Have you ever wondered how to calculate the deformation in hole flanging? Understanding flanging coefficients is crucial for precision in metalworking. This article dives into the key factors influencing these coefficients, from material properties to hole processing methods. By reading further, you’ll grasp the essentials needed to achieve accurate flanging results, ensuring your projects maintain structural integrity and meet high standards. Discover practical insights and improve your metal fabrication skills today.

The degree of deformation in flanging or flanging operations is commonly represented by the flanging coefficient, which is calculated using the following formula:

In the formula:

The higher the value of K, the less deformation occurs; conversely, the lower the value of K, the greater the deformation.

The primary factors affecting the flanging coefficient are as follows:

1. The properties of the material; the better the plasticity, the smaller the K value can be.

2. The relative diameter of the pre-punched hole, t/D0; the smaller the t/D0 value, the larger the K value.

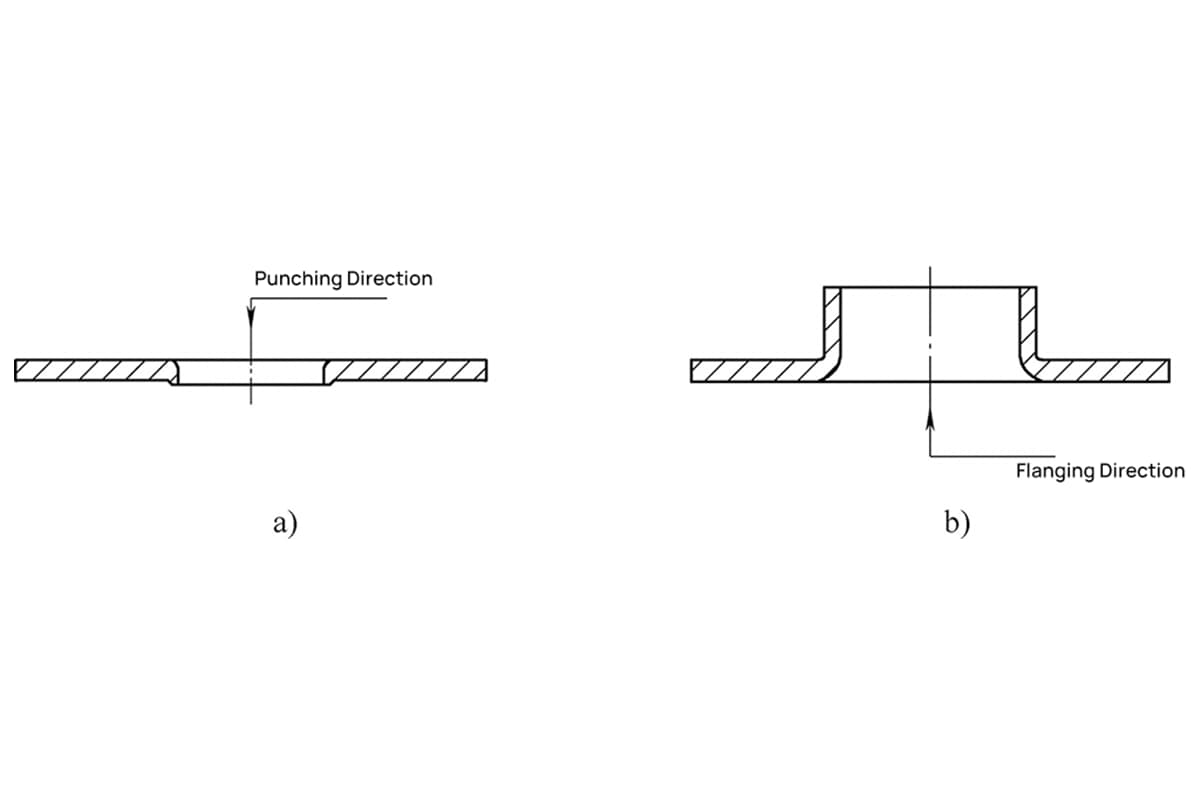

3. The method of hole processing; drilled holes, due to the absence of a tear surface, are less likely to crack during flanging. Punched holes, having some tear surfaces, are prone to cracking, thus requiring a larger K value. If the material is annealed after punching or if the hole is finished, a flanging ratio close to that of drilled holes can be achieved.

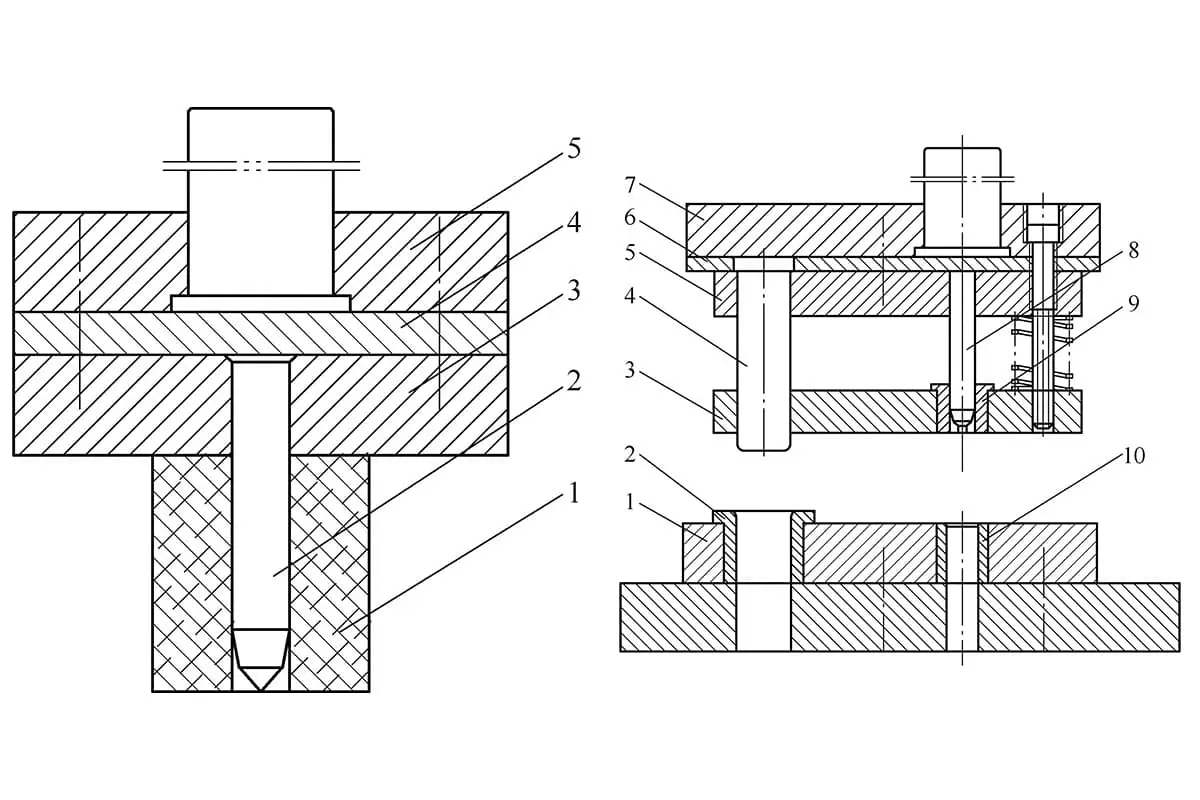

Additionally, reversing the direction of the punching relative to the flanging direction, with the burrs located on the inside of the flange, can reduce cracking, as shown in Figure 5-4.

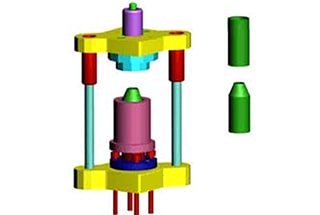

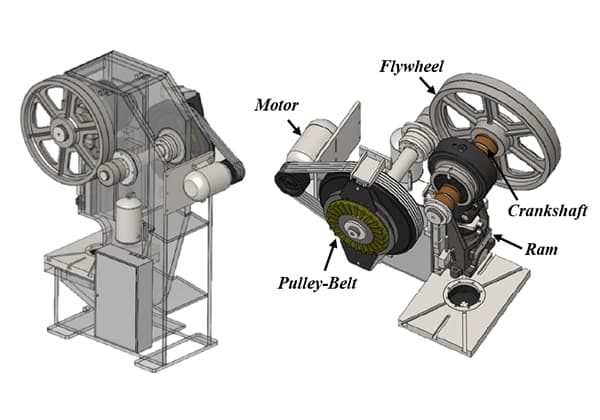

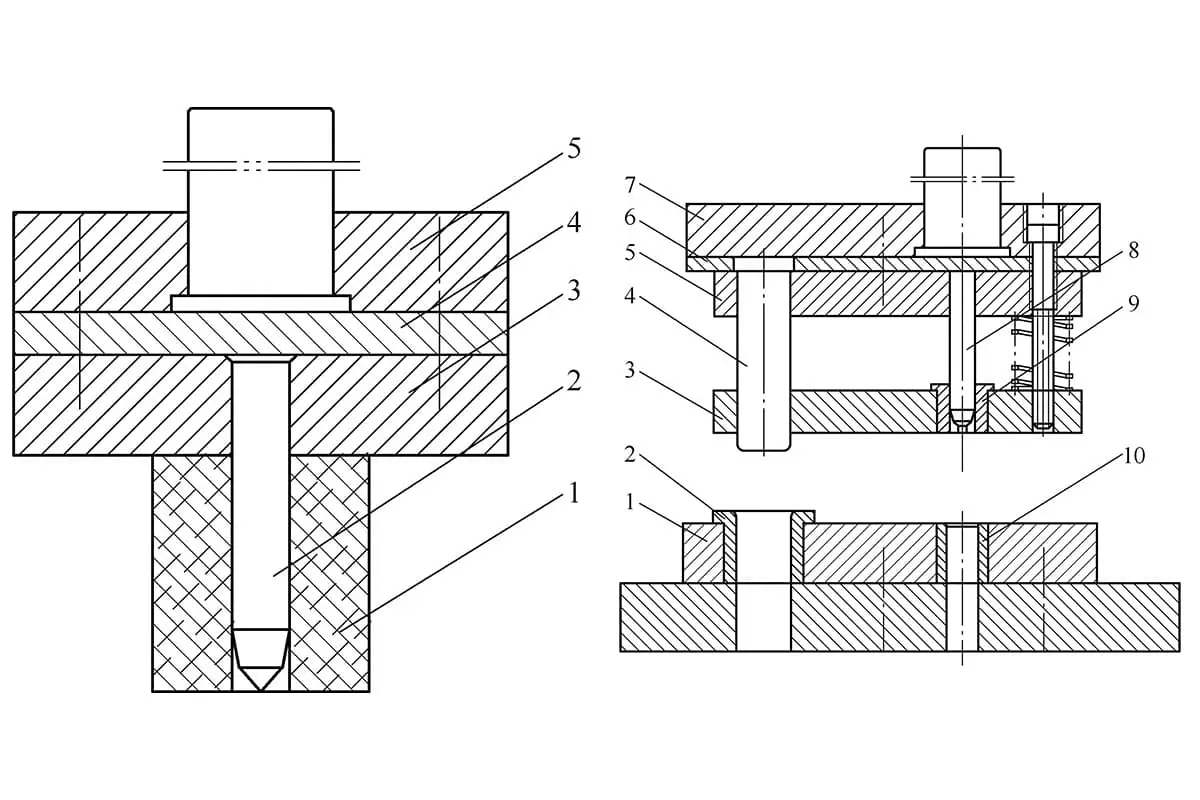

4. When using a spherical, parabolic, or conical punch for piercing, the edges of the hole are smoothly and gradually flared, reducing the K-factor and increasing the degree of deformation. The limit piercing coefficient for low carbon steel is shown in Table 5-1, and the piercing coefficients for various materials are listed in Table 5-2.

5-1 The ultimate piercing coefficient for low-carbon steel.

| Pilot punch profile | Hole Machining Methods | Material relative thickness, d0/t | ||||||||||

| 100 | 50 | 35 | 20 | 15 | 10 | 8 | 6. 5 | 5 | 3 | 1 | ||

| Spherical punch | Deburr after drilling. | 0.70 | 0.60 | 0.52 | 0.45 | 0.40 | 0.36 | 0.33 | 0.31 | 0.30 | 0.25 | 0.20 |

| Punch holes with a punching die. | 0.75 | 0.65 | 0.57 | 0.52 | 0.48 | 0.45 | 0.44 | 0.43 | 0.42 | 0.42 | — | |

| Cylindrical Punch | Deburr after drilling. | 0.80 | 0.70 | 0.60 | 0.50 | 0.45 | 0.42 | 0.40 | 0.37 | 0.35 | 0.3 | 0.25 |

| Punch holes with a punching die. | 0.85 | 0.75 | 0.65 | 0.60 | 0.55 | 0.52 | 0.50 | 0.50 | 0.48 | 0.47 | — | |

5-2 Various Materials’ Flanging Ratios

| Annealed raw material | Hole Flanging Ratio | ||

| K0 | Kmin | ||

| Galvanized steel sheet (white iron) | 0. 70 | 0. 65 | |

| Soft steel | t = 0. 25 ~ 2. 0mm | 0. 72 | 0. 68 |

| t =3. 0 ~ 6. 0mm | 0.78 | 0.75 | |

| Brass H62, thickness ranging from 0.5 to 6.0 mm | 0. 68 | 0. 62 | |

| Aluminum, thickness ranging from 0.5 to 5.0 mm | 0.7 | 0. 64 | |

| Hard aluminum alloy | 0. 89 | 0. 80 | |

| Titanium alloy | TA1 (Cold State) | 0. 64 ~ 0. 68 | 0. 55 |

| TA1 (Heated to 300-400°C) | 0. 40 ~ 0. 50 | – | |

| TA5 (Cold State) | 0. 85 ~ 0. 90 | 0.75 | |

| TA5 (Heated to 500-600°C) | 0. 70 ~ 0. 65 | 0.55 | |

| Stainless steel, high-temperature alloys | 0. 69 ~ 0. 65 | 0. 61 ~ 0. 57 | |