When deciding between hard and soft molds, what factors come into play? This article delves into the distinctions between these two types of molds, focusing on their costs, processes, and lifespans. Readers will learn how the choice between hard and soft molds can impact production time, maintenance requirements, and overall expense, guiding them to make informed decisions for their manufacturing needs.

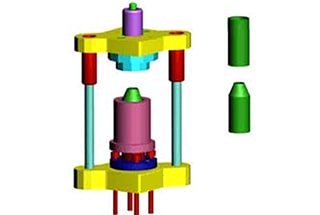

Soft molds (excluding silicone molds) refer to molds made of materials such as NAK80 steel. The mold core of this type of material is generally pre-hardened and can be machined directly without requiring further heat treatment before they can be put into production.

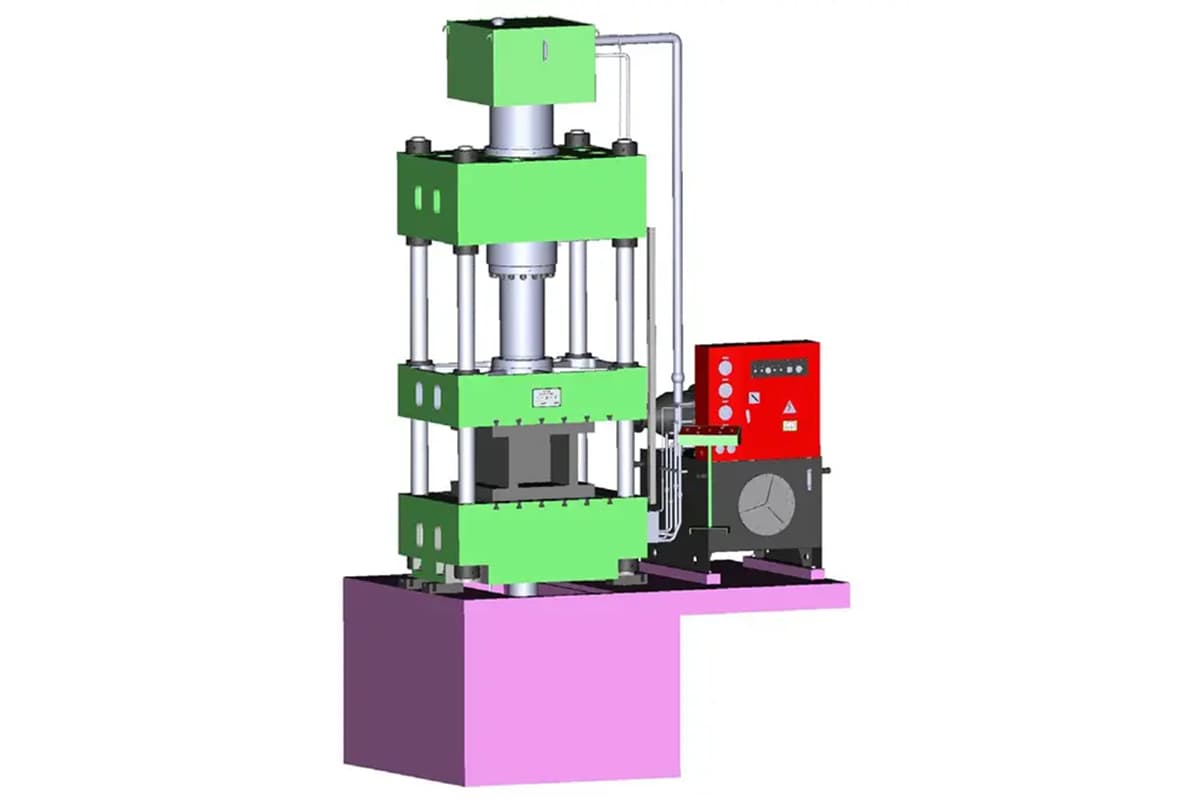

In contrast, hard molds refer to molds in which the mold core material is annealed before mechanical processing, then undergoes heat treatment after machining is complete, and finally undergoes electrical discharge machining to reach the final form.

The following is a comparison of the costs, processes, and lifespan of mold production:

| Comparison Items: | Soft molds | Hard molds |

| Mold frame price | The same | The same |

| Mold core price | According to the size of the product, there is a difference of several hundred to two thousand yuan in the mold core material. | |

| Processing technology and steps | Precision Machining (CNC and Electrical Discharge Machining) | Rough Machining (CNC) Quenching and Tempering for Hardening Precision Machining (Electrical Discharge Machining) |

| Subsequent treatment (polishing or etching) | The same | The same |

| Mold making time | For rough machining, hard molds require 1-2 days. For heat treatment, soft molds are 5-8 days faster than hard molds. Overall, the difference is about 10 days. | |

| Mold precision | The same | The same |

| Mold modification | Soft molds have fewer steps, making them relatively cheaper and easier to work with. | Hard molds have more complex steps, making mold modifications more expensive. |

| Lifespan | 10k-30k pieces | They can reach up to 5,000,000 pieces. |

| Frequency and cost of mold repairs | Producing several thousand pieces may result in defects such as burrs and flash, which requires mold repair. The cost depends on the extent of damage, but it is usually a few hundred yuan. | Mold repair is rarely required, but the cost of repairing molds can be relatively expensive. |

1. If the product size is large, a single mold core of a soft mold can save about 1,000 yuan in costs.

2. The manufacturing process is simple, such as quenching and tempering, which can save about 2,000 yuan per single mold.

3. If a product has many components, more molds will be required, and the total price of soft molds will be significantly lower for Project 1 and Project 2.

4. Due to the lack of quenching and tempering processes, the time taken for mold modification is shorter, and the cost is cheaper.

In summary, the advantages and disadvantages of soft molds are as follows: they have inexpensive mold cores, require fewer processing steps, have shorter mold making cycles, easier to modify, but have a shorter lifespan and may require more frequent repairs. They are suitable for production runs of less than 30,000 pieces.

Overall, when the product size is small, the reduction in mold costs may not be significant. In fact, when considering maintenance costs in the later stages, the actual cost may be higher. In terms of time, a soft mold can be delivered 5 to 8 days earlier.

In the mold development process, we recommend offering a unified price for soft and hard molds. Then, comprehensively consider factors such as cost, time, product procurement volume, and later risks before deciding which mold form to use.