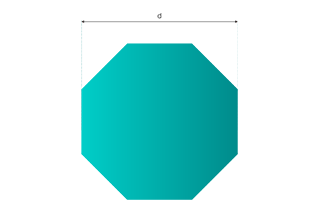

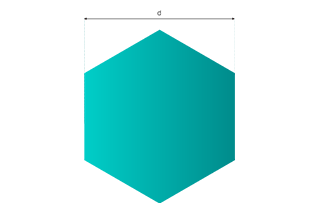

Ever wondered how to precisely calculate the weight of a hexagonal steel bar for your next project? This article introduces a handy hexagonal bar weight calculator that simplifies the process, ensuring accuracy and efficiency. Learn how to input dimensions and obtain the correct weight, vital for material selection and cost estimation in metalworking projects. Dive in to optimize your calculations and streamline your workflow.

Hexagonal steel bar, also known as hex bar or hexagon bar, is a type of structural steel product characterized by its distinctive six-sided cross-section in the shape of a regular hexagon. This unique profile offers a combination of strength, versatility, and aesthetic appeal, making it a popular choice in various industrial and manufacturing applications.

Key features of hexagonal steel bars include:

Hexagonal steel bars are widely used in industries such as automotive, aerospace, construction, and general engineering for applications including fasteners, shafts, fittings, and decorative elements. Their unique shape allows for easy gripping and torque transfer, making them particularly suitable for components that require frequent adjustment or maintenance.

Hot-rolled hexagonal steel bars are standardized according to GB/T 702-2008, which specifies dimensions, shapes, weights, and allowable deviations. The standard covers hexagonal bars with across-flats dimensions ranging from 8 mm to 70 mm.

In the metal fabrication industry, hexagonal bars are typically sold based on either actual weight or theoretical weight, depending on market practices and customer requirements.

To accurately determine the weight of hexagonal steel bars for your projects or inventory management, you can utilize the following hexagonal bar weight calculator. This tool takes into account the specific geometry of hexagonal cross-sections and the density of steel to provide precise weight estimations.

Key features of this calculator:

Note: For the most accurate results in procurement or billing, always refer to the actual measured weight of the material, especially for large quantities or high-precision applications.

Related Tool: Steel Weight Calculator

This chart covers common hexagonal bar sizes ranging from 8mm to 70mm across flats, for three frequently used materials: mild steel. The weights are given in kilograms per meter (kg/m).

| Opposite side width (mm) | Sectional area (cm2) | Weight (kg/m) |

| 8 | 0.5542 | 0.435 |

| 9 | 0.7015 | 0.551 |

| 10 | 0.866 | 0.68 |

| 11 | 1.048 | 0.823 |

| 12 | 1.247 | 0.979 |

| 13 | 1.463 | 1.15 |

| 14 | 1.697 | 1.33 |

| 15 | 1.948 | 1.53 |

| 16 | 2.217 | 1.74 |

| 17 | 2.49 | 1.96 |

| 18 | 2.806 | 2.2 |

| 19 | 3.126 | 2.45 |

| 20 | 3.464 | 2.72 |

| 21 | 3.822 | 3 |

| 22 | 4.191 | 3.29 |

| 23 | 4.581 | 3.59 |

| 24 | 4.993 | 3.92 |

| 25 | 5.412 | 4.25 |

| 26 | 5.847 | 4.59 |

| 27 | 6.313 | 4.96 |

| 28 | 6.79 | 5.33 |

| 30 | 7.794 | 6.12 |

| 32 | 8.868 | 6.96 |

| 34 | 10.01 | 7.86 |

| 36 | 11.22 | 8.81 |

| 38 | 12.51 | 9.82 |

| 40 | 13.86 | 10.88 |

| 42 | 15.27 | 11.99 |

| 45 | 17.54 | 13.77 |

| 48 | 20 | 15.66 |

| 50 | 21.64 | 16.99 |

| 53 | 24.33 | 19.1 |

| 56 | 27.15 | 21.32 |

| 58 | 28.13 | 22.08 |

| 60 | 31.18 | 24.5 |

| 63 | 34.37 | 26.98 |

| 65 | 36.59 | 23.7 |

| 68 | 40.04 | 31.43 |

| 70 | 42.23 | 33.3 |

Notes:

This chart serves as a valuable reference for engineers, designers, and procurement specialists working with hexagonal bars. It enables quick estimation of material requirements, shipping weights, and cost calculations. When selecting hexagonal bars for specific applications, consider factors such as strength requirements, corrosion resistance, and machinability in addition to weight.