Have you ever wondered about the difference between H-beams and I-beams in construction? While they may look similar, these two types of steel beams have distinct characteristics that make them suitable for different applications. In this article, we’ll explore the key differences between H-beams and I-beams, as explained by experienced mechanical engineers. Discover how their unique shapes, load-bearing capacities, and manufacturing processes set them apart, and learn which beam is best suited for your next project.

When it comes to constructing robust and durable structures, the choice of support beams plays a pivotal role. Among the most commonly debated options are H-beams and I-beams, each boasting unique characteristics and advantages. These steel giants are critical in various construction projects, from towering skyscrapers to expansive bridges, but understanding their differences is essential for making informed decisions.

In this article, we will delve into the distinctive features of H-beams and I-beams, exploring their structural nuances and the specific applications each is best suited for. We’ll compare their strength, weight, and load-bearing capacities, and examine how these factors influence their performance in real-world scenarios. Whether you’re an engineer, architect, or construction enthusiast, this comprehensive guide will provide the insights needed to choose the right beam for your next project. Prepare to uncover the key differences and practical uses of H-beams and I-beams, ensuring your construction endeavors stand strong and resilient.

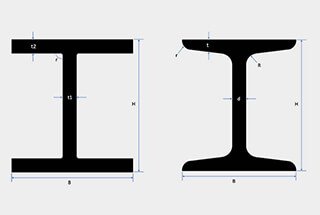

I-beams and H-beams are both essential structural steel components used extensively in construction and engineering. While they share some similarities, their differences in shape, structural properties, and applications make each suitable for specific types of projects.

I-Beams:

H-Beams:

The structural differences between I-beams and H-beams result in distinct load-bearing performances:

H-Beams:

I-Beams:

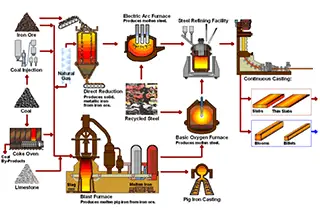

The manufacturing processes for H-beams and I-beams differ significantly:

I-Beams:

H-Beams:

Here is a table comparing H-beam steel and I-beam steel:

| Feature | I-beam Steel | H-beam Steel |

|---|---|---|

| Cross-sectional Dimensions | Relatively high and narrow | Efficient and economical profile with a logically structured cross-section |

| Applications | Used directly in components that bend within the plane of the web or as part of a lattice-type structural component | Suitable for a wide range of structural applications, including beams, axially compressed components, and bending components |

| Flange Width | Smaller | Wider |

| Suitability for Compression and Bending | Unsuitable for axially compressed components or components bending perpendicular to the web plane | Suitable for both axially compressed components and bending components |

| Force Bearing Direction | Can bear unidirectional forces | Can withstand forces in two directions |

| Stability in Steel Structure Buildings | Insufficient alone; even thickened I-beams can become unstable as load-bearing columns | Stable in steel structure buildings |

| Use in Structural Components | Only used for beams | Suitable for load-bearing columns in structures |

| Cross-sectional Mechanical Properties | Inferior to H-beams | Superior to I-beams |

| Flange Thickness | Variable thickness, thicker near the web and thinner externally | Uniform thickness |

| Manufacturing Process | Rolled sections with a 1:10 slope inside the flanges | Rolled sections or assembled sections welded from three plates. Requires an additional set of vertical rolls for rolling |

| Specific Types and Uses | Not specified in detail | Categorized into HW (roughly equal height and flange width, used as rigid steel columns), HM (height to flange width ratio of approximately 1.33 to 1.75, used as frame columns or beams), HN (height to flange width ratio of 2 or more, primarily used for beams) |

Related reading: online H-beam & I-beam Weight Calculator

I-beams:

H-beams:

H-beam Steel:

I-beam Steel:

H-beam Steel:

I-beam Steel:

H-beam Steel:

I-beam Steel:

I-beams:

H-beams:

H-beams:

I-beams:

H-beams:

I-beams:

H-beams:

I-beams:

H-beams:

I-beams:

H-beams:

I-beams:

In the world of construction and engineering, selecting the right beam—H-beam or I-beam—is crucial for ensuring structural integrity, cost efficiency, and overall project success. While both beams offer unique advantages, H-beams are generally more versatile and suitable for a wider range of applications due to their balanced cross-section and superior mechanical properties.

Below are answers to some frequently asked questions:

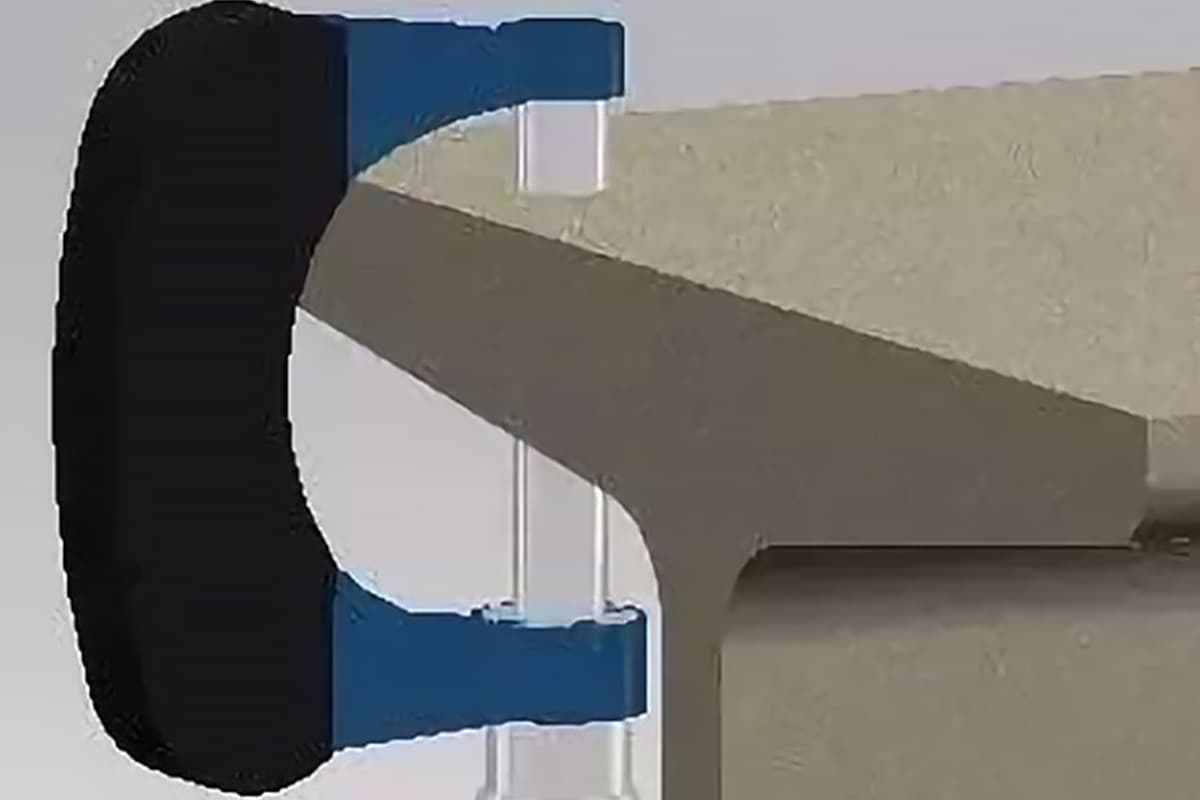

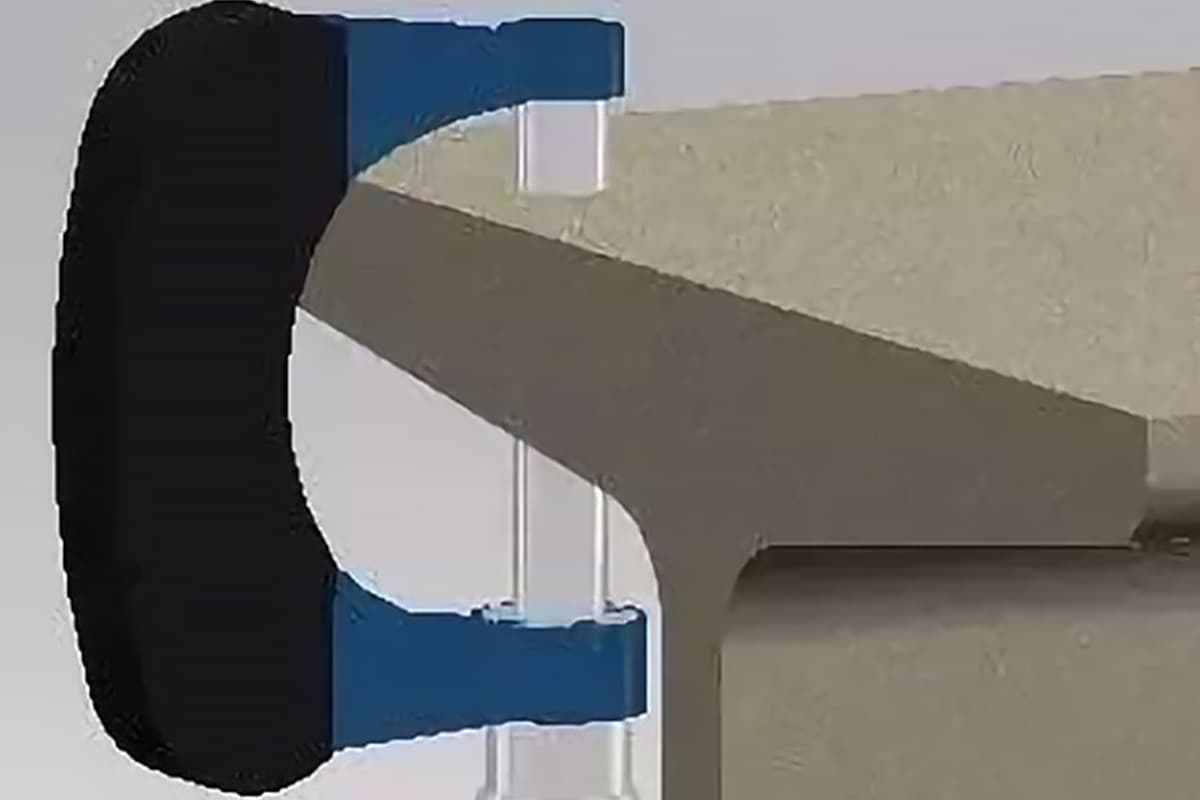

The main differences between H-beams and I-beams lie in their design, structural properties, and applications. H-beams have a thicker web and equal thickness flanges that are parallel to each other, making them resemble the letter “H.” They are designed to handle higher loads due to their greater web thickness and higher moment of inertia, making them suitable for longer spans and heavy load-bearing applications like commercial buildings and bridges. In contrast, I-beams have a thinner web and tapered flanges, resembling the letter “I.” They are better suited for lighter loads and shorter spans, commonly used in residential projects and smaller structural applications. Additionally, H-beams are heavier and more complex to manufacture but offer greater strength and load-bearing capacity, while I-beams are lighter, easier to produce, and more cost-effective for projects with lighter load requirements.

H-beams are generally stronger than I-beams due to several key factors. H-beams have a thicker web and wider flanges, which significantly enhance their load-bearing capacity and resistance to bending and shear stresses. The moment of inertia is also greater in H-beams, making them more efficient at resisting bending and providing better lateral stiffness. Additionally, H-beams can support heavier loads and span longer distances, and they are more resistant to torsional deformation. These characteristics make H-beams the preferred choice for projects requiring high structural integrity and load-bearing capacity.

H-beams are typically used in large-scale construction projects such as high-rise buildings, large commercial centers, industrial plants, bridges, tunnels, and large stadiums due to their excellent load-bearing capacity and stability. They are also utilized in special engineering applications like seismic structures, offshore platforms, and high-load industrial facilities, as well as in heavy industry and maritime constructions like large cargo ships and docks.

I-beams, on the other hand, are commonly employed in small to medium-sized buildings such as residential homes, low-rise office buildings, and small commercial structures due to their lighter weight and sufficient strength. They serve as secondary support structures in larger buildings, including floor beams, roof supports, and internal partitions. Additionally, I-beams are frequently used in temporary structures like scaffolding and construction platforms, as well as in lightweight applications where weight is a concern. They are versatile and often used in general construction to form the framework of buildings and bridges.

H-beams generally weigh more than I-beams due to their thicker central web and larger, equally-sized top and bottom flanges. This robust construction contributes to their greater weight and strength, making H-beams suitable for applications requiring high structural strength and the ability to support heavier loads. Conversely, I-beams are lighter because they have thinner flanges and a tapered design, making them easier to transport and ideal for applications where minimizing structural weight is important. This weight difference also affects their application, with H-beams being used for longer spans and heavier loads, while I-beams are more suitable for shorter spans and lighter loads.

H-beams offer several advantages over I-beams, including greater strength and load-bearing capacity due to their wider and thicker flanges. This makes them ideal for large-span structures and projects that need to handle complex stresses, such as high-rise buildings and long-span bridges. Their design provides better lateral stability and uniform strength in all directions. However, H-beams are generally heavier and more expensive due to their complex manufacturing process, which often involves welding three steel plates together.

On the other hand, I-beams are lighter and more cost-effective, making them suitable for smaller to medium-sized projects where reduced structural weight and cost are significant factors. They are easier to handle and install, which can benefit projects with tight schedules or site limitations. However, I-beams are less capable of handling complex stress conditions and are typically used for simpler bending stresses and as secondary support elements rather than primary load-bearing components.

H-beams and I-beams differ significantly in their span capabilities and load-bearing capacities. H-beams are designed to support longer spans, reaching up to 330 feet (about 100 meters), making them ideal for large-scale structures like industrial buildings, bridges, and high-rise constructions. This is due to their wider flanges and thicker webs, which distribute loads over a larger area and provide greater structural integrity.

On the other hand, I-beams are more suited for shorter to medium spans, typically ranging from 33 to 100 feet (about 10 to 30 meters). They are often used in smaller to medium-sized projects or as secondary supports in larger structures. I-beams have narrower flanges and are lighter, making them appropriate for moderate load requirements. However, they are less capable of handling complex stresses and high lateral loads compared to H-beams.

In summary, H-beams are preferable for longer spans and heavier, more complex loads, while I-beams are better suited for shorter spans and moderate load applications.

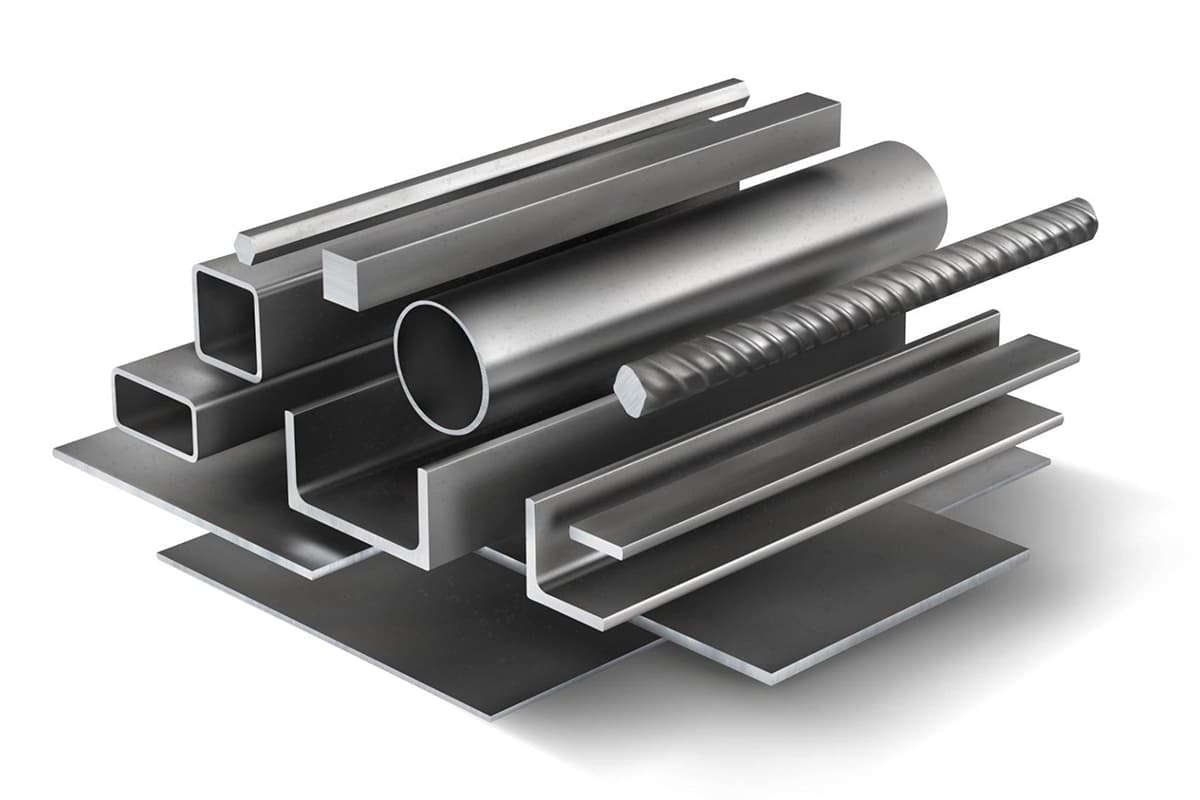

The choice of material depends on various factors:

While Q235B and stainless steel grades are indeed popular, the most common materials for I-beams and H-beams can vary by region and application. Carbon steel grades (Q235, Q345, A992, S355) are generally more common for standard structural applications, while stainless steel grades are used in specialized scenarios requiring corrosion resistance or specific aesthetic properties.

Choosing between I-beam and H-beam steel is a critical decision in structural engineering, as it directly impacts the load-bearing capacity, structural stability, and overall cost-effectiveness of a project. Here’s a detailed analysis to help guide this decision based on key engineering requirements:

When choosing between I-beam and H-beam steel, consider the following factors:

Consulting with structural engineers and conducting a thorough analysis of the project requirements will ensure the optimal choice between I-beam and H-beam steel, leading to a safe, stable, and cost-effective structure.