Have you ever wondered about the hidden world of H-beam steel? In this captivating article, we’ll unravel the mysteries behind these essential construction components. Our expert mechanical engineer will guide you through the intricacies of H-beam dimensions, weights, and calculations. Prepare to gain valuable insights that will elevate your understanding of these structural marvels. Get ready for an enlightening journey into the realm of H-beam steel!

H-beams, also known as wide flange beams, are characterized by their H-shaped cross-section, providing high strength and load-bearing capabilities.

The dimensions and weight of H-beam steel can be determined through several methods. The most common approach is to calculate the cross-sectional area using the formula:

A = t1(H-2t2)+2Bt2+0.858r2

Where:

Once the cross-sectional area (A) is obtained, the weight per unit length of the H-beam can be easily calculated by multiplying A by the density of steel, which is typically 7.85 g/cm3 or 0.00785 kg/cm3. This straightforward calculation provides an accurate estimate of the H-beam’s weight based on its specific dimensions.

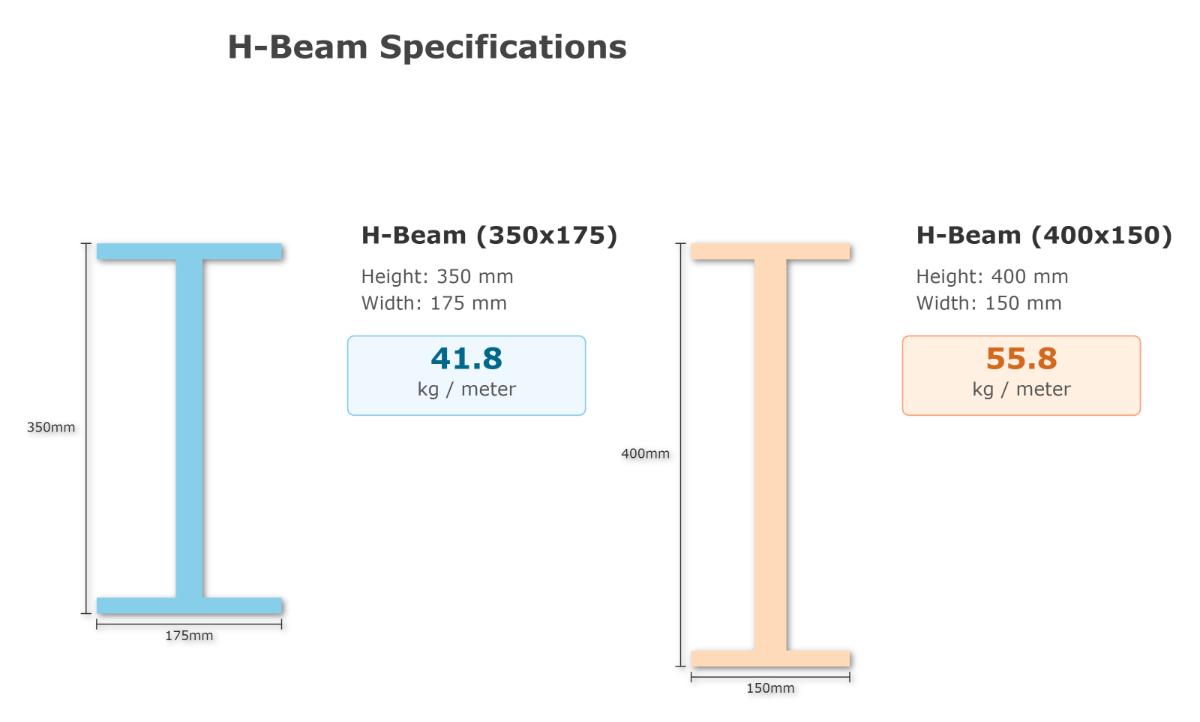

To simplify the process of determining the weight of H-beam steel, manufacturers often provide detailed theoretical weight tables for various standard sizes. These tables list the weight per meter for each H-beam specification, making it easy to find the information you need.

For instance, an H-beam with dimensions of 350mm in height and 175mm in width (350*175mm) has a theoretical weight of 41.8kg per meter. Similarly, an H-beam measuring 400mm in height and 150mm in width (400*150mm) weighs 55.8kg per meter.

These examples demonstrate that the weight of an H-beam is directly related to its dimensions. As the size of the H-beam changes, so does its theoretical weight per unit length. By referring to these weight tables, engineers and contractors can quickly estimate the total weight of the H-beams required for their projects, ensuring accurate material ordering and cost estimation.

While the cross-sectional area formula is the most widely used method for calculating the weight of H-beam steel, there are alternative approaches that can provide similar results. One such method involves using formulas that consider the width of the web plate and the base plate.

Another option is to refer to the standard section sizes and their corresponding weights, which are readily available in reference materials. However, it’s important to keep in mind that these calculations may have slight discrepancies when compared to the actual weight of the H-beam.

Typically, the difference between the theoretical weight and the actual weight falls within a range of 0.2% to 0.7%. This minor variance is due to factors such as manufacturing tolerances and variations in steel density. Despite these potential discrepancies, the formulas and reference tables provide a reliable means of estimating the weight of H-beam steel for practical applications.

What is the specific formula to calculate the weight of H-beam steel based on the width of the web plate and the base plate?

For those who prefer to calculate the weight of H-beam steel using the dimensions of the web plate and base plate, the following formula can be employed:

Weight (kg/m) = 0.00785 × (2.5 × a × t1 + (b – 2 × t1) × t2)

Where:

This formula takes into account the height and width of the web plate, as well as the width and thickness of the base plate. By inputting these parameters, the formula calculates the weight of the H-beam steel per meter length.

The constant 0.00785 in the formula represents the density of steel in kg/cm³, which is used to convert the volume of the H-beam (calculated using the plate dimensions) into its corresponding weight.

This alternative method provides a convenient way to determine the weight of H-beam steel when the dimensions of the web and base plates are readily available, offering an additional tool for engineers and manufacturers to accurately estimate the material requirements for their projects.

H-steel is categorized into four main types based on the width of the flange:

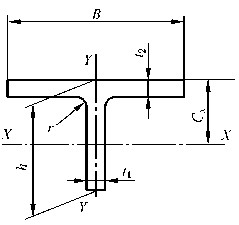

The cross-sectional diagram below illustrates the key dimensions and symbols used to describe H-steel:

Key dimensions:

These dimensions are crucial for determining the size and weight of H-beam steel. The following table provides a comprehensive list of standard H-beam sizes and their corresponding weights for each type of H-steel.

| Type | Model | Height (H) | Width (B) | Web thickness (t1) | Flange thickness (t2) | Radius (r) | Theoretical weight (kg/m) |

| HW Wide flange | 100×100 | 100 | 100 | 6 | 8 | 8 | 16.9 |

| HW Wide flange | 125×125 | 125 | 125 | 6.5 | 9 | 8 | 23.6 |

| HW Wide flange | 150×150 | 150 | 150 | 7 | 10 | 8 | 31.1 |

| HW Wide flange | 175×175 | 175 | 175 | 7.5 | 11 | 13 | 40.4 |

| HW Wide flange | 200×200 | 200 | 200 | 8 | 12 | 13 | 49.9 |

| HW Wide flange | 200×200 | 200 | 204 | 12 | 12 | 13 | 56.2 |

| HW Wide flange | 250×250 | 244 | 252 | 11 | 11 | 13 | 63.8 |

| HW Wide flange | 250×250 | 250 | 250 | 9 | 14 | 13 | 71.8 |

| HW Wide flange | 250×250 | 250 | 255 | 14 | 14 | 13 | 81.6 |

| HW Wide flange | 300×300 | 294 | 302 | 12 | 12 | 13 | 83.5 |

| HW Wide flange | 300×300 | 300 | 300 | 10 | 15 | 13 | 93 |

| HW Wide flange | 300×300 | 300 | 305 | 15 | 15 | 13 | 104.8 |

| HW Wide flange | 350×350 | 338 | 351 | 13 | 13 | 13 | 104.6 |

| HW Wide flange | 350×350 | 344 | 348 | 10 | 16 | 13 | 113 |

| HW Wide flange | 350×350 | 344 | 354 | 16 | 16 | 13 | 129.3 |

| HW Wide flange | 350×350 | 350 | 350 | 12 | 19 | 13 | 134.9 |

| HW Wide flange | 350×350 | 350 | 357 | 19 | 19 | 13 | 154.2 |

| HW Wide flange | 400×400 | 388 | 402 | 15 | 15 | 22 | 140.1 |

| HW Wide flange | 400×400 | 394 | 398 | 11 | 18 | 22 | 146.6 |

| HW Wide flange | 400×400 | 394 | 405 | 18 | 18 | 22 | 168.3 |

| HW Wide flange | 400×400 | 400 | 400 | 13 | 21 | 22 | 171.7 |

| HW Wide flange | 400×400 | 400 | 408 | 21 | 21 | 22 | 196.8 |

| HW Wide flange | 400×400 | 414 | 405 | 18 | 28 | 22 | 231.9 |

| HW Wide flange | 400×400 | 428 | 407 | 20 | 35 | 22 | 283.1 |

| HW Wide flange | 400×400 | 458 | 417 | 30 | 50 | 22 | 414.9 |

| HW Wide flange | 400×400 | 498 | 432 | 45 | 70 | 22 | 604.5 |

| HW Wide flange | 500×500 | 492 | 465 | 15 | 20 | 22 | 202.5 |

| HW Wide flange | 500×500 | 502 | 465 | 15 | 25 | 22 | 239 |

| HW Wide flange | 500×500 | 502 | 470 | 20 | 25 | 22 | 258.7 |

| HM Middle flange | 150×100 | 148 | 100 | 6 | 9 | 8 | 20.7 |

| HM Middle flange | 200×150 | 194 | 150 | 6 | 9 | 8 | 29.9 |

| HM Middle flange | 250×175 | 244 | 175 | 7 | 11 | 13 | 43.6 |

| HM Middle flange | 300×200 | 294 | 200 | 8 | 12 | 13 | 55.8 |

| HM Middle flange | 350×250 | 340 | 250 | 9 | 14 | 13 | 78.1 |

| HM Middle flange | 400×300 | 390 | 300 | 10 | 16 | 13 | 104.6 |

| HM Middle flange | 450×300 | 440 | 300 | 11 | 18 | 13 | 120.8 |

| HM Middle flange | 500×300 | 482 | 300 | 11 | 15 | 13 | 110.8 |

| HM Middle flange | 500×300 | 488 | 300 | 11 | 18 | 13 | 124.9 |

| HM Middle flange | 550×300 | 544 | 300 | 11 | 15 | 13 | 116.2 |

| HM Middle flange | 550×300 | 550 | 300 | 11 | 18 | 13 | 130.3 |

| HM Middle flange | 600×300 | 582 | 300 | 12 | 17 | 13 | 132.8 |

| HM Middle flange | 600×300 | 588 | 300 | 12 | 20 | 13 | 147 |

| HM Middle flange | 600×300 | 594 | 302 | 14 | 23 | 13 | 170.4 |

| HN Narrow flange | 100×50 | 100 | 50 | 5 | 7 | 8 | 9.3 |

| HN Narrow flange | 125×60 | 125 | 60 | 6 | 8 | 8 | 13.1 |

| HN Narrow flange | 150×75 | 150 | 75 | 5 | 7 | 8 | 14 |

| HN Narrow flange | 175×90 | 175 | 90 | 5 | 8 | 8 | 18 |

| HN Narrow flange | 200×100 | 198 | 99 | 4.5 | 7 | 8 | 17.8 |

| HN Narrow flange | 200×100 | 200 | 100 | 5.5 | 8 | 8 | 20.9 |

| HN Narrow flange | 250×125 | 248 | 124 | 5 | 8 | 8 | 25.1 |

| HN Narrow flange | 250×125 | 250 | 125 | 6 | 9 | 8 | 29 |

| HN Narrow flange | 300×150 | 298 | 149 | 5.5 | 8 | 13 | 32 |

| HN Narrow flange | 300×150 | 300 | 150 | 6.5 | 9 | 13 | 36.7 |

| HN Narrow flange | 350×175 | 346 | 174 | 6 | 9 | 13 | 41.2 |

| HN Narrow flange | 350×175 | 350 | 175 | 7 | 11 | 13 | 49.4 |

| HN Narrow flange | 400×150 | 400 | 150 | 8 | 13 | 13 | 55.2 |

| HN Narrow flange | 400×200 | 396 | 199 | 7 | 11 | 13 | 56.1 |

| HN Narrow flange | 400×200 | 400 | 200 | 8 | 13 | 13 | 65.4 |

| HN Narrow flange | 450×200 | 446 | 199 | 8 | 12 | 13 | 65.1 |

| HN Narrow flange | 450×200 | 450 | 200 | 9 | 14 | 13 | 74.9 |

| HN Narrow flange | 500×200 | 496 | 199 | 9 | 14 | 13 | 77.9 |

| HN Narrow flange | 500×200 | 500 | 200 | 10 | 16 | 13 | 88.1 |

| HN Narrow flange | 500×200 | 506 | 201 | 11 | 19 | 13 | 101.5 |

| HN Narrow flange | 550×200 | 546 | 199 | 9 | 14 | 13 | 81.5 |

| HN Narrow flange | 550×200 | 550 | 200 | 10 | 16 | 13 | 92 |

| HN Narrow flange | 600×200 | 596 | 199 | 10 | 15 | 13 | 92.4 |

| HN Narrow flange | 600×200 | 600 | 200 | 11 | 17 | 13 | 103.4 |

| HN Narrow flange | 600×200 | 606 | 201 | 12 | 20 | 13 | 117.6 |

| HN Narrow flange | 650×300 | 646 | 299 | 10 | 15 | 13 | 119.9 |

| HN Narrow flange | 650×300 | 650 | 300 | 11 | 17 | 13 | 134.4 |

| HN Narrow flange | 650×300 | 656 | 301 | 12 | 20 | 13 | 153.7 |

| HN Narrow flange | 700×300 | 692 | 300 | 13 | 20 | 18 | 162.9 |

| HN Narrow flange | 700×300 | 700 | 300 | 13 | 24 | 18 | 181.8 |

| HN Narrow flange | 750×300 | 734 | 299 | 12 | 16 | 18 | 143.4 |

| HN Narrow flange | 750×300 | 742 | 300 | 13 | 20 | 18 | 168 |

| HN Narrow flange | 750×300 | 750 | 300 | 13 | 24 | 18 | 186.9 |

| HN Narrow flange | 750×300 | 758 | 303 | 16 | 28 | 18 | 223.6 |

| HN Narrow flange | 800×300 | 792 | 300 | 14 | 22 | 18 | 188 |

| HN Narrow flange | 800×300 | 800 | 300 | 14 | 26 | 18 | 206.8 |

| HN Narrow flange | 850×300 | 834 | 298 | 14 | 19 | 18 | 178.6 |

| HN Narrow flange | 850×300 | 842 | 299 | 15 | 23 | 18 | 203.9 |

| HN Narrow flange | 850×300 | 850 | 300 | 16 | 27 | 18 | 229.3 |

| HN Narrow flange | 850×300 | 858 | 301 | 17 | 31 | 18 | 254.9 |

| HN Narrow flange | 900×300 | 890 | 299 | 15 | 23 | 18 | 209.5 |

| HN Narrow flange | 900×300 | 900 | 300 | 16 | 28 | 18 | 240.1 |

| HN Narrow flange | 900×300 | 912 | 302 | 18 | 34 | 18 | 282.6 |

| HN Narrow flange | 1000×300 | 970 | 297 | 16 | 21 | 18 | 216.7 |

| HN Narrow flange | 1000×300 | 980 | 298 | 17 | 26 | 18 | 247.7 |

| HN Narrow flange | 1000×300 | 990 | 298 | 17 | 31 | 18 | 271.1 |

| HN Narrow flange | 1000×300 | 1000 | 300 | 19 | 36 | 18 | 310.2 |

| HN Narrow flange | 1000×300 | 1008 | 302 | 21 | 40 | 18 | 344.8 |

| HT Thin-wall | 100×50 | 95 | 48 | 3.2 | 4.5 | 8 | 6 |

| HT Thin-wall | 100×50 | 97 | 49 | 4 | 5.5 | 8 | 7.4 |

| HT Thin-wall | 100×100 | 96 | 99 | 4.5 | 6 | 8 | 12.7 |

| HT Thin-wall | 125×60 | 118 | 58 | 3.2 | 4.5 | 8 | 7.3 |

| HT Thin-wall | 125×60 | 120 | 59 | 4 | 5.5 | 8 | 8.9 |

| HT Thin-wall | 125×125 | 119 | 123 | 4.5 | 6 | 8 | 15.8 |

| HT Thin-wall | 150×75 | 145 | 73 | 3.2 | 4.5 | 8 | 9 |

| HT Thin-wall | 150×75 | 147 | 74 | 4 | 5.5 | 8 | 11.1 |

| HT Thin-wall | 150×100 | 139 | 97 | 3.2 | 4.5 | 8 | 10.5 |

| HT Thin-wall | 150×100 | 142 | 99 | 4.5 | 6 | 8 | 14.3 |

| HT Thin-wall | 150×150 | 144 | 148 | 4.5 | 6 | 8 | 21.8 |

| HT Thin-wall | 150×150 | 147 | 149 | 5 | 7 | 8 | 26.4 |

| HT Thin-wall | 175×90 | 168 | 88 | 3.2 | 4.5 | 8 | 10.6 |

| HT Thin-wall | 175×90 | 171 | 89 | 4 | 6 | 8 | 13.8 |

| HT Thin-wall | 175×175 | 167 | 173 | 5 | 7 | 13 | 26.2 |

| HT Thin-wall | 175×175 | 172 | 175 | 6.5 | 9.5 | 13 | 35 |

| HT Thin-wall | 200×100 | 193 | 98 | 3.2 | 4.5 | 8 | 12 |

| HT Thin-wall | 200×100 | 196 | 99 | 4 | 6 | 8 | 15.5 |

| HT Thin-wall | 200×150 | 188 | 149 | 4.5 | 6 | 8 | 20.7 |

| HT Thin-wall | 200×200 | 192 | 198 | 6 | 8 | 13 | 34.3 |

| HT Thin-wall | 250×125 | 238 | 173 | 4.5 | 6 | 8 | 20.3 |

| HT Thin-wall | 250×175 | 238 | 173 | 4.5 | 8 | 13 | 30.7 |

| HT Thin-wall | 300×150 | 294 | 148 | 4.5 | 6 | 13 | 25 |

| HT Thin-wall | 300×200 | 286 | 198 | 6 | 8 | 13 | 38.7 |

| HT Thin-wall | 350×175 | 340 | 173 | 4.5 | 6 | 13 | 29 |

| HT Thin-wall | 400×150 | 390 | 148 | 6 | 8 | 13 | 37.3 |

| HT Thin-wall | 400×200 | 390 | 198 | 6 | 8 | 13 | 43.6 |

| HL Light-weight | 80×40 | 77 | 40 | 3 | 3.5 | 5 | 4.01 |

| HL Light-weight | 100×50 | 97 | 50 | 2.3 | 3.2 | 6 | 4.39 |

| HL Light-weight | 100×50 | 97 | 50 | 3 | 3.5 | 6 | 5.11 |

| HL Light-weight | 100×50 | 100 | 50 | 3.2 | 4.5 | 8 | 6.06 |

| HL Light-weight | 100×100 | 97 | 100 | 4.5 | 6 | 8 | 12.85 |

| HL Light-weight | 120×60 | 117 | 60 | 3.2 | 4.5 | 8 | 7.38 |

| HL Light-weight | 120×60 | 120 | 60 | 4.5 | 6 | 8 | 9.9 |

| HL Light-weight | 120×120 | 117 | 120 | 3.2 | 4.5 | 8 | 11.62 |

| HL Light-weight | 120×120 | 120 | 120 | 4.5 | 6 | 8 | 15.55 |

| HL Light-weight | 140×70 | 137 | 70 | 3.2 | 4.5 | 8 | 8.59 |

| HL Light-weight | 140×70 | 140 | 70 | 4.5 | 6 | 8 | 11.55 |

| HL Light-weight | 150×75 | 147 | 75 | 3.2 | 4.5 | 8 | 9.2 |

| HL Light-weight | 150×75 | 150 | 75 | 4.5 | 6 | 8 | 12.37 |

| HL Light-weight | 150×100 | 147 | 100 | 3.2 | 4.5 | 8 | 10.96 |

| HL Light-weight | 150×100 | 150 | 100 | 4.5 | 6 | 8 | 14.73 |

| HL Light-weight | 150×150 | 147 | 149 | 6 | 8.5 | 13 | 27.15 |

| HL Light-weight | 175×90 | 172 | 90 | 4.5 | 6.5 | 10 | 15.5 |

| HL Light-weight | 175×175 | 172 | 175 | 6.5 | 9.5 | 13 | 35.05 |

| HL Light-weight | 200×100 | 196 | 99 | 4.5 | 6 | 13 | 16.96 |

| HL Light-weight | 200×150 | 191 | 149 | 5 | 7.5 | 16 | 26.18 |

| HL Light-weight | 200×200 | 197 | 199 | 7 | 10.5 | 16 | 44.2 |

| HL Light-weight | 250×125 | 246 | 124 | 4.5 | 7 | 13 | 22.96 |

| HL Light-weight | 250×175 | 241 | 175 | 6 | 9.5 | 16 | 38.28 |

| HL Light-weight | 300×150 | 296 | 148 | 4.5 | 7 | 16 | 27.95 |

| HL Light-weight | 300×200 | 291 | 199 | 7 | 10.5 | 20 | 50.34 |

| HL Light-weight | 350×175 | 343 | 174 | 5.5 | 7.5 | 16 | 36.37 |

| HL Light-weight | 400×150 | 396 | 149 | 7 | 11 | 16 | 48.01 |

| HL Light-weight | 400×200 | 393 | 199 | 6 | 9.5 | 16 | 49.02 |

By referring to this table, engineers and contractors can easily select the appropriate H-beam size for their specific project requirements, ensuring optimal strength, stability, and cost-effectiveness.

H-beams, also known as I-beams, are a fundamental component in structural engineering, offering robust support and load-bearing capabilities. They are classified based on various criteria, including flange width, usage, production method, and size. Understanding these classifications is crucial for selecting the appropriate beam for specific applications, ensuring optimal performance, and adhering to relevant industry standards.

H-beams are further classified based on their flange width, with each category having its own set of commonly used specifications:

Wide flange H-beams are typically denoted by the product of their web height and flange width. Common models include:

The notation for wide flange H-beams follows the format: web height (H) × flange width (B) × web thickness (t1) × flange thickness (t2). A key characteristic of wide flange H-beams is that the height and width dimensions are often identical.

Medium flange H-beams are also represented by the product of their web height and flange width. Frequently used models include:

The notation for medium flange H-beams is similar to wide flange H-beams: web height (H) × flange width (B) × web thickness (t1) × flange thickness (t2). In medium flange H-beams, the height dimension is typically slightly larger than the width dimension.

Narrow flange H-beams are denoted by the product of their web height and flange width. Standard models include:

The notation for narrow flange H-beams follows the same format as wide and medium flange H-beams: web height (H) × flange width (B) × web thickness (t1) × flange thickness (t2). Narrow flange H-beams are characterized by a higher height-to-width ratio compared to the other categories.

The specific applications of H-beams lead to their classification based on usage, ensuring that each type of beam meets the demands of its intended function.

Primarily designed to bear bending loads, beams are used as horizontal support elements in buildings and bridges. In residential construction, beams are crucial for supporting floors and ceilings, distributing loads to the vertical columns.

Columns are designed to withstand axial loads, providing vertical support in structures. They are commonly used as vertical structural elements in buildings, bridges, and towers. For example, in skyscrapers, columns are essential for transferring loads from the upper floors to the foundation.

Piles are engineered to be driven into the ground to support foundations, particularly in areas with unstable soil conditions. They are utilized in deep foundation systems for buildings, bridges, and other structures requiring substantial ground support. An example is the foundation of offshore oil rigs, where piles provide stability in soft seabed conditions.

The production method used for manufacturing H-beams also serves as a basis for classification, affecting their uniformity and customization potential.

Rolled H-beams are produced by rolling a single piece of steel into the desired shape, ensuring uniform strength and ease of production. These beams are widely used due to their consistency and cost-effectiveness. They are commonly found in standard construction projects, such as commercial buildings and warehouses.

Welded H-beams are fabricated by welding together steel plates to form the H-shape, allowing for customization to specific dimensions or configurations. These beams are particularly useful in unique construction projects where standard sizes are insufficient. For example, custom-welded H-beams are used in specialized industrial equipment frames.

H-beams are further classified into size categories to accommodate different structural needs, from lightweight applications to heavy-duty support.

Small H-beams are suitable for lighter loads, making them ideal for residential construction and smaller structural projects. They are often used in home renovation projects, such as reinforcing floor joists or creating open-plan living spaces.

Medium H-beams offer a balance between load capacity and material cost, commonly used in commercial construction and mid-sized infrastructure projects. They are integral to the structural framework of office buildings and shopping centers.

Large H-beams are designed for heavy loads and substantial structural support, essential in large-scale constructions such as skyscrapers, bridges, and heavy industrial facilities. An example is the structural support of large stadium roofs, where large H-beams provide the necessary strength to span wide distances.

Understanding the classification and types of H-beams, along with their specific applications, is crucial for engineers and architects. This knowledge ensures the selection of the appropriate beam for each project, optimizing structural integrity and performance.

Related reading:

H-beam steel is a highly efficient and cost-effective structural profile that offers an optimal distribution of sectional area and an excellent strength-to-weight ratio. Its cross-section resembles the letter “H,” hence its name.The components of an H-beam are arranged at right angles, providing strong resistance to bending forces. This characteristic makes the construction process simple, cost-effective, and results in lightweight structural strength in all directions. Due to these advantages, H-beam steel is widely used in various construction applications.H-beam steel is also known by other names, such as:

The cross-section of an H-beam comprises a web plate and two flange plates, which contribute to its unique properties and performance.

Adherence to industry standards ensures that H-beams meet specific dimensional, material, and performance criteria. These standards are essential for ensuring structural integrity, safety, and interoperability.

The Japanese Industrial Standards (JIS) specify the dimensions, tolerances, and material properties for H-beams used in Japan.

The American Society for Testing and Materials (ASTM) provides standards for H-beams used in the United States.

European Norms (EN) specify the requirements for H-beams used in Europe, ensuring their suitability for various structural applications.

British Standards (BS) provide guidelines for the dimensions and material properties of H-beams used in the United Kingdom.

Australian Standards (AS) outline the requirements for H-beams used in Australia, ensuring their compliance with local construction practices.

H-beams are extensively used in building construction as primary structural elements. They form the backbone of various structures, providing support for floors, roofs, and walls.

H-beams are essential in infrastructure projects due to their ability to support heavy loads and withstand environmental stresses.

In shipbuilding, H-beams provide structural support for various components of a vessel.

In mechanical manufacturing, H-beams are used as structural supports and frames for various machinery and equipment.

Below are answers to some frequently asked questions:

H-beams, also known as wide flange beams or W beams, are defined by their specific dimensions, which include the height of the web (H) and the width of the flange (B). For instance, a 150×100 mm H-beam has a web height of 150 mm and a flange width of 100 mm. The dimensions of H-beams vary significantly, commonly ranging from 100×50 mm to 900×300 mm. Specific examples include 150×75 mm, 200×100 mm, 250×125 mm, and 300×150 mm.

The thickness of the web (t1) and flange (t2) also varies. For example, a 150×100 mm H-beam might have a web thickness of 6 mm and a flange thickness of 9 mm. Some specific dimensions are:

H-beams can be classified based on their flange width into wide flange, medium flange, and narrow flange beams, where the wide flange beams have a flange width greater than or equal to the web height, and narrow flange beams have a flange width approximately equal to half the web height. H-beams are typically available in lengths ranging from 6 meters to 15 meters, with 6 meters and 12 meters being the most common.

Manufacturing standards for H-beams include international specifications such as JIS, ASTM, EN, BS, and AS, ensuring consistency and suitability for various applications like construction, mechanical manufacturing, and shipbuilding.

H-beams are classified based on several criteria that highlight different aspects of their design, application, and production methods.

Firstly, H-beams can be categorized by flange width. Wide Flange H-Beams have a flange width that is equal to or greater than the web height. Medium Flange H-Beams fall between wide and narrow flange beams. Narrow Flange H-Beams have a flange width approximately half the web height.

Secondly, H-beams are classified by their intended use. General H-Beams are used in various structural applications. H-Beam Columns are specifically used as columns due to their strength and stability. H-Beam Piles are utilized in underground engineering and foundation work. Very Thick Flange H-Beams are designed for applications requiring extra strength and stability. Additionally, Parallel-Legged Channels and Parallel-Flange T-Beams are sometimes included in the H-beam category.

Thirdly, H-beams are distinguished by their production method. Welded H-Beams are fabricated by welding the flanges to the web, while Rolled H-Beams are made from rolled steel, forming the H-section directly.

Lastly, H-beams are categorized by size specification. Large H-Beams have a web height above 700mm, Medium H-Beams have a web height between 300mm and 700mm, and Small H-Beams have a web height less than 300mm.

Each of these classifications helps to determine the most appropriate type of H-beam for a specific application, ensuring structural integrity and efficiency in construction projects.

The weight per meter of an H-beam varies based on its dimensions and specifications. For example, an H-B 150 beam can weigh 27.1 kg/m, 30.6 kg/m, or 34.6 kg/m depending on the thickness of the flange. Similarly, an H-B 200 beam can weigh 37.3 kg/m, 40.0 kg/m, or 60.0 kg/m, and an H-B 300 beam can weigh 32.0 kg/m, 36.7 kg/m, or 94.0 kg/m, all depending on their specific dimensions. The weight per meter of an H-beam can also be calculated using the formula:

The cross-sectional area is determined by the dimensions of the H-beam, including height, flange width, and flange thickness, considering the density of steel at approximately 7850 kg/m³.

The standard lengths of H-beams typically start at 6 meters and can increase in increments of 500 mm up to a maximum of 24 meters. For lengths beyond 15 meters, it is advisable to consult with the supplier to ensure availability and confirm turnaround times.

Specific suppliers may have their own guidelines. For instance, Metals Depot offers steel beams in lengths of 5 feet, 10 feet, 20 feet, 25 feet, or can cut to custom sizes. Similarly, Yamato Steel Co., Ltd. provides standard lengths starting from 6 meters with increments of 500 mm up to 24 meters, recommending special arrangements for lengths over 15 meters.

Additionally, many suppliers offer the option to cut H-beams to custom lengths, accommodating projects that require specific dimensions. Always check with the supplier for the most accurate and up-to-date information regarding availability and custom options.

For more information on H-beams and related topics, consider exploring the following resources:

These tools can help you quickly determine the weight of H-beams and I-beams based on their specific dimensions, making it easier to plan and execute your construction projects efficiently.