Have you ever struggled to calculate the weight of H-beam steel for your construction project? Understanding the weight of these beams is crucial for efficient design and budgeting. In this article, you’ll discover a simple, accurate H-beam steel weight calculator. This tool will help you determine the weight of various H-beam types based on their dimensions, ensuring precision in your projects. Learn how to use this calculator and make your construction planning smoother and more reliable.

H-beam steel, also known as wide flange beam or W-beam, is a high-efficiency structural steel profile characterized by its distinctive H-shaped cross-section. This design optimizes the distribution of sectional area, resulting in an exceptional strength-to-weight ratio that makes it a cost-effective choice for various engineering applications.

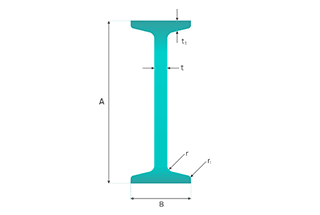

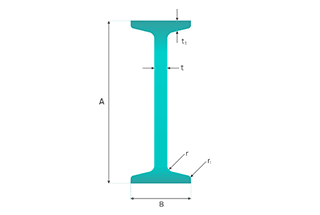

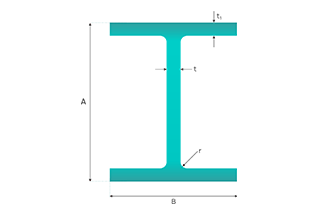

The profile consists of two main components: the web (vertical element) and the flanges (horizontal elements). The flanges are typically wider than the web, providing superior resistance to bending forces in both the strong and weak axes. This orthogonal arrangement of elements contributes to the beam’s excellent performance in all loading directions.

Key features of H-beam steel include:

H-beam steel is often referred to by several names in the industry, including:

The standardized dimensions and properties of H-beam steel are typically specified by international standards such as ASTM A992/A992M or EN 10025, ensuring consistency and reliability in structural design and fabrication processes.

H-beam steel, a crucial structural element in construction and engineering, is classified into several categories based on various criteria:

(1) Flange Width Classification:

• Wide Flange: Flange width (B) ≥ Web height (H)

• Medium Flange: Flange width (B) ≥ Web height (H)

• Narrow Flange: Flange width (B) ≈ 1/2 Web height (H)

(2) Functional Classification:

• Beam H-sections

• Column H-sections

• Pile H-sections

• Extra-thick flange H-sections

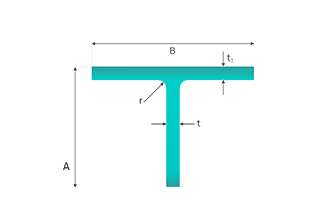

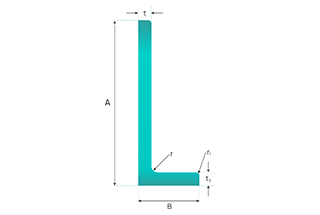

Parallel leg channel steel and parallel flange T-shaped steel are sometimes included in the H-beam family. Typically, narrow flange H-beams are utilized as beams, while wide flange H-beams serve as columns.

(3) Manufacturing Method:

• Welded H-beams: Fabricated by welding separate plates

• Rolled H-beams: Produced through hot rolling process

(4) Size Classification:

• Large: Web height (h) > 700mm

• Medium: Web height (h) = 300-700mm

• Small: Web height (h) < 300mm

As of late 1990, the world’s largest H-beam featured a web height of 1200mm and a flange width of 530mm, showcasing the advancement in manufacturing capabilities.

H-beam standards are primarily divided into two systems:

Despite the difference in measurement units, H-beam specifications universally incorporate four key dimensions:

While nomenclature and expression of H-beam sizes may vary globally, the actual size ranges and manufacturing tolerances remain consistent across different regions. This standardization facilitates international trade and ensures compatibility in global construction projects.

Hot-rolled H-section and T-section steel are classified into four categories according to GB/T 11263-2005, which specifies dimensions, shapes, weights, and allowable deviations. These categories are:

In industrial practice, H-beams are typically supplied based on either theoretical weight or actual quantity, depending on customer requirements and industry standards.

The allowable deviation between a single H-beam’s theoretical weight and its actual weight is strictly regulated to ensure structural integrity and design accuracy. According to industry standards, this deviation must not exceed ±6%. This tolerance accounts for minor variations in manufacturing processes while maintaining the necessary load-bearing capabilities.

To calculate the weight of an H beam, you need to understand its dimensions and material properties. Accurate weight determination is crucial for engineering, ensuring safety and efficient resource allocation in construction projects.

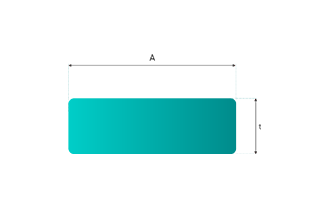

Here are the key dimensions and properties used in the calculation:

The weight of an H beam per meter can be calculated using the following formula:

To facilitate accurate material estimation and structural calculations, you can utilize the H-beam weight calculator provided below. This tool incorporates the latest industry standards and material properties to deliver precise weight calculations based on the beam’s dimensions and steel grade.

When using this calculator, consider the following factors:

Accurate weight calculation is crucial for various aspects of structural engineering and construction, including:

By leveraging this calculator and understanding the industry standards for H-beam classifications and tolerances, engineers and project managers can optimize their material selection, ensure compliance with building codes, and improve overall project efficiency.

Related Tool: Steel Weight Calculator

The theoretical weight of an H beam is derived from mathematical formulas that factor in its dimensions and steel’s density. This weight represents an idealized value assuming perfect manufacturing conditions. Key factors used in the calculation include:

Cross-Sectional Dimensions: The height, flange width, web thickness, and flange thickness of the H beam.

Steel Density: Typically 7.85 g/cm³ or 7850 kg/m³ for standard structural steel.

Mathematical Formula:

Here, ( H ) is the web height, ( B ) is the flange width, ( t_1 ) is the web thickness, ( t_2 ) is the flange thickness, and ( R ) is the fillet radius.

The weight per meter can be determined using:

This calculated weight is used for design and estimation purposes.

The actual weight of an H beam often differs from its theoretical weight due to real-world factors, including manufacturing variations, dimensional tolerances, and environmental influences.

Dimensional tolerances, such as those in standards like GB/T 33814-2017, allow variations of +/- 6% for welded H beams and +/- 4% for hot-rolled beams. These minor deviations can affect weight.

Temperature fluctuations can slightly alter steel density, while wear and tear during handling may cause subtle dimensional changes.

To save costs, manufacturers frequently target the lower tolerance limit, which often results in actual weights falling below theoretical estimates.

Understanding the potential gap between theoretical and actual weights is critical in construction and engineering. Key considerations include:

By accounting for these factors, engineers and project planners can better align theoretical calculations with real-world applications.

| Category | Spec. | Weight kg/m | Section area mm2 |

| HW | 100*100*6*8 | 17.2 | 21.9 |

| 125*125*6.5*9 | 23.8 | 30.31 | |

| 150*150*7*10 | 31.9 | 40.55 | |

| 175*175*7.5*11 | 40.3 | 51.43 | |

| 200*200*8*12 | 50.5 | 64.28 | |

| 200*204*12*12 | 56.7 | 72.28 | |

| 250*250*9*14 | 72.4 | 92.18 | |

| #250*255*14*14 | 82.2 | 104.7 | |

| #294*302*12*12 | 85 | 108.3 | |

| 300*300*10*15 | 94.5 | 120.4 | |

| 300*305*15*15 | 106 | 135.4 | |

| 344*348*10*16 | 115 | 146 | |

| 350*350*12*19 | 137 | 173.9 | |

| 388*402*15*15 | 141 | 179.2 | |

| 394*398*11*18 | 147 | 187.6 | |

| 400*400*13*21 | 172 | 219.5 | |

| 400*408*21*21 | 197 | 251.5 | |

| 414*405*18*28 | 233 | 296.5 | |

| 428*407*20*35 | 284 | 361.4 | |

| 458*417*30*50 | 415 | 529.3 | |

| 498*432*45*70 | 605 | 770.8 | |

| HM | 148*100*6*9 | 21.4 | 27.25 |

| 194*150*6*9 | 31.2 | 39.76 | |

| 244*175*7*11 | 44.1 | 56.24 | |

| 294*200*8*12 | 57.3 | 73.03 | |

| 340*250*9*14 | 79.7 | 101.5 | |

| 390*300*10*16 | 107 | 136.7 | |

| 440*300*11*18 | 124 | 157.4 | |

| 482*300*11*15 | 115 | 146.4 | |

| 488*300*11*18 | 129 | 164.4 | |

| 582*300*12*17 | 137 | 174.5 | |

| 588*300*12*20 | 151 | 192.5 | |

| 594*302*14*23 | 175 | 222.4 | |

| HN | 100*50*5*7 | 9.54 | 12.16 |

| 125*60*6*8 | 13.3 | 17.01 | |

| 150*75*5*7 | 14.3 | 18.16 | |

| 175*90*5*8 | 18.2 | 23.21 | |

| 198*99*4.5*7 | 18.5 | 23.59 | |

| 200*100*5.5*8 | 21.7 | 27.57 | |

| 248*124*5*8 | 25.8 | 32.89 | |

| 250*125*6*9 | 29.7 | 37.87 | |

| 298*149*5.5*8 | 32.6 | 41.55 | |

| 300*150*6.5*9 | 37.3 | 47.53 | |

| 346*174*6*9 | 41.8 | 53.19 | |

| 350*175*7*11 | 50 | 63.66 | |

| 400*150*8*13 | 55.8 | 71.12 | |

| 396*199*7*11 | 56.7 | 72.16 | |

| 400*200*8*13 | 66 | 84.12 | |

| 450*150*9*14 | 65.5 | 83.41 | |

| 446*199*8*12 | 66.7 | 84.95 | |

| 450*200*9*14 | 76.5 | 97.41 | |

| 500*150*10*16 | 77.1 | 98.23 | |

| 496*199*9*14 | 79.5 | 101.3 | |

| 500*200*10*16 | 89.6 | 114.2 | |

| 506*204*11*19 | 103 | 131.3 | |

| 596*199*10*15 | 95.1 | 121.2 | |

| 600*200*11*17 | 106 | 135.2 | |

| 606*200*12*20 | 120 | 153.3 | |

| 692*300*13*20 | 166 | 211.5 | |

| 700*300*13*24 | 185 | 235.5 | |

| 792*300*14*22 | 191 | 243.4 | |

| 800*300*14*26 | 210 | 267.4 | |

| 890*299*15*23 | 213 | 270.9 | |

| 900*300*16*28 | 243 | 309.8 | |

| 912*302*18*34 | 286 | 364 |

Accurate weight calculation of H beams is crucial for ensuring structural integrity and project efficiency. However, several common errors can occur during this process, which can be mitigated with careful attention to detail.

Theoretical weight calculations often differ from actual weights due to simplifications and assumptions, commonly arising from variations in material properties, manufacturing tolerances, and additional surface treatments. These discrepancies include:

Errors introduced during manufacturing processes can affect the weight of H beams, including precision losses during cutting, welding, and heat treatment, and dimensional inaccuracies within acceptable tolerance ranges.

National and international standards define permissible tolerance ranges for H beams, ensuring consistency and reliability. These standards account for dimensional tolerances, typically within +/- 6% for welded H beams and +/- 4% for hot-rolled beams, and acceptable weight discrepancies due to manufacturing variations.

Accurate weight calculations are crucial for ensuring structural safety and integrity. Miscalculations can compromise structural safety by underestimating or overestimating load-bearing capacity, affect resource allocation and cost management, and lead to non-compliance with safety regulations and building codes.

Online H beam weight calculators and theoretical weight charts are invaluable tools that streamline the process and reduce the risk of human error. Ensure accurate input of dimensions and material properties for reliable results.

Advanced tools like FEA and CAD software provide detailed analysis and predictions of structural behavior under various load conditions, helping predict structural performance and optimize designs.

Accurate weight calculations influence project planning aspects such as transportation, installation, and cost management, ensuring proper weight estimates for transportation, suitable installation methods and equipment, and optimized project costs.

Always ensure that weight calculations align with national and international standards to maintain consistency, reliability, and regulatory compliance.

Be aware of material property variations, such as negative tolerance phenomena where actual weight may be less than theoretical estimates, and adjust calculations accordingly.

Utilize calculators and software that handle various loading types and conditions for a thorough analysis of the beam’s structural behavior, enhancing project accuracy and efficiency.

By addressing these common errors and considerations, engineers and construction professionals can ensure accurate weight calculations, enhancing the safety, efficiency, and structural integrity of their projects.

Below are answers to some frequently asked questions:

To calculate the weight of an H beam manually, follow these steps:

Determine the Cross-Sectional Area:

Calculate the area of the flanges:

For both flanges:

Calculate the area of the web:

Sum the areas to get the total cross-sectional area:

Calculate the Volume:

Multiply the cross-sectional area by the length of the beam:

Calculate the Weight:

Multiply the volume by the density of the material (for steel, typically 7850 kg/m³):

For example, for an H beam with a flange width of 0.2 m, flange thickness of 0.02 m, web height of 0.3 m, web thickness of 0.015 m, and length of 6 m:

Calculate the cross-sectional area:

Calculate the volume:

Calculate the weight:

This method ensures accurate manual calculation of the H beam’s weight.

Standard sizes of H beams vary depending on the regional standards and classifications. In the ASTM A6/A6M standard, H beams (S-Shapes) range in depth from 100mm (4 inches) to over 900mm (36 inches), with flange widths from 50mm (2 inches) to over 300mm (12 inches). European wide flange beams, designated as HEA, HEB, and HEM, have specific sizes like HEA 100, HEA 200, HEB 200, HEB 300, HEM 180, and HEM 300. Japanese standards (JIS) include sizes such as H100x100, H150x150, H300x300, and H500x500. Chinese standards (GB) feature sizes like 100×100, 200×200, and 300×300. These sizes are classified by web height into large (above 700mm), medium (300mm to 700mm), and small (below 300mm) categories.

The actual weight of an H beam can differ from the theoretical weight due to several factors. Manufacturing tolerances can cause slight variations in the dimensions of the H beam, such as the thickness of the web and flanges, leading to differences in weight. Variations in the material density of the steel used, even though it is generally taken as 7.85 g/cm³, can also affect weight calculations. Calculation methods often assume ideal conditions and may not account for all nuances of the manufacturing process, introducing minor errors. National standards specify error ranges, acknowledging potential variations. Additionally, practical considerations such as the hot rolling process or the fabrication of built-up units can further contribute to weight discrepancies. These factors highlight the importance of considering a margin of error when using H beam weight calculators for accurate and reliable estimations.

Yes, you can use an online calculator for all types of H beams. These calculators are designed to handle various dimensions and specifications, making them versatile tools for quick and accurate weight calculations. They typically require you to input the dimensions of the H beam, such as height, flange width, web thickness, and length, and then calculate the weight based on the material’s density. While they are highly effective for most standard and custom H beams, it’s important to consider that there may be minor discrepancies between theoretical and actual weights due to manufacturing variations. Nonetheless, online calculators are a practical and efficient solution for determining the weight of H beams in construction and engineering projects.

Common mistakes in calculating H beam weights include:

By avoiding these common errors, users can achieve more accurate H beam weight calculations, ensuring structural integrity and safety in construction projects.

H beam weight calculations are used in construction projects to ensure structural integrity and safety. By accurately determining the weight of H beams, engineers can assess the load-bearing capacity and stability of the structure. This information is crucial for designing foundations, estimating material costs, and planning transportation and installation processes. Accurate weight calculations also aid in selecting the appropriate beam sizes and specifications, ensuring that the beams can support the intended loads without compromising safety. Additionally, these calculations help in optimizing project timelines and resource allocation, ultimately contributing to the efficiency and success of construction projects.