What if you could significantly boost your production efficiency with cutting-edge technology? This article dives into high-power laser cutting machines, especially those with 10,000+ watt capabilities. Discover how these machines are revolutionizing industrial processes by enhancing cutting precision and reducing material waste. Learn about the latest advancements, challenges, and market trends in high-power laser technology, equipping you with the knowledge to make informed decisions for your manufacturing needs.

In recent years, laser technology has become increasingly important in industrial production. The advancement of the manufacturing industry towards high-end, intelligent transformation processes has made it difficult for traditional processing technology to meet the market demands for higher efficiency and accuracy in product production.

Laser technology, with its high efficiency, low consumption, minimal material deformation, and adaptability to the processing object, has increased its penetration rate in all aspects of industrial production and has become an indispensable tool in high-end manufacturing.

The laser industry has seen rapid development in recent years, with improved stability and increased power. The release of 10,000-watt fiber lasers and processing equipment products has become a common occurrence, with similar news being reported once or twice a month.

We can’t help but wonder why everyone is pushing for 10,000+ watt fiber lasers and whether a bigger power is always better for fiber lasers. We also question the size of the high-power fiber laser market and the technical solutions available.

To gain a better understanding of the market, we conducted interviews with representative companies in the fiber laser industry chain, including those that have already launched 10,000-watt fiber lasers, those that plan to do so, and fiber laser manufacturers and downstream equipment manufacturers. Our aim was to be comprehensive and objective.

During our month-long research, we visited several fiber laser manufacturers, equipment manufacturers, technical experts in the fiber laser industry, and market experts. Our findings indicate that the current state of high-power fiber lasers still has a long way to go.

Note: In this article, high-power fiber lasers refer to those with a power of 10,000+ watts unless otherwise specified.

The laser cutting market dominates among the many industrial applications, and fiber lasers have become increasingly popular. With the growth of demand for medium-thick plate processing, high-power laser cutting machines with clear advantages are becoming the new market favorites.

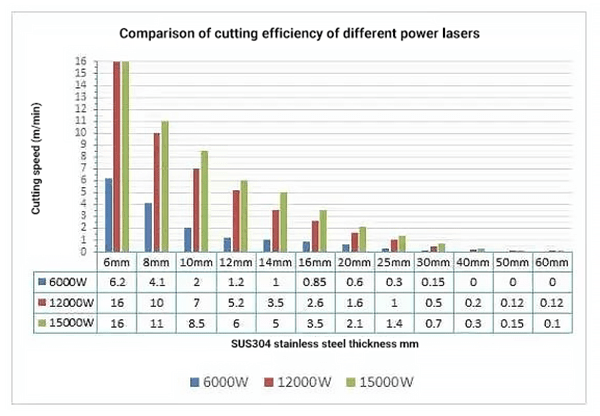

Compared to small and medium-power laser cutting machines, high-power laser cutting machines are more efficient for processing plates of the same thickness. The significant increase in power has also led to a revolutionary upgrade in the cutting process, reducing processing costs for users and solving major problems like “unstable production of thick carbon steel plates.”

In 2017, leading laser equipment manufacturers such as Hans’laser launched 12KW laser cutting equipment and achieved small-scale shipments. In 2018, 12KW laser cutting machines became prominent at major exhibitions, and after Hans’laser launched 15KW laser cutting equipment, other manufacturers followed suit and launched their own 15KW products. In 2019, Hans’laser updated the power limit again, launching a 20KW fiber laser cutting machine for the end market.

Fiber lasers have also gradually broken through the power limit, with the highest power of 30KW fiber lasers now available in the market. The power has increased from 12KW to 20KW, 25KW, and beyond.

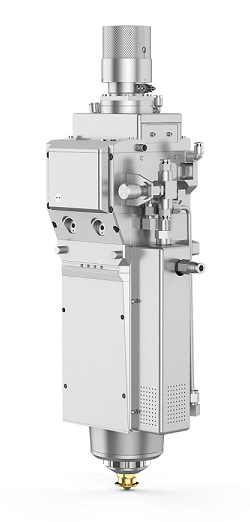

Functional components have become the main limitation. Despite the rapid development of high-power laser applications, the stability of functional components is hindering the development of ultra-high-power laser cutting equipment. The growth in cutting head power has lagged behind the growth in laser and laser cutting machine power.

The main components of the laser cutting head are nozzles, focusing lenses, and focusing tracking systems.

Nozzles are the most commonly used consumables in fiber laser cutting machine tools, and there are three main types: parallel, convergent, and conical. The cutting quality is closely related to the nozzle form and size.

The focusing lens is the core component of the cutting head. The light beam emitted by the laser is focused by the lens to form a high-energy density spot.

With increasing market demand for high-power lasers, the focal depth and focal spot of traditional lenses are limited. Increasing the focal depth will result in an expansion of the focal spot size, which cannot meet the requirements of laser processing in many cases. As a result, there is a growing demand for focusing lenses with long focal depth and high resolution.

Both the focal length and focus position of the focusing lens affect the quality of laser cutting. Short focal length lenses are suitable for high-speed cutting of thin materials, while long focal length lenses are suitable for cutting thick workpieces.

The focus tracking system of a laser cutting machine is usually composed of a focus cutting head and a tracking sensor system. During the processing of the laser cutting machine, the tracking system prevents collisions and uneven cutting, quickly processes graphics, and reduces the rate of defective products.

There are currently two main types of tracking systems: a capacitive sensor tracking system, also known as a non-contact tracking system, and an inductive sensor tracking system, also known as a contact tracking system.

Precitec currently dominates the domestic high-power cutting head market. Most laser cutting machines with a power above 10,000 watts are equipped with Precitec cutting heads. In light of this, some Chinese laser and equipment manufacturers have been making efforts to catch up and have increased their R&D investment in cutting heads for the stability of their high-power laser equipment. They have achieved certain results, with some companies launching cutting heads that can withstand 15kW ultra-high power and achieving mass production. The technology for 30kW cutting heads has also made a breakthrough.

According to a senior researcher who has extensive experience in fiber laser research, to obtain a larger fiber laser output, such as a 10,000-watt fiber laser, combining multiple medium-power fiber lasers is an effective method. The key component in this process is the fiber combiner.

Therefore, the beam combiner, thermal management technology in the beam combiner, and the quality of the output beam after the beam combiner are crucial for high-quality high-power fiber lasers in the industry today. Most of the new applications that involve high-power fiber lasers require high beam quality. These three perspectives can be compared to determine the stability, reliability, and technological advancement of a particular high-power fiber laser.

In the military field, fiber lasers mostly use spectral beam combining to achieve high power, but in the industrial field, there has been no technological innovation in China and beam combining is still mostly achieved by using multiple single fiber modules. For example, multiple 2000W and 3000W modules are used for beam combining to obtain a 10,000W fiber laser.

The high power of the combined beam converges in the beamer, and if the beamer is not capable of carrying such high power, it is prone to burning out. The high-power combiner is mostly imported from abroad, and only a few domestic manufacturers can produce it. In addition to the technical gap between domestic and foreign fiber lasers, high-power fiber laser products that support the laser cutting head also have higher requirements.

For example, when using a fiber laser as the light source for a laser cutting machine, the laser must match the cutting head. However, there are few domestic manufacturers of high-power laser cutting heads, which require high overall stability of the equipment and represent the highest level of the industry. According to industry insiders, domestic cutting heads are mainly used for low-power matching cutting heads, while foreign cutting heads are mainly used for high-power lasers above 6000W.

For high-power laser cutting, the stability of the cutting head is a major problem. The difficulties in the cutting head are mainly reflected in the lens coating techniques, optical path design, cooling system, and motor positioning.

The biggest challenge for high-power cutting heads is the lens. As the laser power increases, so does the power density of the lens. To ensure the stability of high-power cutting heads, the lens is the biggest difficulty.

Some companies have overcome this challenge by making breakthroughs in lens coating technology. Currently, the cutting heads on the market can stably handle a power output of 15kw.

After the lens, another major challenge is the optical design. The zoom mode of the high-power cutting head is mainly collimating lens zoom, which is different from the traditional low-power cutting head that uses focus lens zoom. For high-power laser heads, if the collimator moves closer to the fiber, the power density will increase.

In addition to the lens coating process and optical path design, the cooling systems and motor precision control of the cutting head are also challenging problems in high-power cutting heads. During plate cutting, the increase in laser power brings more energy and increases the likelihood of temperature rise in the lens and cutting nozzle. Cooling must be ensured through water cooling or other refrigeration methods.

In terms of motor control, feedback methods are implemented on the motor to correct its position through feedback, ensuring more accurate positioning and faster response speed in focusing.

High-power fiber lasers are mainly used for laser cutting and welding in the industrial field. The belief that the higher the power, the better is prevalent among many laser companies we interviewed, who introduced the concept of “limit power”. They believe that for laser cutting applications, there is a limit to the cutting process power beyond which the cutting quality and speed will no longer improve. In some cases, switching to other lasers such as excimer or CO2 lasers may be more cost-effective.

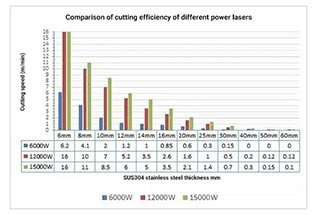

These companies generally believe that for the industrial market, 6 kW can meet more than 95% of the cutting demand, and fiber lasers with more than 6 kW are a small market in the cutting field. The introduction of 12 kW, 20 kW and 30 kW fiber laser cutting equipment only demonstrates the demand for high-power laser equipment in the market, but this is a specific requirement for a small range and there is no need for large-scale applications. Hence, high-power fiber lasers are considered a development direction until fiber lasers have not broken through 10,000 watts.

However, in the processing of special materials that are difficult to cut, low-power lasers are slow and the cutting effect is poor. High-reflection materials also require higher energy to meet processing needs, which is where 10,000-watt lasers are used. Laser equipment manufacturers have reported that high-power lasers are mainly used in the processing market, and the demand from enterprise customers in the processing market is mostly for lasers with a power output between 6,000-8,000 W. The capacity of the entire market is closely tied to the national macro-economy.

Stainless steel cutting – efficiency up to 400%

Carbon steel cutting – high speed cutting of medium and thin plates with air instead of oxygen

According to the figure above, the limit power of cutting the bright surface of carbon steel is determined by the plate thickness. If the actual power is less than the limit power, the cutting speed will increase as the power increases. However, if the actual power is greater than the limit power, the cutting speed will remain unchanged and will not improve, even with the increase in power. The cutting effect will also not change.

Most laser manufacturers still view 3000-8000W as the main competition area of the market, despite having the technology and prototypes of 10,000-watt lasers. This is based on the limited power of industrial processing.

However, there is another perspective where the higher the power, whether it is instantaneous or average, the better the processing capability of the laser as a tool and heat source in laser processing. This has been proven through the application of 15 kW/20 kW fiber laser products in ultra-high power processing and heat treatment effects, which have been found to perform better compared to 6000W fiber lasers.

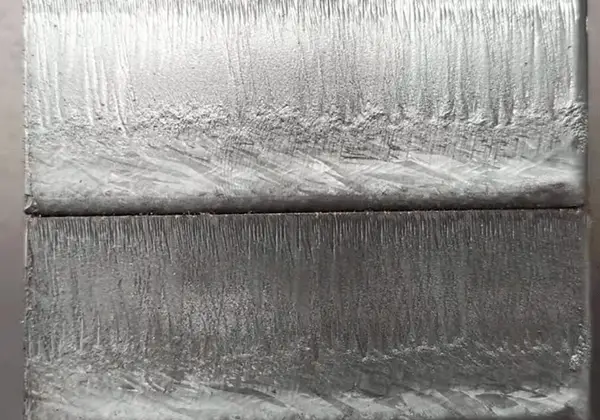

Current products with a capacity of 10,000 W can effectively cut through medium to thick plates, such as those made of carbon steel, eliminating the need for additional grinding processes.

As the capabilities and output of high-power lasers continue to improve, users will likely switch to these lasers when the benefits outweigh the costs.

The melting threshold for metals is set at one million watts per square centimeter, while the threshold for modifying metal surfaces is 10,000 watts per square centimeter.

Based on these two basic data points, it is likely that laser power with a capacity of 100,000 watts or even one million watts will become more common in the future.

High-power lasers have a wide range of potential applications, including rail transportation, aerospace, shipbuilding, and military applications.

In the realm of ship welding, high-power lasers are well-suited, although they have not yet been implemented in China.

The advantage of laser technology is its high quality and efficiency, due to the quality of optical fiber transmission and the efficiency of photoelectric conversion. The higher the power, the deeper the processing and the faster the welding speed.

However, these advantages and disadvantages are interdependent. For high-tech enterprises, investment in technology and product R&D is the first cost category, requiring investment in corresponding talent, funds, and time. Some core components cannot be sourced internally, and raw materials such as optical fiber, pumping source, combiner, grating, and circuit control systems must be purchased, sometimes accounting for up to 70% of the total cost.

So why do enterprises move towards high-power lasers despite the high investment costs? The answer is driven by profit.

Industry experts say that although China’s low-power market is dominated by domestic fiber laser brands, these products have won a rolling victory over imported products. However, there are too many companies entering the market, causing prices to drop sharply and leading to fierce competition and low profit margins, such as in the 1000-3000W fiber laser market.

On the other hand, the total market demand for lasers with higher power, such as 3000-6000W, 10 kW, is small but they offer opportunities for differentiated competition.

The high added value of high-power laser products and the relatively large profit margins make them a new market opportunity for enterprises to enter.

In addition, demonstrating technical strength is also a significant factor. For instance, IPG Photonics publicly advertises that it can sell custom 500,000-watt all-fiber industrial-grade lasers, even if we do not know of any industries currently using these products. The fact that a company is able to develop such high-power lasers is a testament to its R&D capabilities and product quality, making it a key promotional point.

From the perspective of equipment manufacturers, industry experts say that only a few manufacturers of 10,000-watt products can meet their requirements for quality and stability. Other laser suppliers still need to go through a promotional and feedback process.

As more fiber laser companies enter the market, equipment manufacturers will have more choices and the purchase price ratio will naturally increase.

Whether higher power fiber lasers are “better” is not a question with a definite answer. Advances in technology, localization of core components, improvement of supporting equipment, market demand, and the development of application areas will all drive the growth of fiber lasers and the transformation and upgrading of manufacturing.

High-power fiber lasers still have a long way to go.