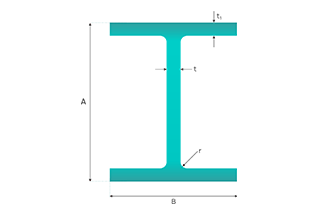

Galvanized Iron (GI) sheets are a fundamental material in various industries due to their enhanced durability and corrosion resistance. These steel sheets are coated with a layer of zinc, which acts as a protective barrier against environmental elements, significantly extending their service life.

GI sheets are produced through two main galvanization methods: Hot-Dip Galvanizing and Electro-Galvanizing.

In this process, steel sheets are immersed in a molten zinc bath at temperatures around 500 degrees Celsius. This method results in a thicker zinc coating, often displaying crystallized zinc spangles. Hot-dip galvanizing is particularly suitable for applications exposed to harsh environments, such as construction, machinery, and infrastructure.

Electro-galvanizing involves applying a zinc layer through an electrolytic process at room temperature. This method produces a thinner but more uniform zinc coating, making it ideal for indoor applications where aesthetics and less severe corrosion resistance are required, such as in the automotive, furniture, and home appliances industries.

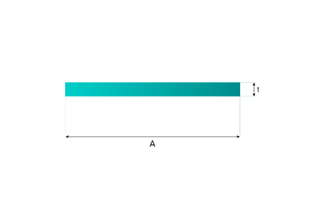

Calculating the weight of a Galvanized Iron (GI) sheet is crucial for various applications, including material management, cost estimation, and structural planning. Understanding how to accurately determine the weight of a GI sheet ensures efficient use of materials and compliance with load requirements.

The weight of a GI sheet can be calculated using a simple formula:

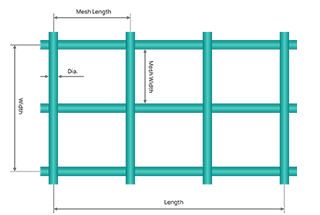

Weight = Length (L) × Width (W) × Thickness (T) × Density

The density of GI sheets is approximately 7850 kg/m³ because it reflects the density of steel, the primary material used in GI sheets. This density can vary slightly depending on the specific composition and manufacturing process. For instance, different grades of steel or additional alloying elements can affect the density.

Consider a GI sheet with the following dimensions:

Using the formula:

Weight = 2m × 1 m × 0.001 m × 7850kg/m3 = 15.7kg

Therefore, the weight of the GI sheet is 15.7 kilograms.

For a GI sheet with different dimensions:

Using the formula:

Weight = 3 m x 1.5 m x 0.002 m × 7850kg/m3 = 70.65 kg

Thus, the weight of this GI sheet is 70.65 kilograms.

The density of 7850 kg/m³ is used because it represents the density of steel, which is the base material for GI sheets. Variations in density can occur due to different grades or additional coatings, but 7850 kg/m³ is a standard reference for general calculations.

If the GI sheet has additional coatings or finishes, their weight should be added to the base weight calculated using the formula. Coatings like paint or laminate can add a small but significant amount to the overall weight.

When handling and measuring GI sheets, always prioritize safety:

By understanding the basic formula and considering these practical tips, professionals can ensure accurate calculations and safe handling of GI sheets.

Galvanized sheets are usually delivered based on their theoretical weight, whereas galvanized steel strips are typically delivered based on their actual weight.

The theoretical weight of galvanized sheets takes into account the weight of the cold-rolled or hot-rolled steel plate on which they are based. This weight includes two parts:

You can use the below galvanized sheet weight calculator to calculate the weight of the galvanized sheet.

Related Calculator:

Nominal Coating Weight Range

| Coating form | Applicable coating surface structure | Nominal coating weight range (g/m2) | |

|---|---|---|---|

| Pure zinc coating (Z) | Zinc iron alloy coating (ZF) | ||

| Equal thickness coating | N, M, F, R | 50~600 | 60~180 |

| Differential coating | N, M, F | 25 ~ 150 (each side) | — |

Note:

Nominal Coating Weight and Corresponding Coating Code

| Coating type | Coating form | Recommended nominal coating weight (g/m²) | Coating code |

|---|---|---|---|

| Pure zinc coating (Z) | Equal thickness coating | 60 | 60 |

| 80 | 80 | ||

| 100 | 100 | ||

| 120 | 120 | ||

| 150 | 150 | ||

| 180 | 180 | ||

| 200 | 200 | ||

| 220 | 220 | ||

| 250 | 250 | ||

| 275 | 275 | ||

| 350 | 350 | ||

| 450 | 450 | ||

| 600 | 600 | ||

| Zinc iron alloy coating (ZF) | Equal thickness coating | 60 | 60 |

| 90 | 90 | ||

| 120 | 120 | ||

| 140 | 140 | ||

| Pure zinc coating (Z) | Differential coating | 30/40 | 30/40 |

| 40/60 | 40/60 | ||

| 40/100 | 40/100 |

| Thickness (mm) | Weight (Kg/m²) | Thickness (mm) | Weight (Kg/m²) |

| 0.1 | 0.785 | 1.5 | 11.775 |

| 0.12 | 0.942 | 1.6 | 12.56 |

| 0.15 | 1.1775 | 1.7 | 13.35 |

| 0.18 | 1.413 | 1.8 | 14.13 |

| 0.2 | 1.57 | 1.9 | 14.92 |

| 0.22 | 1.727 | 2 | 15.7 |

| 0.24 | 1.884 | 2.2 | 17.27 |

| 0.25 | 1.9625 | 2.5 | 19.625 |

| 0.28 | 2.198 | 2.8 | 21.98 |

| 0.3 | 2.355 | 3 | 23.55 |

| 0.32 | 2.512 | 3.2 | 25.12 |

| 0.35 | 2.7475 | 3.5 | 27.475 |

| 0.38 | 2.983 | 3.8 | 29.83 |

| 0.4 | 3.14 | 4 | 31.4 |

| 0.42 | 3.297 | 4.2 | 32.97 |

| 0.45 | 3.5325 | 4.5 | 35.325 |

| 0.48 | 3.768 | 4.8 | 37.68 |

| 0.5 | 3.925 | 5 | 39.25 |

| 0.55 | 4.318 | 5.5 | 43.18 |

| 0.6 | 4.71 | 6 | 47.1 |

| 0.65 | 5.103 | 6.5 | 51.03 |

| 0.7 | 5.496 | 7 | 54.96 |

| 0.75 | 5.8875 | 8 | 62.8 |

| 0.8 | 6.28 | 9 | 70.65 |

| 0.9 | 7.065 | 10 | 78.5 |

| 1 | 7.85 | 11 | 86.35 |

| 1.1 | 8.635 | 12 | 94.2 |

| 1.2 | 9.42 | 13 | 102.1 |

| 1.3 | 10.21 | 14 | 109.9 |

| 1.4 | 10.99 | 15 | 117.75 |

Steel plate weight(kg)=7.85×Thickness×Length×Width

1 m long and 1 m wide respectively

See also:

Generally, the thicker the galvanized sheet, the greater the allowable error range, rather than a fixed 0.02-0.04 millimeters. The thickness deviation also varies depending on factors such as yield point and tensile coefficient. This implies that galvanized sheets of different thicknesses will have noticeable weight differences, especially in the case of thicker galvanized sheets.

Understanding units of measurement and their conversion is crucial when calculating the weight of Galvanized Iron (GI) sheets. Accurate measurements ensure precise calculations, whether using manual methods or online calculators. This is particularly important in industries such as construction, manufacturing, and engineering, where precise weight calculations are essential for structural integrity and cost estimation.

The metric system is widely used globally and is based on the decimal system, making it easy to convert between units. Common metric units relevant to GI sheet weight calculation include:

For GI sheets, the primary measurements involve length, width, and thickness, typically in meters or millimeters, and weight in kilograms.

The imperial system, used mainly in the United States, includes different units for length, weight, and volume:

When working with GI sheets, dimensions might be given in inches or feet, requiring conversion to metric units for calculation.

Accurate unit conversion is essential to ensure consistency in calculations. Here are some basic rules and methods for converting units:

Conversion factors express the relationship between units. Use these factors to convert between metric and imperial units:

Galvanized sheet refers to a steel plate that has a layer of zinc on its surface. Galvanizing is a widely used, economical, and effective method of preventing corrosion.

Approximately half of the world’s zinc production is utilized in this process to prevent corrosion on the surface of steel plates and extend their service life.

According to different production and processing methods, galvanized steel sheet can be divided into:

The most commonly used type of coating surface is still hot-dip galvanized plate.

There are three types of surface coatings available, namely ordinary zincification, small zinc flower, and no zinc flower.

As per the current national standard for continuous hot dip galvanized steel sheet and strip (GB/t2518-2008), the nominal thickness of the galvanized sheet ranges from 0.3mm to 5.0mm, the nominal width ranges from 600mm to 2050mm, and the nominal length ranges from 1000mm to 8000mm.

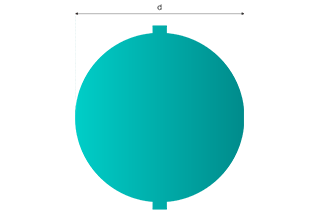

To accurately measure the actual weight of a galvanized sheet, you first need to understand the density and thickness of the galvanized sheet. The density of a galvanized sheet is typically 7.85g/cm³. Next, there are several methods to measure the weight of the galvanized sheet.

Weighing Method: This is a direct method by calculating the weight of the galvanized layer through the weight difference before and after weighing the galvanized sheet. This method is simple and direct, and is suitable for situations recommended in product standards.

X-Ray Fluorescence Spectrometry: This method determines the weight of the galvanized layer by analyzing the radiation intensity of zinc in the sample plating layer. First, a set of standard plates is made, and a relationship curve between the X-ray intensity of zinc and the weight of the coating is established. Then, the zinc radiation intensity in the sample is measured by regression.

Coulometric Analysis: This is a method described in the ASTM A90/A90M-13 standard for measuring the weight of galvanized and galvanized alloy steel products.

Weighing Method by Removing Galvanized Layer: By using a stripping solution to dissolve the zinc on the surface, then weighing the weight of the sample before and after stripping, the thickness of the coating is calculated according to the density of zinc (7.2g/cm³). This method is suitable for situations where the galvanized layer needs to be removed to assess its thickness.

Which method to choose depends on the specific testing requirements and available equipment conditions. In actual operation, it may be necessary to combine various methods to ensure the accuracy of the measurement results.

The weight of 18 gauge GI sheet is 9.42kg/m2.

The weight of 20 gauge GI sheet is 7.06kg/m2.

The weight of 22 gauge GI sheet is 5.88kg/m2.

The weight of 24 gauge GI sheet is 4.71kg/m2.

The weight of 26 gauge GI sheet is 3.53kg/m2.

The weight of 1.2mm GI sheet is 9.42kg/m2.

See also: