What exactly makes a welding joint reliable and strong? The answer lies in the type of groove used. This article explores the various groove forms essential for welding, such as V-type, K-type, and U-type. Each form has unique characteristics that suit different material thicknesses and welding quality requirements. By the end of this read, you’ll understand how to choose the right groove form to ensure the best welding outcomes for your projects.

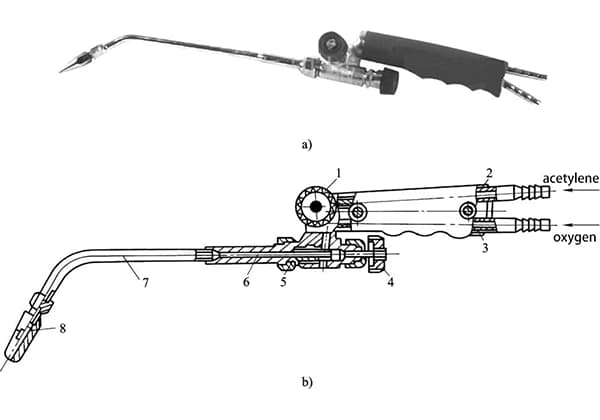

To ensure welding quality, it’s necessary to process the parts of the workpiece that require welding before starting the process. This is done through gas cutting or cutting, which typically involve inclined planes or sometimes curved surfaces.

For instance, if two 10mm thick steel plates need to be butt welded, a chamfer will be milled on the edge of the plate for a secure weld. This process is called beveling.

The welding joint form and groove shape vary depending on the material thickness and welding quality requirements. The groove form is generally categorized as K-type, V-type, I-type, U-type, X-type, etc.

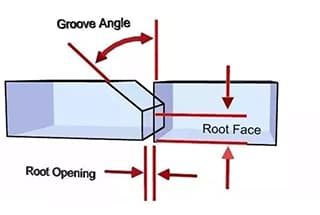

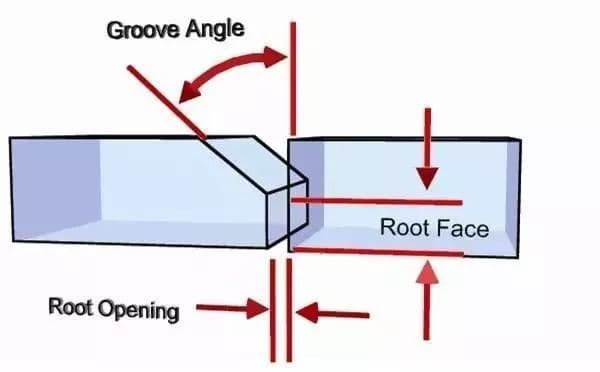

(1) Groove surface

The groove surface on the piece to be welded is called groove surface.

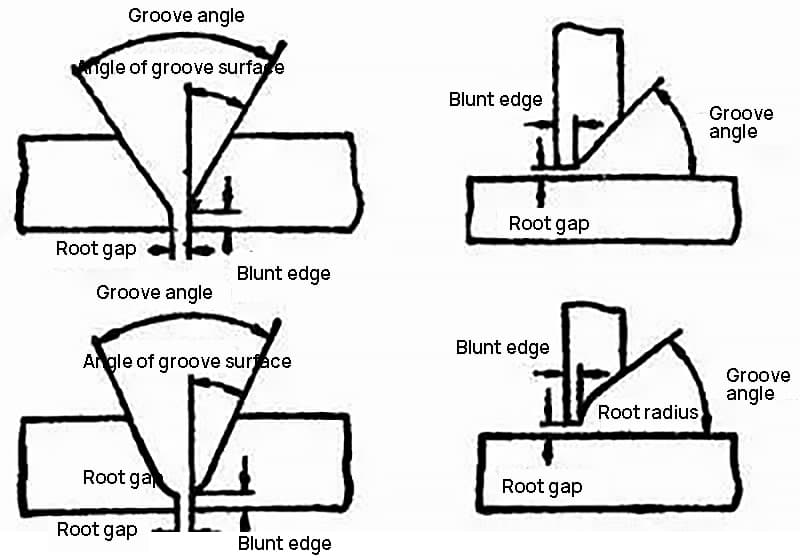

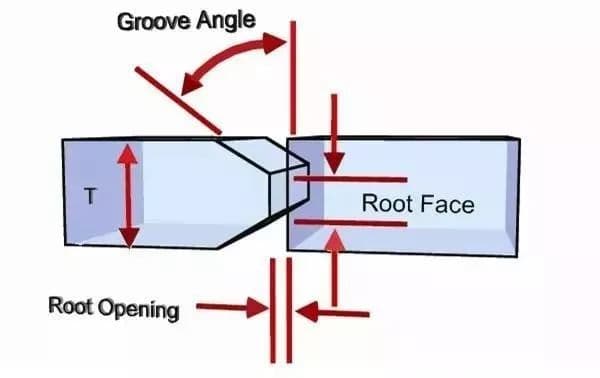

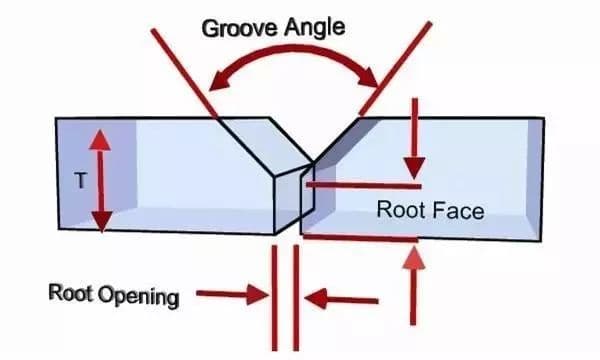

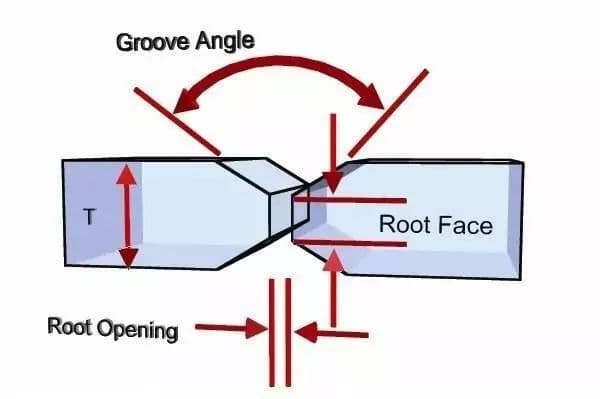

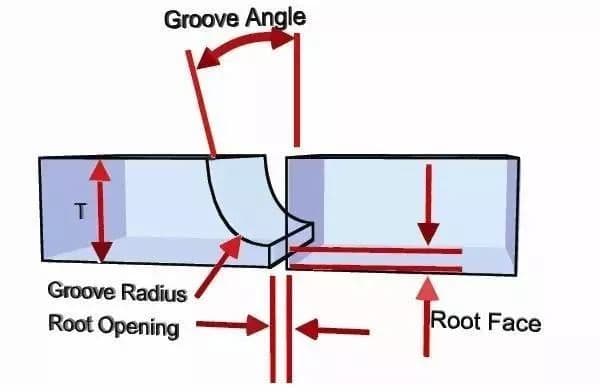

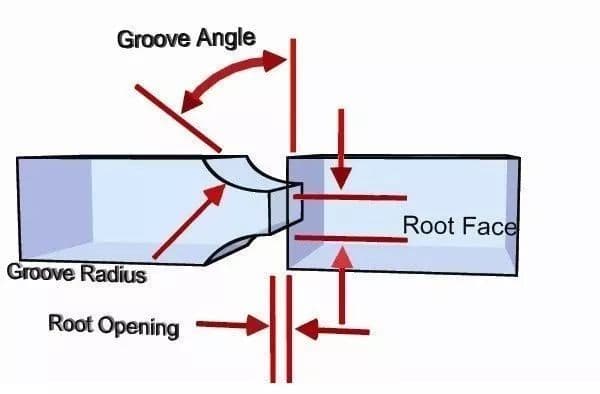

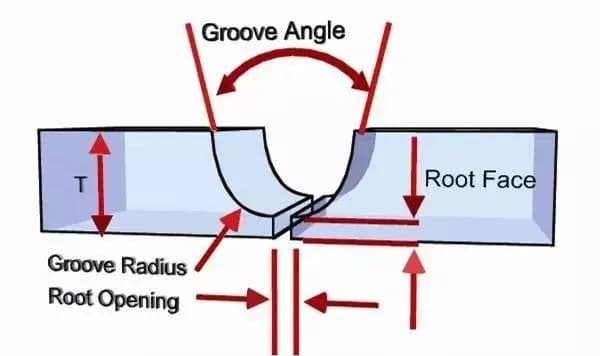

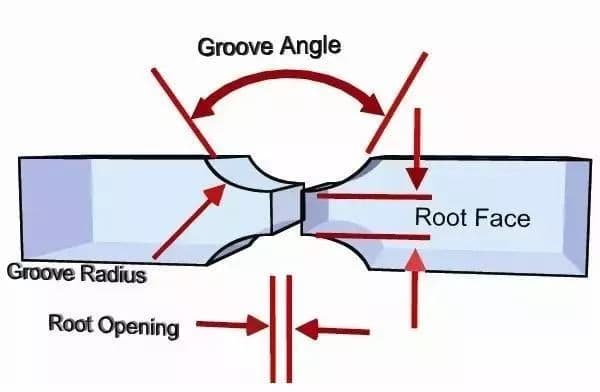

(2) Groove face angle and groove angle

The angle included between the end face of the groove to be processed and the groove surface is known as the groove surface angle. Similarly, the angle included between the two groove surfaces is referred to as the groove angle.

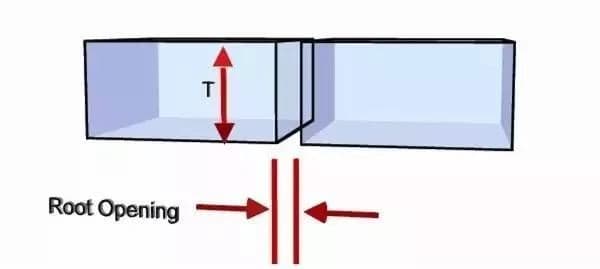

(3) Root gap

The space left between the joint’s root before welding is known as the root gap. Its purpose is to facilitate root penetration during backing welding.

The assembly clearance is also referred to as root clearance.

(4) Blunt edge

When the weldment is beveled, the straight edge of the end face along the root of the weldment joint groove is referred to as a blunt edge.

The purpose of the blunt edge is to prevent the root from burning through.

(5) Root radius

The radius of the curve at the bottom of J-shaped and U-shaped grooves is known as the root radius. Its purpose is to provide additional space at the root of the groove, enabling it to be welded through.

Single side V-groove with blunt edge:

K-groove:

I-groove:

V-groove:

X-groove:

J-groove:

Fig.: single J-groove

Figure: double J-groove

U-groove:

Figure: single U-groove

Figure: Double U-groove