Cracks during the heat treatment of shaft workpieces can lead to catastrophic failures in machinery. This article delves into the causes behind these cracks, focusing on factors like material properties, stress during quenching and tempering, and flaws in the manufacturing process. By understanding these issues, engineers can implement strategies to prevent such defects, ensuring the durability and reliability of critical components. Expect to learn about specific analysis techniques and preventive measures that can significantly enhance the quality of shaft workpieces.

42CrMo is a high-strength alloy steel known for its excellent mechanical properties such as high strength and toughness, good hardenability, and absence of temper brittleness.

After quenching and tempering, it exhibits a high fatigue limit, impact resistance, and good low-temperature impact toughness, making it ideal for manufacturing large and medium-sized steel components that require both strength and toughness.

Our company has chosen 42CrMo steel to manufacture a large pivot, and the manufacturing process involves the following steps: blank forging, normalizing, rough machining, quenching and tempering, finishing, induction hardening excircle, and grinding excircle.

The pivot structure is illustrated in Figure 1.

Fig. 1 Pivot Structure

Cracks can occur on the pivot shaft during quenching, tempering, and quenching processes.

The crack usually appears in the transition arc area between the pivot shaft root and the flange.

The entire pivot shaft breaks along the radial direction and extends to the big end flange.

The pivot shaft can crack entirely. Please refer to Fig. 2 for the crack’s shape and location.

Fig. 2 Crack morphology after quenching, tempering and quenching

The quenching and tempering process for this piece involves holding it at 840 ℃ for 3 hours, followed by oil cooling quenching once it’s taken out of the furnace. The quenching time is 30 minutes, and Houghton K oil is used as the quenching oil.

Several batches of this product have been produced without any cracks.

To analyze the causes of cracks, a cracked workpiece was sampled at the big end flange, and its chemical composition, metallographic structure, and cracks were analyzed. Samples were taken from the flange crack (refer to Fig. 3) for analysis.

Fig. 3 Sampling at flange

See Table 1 for chemical composition analysis results

Table 1 Chemical Composition (Mass Fraction) of 42CrMo Steel Pivot (%)

| Element | Standard value | Measured value |

| C | 0.38~0.45 | 0.43 |

| Si | 0.17~0.37 | 0.28 |

| Mn | 0.5~0.8 | 0.68 |

| S | ≤0.035 | 0.007 |

| P | ≤0.035 | 0.016 |

| Cr | 0.9~1.2 | 1 |

| Mo | 0.15~0.25 | 0.2 |

| Ni | ≤0.30 | 0.034 |

| Cu | ≤0.30 | 0.046 |

| Al | – | 0.026 |

The metallographic structure is shown in Fig. 4.

Fig. 4 Metallographic Structure of Crack and Surface

The analysis results indicate that the chemical composition of the 42CrMo steel meets the technical requirements. The measured surface hardness is 296HBW, which falls within the required range of 277-331HBW. The metallographic structure is tempered sorbite, and the central structure is tempered sorbite+ferrite.

The workpiece’s crack is arc-shaped, and there is no decarburization on either side of the crack, indicating that there was no crack before quenching and tempering, and no other abnormalities were observed.

The physical and chemical analysts attribute the crack to excessive stress during quenching, tempering, and quenching, based on the sample.

However, due to the piece’s size and the challenge of sampling, the author suggests that the sample cutting position may be the crack growth area rather than the crack initiation site, and further analysis is needed.

Since the crack source cannot be identified through the fracture surface, it is proposed to cut the workpiece to locate the crack source. Flame or plasma cutting may impact the fracture location, so wire cutting is recommended to cut the crack location at the shaft transition zone of the faulty part.

When the cutting reaches 1/3 of the diameter, the pivot shaft breaks into two sections, enabling further analysis of the cause of the crack.

The fracture morphology after wire cutting is shown in Fig. 5.

Fig. 5 Crack Fracture Position after Wire Cutting

The center of the fracture appears brown, while the outer part exhibits normal metal coloration. The brown coloration in the center is abnormal and is likely caused by oxidation.

Analysis indicates that cracks likely existed in the part’s center prior to quenching, tempering, and subsequent forging, normalizing, and quenching processes. The cracks would have undergone oxidation during these processes, leading to the brown discoloration.

To confirm this hypothesis, a sample was taken from the brown area and analyzed. The sample was cut from the center in an axial direction. Upon cutting and processing, it was discovered that numerous cracks were distributed radially, as depicted in Figure 6.

Fig. 6 Crack Fracture Location

The analysis of the sample shows that the sample has an obvious banded structure (Grade 4), as shown in Fig. 7.

Fig. 7 Metallographic Structure of the Crack Center

The cracks, which are multiple and roughly parallel, are distributed along the banded structure direction and perpendicular to the forging direction.

The author believes that there were cracks present before the quenching and tempering process of the pivot shaft, and these cracks were located in the center, with no cracks visible on the surface.

During the quenching and tempering process, the cracks expanded due to the influence of organizational and thermal stress, with the banded structure also playing a role.

As a result, it is necessary to conduct a further analysis to determine if there were issues such as insufficient forging temperature and unreasonable forging ratio during the forging process.

To prevent any faulty parts from entering the market, in-process products were thoroughly investigated.

All in-process products underwent NDT testing using an ultrasonic flaw detector.

Upon investigation, two abnormal products were discovered, and their production serial numbers were checked.

The production serial numbers of the two abnormal products were found to be part of the same batch of forged products that contained the cracked parts.

To validate the early analysis and judgment, wire cutting was performed on the abnormal parts found along the axial direction.

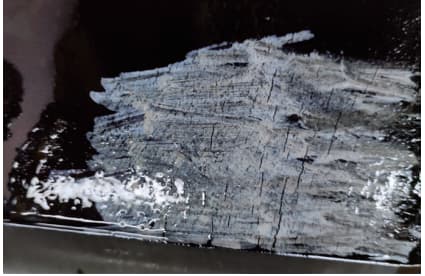

The cutting surface clearly revealed the presence of several detailed cracks, which were perpendicular to the forging direction, as illustrated in Fig. 8.

Fig. 8 Cutting surface of defective parts

Through further verification, it was judged that the crack was generated during forging.

1)The fracture of the pivot shaft can be directly attributed to the forging crack formed during the piece’s forging process. This crack expanded during the quenching and tempering, and the presence of a banded structure also contributed to its growth.

2)When conducting fault analysis, it’s important to carefully locate the source of the crack. Different sampling locations can significantly impact the analysis results. Therefore, it’s essential to analyze and identify the cause from the source to avoid misdirection.

3)Strengthening the incoming inspection of raw materials is crucial in preventing defective parts from entering the production process.