Choosing between gravity casting and pressure casting can feel like a daunting decision for manufacturers. Should you opt for the simplicity and cost-effectiveness of gravity casting, or the precision and efficiency of pressure casting? This article explores the key differences, advantages, and limitations of both methods, helping you understand which technique best suits your product needs. By the end, you’ll have a clear understanding of which casting method aligns with your project’s requirements, ensuring optimal performance and cost efficiency.

Gravity casting is the process of injecting molten metal into a mold under the force of gravity, also known simply as casting.

The broader definition of gravity casting encompasses various methods, including sand mold casting, metal mold casting, lump mold casting, disappearing mold casting, and clay mold casting.

However, in a narrower sense, gravity casting specifically refers to metal mold casting.

Metal mold casting is a modern technique that uses heat-resistant alloy steel to create molds.

The liquid metal is typically poured into the gate manually, and the final product is produced by filling the mold cavity, venting, cooling, and opening the mold through the force of the liquid metal’s weight.

The process involves the following steps: smelting, pouring material into the mold, venting, cooling, opening the mold, heat treatment, and post-processing.

The following are the characteristics of gravity casting:

Pressure casting is divided into two categories: high pressure casting and low pressure casting.

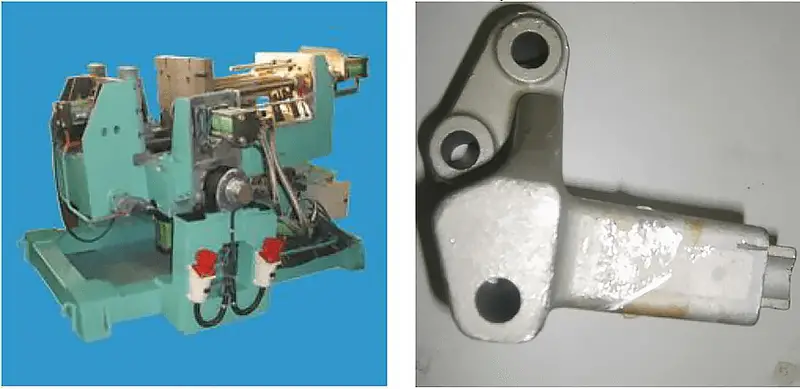

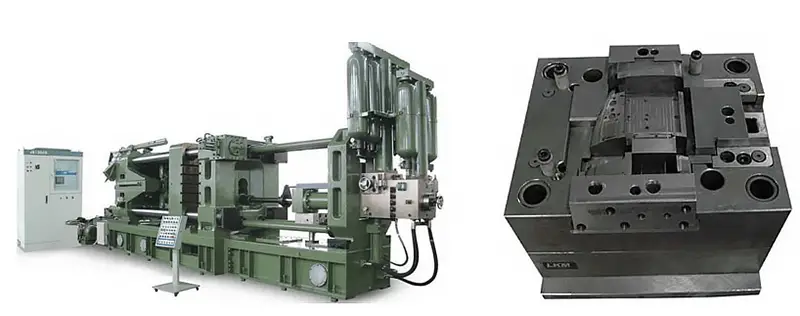

High pressure casting is a casting technique where molten alloy is rapidly poured into a steel mold’s cavity within a pressure chamber, solidifying under high pressure.

(1) The metal liquid is filled into the cavity under pressure and solidifies through crystallization, typically with a pressure range of 15-100 MPa.

(2) The metal liquid is filled into the cavity at high velocity, with speeds ranging from 10-50 m/s and in some cases, even exceeding 80 m/s, which is introduced through the internal gate. This results in a very short filling time of the metal liquid, typically only 0.01-0.2 seconds, depending on the size of the casting.

The features of high pressure casting include:

However, high pressure casting has high mold costs and low mold life.

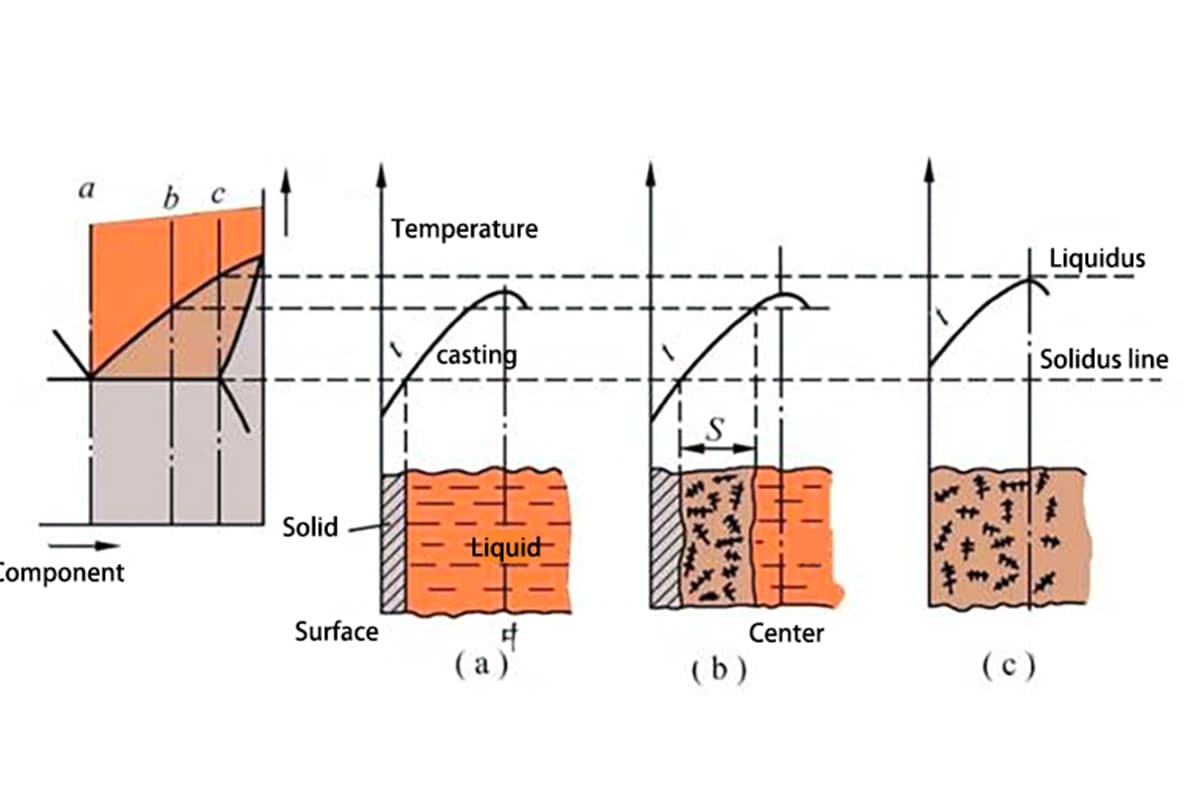

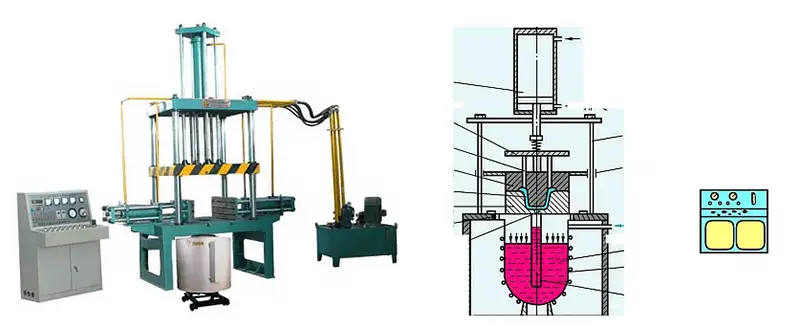

The process of low pressure casting technology is as follows: Dry, compressed air is introduced into the sealed crucible or tank. Under the influence of gas pressure, the liquid metal rises along the riser and into the sprue, entering the mold cavity smoothly. The gas pressure is maintained on the liquid level in the crucible until the casting is fully solidified.

After solidification, the gas pressure on the liquid surface is released, causing the liquid metal in the riser to flow back into the crucible.

Finally, the mold is opened and the casting is removed.

Low pressure casting differs significantly from high pressure casting in terms of equipment, process, and product performance.

The pressure applied in low pressure casting is relatively low, typically ranging from 20 to 60 kPa, and the pressure source is provided by gas.

Due to the low pressure, the filling of the product is slower and the production efficiency is lower, however, the product’s porosity is improved, allowing it to undergo heat treatment.

In general, low pressure casting is a balance between the advantages of high pressure casting and gravity casting.

| Tecniques | Mold cost | Die life | Porosity | Heat treatment | Machining allowance | Surface finish | Suitable products | Production efficiency | |

| High pressure casting | complex | high | short | bad | no | small | high | Thin walled parts | high |

| Low pressure casting | simple | low | long | good | yes | big | high | Middle wall parts | medium |

| Gravity casting | simple | low | long | good | yes | big | low | Thick wall parts | low |

The strength of aluminum alloys can vary greatly due to differences in raw materials. Die casting products, on the other hand, have high density and strength due to being formed under high pressure. For instance, A380 die cast products have a strength of 360MPa and an elongation of only 3.7%.

Gravity casting products generally have lower strength compared to die cast products. For example, ZL101A has a strength of 310MPa after heat treatment, but with an elongation of 5-6%. There are also materials, such as ZL201a and ZL204a, with a strength above 380MPa.

When choosing a production process, the wall thickness of the product is the main consideration. High-pressure casting is a highly efficient process and should be the first choice as long as the production process and product performance meet the requirements. However, if the product wall thickness is greater than 8mm, high-pressure casting may not meet the desired strength requirements due to internal pores, in which case gravity casting or low-pressure casting can be considered.