Imagine cutting metal with a precision so fine it saves time and reduces costs. High-speed cutting tools are revolutionizing manufacturing by offering this very capability. This article explores the materials used in these tools—like diamond, boron nitride, and ceramics—and their specific applications. By reading further, you’ll learn how these advanced materials enhance cutting efficiency and discover the best options for your machining needs.

High-speed cutting (HSC) technology represents a significant advancement in manufacturing, characterized by elevated cutting speeds and feed rates that substantially reduce machining time for tools and components. This innovative approach not only decreases production costs but also enhances overall manufacturing efficiency.

A key attribute of HSC is its capacity for high precision machining, making it particularly suitable for components with stringent accuracy requirements. The implementation of HSC technology has enabled enterprises to dramatically improve their production throughput and maintain a competitive edge in the global market.

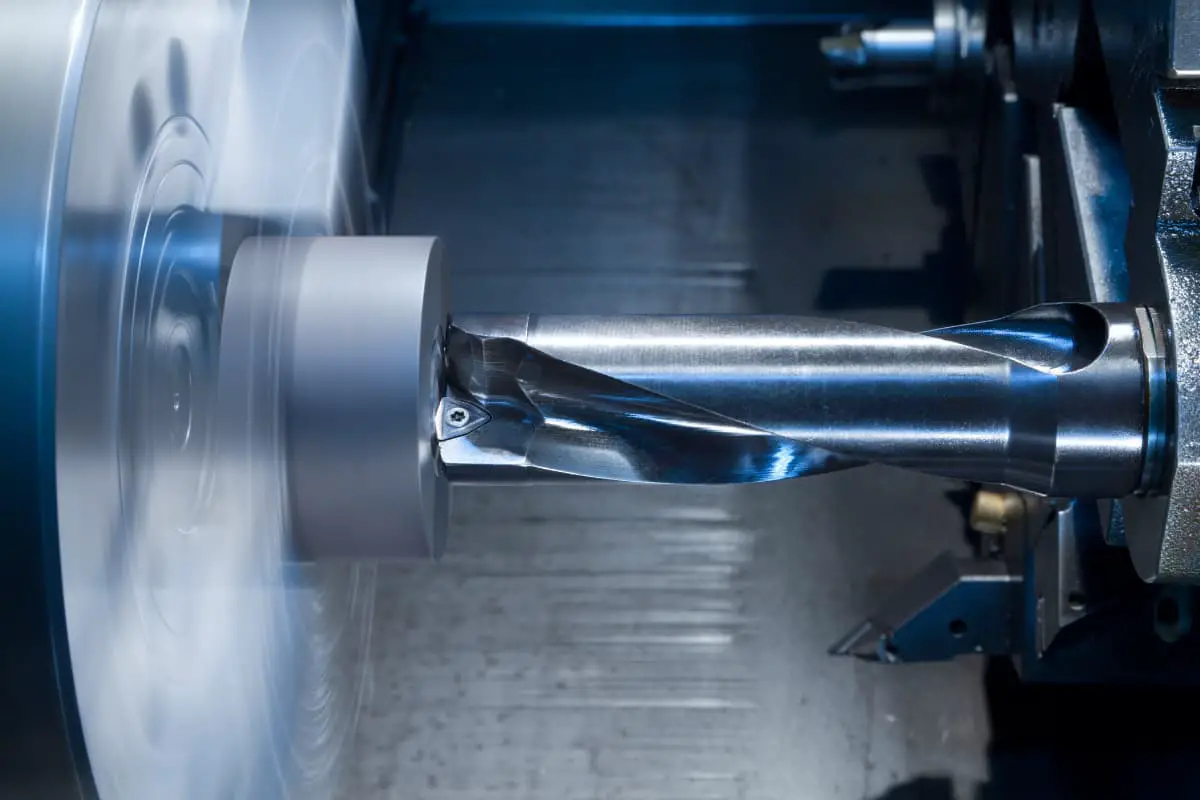

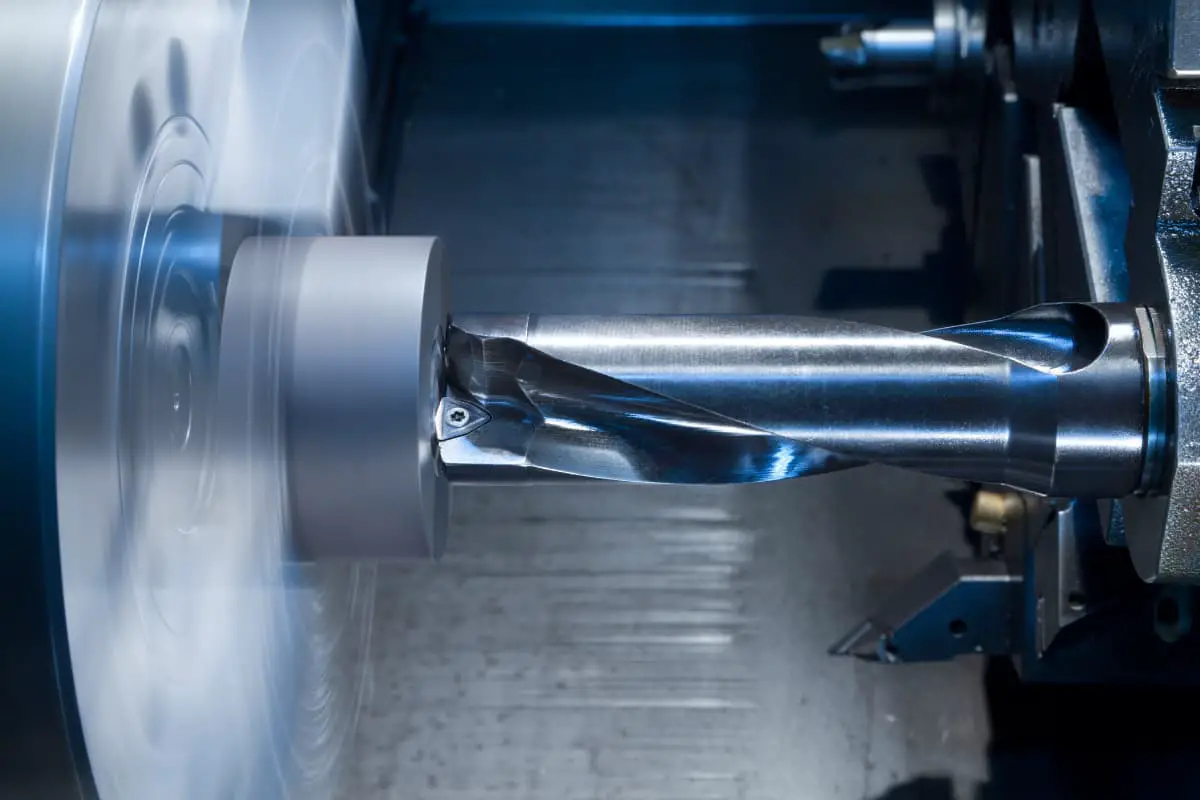

The cutting tool serves as the cornerstone of HSC technology, directly interfacing with the workpiece material during the high-speed machining process. Consequently, the tool’s performance—including its material composition, geometry, and coating—directly influences the cutting efficacy, surface finish, and tool life.

A diverse array of cutting tool materials are employed in HSC applications, each with specific advantages:

Hard alloy, also known as cemented carbide, is a composite material manufactured through powder metallurgy techniques, combining hardening compounds of refractory metals with bonding metals, typically cobalt. This advanced material exhibits exceptional properties, including high hardness, wear resistance, and thermal stability, making it invaluable in various industrial applications.

The production process involves carefully blending carbide powders (usually tungsten carbide) with metallic binders, followed by compaction and sintering at high temperatures. This results in a unique microstructure that balances hardness and toughness, crucial for demanding cutting operations.

In practice, hard alloys excel in machining a wide range of materials, including:

While hard alloys continue to play a significant role in the cutting tool industry, evolving manufacturing demands have led to further innovations. Modern cutting processes often require materials with enhanced performance characteristics, such as:

Consequently, hard alloys are frequently used as substrates for advanced coatings (e.g., PVD, CVD) or in hybrid tool designs, combining the benefits of hard alloys with other cutting-edge materials. This evolution ensures that hard alloys remain relevant in today’s high-performance machining landscape, albeit not always as standalone cutting tool materials.

2.1 Advanced Alloy Doping for Cutting Tools

As cutting technology evolves, traditional monolithic hard alloy cutting tools have shown limitations in hardness, wear resistance, and thermal stability. To address these challenges, researchers and manufacturers have turned to strategic alloy modification through doping.

Extensive studies have demonstrated that incorporating elements such as nickel, cobalt, and tungsten carbide into hard alloys significantly enhances their properties. These modifications have resulted in marked improvements across key performance metrics, including hardness, oxidation resistance, wear resistance, and thermal stability. The degree of enhancement varies based on the specific dopant combination and concentration.

For widely utilized titanium carbide-based hard alloys, the addition of nitrides has proven particularly effective in boosting overall performance. The introduction of nitrides, such as titanium nitride (TiN) or aluminum nitride (AlN), creates a complex carbide-nitride structure that synergistically improves the alloy’s mechanical and thermal properties. This enhancement is attributed to the formation of fine precipitates and solid solution strengthening mechanisms.

However, it’s crucial to note that while these modified titanium carbide-based alloys exhibit superior characteristics for many applications, they are not universally optimal. Specifically, they demonstrate limitations when machining ultra-high temperature metals, advanced high-temperature alloys, and certain non-ferrous metals. For these challenging materials, alternative cutting tool compositions, such as cubic boron nitride (CBN) or polycrystalline diamond (PCD), may be more suitable, depending on the specific cutting requirements and workpiece properties.

2.2 Advanced Coatings for High-Performance Cutting Tools

The limitations of conventional hard alloys in meeting the demands of modern high-speed machining have led to the development of advanced coating technologies. By applying one or more layers of high-performance materials to the surface of hard alloy cutting tools, their capabilities can be significantly enhanced. These coatings are characterized by superior hardness, wear resistance, low friction coefficients, and high melting points.

Current cutting-edge coating materials include titanium carbide (TiC), alumina (Al2O3), diamond, and various nanomaterials. Each offers unique properties that can be leveraged to optimize tool performance for specific applications:

The selection of coating type and composition depends on the specific machining parameters, workpiece material, and desired outcomes. As coating technologies continue to advance, they promise to further extend tool life, improve machining efficiency, and enable the processing of increasingly challenging materials.

Ceramic materials represent a pinnacle in advanced cutting tool technology, offering a unique combination of properties that make them exceptionally suited for high-performance machining operations. Their hallmark characteristics include exceptional hardness, superior wear resistance, low chemical affinity with metals, outstanding chemical stability, and extended service life.

One of the most significant advantages of ceramic cutting tools is their ability to maintain effectiveness during high-speed cutting operations at elevated temperatures. This thermal resilience allows for efficient chip evacuation from the cutting zone, even under extreme conditions. The excellent thermal stability of ceramics not only reduces the risk of cutting-related incidents but also contributes to superior surface finish quality on the workpiece.

The exceptional performance of ceramic tools enables a revolutionary approach known as “turning instead of grinding.” This technique allows manufacturers to achieve finish-quality surfaces through turning operations that traditionally required a separate grinding process. By consolidating these operations into a single lathe-based process, manufacturers can significantly streamline their production workflows, reduce processing time, and enhance overall efficiency.

In industrial applications, two primary categories of ceramic cutting tools dominate: alumina-based ceramics and silicon nitride ceramics.

3.1 Alumina-based ceramic materials

Alumina-based ceramics encompass a diverse range of compositions, including pure alumina ceramics, alumina-carbide ceramics, alumina-metal ceramics, and alumina-metal-carbide ceramics. Each variant offers unique properties tailored for specific industrial applications.

Pure alumina ceramics, primarily composed of Al2O3, are often enhanced with small quantities of additives such as nickel oxide, magnesium oxide, or yttria to improve their mechanical properties, particularly flexural strength. These ceramics exhibit exceptional high-temperature stability, chemical inertness, and wear resistance. Their superior performance in high-speed cutting operations makes them ideal for machining hard and brittle materials like chilled cast iron and quenched steel, where high dimensional accuracy is critical.

To further enhance the mechanical and thermal properties of alumina ceramics, various reinforcing phases are incorporated. The addition of metals (e.g., titanium, zirconium), carbides (e.g., titanium carbide, silicon carbide), or nitrides (e.g., silicon nitride) results in composite ceramic materials with improved flexural strength, fracture toughness, and hardness. These additions can also enhance thermal conductivity and reduce thermal expansion, leading to better thermal shock resistance.

Among these composites, alumina-metal-carbide ceramics stand out for their exceptional thermal stability and ultrahigh hardness. The synergistic combination of alumina’s inherent properties with the toughness of metals and the hardness of carbides creates a versatile material suitable for a wide range of cutting applications. These ceramics excel in machining challenging materials such as alloy steels, quenched and tempered steels, cast steels, and high-temperature nickel-chromium alloys. Their capabilities extend beyond metallic materials, proving effective in processing abrasive non-metallic materials like fiberglass reinforced plastics.

The development of these advanced alumina-based ceramics continues to push the boundaries of cutting tool performance, enabling higher cutting speeds, extended tool life, and improved surface finish in increasingly demanding machining operations.

3.2 Silicon nitride ceramic materials

Silicon nitride (Si3N4) based ceramics offer superior mechanical and thermal properties compared to alumina-based ceramics, making them particularly suitable for demanding cutting applications. These materials exhibit higher strength, fracture toughness, and thermal shock resistance, coupled with a lower thermal expansion coefficient. Their unique combination of properties makes silicon nitride ceramics ideal for high-speed machining of cast iron and other abrasive materials.

Key advantages of silicon nitride ceramics include:

However, silicon nitride ceramics also have some limitations:

The primary application for silicon nitride cutting tools is high-speed machining of cast iron components, where their unique property profile allows for significant productivity improvements. These tools excel in both continuous and interrupted cutting operations, offering extended tool life and superior surface finish quality compared to conventional cutting materials.

Diamonds are renowned for their exceptional properties, including unparalleled hardness, superior thermal stability, and outstanding chemical inertness. These characteristics make them the preeminent material for drilling bits in demanding drilling operations across various industries.

The extraordinary performance of diamonds extends beyond drilling applications, positioning them as a premier material for high-speed cutting tools. Their ability to maintain sharp edges under extreme conditions makes them invaluable in precision machining and high-volume production environments.

In industrial applications, diamond cutting tools are available in several forms:

Natural diamond cutting tools represent the pinnacle of performance due to their unmatched wear resistance and hardness. They excel in ultra-precision machining, capable of achieving nanometer-level surface finishes and sub-micron tolerances. These tools are ideal for manufacturing high-precision components such as optical mirrors, semiconductor devices, and advanced MEMS (Micro-Electro-Mechanical Systems). However, their scarcity and complex processing requirements make them the most expensive option in the cutting tool spectrum.

Synthetic single crystal diamonds offer a more cost-effective alternative to natural diamonds without significantly compromising performance. Produced under controlled conditions, they exhibit consistent properties and can be tailored in size and shape to suit specific applications. Their chemical stability and controllable characteristics make them widely adopted in mechanical processing, PCB (Printed Circuit Board) manufacturing, optical glass finishing, and the production of wear-resistant surfaces in industrial and architectural applications.

Polycrystalline diamonds (PCD) are engineered materials formed by sintering diamond particles at extreme temperatures (typically 1400-1600°C) and pressures (5-7 GPa), using cobalt as a binding agent. The resulting material combines the hardness of diamond with enhanced toughness due to its polycrystalline structure. PCD tools excel in machining non-ferrous metals, fiber-reinforced composites, ceramics, and other abrasive materials where tool life is critical. Their ability to maintain a sharp cutting edge over extended periods makes them particularly valuable in high-volume production environments, such as automotive and aerospace industries.

Each type of diamond cutting tool offers unique advantages, and the selection depends on specific application requirements, including material properties, desired surface finish, production volume, and economic considerations. As manufacturing technologies continue to advance, the development of novel diamond tool compositions and fabrication methods remains an active area of research, promising even greater performance and cost-effectiveness in future cutting tool applications.

High-speed cutting technology has become a crucial competitive advantage for machining enterprises in today’s demanding market. By leveraging advanced high-speed cutting techniques, manufacturers can significantly enhance both processing speed and precision, leading to improved productivity and product quality.

As high-speed cutting technology continues to evolve, the materials used in cutting tools undergo constant innovation and refinement. This symbiotic relationship between cutting technology and tool materials drives the industry forward, necessitating a strategic approach to tool selection.

It is imperative for manufacturers to choose cutting tools that not only align with current process characteristics and machining requirements but also anticipate future technological advancements. This forward-thinking approach ensures optimal performance and longevity of investments in tooling.

To stay at the forefront of the industry, continuous research and development in cutting tool materials is essential. By incorporating new materials and advanced technologies in the design and manufacture of high-speed cutting tools, we can achieve substantial improvements in tool performance. Key areas of focus include:

These advancements in cutting tool technology play a pivotal role in driving the rapid development and competitiveness of the machining industry. By embracing these innovations, manufacturers can achieve higher levels of efficiency, precision, and cost-effectiveness in their operations.