Heat treatment is a critical process in manufacturing, but it’s often overlooked. In this blog post, we’ll explore the fascinating world of heat treatment and its impact on the quality and performance of metal components. Our expert mechanical engineer will guide you through the various heat treatment techniques, explaining their benefits and applications in a clear and engaging way. By the end of this article, you’ll have a deeper appreciation for this essential process and how it shapes the products we use every day.

Operation Method:

The steel is heated to a temperature of Ac3 + 30 – 50 degrees, Ac1 + 30 – 50 degrees, or below Ac1 (as advised by relevant materials) and is then slowly cooled within the furnace.

Objectives:

Key Applications:

(1) This method is appropriate for treating alloy structured steel, carbon east-west steel, alloy east-west steel, high-speed steel forgings, welding components, and raw materials with suboptimal supply conditions.

(2)Typically, this process is used in the rough condition and is called “annealing.

Operation Method:

To perform normalizing, heat the steel to a temperature of 30 – 50 degrees above Ac3 or Accm, and after soaking, cool it at a slightly faster rate than during annealing.

Objectives:

The purpose of normalizing is to reduce hardness, improve plasticity and enhance cutting and pressure processing capabilities. It also helps to refine the grain structure, improve mechanical properties, and prepare the material for subsequent processing. Normalizing also helps to eliminate internal stresses that may have been caused by cold or hot working.

Key Applications:

Normalizing is commonly used as a pre-treatment process for forgings, weldments, and carburized parts. For low to medium-carbon steels and low-alloy steel components with low functional requirements, normalizing can be performed as the final heat treatment process. However, for ordinary medium and high-alloy steels, air cooling can result in full or partial hardening, so it cannot be used as the final heat treatment process.

Operation Method:

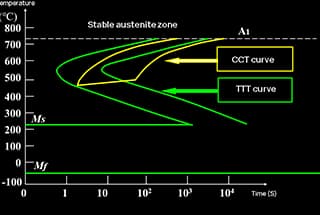

The steel piece is heated to a temperature above the Ac3 or Ac1 phase transition temperature, held for a specified duration, and then rapidly cooled in water, nitrate, oil, or air.

Objectives:

Quenching is typically performed to achieve a martensitic structure with high hardness.

In some cases, quenching high-alloy steel (such as stainless steel or wear-resistant steel) is done to obtain a single, uniform austenitic structure to enhance wear resistance and corrosion resistance.

Key Applications:

(1) Usually applied to carbon steel and alloy steel with a carbon content greater than 0.3%.

(2) Quenching maximizes the strength and abrasion resistance of steel, but it also results in high internal stress that reduces steel’s plasticity and impact toughness.

Thus, tempering is necessary to obtain improved mechanical properties.

Operation Method:

The quenched steel parts are heated to a temperature below Ac1, held for a period of time, and then cooled in air, oil, or hot water.

Objectives:

To reduce or eliminate internal stress after quenching, minimize deformation and cracking of the workpiece.

To adjust hardness, improve plasticity and toughness, and achieve the mechanical properties required for the application.

To stabilize the size of the workpiece.

Key Applications:

(1) Low temperature tempering is used when high hardness and wear resistance are desired in the quenched steel.

(2) Medium temperature tempering is used to improve the elasticity and yield strength of steel while maintaining a certain degree of toughness.

(3) High temperature tempering is used to prioritize high impact toughness and plasticity, and is used when sufficient strength is present.

It is generally advised to avoid tempering between 230-280 degrees for steel and 400-450 degrees for stainless steel, as this range can cause temper brittleness.

Operating Procedure:

The process of heating steel to a temperature that is 10-20 degrees higher than during quenching, after which quenching is performed, is referred to as quenching and tempering.

After holding at high temperature, the steel is quenched, then tempered at a temperature range of 400-720 degrees.

Objectives:

Key Applications:

This process is suitable for high-hardenability alloys, such as alloy tool steel, alloy high-speed steel, and alloy structural steel.

It can serve as the final heat treatment for critical components and also as a pre-heat treatment for tight parts, such as screws, to reduce deformation during processing.

Operating Procedure:

The steel is heated to a temperature range of 80-200 degrees and held at this temperature for 5-20 hours or longer. After that, it is removed from the furnace and cooled in the air.

Objectives:

Key Applications:

This process is suitable for all steel types after quenching.

It is commonly used for tight components whose shape does not change, such as tight screws, measuring instruments, bed frames, etc.

Operating Procedure:

The quenched steel components are cooled in a low-temperature medium, such as dry ice or liquid nitrogen, to a temperature of -60 to -80 degrees or lower. The temperature is then evenly removed, and the parts are allowed to reach room temperature.

Objectives:

Key Applications:

Steel components should undergo cold treatment immediately after quenching and then be tempered at low temperature to eliminate internal stress during low-temperature cooling.

Cold treatment is primarily suitable for tight tools, measuring tools, and tight components made of alloy steel.

Operating Procedure:

A flame produced by a mixture of oxygen and acetylene gas is directed onto the surface of the steel component, rapidly heating it. When the desired quenching temperature is reached, the steel is immediately cooled by spraying it with water.

Objectives:

To improve the hardness, wear resistance, and fatigue strength of the steel component while maintaining its toughness.

Key Applications:

Operating Procedure:

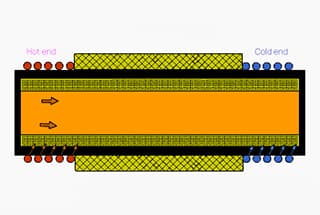

The steel components are placed in an inductor, where the surface of the components is subjected to an electrical current. The steel is heated to the desired quenching temperature in a very short amount of time, and then cooled by spraying with water.

Objectives:

To enhance the hardness, wear resistance, and fatigue strength of the steel components, while retaining their toughness.

Key Applications:

This process is mainly used for medium-carbon steel and medium-alloy steel components.

The depth of the induction-hardened layer depends on the frequency of the electrical current used: high-frequency induction hardening typically results in a layer that is 1 to 2mm deep, intermediate frequency hardening typically results in a layer that is 3 to 5mm deep, and high-frequency hardening typically results in a layer that is greater than 10mm deep. This is due to the “skin effect,” where the electrical current is concentrated in the outermost layer of the component.

Operation method:

Place the steel parts in a carburizing medium, heat it to a temperature between 900-950 degrees and hold it there. This allows the surface of the steel parts to form a carburizing layer with a specific concentration and depth.

Objectives:

To improve the external hardness, wear resistance, and fatigue strength of the steel parts while maintaining its resistance.

Key Applications:

(1) This method is mostly used for low-carbon steel and low-alloy steel parts with a carbon content ranging from 0.15% to 0.25%. The depth of the carburized layer is typically between 0.5mm to 2.5mm.

(2) After carburizing, it’s necessary to undergo quenching to achieve martensite on the surface and complete the carburizing process.

Operation Method:

The surface of the steel is saturated with nitrogen through the use of active nitrogen atoms separated by ammonia gas at temperatures between 500-600 degrees.

Objectives:

The hardness, wear resistance, fatigue strength, and corrosion resistance of steel parts are improved.

Key Applications:

This method is mostly used for medium-carbon alloy steels rich in alloy elements such as aluminum, chromium, molybdenum, carbon steel, and cast iron. The depth of the nitrided layer is typically between 0.025 to 0.8mm.

Operation method:

The steel surface is treated through a combination of carburizing and nitriding.

Objectives:

To enhance the hardness, wear resistance, fatigue strength, and corrosion resistance of steel parts.

Key Applications:

(1) Primarily used for low-carbon steel, low-alloy structured steel, and cast steel parts, with a typical nitriding layer depth of 0.02 to 3mm;

(2) After nitriding, quenching and low-temperature tempering are necessary.