Is the future of metal cutting set to be revolutionized by high-power laser cutters? As industries demand faster, more precise, and thicker material processing, high-power laser cutting machines are becoming a pivotal tool. This article explores their technological advancements, capabilities, and market trends, offering insights into how these powerful machines are enhancing efficiency and quality in metalworking. Discover how high-power lasers are shaping the future of industrial cutting and what benefits they bring to modern manufacturing.

With the steady growth of the heavy industry, laser cutting technology has advanced from cutting thin plates to cutting large and thick plates.

Laser cutting has now entered the high power era.

This new era demands higher accuracy, speed, and thickness in metal plate cutting from industrial manufacturing. As a result, the power of laser cutting machines is continually increasing.

From an industrial standpoint, high-power laser cutting machines are not only a natural progression in their development but also align with the overall trend in industrial development.

In the sheet metal processing industry, the advantages of laser cutting machines are highly significant. Their high precision, speed, and quality have led to their gradual replacement of traditional processing methods and establishment as the primary equipment for cutting sheet metal.

Since the advent of laser cutting machines, the use of fiber laser cutting machines has surpassed that of YAG and CO2 machines, and the trend towards high-power laser cutting machines has emerged. These high-power machines have become the norm for cutting thick plates and boosting cutting efficiency.

Recently, high-power laser cutting machines have become a popular topic in the laser cutting field, with many companies introducing fiber laser cutting equipment with power levels above 10,000 watts.

For the sheet metal processing industry, the introduction of high-power cutting machines has significantly improved the thickness and efficiency of sheet metal cutting. These machines are constantly pushing the limits of material cutting thickness.

This, combined with the declining cost of processing thick plates, creates a positive cycle and drives the expansion of laser cutting applications.

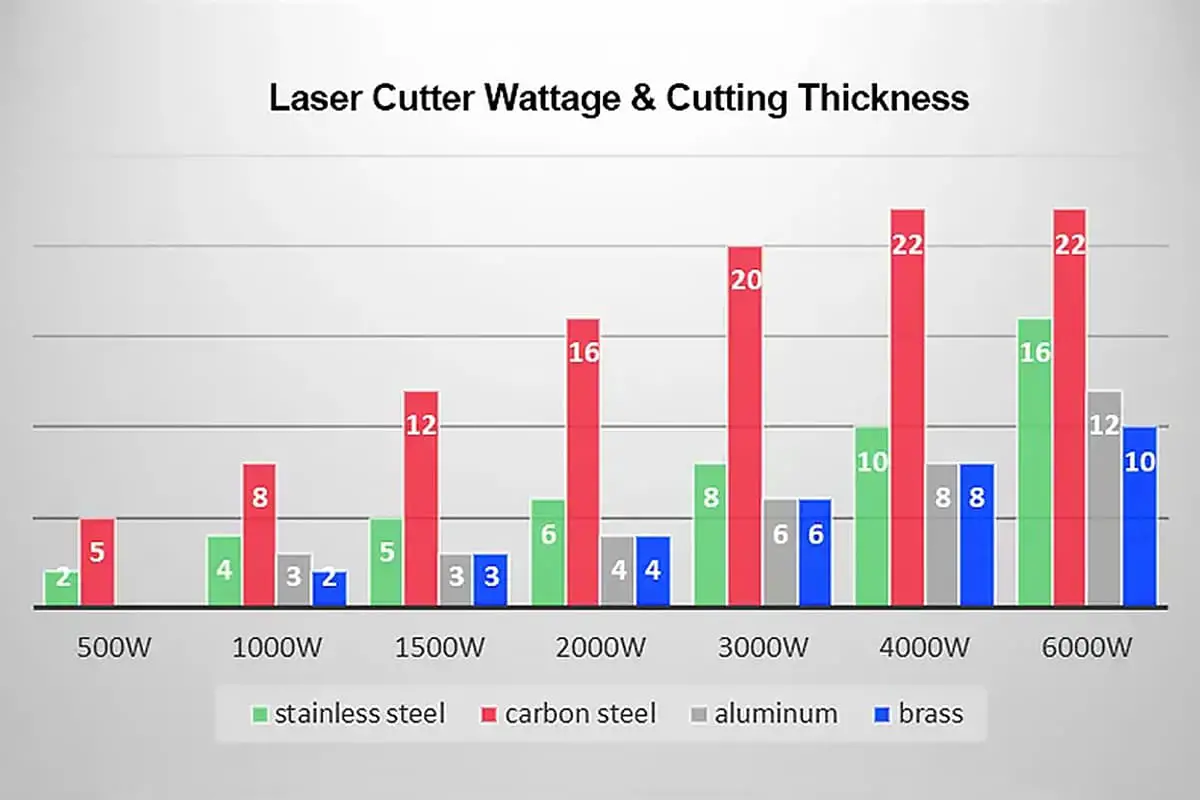

Laser cutting machines can be classified into three categories based on their power: low power, medium power, and high power.

Low-power laser cutting machines are suitable for cutting stainless steel and carbon steel with a general thickness.

High-power laser cutting machines are ideal for cutting thick plates and maximizing cutting efficiency.

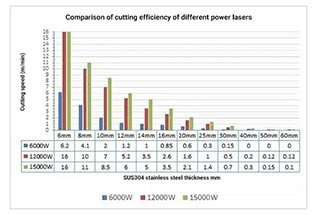

As a result, laser cutting machines with a laser power output of 10,000 watts or higher are commonly referred to as high-power laser cutting machines. (Refer to Figure 1)

Fig. 1 High power laser cutting machine

According to the varying thickness of metal plates that are subjected to laser cutting, the power specifications of the fiber laser used on the high-power cutting machine must also vary.

The current trend in the metal processing market shows that large, medium, and small enterprises are gradually upgrading to various specifications, as indicated in Table 1.

Table 1 Specifications of high power fiber laser

| Power/Kw | 10 | 12 | 15 | 20 | 25 | 30 | 35 |

| Note | Normal | Normal | Normal | Rare | Rare | Rare | Rare |

When the high-power laser cutting machine operates, it is crucial to maintain the cutting accuracy, speed, and quality of the cut. To achieve these benefits, the oxygen used must have a high degree of purity, usually 99.99%.

(1) High-Speed Cutting Machine with Improved Dynamic Performance

This machine tool, equipped with a 10000-watt fiber laser, features a new triangular beam structure that offers the following benefits:

① The weight has been reduced by 30%, resulting in improved dynamic performance.

② It can reach a maximum moving speed of 200m/min and has an acceleration of 4G.

③ The weight of the base has been increased by approximately 20% to change the fixing mode of the machine tool and eliminate any impact high acceleration may have on its performance.

(2) New software system

The software and control system of a machine tool act as its brain and command center. Upgrading the hardware may bring additional benefits, but the main difference in machine performance lies in the software and control system, which can vary greatly.

(3) It can realize stable cutting at a speed of 100M / min

① The response time of the capacitive sensor is three times faster than that of a traditional cutting head.

② The z-axis speed has been increased, resulting in smoother, non-stop operation. This has led to a more than 30% increase in sheet cutting efficiency, improved leapfrog function, and improved acceleration adaptation function.

③ The functions of rapid perforation, precise perforation, and remote diagnosis have been improved and an intelligent interface has been added to facilitate the implementation of “Industry 4.0” capabilities.

The high-power cutting head is the key component for ensuring stability during continuous high-power operation. It features:

① Improved sealing and enhanced cooling system, as well as wider focus range and high-temperature resistant lenses.

② To overcome the issue of focus drift caused by the high-power thermal lens effect during extended use, the high-power cutting head has adopted a new gas path design structure and replaced the nozzle with a new design, enhancing both cutting speed and stability.

(1) The thickness of cutting thick plates is increasing

The high-power cutting head is the key component for ensuring stability during continuous high-power operation. It features:

① Improved sealing and enhanced cooling system, as well as wider focus range and high-temperature resistant lenses.

② To overcome the issue of focus drift caused by the high-power thermal lens effect during extended use, the high-power cutting head has adopted a new gas path design structure and replaced the nozzle with a new design, enhancing both cutting speed and stability.

Fig. 2 Workpiece for cutting thick plate

(2) Efficiency multiplication of thin plate in cutting

① When cutting stainless steel plates with a thickness of 3 to 10mm, the cutting speed of a 10000W laser cutting machine is more than twice that of a 6000W machine.

② In the cutting application of carbon steel, a 10000W laser cutting machine can achieve fast and bright surface cutting at a speed of 18 to 20mm/s, which is twice the ordinary standard cutting speed.

③ Carbon steel plates up to 12mm thick can be cut using compressed air or nitrogen, resulting in cutting efficiency that is 6 to 7 times greater than using oxygen.

(1) The equipment is equipped with super load-bearing mechanical structure

The high-powered cutting machines feature a cast iron bed that is cast as a single piece using flake graphite cast iron, with a minimum tensile strength of 200MPa. This results in significant improvements in carbon content, compressive strength, vibration damping, and wear resistance (as shown in Figure 3).

Fig. 3 Machine bed

(2) Characteristics of cast iron bed

① The bed has excellent lubrication performance, is highly resistant to corrosion, and boasts remarkable dimensional stability, minimizing machining errors caused by bed vibrations.

② This results in a reduction of equipment loss during use and an improvement in the stability coefficient by over 30%. The quality accuracy is also increased by more than 30% and the service life of the bed is extended by over 70 years.

(1) Manual nozzle change mode

When cutting, the nozzle must be swapped out based on the thickness and type of material being cut.

In the past, nozzle replacement was performed manually, which was not only time-consuming and required repeated effort from technicians, but also challenging to ensure accuracy and stability after the replacement was made.

Finding an efficient and quick method to replace the nozzle while ensuring each replacement is safe and accurate is a technical challenge in the field of laser cutting.

(2) Automatic nozzle replacement technology

The High-Power Laser Cutting Machine features automatic nozzle replacement.

It boasts several functions such as automatic nozzle replacement, laser head calibration, and nozzle cleaning, reducing the need for manual labor.

To replace the nozzle, simply operate the appropriate command on the touch screen.

The benefits of this automatic nozzle replacement technology include:

(1) Lightning perforation

It boasts the benefits of a short perforation time, low thermal focusing energy, a stable starting point, and the preservation of stability in the servo system, resulting in optimal cutting performance.

The advantages of lightning perforation are shown in Table 2.

| Item | Index | Note |

| Perforation time | Reduced by about 90% | Improve processing efficiency |

| Waste porosity rate | From about 10% to about 0.3% | Improve workpiece integrity |

| Save gas and electricity | The damage of laser and cutting head is reduced | Improve material utilization |

(2) Limit hole

The laser cutting industry has long held that the thickness of the plate determines the minimum diameter of the cutting hole.

However, with the use of high-powered laser cutting machines, it is possible to achieve a hole diameter that is even smaller, with a ratio as low as 0.15 times the thickness of the plate, as demonstrated in Figure 4.

Fig. 4 Minimum hole cutting sample

(1) High speed

The laser cutting speed has surpassed 20 m/min. The processing cutting machine’s two-axis moving speed can reach a maximum of 250 m/min and its acceleration during operation is approximately 10 g.

(2) High precision

A 1mm thick plate can be cut into approximately 500 pieces per minute for a small hole of around 10mm in diameter. The cutting process results in minimal error between the holes.

(3) Develop towards the thick plate

The power of high-power laser cutting machine is gradually increasing, and the size of the thick plate is also increasing.

(4) Developing towards large size

The processing size range of laser cutting technology is also increasing, and laser cutting technology has begun to develop towards large size.

(5) Automatic unmanned

It is crucial and pressing to advance the technology of automatic and unmanned laser cutting.

① The integration of computer network technology has transformed laser cutting into a fully automatic and unmanned process.

② The growing demand in the market for this technology is driving the need for full automation in laser cutting.

(6) Intellectualization

Follow the pace of intelligent manufacturing in accordance with the technical demands of Industry 4.0. This approach utilizes precise graphic recognition technology and a user-friendly interface for seamless human-computer interaction.

The combination of laser and computer control, numerical control technology, an optical system, high-precision automatic positioning devices, and integrated functions such as automatic discharge, a cutting process database, remote fault diagnosis, and remote control enable the efficient processing of mass and complex parts.

(1) Development of high power equipment

Laser cutting is considered to be an ideal method in cutting processing and represents the advancement of modern metal processing technology. Currently, high-power laser cutting machines are undergoing key research and development in areas such as high speed, high precision, large format, three-dimensional cutting, and special material cutting to drive the technical advancement of high-power laser cutting and meet the increasing market demands.

(2) High power equipment selection

When selecting high-power laser cutting equipment, enterprises need to consider various factors carefully: besides cutting speed and accuracy, the stability and consistency of full-power continuous cutting, the machine tool’s ability to match speed, the advanced quality of the machine tool, and the precision life must also be assessed.

It’s not enough to merely compare prices when purchasing high-power laser cutting equipment. This type of equipment requires a high investment, which brings with it a higher level of risk.

Therefore, when entering the high return market of laser cutting, enterprises must acknowledge and understand the risks involved.