Imagine revolutionizing production efficiency with machines that seem almost alive in their precision. High-speed stamping production lines are transforming the way we manufacture, offering unmatched speed and accuracy. This article explores how these automated lines work, their key components, and the benefits they bring to modern manufacturing. Dive in to learn how advanced technology is driving down costs, boosting quality, and setting new standards in industrial production.

The rapid development of science and technology has greatly improved the production efficiency, which is reflected in the continuous improvement of equipment automation in the stamping production line, which promotes the stamping production with high production efficiency to a new height, and can improve the product quality and reduce the single piece production cost under the condition of mass production.

At present, most of the stamping workshops in automobile factories use high-speed automatic stamping lines.

There are great differences in the degree of automation of these production lines, so the beat is different, and there is still much room for improvement.

The maximum production beat of the stamping line using servo direct drive technology officially adopted by a high-end German automobile manufacturer has reached 23 times/min.

The stamping production line can realize the stamping production of automobile panels and other large formed parts.

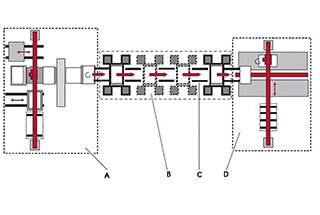

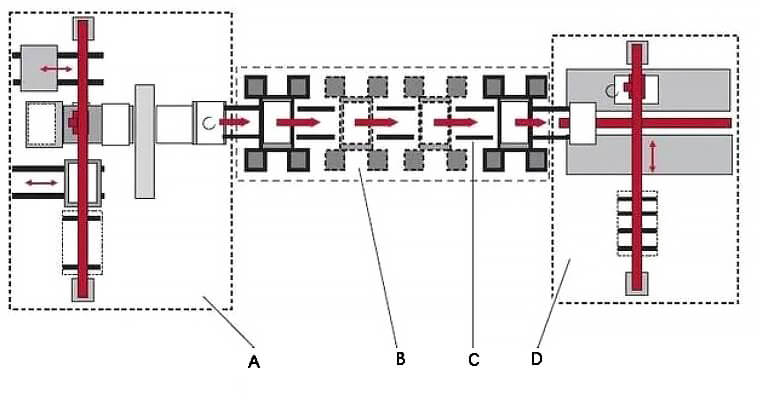

As shown in Fig. 1, the stamping line of the whole vehicle factory is composed of line head system (A), large press (B), handling equipment (C) and line tail system (D).

Compared with the traditional manual production line with very low efficiency, the application of automatic equipment can reduce the cost and increase efficiency.

The head loading unit unpacks and transports the sheet metal to the grab position of the first handling equipment, which is completely composed of:

2 loading metal plate cars (with adjustable magnetic separator), material height detector (which can be placed on the plate car or the beam of the destacking hand), end material detector, destacking hand (manipulator or robot), servo feeding device (generally magnetic conveyor belt), double material detection device, scanner, plate washer, plate oiler, centering table and its servo control system.

Now we will discuss the scanner and its related technologies.

The stamping production line can operate normally and quickly to produce high-quality parts. Rapid and accurate alignment of sheet metal is essential.

Using scanner and image scanning technology in optical centering platform can improve the grasping accuracy of the equipment and reduce the failure rate.

When using different handling equipment, the application of the scanner is different.

Fig. 2 shows an arrangement mode, in which A is the scanner and B is the centering platform.

In the stamping line in which the mechanical arm is used to grasp the parts, because the stamping parts are always on the fixed height plane of the upper surface of the conveyor belt, the application of this technology is actually a quantitative analysis of the part position offset on a two-dimensional plane.

By vertically installing the scanner on the beam, the image passing through the sheet can be recorded, and then the image can be transmitted to the scanner controller.

Through the comparison between the standard position and the actual position, the corresponding signal can be output to the center console driving device, which controls the servo motor to make the corresponding action to ensure the accuracy of the sheet position grasped by the subsequent handling device.

If the process requires the surface cleanliness of the sheet metal, it can also directly judge whether there is excessive oil stain by analyzing the image of the sheet metal.

When the cross bar robot is used as the handling equipment between the presses, the six axes provided by the robot itself, supplemented by the longitudinal feeding axis of the girder and the carrier axis of the end pickup, can make the handling equipment have a very high degree of freedom, so that its grasping attitude can be adjusted according to the offset of the sheet metal.

The deviation vector between the plate teaching position and the actual position calculated by the scanner controller is transmitted to the robot control system through the fieldbus to realize the accurate grasping of the robot.

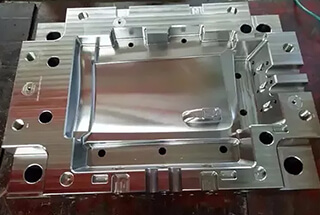

In the stamping production line, the press is the equipment that has the greatest impact on the quality of formed parts.

By setting reasonable parameters for each part, various automobile panels that meet the design requirements can be stamped.

Press can be divided into the mechanical press and hydraulic press according to the working principle. The hydraulic press is a machine that uses Pascal principle and liquid pressure to transmit power, while the mechanical press converts the rotating motion of the motor into the vertical motion of the slider through the mechanical structure (such as crank connecting rod).

Compared with mechanical press, the hydraulic press has the advantages of large working pressure, large adjustable range of working stroke, maximum pressure output at any position of stroke, stepless speed adjustment and so on, but it has great shortcomings in working frequency.

In the stamping production line produced by the vehicle factory, the hydraulic press is not applicable due to the requirements of production beat.

Mechanical press can be subdivided into servo press (also known as CNC Press) and general mechanical press.

The traditional mechanical press controls the speed of AC motor through frequency converter, uses flywheel to store energy and clutch to control power transmission.

Its pressure curve is generally sinusoidal, that is, the nominal tonnage is always reached before the bottom dead center, and the stroke is fixed and adjustable.

The servo press uses servo technology and traditional mechanical technology to control the movement of the slider through a complex electrical control system.

The servo press can arbitrarily program the speed and pressure of a certain position in the slider stroke, and can also reach the nominal ton of the press at low speed.

Some press manufacturers at home and abroad have made achievements in this field and launched commercialized products, which are called “the third generation press”.

Servo press is undoubtedly a major direction of the development of forming equipment. Its advantages are shown in Table 1.

Table 1 advantages of servo press

| High-precision | The slider position is controllable (servo control and position feedback device control), and the general position accuracy can reach 0.01mm. |

| Flexibility and intelligence | By using servo motor instead of ordinary induction motor, arbitrary slider characteristics can be obtained and the corresponding process curve can be optimized. |

| Transmission optimization | Fax reception does not use intermediate transmission devices such as clutch and flywheel, which reduces vibration, noise (about 159% can be reduced by 250) and energy loss, and is easy to maintain. |

| Improve equipment life and work efficiency | The structure is simple, the service life of the die can be increased to three times, and the service life of the equipment can also be improved: the characteristic of adjustable stroke greatly improves its working efficiency. |

Automobile lightweight is one of the development directions of automobile.

Automobile lightweight is to reduce the vehicle weight, reduce fuel consumption, reduce emission pollution, and improve the power of automobile, but ensure that the strength and safety performance of automobile are not reduced.

In stamping forming, the selection of ultra-high strength steel is an important way to realize automobile lightweight.

At room temperature, ultra-high strength steel has low plasticity and difficult forming.

Due to the limitations of cold stamping, it is difficult to solve the problems such as stamping crack, geometric accuracy, wrinkling and springback.

The production process of cold stamping is difficult to meet the requirements of forming accuracy.

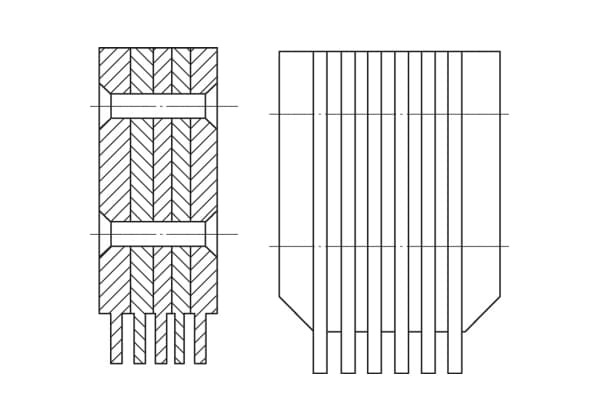

Therefore, hot stamping technology came into being.

This technology is to heat the sheet to above the austenitizing temperature, then press and form, at the same time, quench in the press at a cooling rate greater than 27 ℃ / s to obtain martensite, so that the stamped parts can meet the requirements in mechanical properties and dimensional accuracy.

The advantages and disadvantages of different heating methods are as follows:

(1) Radiation heating has the advantages of low heat utilization rate, wide land occupation and high cost.

(2) Conduction heating (resistance effect), poor heating uniformity and high requirements for sheet metal.

(3) Induction heating (electromagnetic induction), high heat utilization, fast speed and small space.

Due to technical reasons, at present, the heating equipment of stamping production line basically adopts radiation heating furnace.

Nearly 100 domestic enterprises have hot stamping production lines, which can produce TS1500 automotive panels.

Under the background of the wider application prospect of ultra-high strength steel, hot stamping equipment and technology is also a major development direction.

Generally, the handling equipment has at least four moving shafts.

Through pre teaching the position of sheet metal and using the special end pickup for each part, the handling of sheet metal on the stamping production line is realized, which is mainly divided into manipulator and robot.

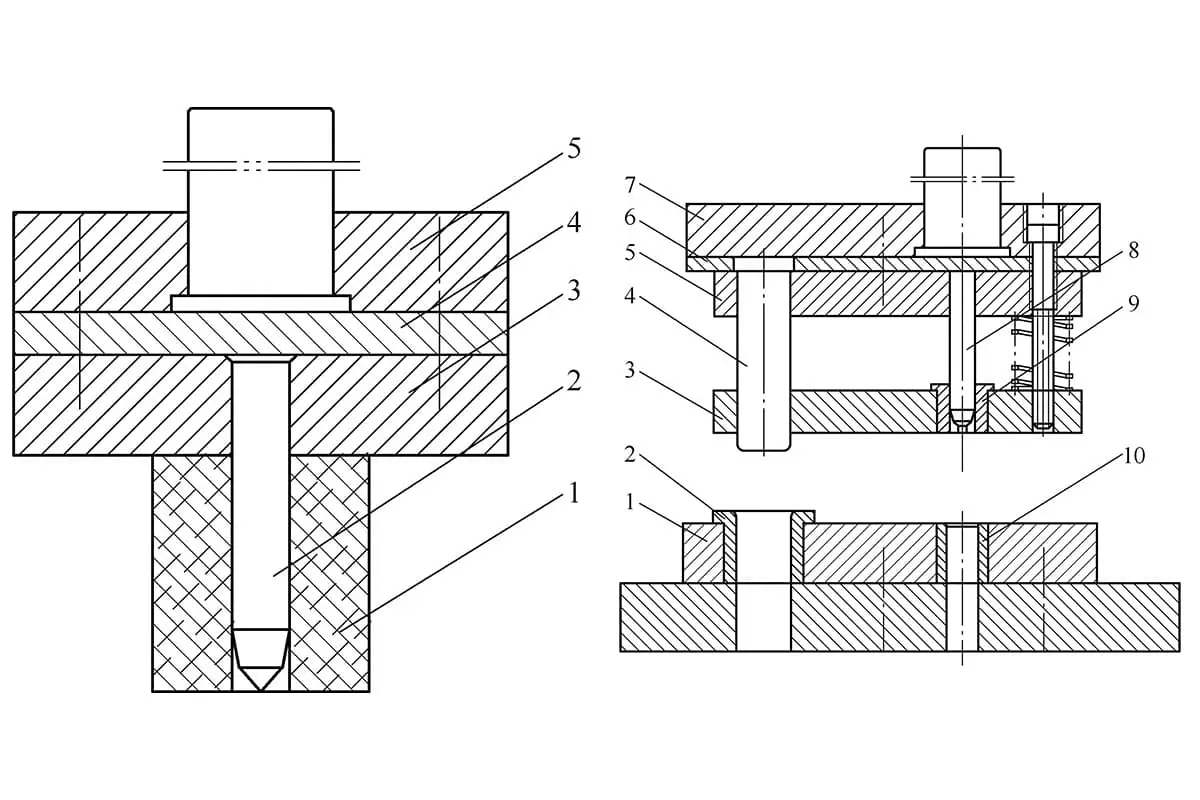

Fig. 3 shows a four axis press handling manipulator.

The automatic control software identifies the position of the slider of the upper press and confirms that there is no interference in the material grasping of the manipulator at this position.

Then, the output signal controls the manipulator to move to the teaching grasping position of the part.

The vacuum generator on the end pickup realizes the grasping and lowering of the sheet through air suction and blowing action, so as to realize the automatic handling of workpieces between presses.

The manipulator production line can also be divided into single arm line and double arm line.

Compared with single arm line, double arm line has higher efficiency and less error.

At present, many main engine plants have been put into use and are expected to be more widely used in the future.

When the robot is used as the handling equipment of stamping parts, compared with the manipulator, the robot has more degrees of freedom, more complex structure and great difference in cost.

The crossbar robot is a typical product. The robot combines crossbar technology and robot technology to achieve 8 moving axes and higher production efficiency.

In some special occasions, such as the transformation line of manual production or limited by other problems on site, the layout robot has its unique advantages.

The blanking press of the production line of an automobile factory uses FANUC robot as the loading and unloading handling equipment.

The line tail system (also known as the line tail stacking system) transports the sheet metal transported by the last manipulator to the specified position, and then carries out framing and warehousing.

The traditional tail system mostly uses belt conveyor to transport parts (similar to the head conveyor belt), and then manually frame, and then the material frame is stored by forklift.

Because the beat of the automatic stamping line can basically reach 10 pieces/min, and a single stacking station generally can not meet the requirements, most production lines will divert the finished products, and then load the sheet into the material frame after checking the part quality manually or by equipment.

At present, the tail station is one of the main human stations in the stamping production line, and the work intensity is high, which is not conducive to ergonomics, and the frequent transfer of material frame by forklift also has a certain collision risk.

This post introduces mature automatic traction equipment – AGV trolley, which has high degree of automation, small volume and easy control.

The trolley is equipped with electromagnetic or optical automatic guidance devices, which can travel along the specified guidance path, and the travel path can be controlled by the computer or electromagnetic track.

The reasonable arrangement of AGV trolley in the line tail system can improve the automation rate and reduce the risk of man-machine interference.

The automation of the stamping production line has been greatly improved, but with the improvement of market demand and the continuous application of new technology, the stamping equipment is constantly updated.

Understanding various stamping automation equipment in the market and its working principle can effectively improve the technical ability of equipment engineers and continuously optimize the performance of stamping equipment in terms of quality improvement, capacity improvement, safety, energy saving and cost reduction.