Imagine cutting through thick stainless steel with the precision and speed of light. Ultra-high power fiber lasers, now reaching up to 40kW, are revolutionizing the cutting industry. This article explores how these lasers achieve unparalleled cutting quality and productivity, making air cutting faster and more economical. Learn about the latest advancements, practical applications, and the substantial benefits of adopting this cutting-edge technology in your manufacturing processes.

Ultra-high power fiber laser can achieve fast and high-quality thick plate cutting, including the use of air as an auxiliary gas to cut stainless steel, and many advantages over other cutting solutions.

In recent years, ultra-high power (UHP) fiber lasers with power ranging from 10kW to 40kW have been rapidly applied in the cutting market, and the highest laser power used for cutting applications is expected to continue to increase.

We will demonstrate the cutting application effect in this power range, and discuss the main factors driving the application of ultra-high power fiber lasers: significant productivity advantages, improved cutting quality, and the ability to cut to the limit thickness (for example, as shown in this article, cutting 230mm thick stainless steel at a power of 40kW).

In this article, the power of ultra-high power lasers is defined as lasers with a power greater than 10kW. They enable new process methods to promote laser cutting expansion into new markets (e.g., using air as an auxiliary gas to cut stainless steel up to 50mm thick at speeds 4 times faster than high-power plasma cutting).

The results of the application show that ultra-high power lasers are changing the way stainless steel is cut by using air cutting technology instead of nitrogen and oxygen cutting technology to achieve high-quality, high-speed, and economical cutting.

6-Year Development Trend: The Highest Laser Power Used for Cutting Applications

More than 50 years ago, laser cutting technology emerged. Since then, laser cutting has entered a period of rapid technological development.

In the 1970s, commercial laser cutting machines were introduced, and early adopters used them for large-scale production.

In the 1980s, carbon dioxide (CO2) laser cutting equipment became widely used.

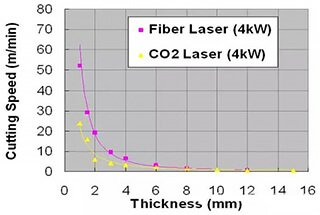

By the late 1990s and early 2000s, high-power fiber lasers were introduced.

The development of kilowatt-level fiber laser cutting machines by the late 2000s transformed laser cutting from a small-scale application to a mainstream manufacturing process.

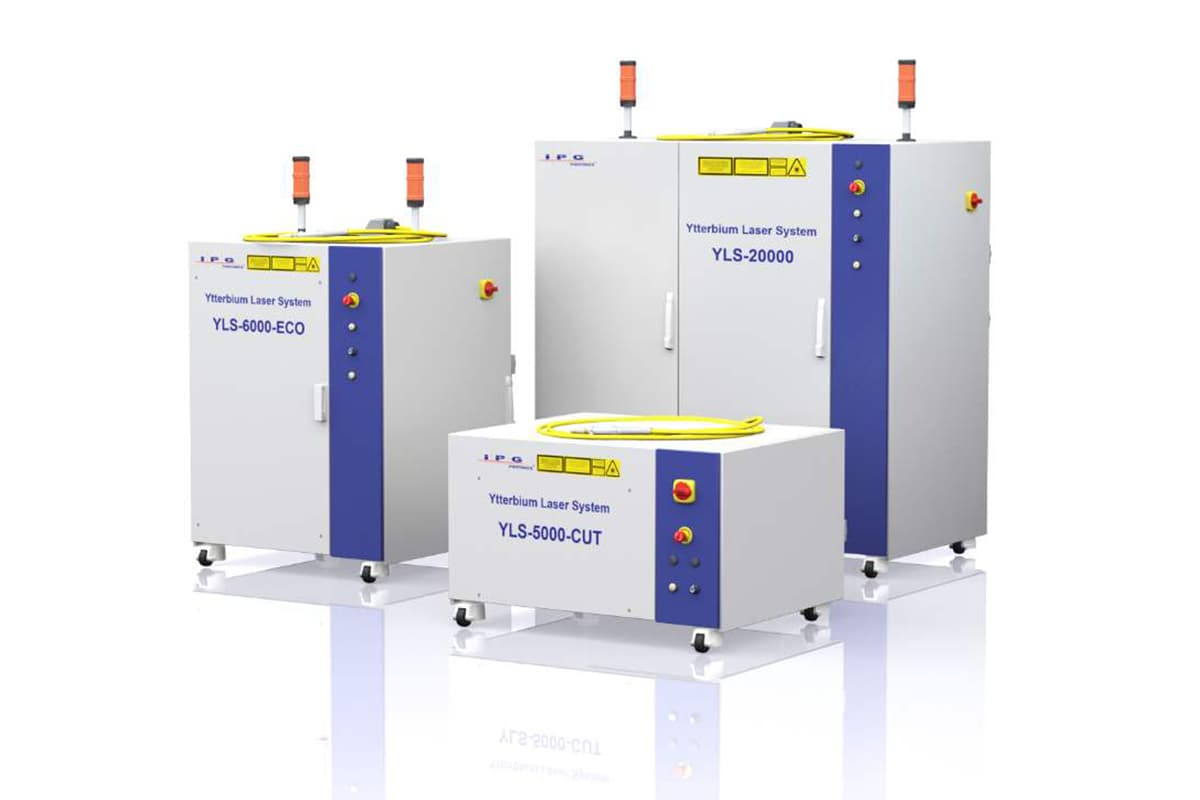

Fiber laser cutting machines have an important position in the metal sheet laser cutting market, mainly due to the ease of integration, reliability, low maintenance, relatively low investment and operating costs, high cutting output, and power scaling feasibility of fiber lasers.

In the late 2010s and early 2020s, there are two growth paths in the laser cutting market.

The first trend covers the low-power end of the market, where demand for 1-3kW cutting machines has surged due to lower equipment capital costs.

The second trend is in the high-power end of the market, which has led to increasing demand for ultra-high power fiber lasers.

This is driven by the high cost-effectiveness of ultra-high power lasers in providing high productivity and technical capabilities.

Moreover, the laser cutting field has undergone a revolutionary “power shift,” which is unprecedented in other sheet metal manufacturing processes during the same period.

From manufacturing exhibitions, we can see that the highest laser power exhibited in cutting machines has increased from 6kW in 2015 to an expected 40kW in 2022, nearly seven times growth (refer to Figure 1).

In just the past three years, the highest power of laser equipment has increased from 15kW to 40kW, a surge of 2.5 times!

Reliable high-power fiber lasers had already emerged a few years before the trend of ultra-high power cutting began. Industrial fiber lasers with 100kW output were available as early as 2013.

However, it was only in the past few years when the price per kilowatt of laser equipment rapidly decreased that the threshold for entering ultra-high power laser cutting was lowered, and cutting heads capable of carrying such high laser power in harsh cutting environments also became available.

In addition, cutting databases that can be adapted to ultra-high power cutting equipment are also becoming increasingly sophisticated.

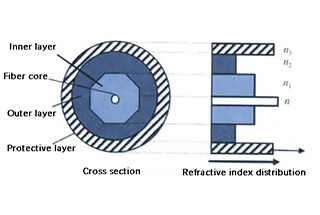

The table shows the cutting speed and quality of different metals evaluated using IPG’s YLS-40000 with 40kW and YLS-30000-ECO2 with 30kW high-electrical-optical conversion efficiency fiber lasers configured with a 100μm fiber core diameter and IPGCut-HP cutting head.

According to current understanding, 40kW laser power with a 100μm fiber core diameter is currently the highest laser power that can be provided by a laser source used in industrial laser cutting.

We chose a 100μm fiber core diameter because it provides a 10-25% increasese in cutting speed compared to a 150μm fiber core diameter.

Our experiments showed that for all tested metals, including stainless steel, carbon steel, and aluminum, laser cutting speeds increased with increasing average power (up to 40kW).

Figure 2 shows the increase in cutting speed with laser power for cutting 6-40mm thick carbon steel using air cutting technology in the range of 12kW to 40kW.

The rate of speed increase increases with increasing metal thickness.

For example, when cutting 12mm thick carbon steel, the cutting speed at 40kW is 280% faster than that at 15kW (with a power increase of 270%), while for 20mm thick carbon steel, the cutting speed at 40kW is 420% faster than that at 15kW. For 30mm thick carbon steel, as the power increases from 30kW to 40kW (a power increase of 33%), the cutting speed increases by 66%.

Therefore, higher power ultra-high power lasers will further improve the productivity of thick plate cutting.

To take advantage of the faster cutting speed provided by ultra-high power lasers and significantly shorten production cycles, it is necessary to cut workpieces at high acceleration, especially thinner ones.

In recent years, maximum acceleration of laser cutting machines has increased from 1G to 3G to adapt to higher laser power.

In the high-end market, the maximum acceleration of ultra-high power laser cutting machines can reach 6G, and their mechanical design can ensure that the cutting trajectory does not deviate significantly.

Compared to lower power, ultra-high power laser cutting significantly reduces the processing cost per unit and brings faster return on investment and higher profitability.

In laser cutting, the cost of processing mainly comes from gas consumption, which often increases significantly with increasing part thickness.

Ultra-high power laser cutting requires the same or smaller gas pressure and nozzle size as low-power cutting.

However, ultra-high power lasers have faster cutting speeds, which reduce the cutting time per unit and greatly reduce gas consumption.

For example, compared to a 15kW laser, a 30kW laser can cut a typical 16mm thick stainless steel part in half the production cycle, reducing gas consumption by half.

The power consumption of lasers and water chillers usually increases linearly with laser power.

Nevertheless, the other power consumption of cutting machines remains almost the same. Therefore, in the previous case where the production cycle per unit was shortened by half, we reduced the total power consumption per unit by increasing the laser power.

With the continuous development of PG technology, the electro-optical conversion efficiency of high-power fiber lasers exceeds 50%, which is more conducive to energy saving.

In addition to faster cutting speeds, ultra-high power lasers can also save gas usage. Compared to more expensive nitrogen or slower oxygen cutting, ultra-high power lasers allow for fast, slag-free cutting of thick carbon steel using high-pressure air.

With ammonia and air cutting, ultra-high power allows for a reduction in the gas pressure required for slag-free cutting.

For example, when cutting 20mm thick carbon steel without slag using a 15kW laser, a gas pressure greater than 16ba is required, while 10-12bar is sufficient when using a 20kW or higher power.

As gas usage varies approximately linearly with pressure (under the same nozzle size), significant depressurization helps to reduce gas consumption and simplify the specifications of gas generation equipment.

The production efficiency of high-power laser cutting equipment is twice that of low-power laser cutting equipment, but the equipment price is not twice as much. This is because the cost per kilowatt decreases with increasing laser power.

In addition, the cost of higher power lasers is included in the total equipment cost, which increases marginally (compared to lower power laser equipment).

Therefore, ultra-high power laser cutting machines can achieve twice the production efficiency through higher laser power, while equipment costs only increase by 30-40%.

Due to significantly improved production efficiency, ultra-high power equipment can replace multiple low-power equipment, reducing floor space, operator numbers, and facility preparation accordingly.

On the other hand, to ensure production efficiency, the reliability requirements for laser sources and cutting heads are higher for ultra-high power fiber laser cutting machines.

That is, for fiber laser sources, long-term stable power output and beam quality are required, which are affected by the quality of diodes, components, and optical integration.

As for ultra-high power cutting heads, they need to withstand high laser power, high-pressure gas, dust, process heat, and high acceleration to achieve stable and reliable processing.

| Oxygen | Nitrogen | High pressure air | |

| Cost of gas cutting equipment | low | Low to High | high |

Operating cost of gas cutting | low | high | Very low |

Flux | low | Very high | Very high |

Slag | None/Low | medium | None/Low |

Long-term repeatability of production quality | Medium/High | Very high | Very high |

Sensitivity to material surface environment | medium | low | low |

Sensitivity to material composition | high | low | low |

Heat affected zone | medium | Small | Small |

Ability to cut complex or high-depth-to-width ratio workpieces | medium | high | high |

Degree of surface oxidation during cutting | serious | nothing | moderate |

| Surface roughness after cutting (Rz) | low | secondary | Medium/High |

| Surface aesthetics after cutting | good | secondary | Poor |

Width of the cut | large | Small | Small |

Laser power required for slag free cutting | low | N/A | medium |

Carbon steel can be cut using oxygen, nitrogen, or air as auxiliary gas.

Figure 3 summarizes the advantages and disadvantages of using each type of auxiliary gas.

Although oxygen cutting is good at cutting thick carbon steel with lower laser power due to its additional oxidation energy, the production efficiency is lowered as the cutting speed is not proportional to the laser power.

In contrast, the cutting speed of air-assisted carbon steel is proportional to the power (see Figure 2).

For example, for 16m carbon steel with a power between 10kW and 30kW, the oxygen cutting speed remains unchanged at about 2 m/min, while the air cutting speed is more than 9m/min at 30kW, which is 4.5 times faster than the oxygen cutting speed.

The thickness that was once only cut by oxygen at lower power and speed can now be processed using ultra-high power lasers and air, which has greatly improved the speed and quality.

For low-power lasers, air cutting may cause difficult-to-remove dross and poor surface quality.

For industries such as construction equipment manufacturing and heavy industry with huge amounts of thick plate processing, this innovative and efficient ultra-high power processing plan is highly welcomed.

(a) Cutting 70mm thick stainless steel with nitrogen at a power of 30kW;

(b) Cutting 230mm thick carbon steel with air at a power of 40kW.

Tests have shown that as the power of ultra-high power lasers increases, the cutting thickness also increases. For example, Figure 4 shows cutting 70mm thick stainless steel with nitrogen at 30kW and cutting 230mm thick carbon steel with air at 40kW, both of which are performed in pulse cutting mode.

(a) Air cutting 28mm thick carbon steel at 4.5m/min (177ipm) with IPG40 KW YLS laser;

(b) Air cutting 40mm thick stainless steel at 2.3m/min (90ipm) with IPG40 kW YLS laser;

(c) Nitrogen cutting of 3-25mm thick stainless steel profiles with IPG30 kW YLS-ECO laser;

(d) Cutting 30mm thick carbon steel with oxygen at a power of 15kW.

In the continuous wave (CW) full-speed cutting mode, 20kW non-slag air is used to cut 20mm thick carbon steel, 40kW non-slag air is used to cut 30mm thick carbon steel, and 40kW non-slag air is used to cut 40mm thick carbon steel (see Figure 2 and Figure 5 above). For cutting stainless steel, it is easier to achieve a non-slag effect, so the maximum cutting thickness is thicker than that of carbon steel (see Figure 5b and Figure 5c).

For continuous nitrogen and air cutting, only a certain thickness can achieve non-slag cutting and good cutting surface at any given power. Beyond a certain thickness, pulse cutting (slower speed than continuous) must be used to achieve qualified quality; otherwise, laser power must be increased.

Usually, a cutting speed below 2m/min means that the laser power is insufficient in continuous mode to achieve the best cutting quality.

For oxygen cutting of carbon steel, increasing the power will increase the maximum cutting thickness while ensuring “smooth cutting surface”. For example, the maximum cutting thickness with 4kW is about 6-8mm, while the maximum cutting thickness with 15kW is 30mm. Figure 5d shows a 30mm thick carbon steel sample cut with a 15kW laser.

By using the high peak power of ultra-high power laser in pulse mode, thick metals can be pierced quickly with less spatter. The piercing time for 16mm stainless steel has been greatly reduced from >1 second at 6kW to 0.5 seconds at 10kW and 0.1 seconds at 20kW.

In practical applications, piercing times of ≤0.1 seconds are usually considered “instantaneous”. The higher peak power increases the depth-to-width ratio of the melt pool, which allows for faster bridging of thickness with less lateral melting. The reduction in lateral melting of the material also maximally reduces top surface spatter.

In the past six years, several technological developments have driven the improvement of laser cutting performance, including:

Although the needs of different industries are different and all enabling technologies are used in specific areas, ultra-high power laser cutting is a leading technology trend that drives the improvement of laser cutting performance.

This is evidenced by the widespread adoption of ultra-high power lasers in laser cutting machines worldwide.

As more and more application engineers adopt ultra-high power lasers, they understand that the production and quality benefits of ultra-high power cutting machines are multifaceted and surpass those of lower laser power technologies with less complexity.

Ultra-high power lasers have significant advantages in cutting thickness, quality, and cost-effectiveness for thick plate cutting, especially at 15kW and higher powers, making them more competitive than high-current plasma cutting machines.

Comparative tests show that for stainless steel up to 50mm thick, a 20kW fiber laser is 1.5-2.5 times faster than a high-current plasma cutting machine (300A). For carbon steel, it also shows that the cutting speed for up to 15mm thickness is more than twice as fast.

Calculations show that for 15mm thick carbon steel, the total cutting cost per meter using a 20kW laser is about half of that using plasma.

Due to its faster cutting speed for 12-50mm thick stainless steel sections and 12-30mm thick low carbon steel sections when compared to high-power plasma cutting, using a 40kW laser for these materials yields an even greater difference in productivity.

Compared to low-power lasers and other cutting processes (such as plasma cutting), the main driving force for adopting ultra-high power lasers for cutting is higher productivity and lower cutting costs per part.

The speed gains from using ultra-high power lasers provide economies of scale for manufacturers; for example, increasing power from 30kW to 40kW increases cutting speed by 66%.

Ultra-high power lasers enable high-quality, fast air cutting of carbon steel, which is more advantageous than slower oxygen cutting and more expensive nitrogen cutting. In our tests, using a 40kW air cut to cut carbon steel up to 50mm thick was three to four times faster than high-power plasma cutting.

Ultra-high power lasers make laser cutting more competitive in many other ways. For example, increasing cutting thickness and quality (materials up to 230mm thick can be cut), reducing or eliminating post-processing costs (maximally reducing slag hanging), reducing footprint and facility costs, lowering labor requirements, and improving piercing quality and yield.

As the power and efficiency of ultra-high power lasers continue to improve, these advantages will become even more apparent – enhancing their ability to rapidly and economically change cutting applications across different industries.